7

www.purepowerequipment.com

INSTALLATION & GROUNDING

Lubrication and Oil: This compressor requires no lubrication or oiling. No break

in procedure is required by the user. This product is factory tested to ensure

proper operation and performance.

Location of the Air Compressor: The air compressor should always be

located in a clean, dry, and well-ventilated environment. The unit should have at

minimum, 30cm of space on each side. The air filter intake should be free of any

debris or obstructions. Check the air filter on a daily basis to be sure it is clean

and in working order.

Extension Cords: We do not recommend the use of an extension cord with this

product. This may result in the loss of power and overheating of the motor. An

additional air hose should be used instead of an extension cord. However, if the

use of an extension cord is unavoidable, use only UL listed wire extension cords

that have three-pronged grounding type plugs and three prong receptacles that

accept the tool’s plug. Improper use of extension cords may cause inecient

operation of your compressor, which can result in overheating.

Be sure your extension cord is rated to allow sucient ow to motor. Refer to the

guide for minimum gauge required for extension cords.

Use of an extension cord heavy enough to carry the current the tool will draw is

very important. Especially when the power source is of great distance. An exten-

sion cord that is insucient will cause a drop in line voltage, resulting in power

loss and causing the motor to overheat.

Guard against electrical shock. Avoid body contact with grounded surfaces such

as pipes, radiators, ovens, stoves, and refrigerator enclosures. If not properly

grounded, this power tool can incur the potential hazard of electrical shock,

particularly when used in damp locations. If an electrical shock occurs, there is

the potential of a secondary hazard such as your hands contacting an operating

air tool.

Grounding Instructions: This product

should be grounded. In the event of an

electrical short circuit, grounding reduces

the risk of electric shock by providing an

escape wire for the electric current. This

product is equipped with a cord having

a grounding wire with an appropriate

grounding plug. The plug must be plugged

into an outlet that is properly installed

and grounded in accordance with all local

codes and ordinances. Check with a

qualified electrician or service personnel

if these instructions are not completely

understood or if in doubt as to whether the

tool is properly grounded.

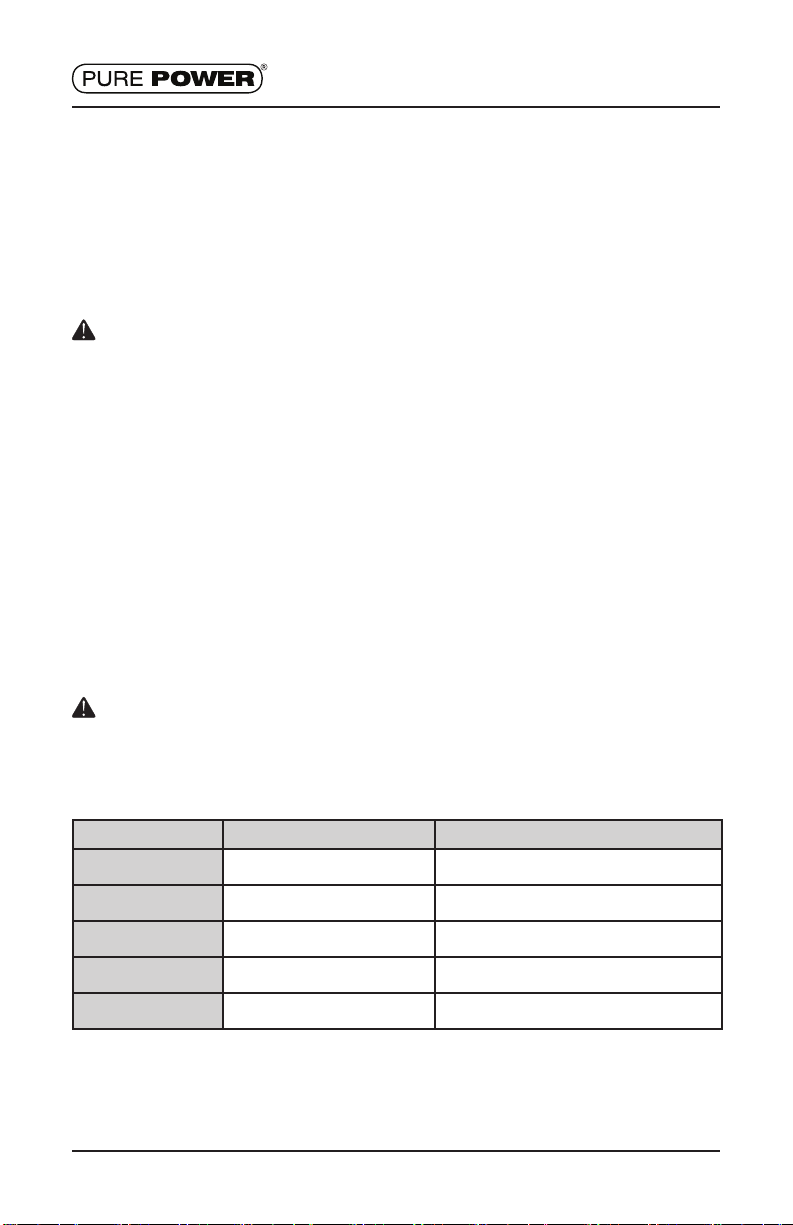

EXTENSION CORD LENGTH WIRE SIZE (A.W.C.)

Up to 25 Feet 14

26 to 50 Feet 12

51 to 100 Feet 10

PLUG

GROUNDING

PIN

GROUNDED

OUTLET