English |5

Qfix | 440 Church Road |Avondale, Pennsylvania 19311 USA | +1 610-268-0585 | +1 610-268-0588 |www.Qfix.com |2007856_C

The installation area should be kept clear to ensure doors, corridors, and passageways

are accessible.

The oven shall be installed in enclosed and well-ventilated areas (not outdoors).

Before positioning the oven, verify the overall dimensions and the exact positions of the

electrical power outlet.

The oven must be placed on a flat surface. Verify that the oven will not slip, fall, or flip

over.

The installation area must be able to support the weight of the oven. See the

information plate on the back of the oven for the gross weight.

The oven should be positioned to allow for easy access to the back of the oven for

maintenance.

The oven should be located near the connections to the power outlet.

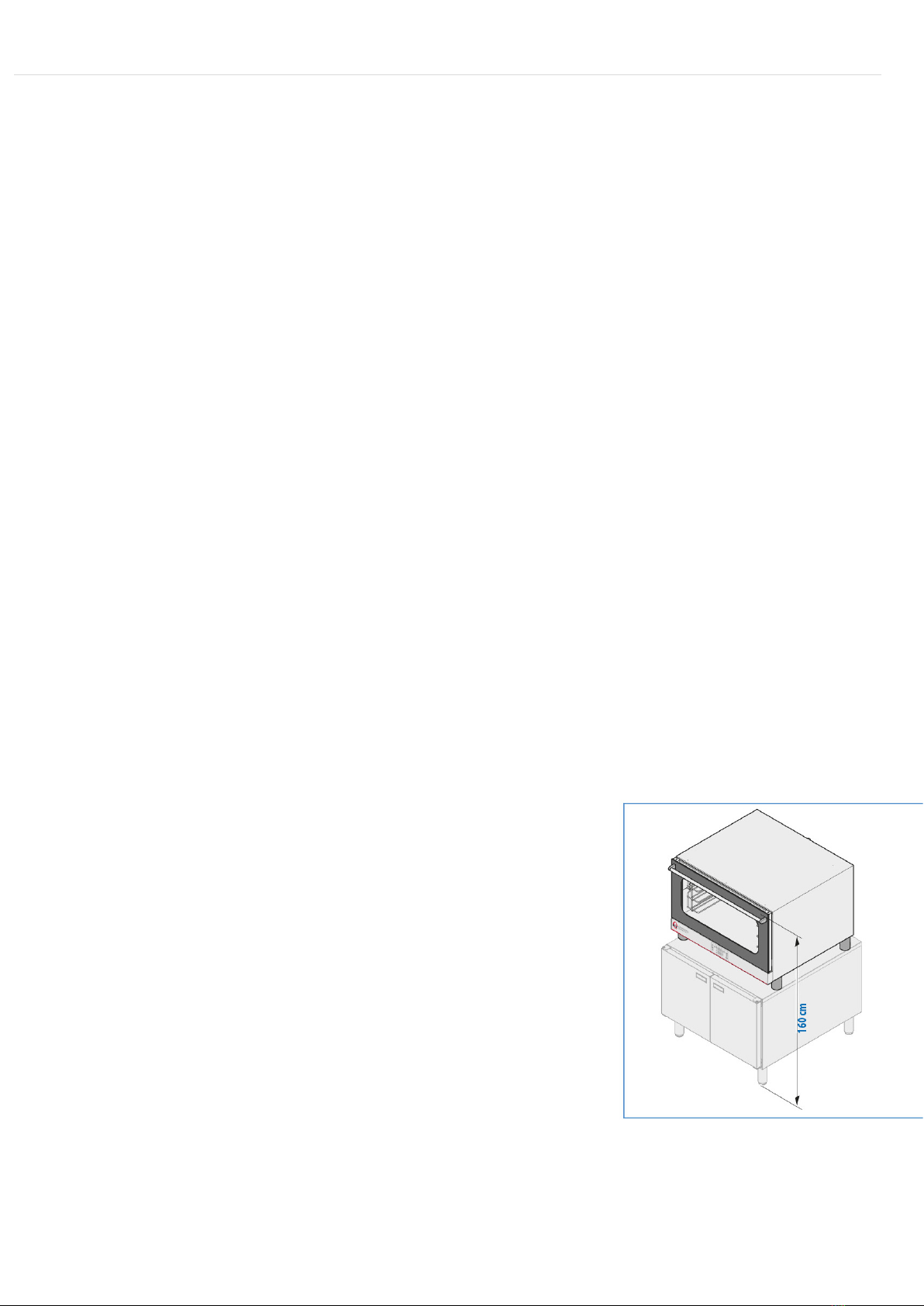

To facilitate easy viewing of the thermoplastic during the softening process, it is

recommended the inside of the oven be approximately at eye level. A suggested

installation height of 160 cm (5.25 feet) is recommended. When positioning the oven on

top of cabinets, stainless steel tables, or other ovens, consider the height requirements

of the user.

The oven is not meant to be tightly fitted inside an enclosure. A 10 cm (4 inch) gap must

surround the oven.

Do not place the oven near heat or other hot liquids.

Do not place the device near materials such as walls,

furniture, screens, or containers of flammable liquids such

as gas canisters due to fire hazards.

Maintain the following distances from machinery: 50 cm

(20 inches) from the oven sides, 50 cm (20 inches) above

the top of the oven, and 70 cm (28 inches) from behind the

oven.

Verify the door may be fully opened.

The vents and aeration slits should be open and clear of

obstructions.