SUBJECT ................................................................................................................................................ See page:

1. INTRODUCTION .............................................................................................................................. 1.1

2. FUNCTION OF THE COMPRESSOR IN THE REFRI ERATIN PLANT........................................... 2.1

3. TECHNICAL DATA

3.1 General technical data.............................................................................................................. 3.1

3.2 Connections and required free space ...................................................................................... 3.2

3.3 Lubrication data........................................................................................................................ 3.4

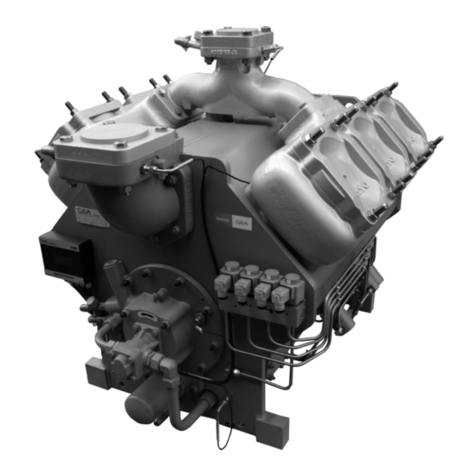

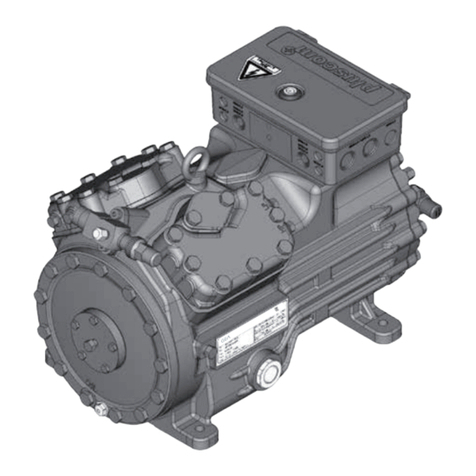

4. ENERAL DESCRIPTION OF THE COMPRESSOR

4.1 Compressor housing ................................................................................................................. 4.1

4.2 Cylinders and moving parts...................................................................................................... 4.1

4.3 Rotary shaft seal ....................................................................................................................... 4.2

4.4 Suction and discharge valves.................................................................................................... 4.2

4.5 Valve-lifting mechanism............................................................................................................ 4.3

4.6 Cylinder head cooling ............................................................................................................... 4.3

4.7 Principal connections and suction gas strainer........................................................................ 4.3

4.8 Pressure equalizing line and overflow safety valves ............................................................... 4.3

4.9 Oil pump, filters and control oil system................................................................................... 4.4

4.10 Lubrication system .................................................................................................................. 4.5

5. DESCRIPTION AND OPERATION OF ACCESSORIES

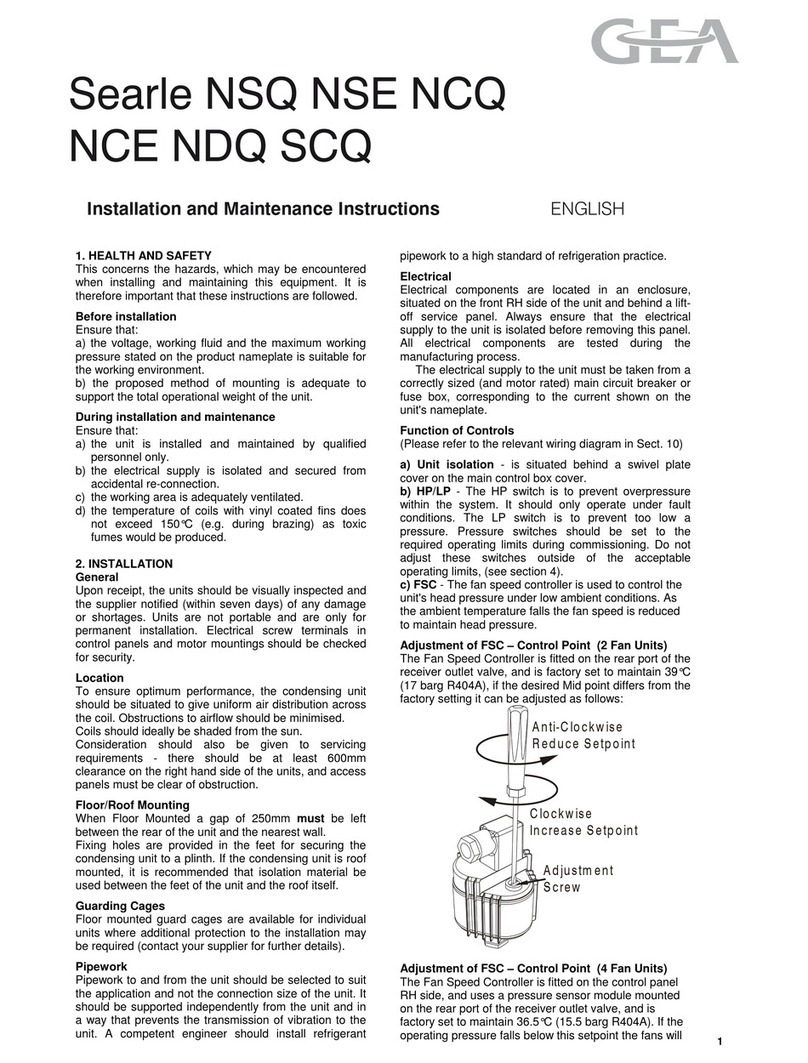

5.1 Pressure gauges ........................................................................................................................ 5.1

5.2 Pressure safety switches ........................................................................................................... 5.1

5.3 Crankcase heating..................................................................................................................... 5.2

5.4 Cylinder head temperature safety device................................................................................ 5.2

5.5 Capacity control

5.5.1 Manually operated capacity control............................................................................... 5.3

5.5.2 Electrically operated capacity control............................................................................. 5.5

5.6 Injection interstage gas cooler ................................................................................................. 5.5

6. OPERATION OF THE COMPRESSOR

6.1 Unloaded starting ..................................................................................................................... 6.1

6.2 Loaded operation of the compressor...................................................................................... 6.1

6.3 Liquid hammer .......................................................................................................................... 6.1

7. STARTIN , STOPPIN AND ADJUSTMENT OF COMPRESSOR

7.1 Starting the compressor ........................................................................................................... 7.1

7.2 Stopping the compressor ......................................................................................................... 7.1

7.3 Setting of the oil pressure regulator........................................................................................ 7.1

7.4 Setting of pressure safety switches.......................................................................................... 7.3

8. PERIODICAL INSPECTIONS OF THE OPERATIN COMPRESSOR

8.1 Survey of periodical inspections (Check list)............................................................................ 8.1

8.2 Explanation to the survey of periodical inspections ............................................................... 8.2

9. COMPRESSOR MAINTENANCE

9.1 Maintenance schedule.............................................................................................................. 9.1

9.2 Lubrication data........................................................................................................................ 9.1

9.3 Topping up oil with compressor operating............................................................................. 9.1

9.4 Evacuation of compressor ........................................................................................................ 9.2

9.5 Draining and change of oil....................................................................................................... 9.2

9.6 Cleaning of oil filters................................................................................................................. 9.2

9.7 Cleaning of the suction gas strainer ........................................................................................9.3

9.8 Dismounting, inspection and reassembly of suction and discharge valves ........................... 9.3

9.9 Compressor purging ................................................................................................................. 9.5

10. FAULT FINDIN TABLE................................................................................................................. 10.1 & ff

Appendix: STANDARD ILLUSTRATED PARTS LIST........................................................................... 1 - 23

Refrigeration Division

rasso

TABLE OF CONTENTS

v002.97.10.en Refrigeration Compressors Series RC9 Page I