6

About the EPP Airframe

Your EPP parts are 1.3 lbs/cu.ft., so that

makes them light weight yet still posses

enough structural integrity to take a

great deal of abuse without breaking.

If you ever break a foam component you

can use a variety of adhesives to fix a

break. Use epoxy or expanding

polyurethane glues, like Gorilla Glue®,

in areas you want to make stiffer. Use

flexible glues like the polyurethane

sealant used to attach the skins or

products like Zap-A-Gap™, Goop™, or

silicone-based adhesive to keep a repair

area capable of flexing. You can even

use regular CA glue as it will not harm

EPP. CA glues vary so testing is

suggested.

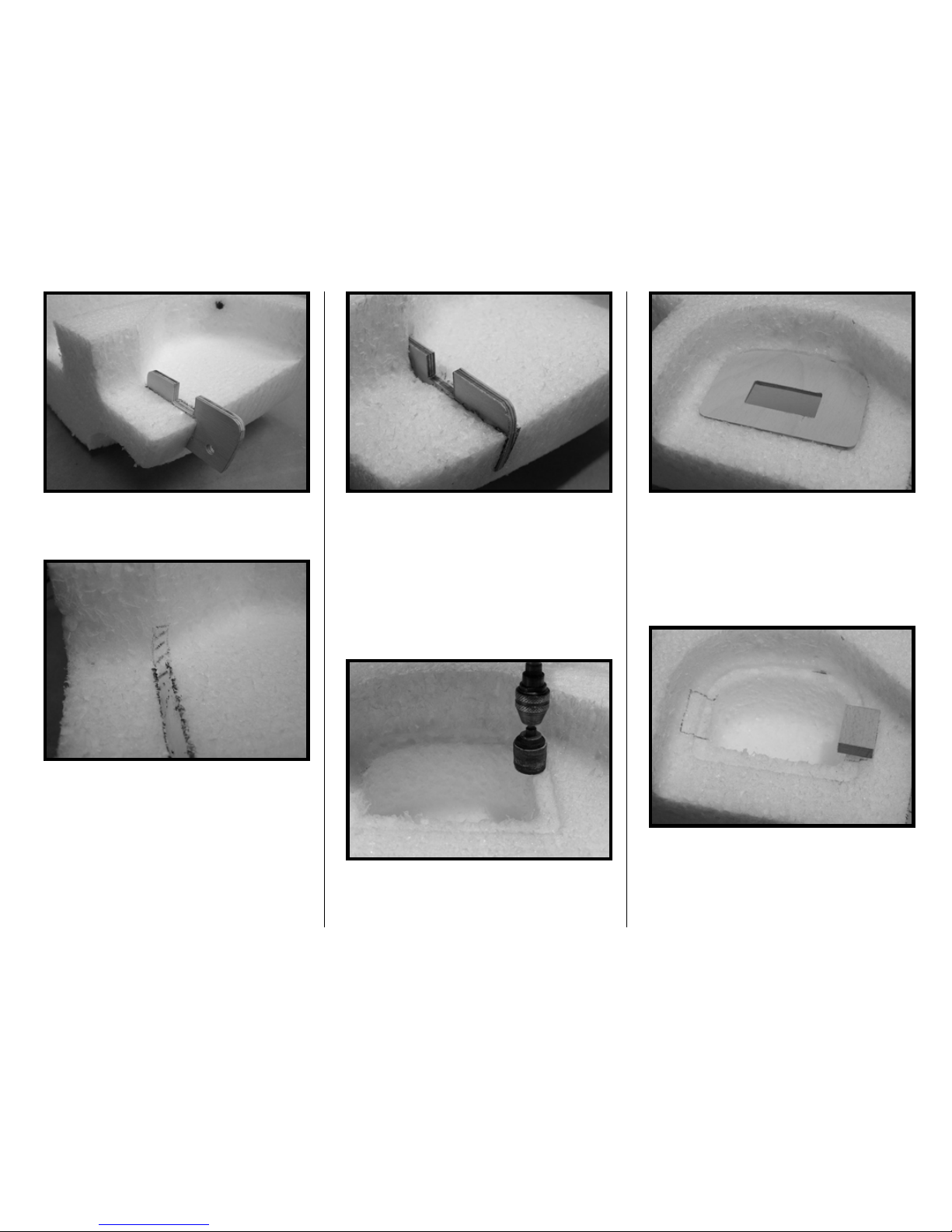

Your airfoil components come with their

foam saddles. After assembly, you can

use this extra foam for repairs (to

replace heavily damaged sections of the

airframe), transportation cushioning, etc.

Unlike expanded polystyrene

(Styrofoam™), EPP is not adversely

affected by gasoline or glo fuels,

however, due to its cellular structure, the

foam could absorb liquids so those

areas exposed to fluids, (under the

lower cowl, nose wheel cavity and fuel

tank area) should be coated with a thin

coat of epoxy to act as a barrier.

In the back of this manual there is an

inventory of all provided EPP

components. Please check that your kit

includes these parts before you begin

assembly.

About the Polycarbonate Skins

This material is amazingly durable

compared to other plastics used in the

modeling industry. Here are some facts

about polycarbonate and our use of this

material as model aircraft skin.

Do not apply solvents like M.E.K.,

acetone, turpentine or toluene to the

skins as this will cause them to crack.

To clean bare polycarbonate use

products like mineral spirits or mild

cleaning agents like Windex. To learn

more about polycarbonate’s

compatibility with other chemicals go to:

http://www.sheffieldplastics.com/web_do

cs/BRO002.pdf

Applying paint to the skins will protect

the polycarbonate from fuel residue, so

only run an installed engine on a model

with primer or paint. As with most

plastics, polycarbonate could tear if a

crack is present so radius corners of cut

lines, where possible.

We form the skins using both male and

female vacuum form molds, therefore,

some skins may have the green

protective film on the outside surface

and the clear protective film on the

inside. Other skin parts may be the

opposite. Some skins may not have film

on one side and some skins may have

no film at all. Your parts may look

different from parts shown in this

manual.

Throughout the manual we will direct

you to trim the skins to fit a specific

airframe part. We will use primarily two

terms; rough trim and finish trim. Rough

trim is basically cutting off the remaining

flashing – the part of the plastic that is

not part of the formed skin detail,

whereas finish trimming will involve

measurements, trial fitting, marking and

cutting to final shape. Since you won’t

initially know where a certain part needs

to be finished trimmed, your rough trims

should maximize the material that can

be distinguishable as the part’s skin. If

you make a mistake and remove too

much material you could use scrap

plastic to make a scale-like panel or call

us and we can get a replacement skin to

you quickly. We suggest you retain all

cut off plastic pieces (except the very

small remnants) so you can use the

excess as scrap when needed during

the assembly process or a future crash

repair.

The skins are primarily .010” thick. This

is good from a weight standpoint.

Additionally, the use of this thin material

as skin will produce the slightly wavy

appearance similar to the aluminum

surface on a full-size aircraft. The

model’s surfaces will not be perfectly

smooth. Smooth surfaces are a

condition we have come to expect in

model aviation, however such conditions

rarely occur in full-scale and certainly