CONTENTS

PART A: INFORMATION FOR THE USER

1.0 GENERAL CHARACTERISTICS

2.0 INTENDED USE

3.0 OPERATION

4.0 GENERAL SAFETY STANDARDS

5.0 DESCRIPTION OF DANGER SIGNALS

6.0 DANGER ZONES

7.0 SAFETY DEVICES

8.0 POSITION OF PLATES

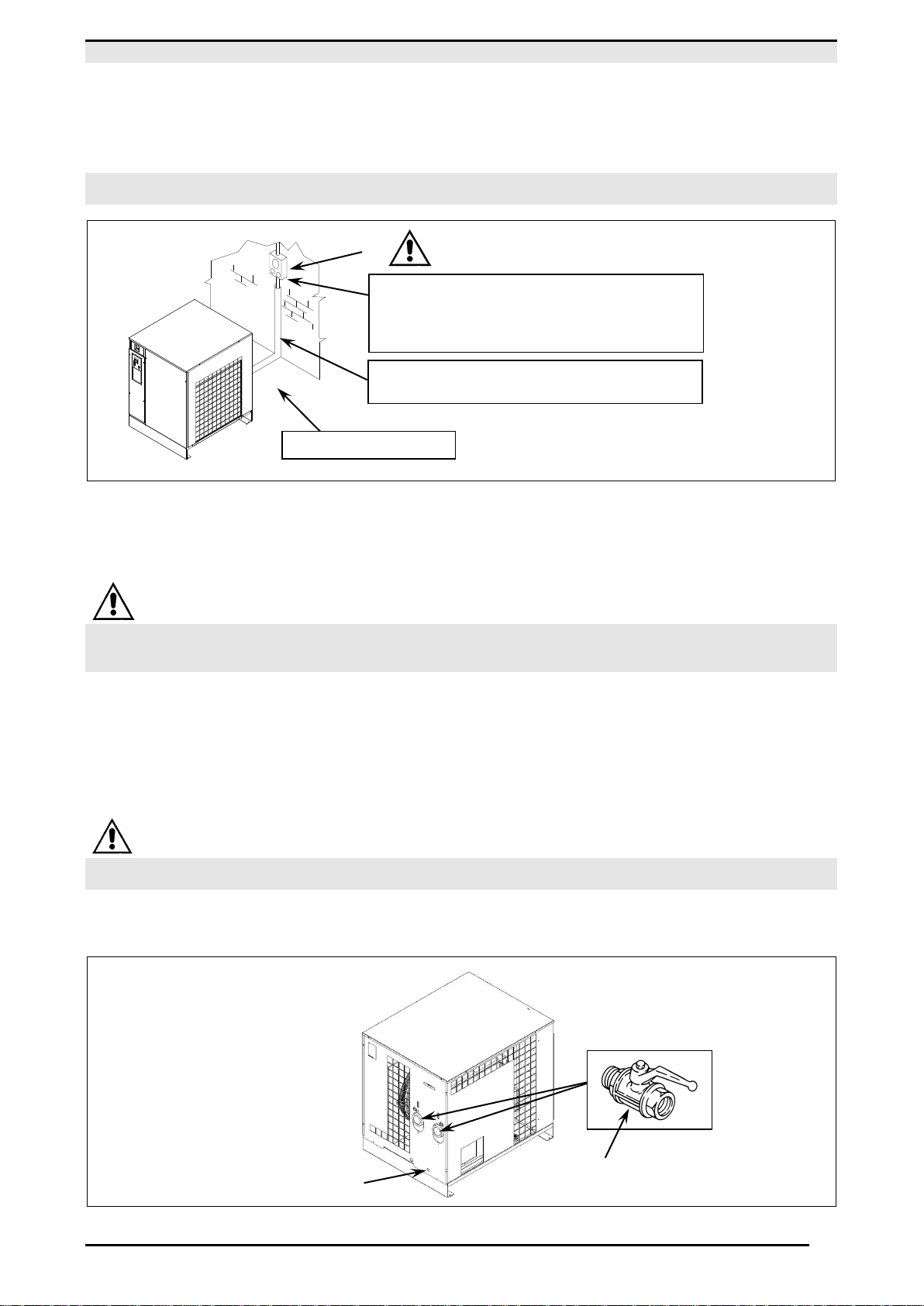

9.0 DRYERS ROOM

10.0 TRANSPORT AND HANDLING

11.0 UNPACKING

12.0 INSTALLATION

13.0 DIMENSIONS AND TECHNICAL DATA

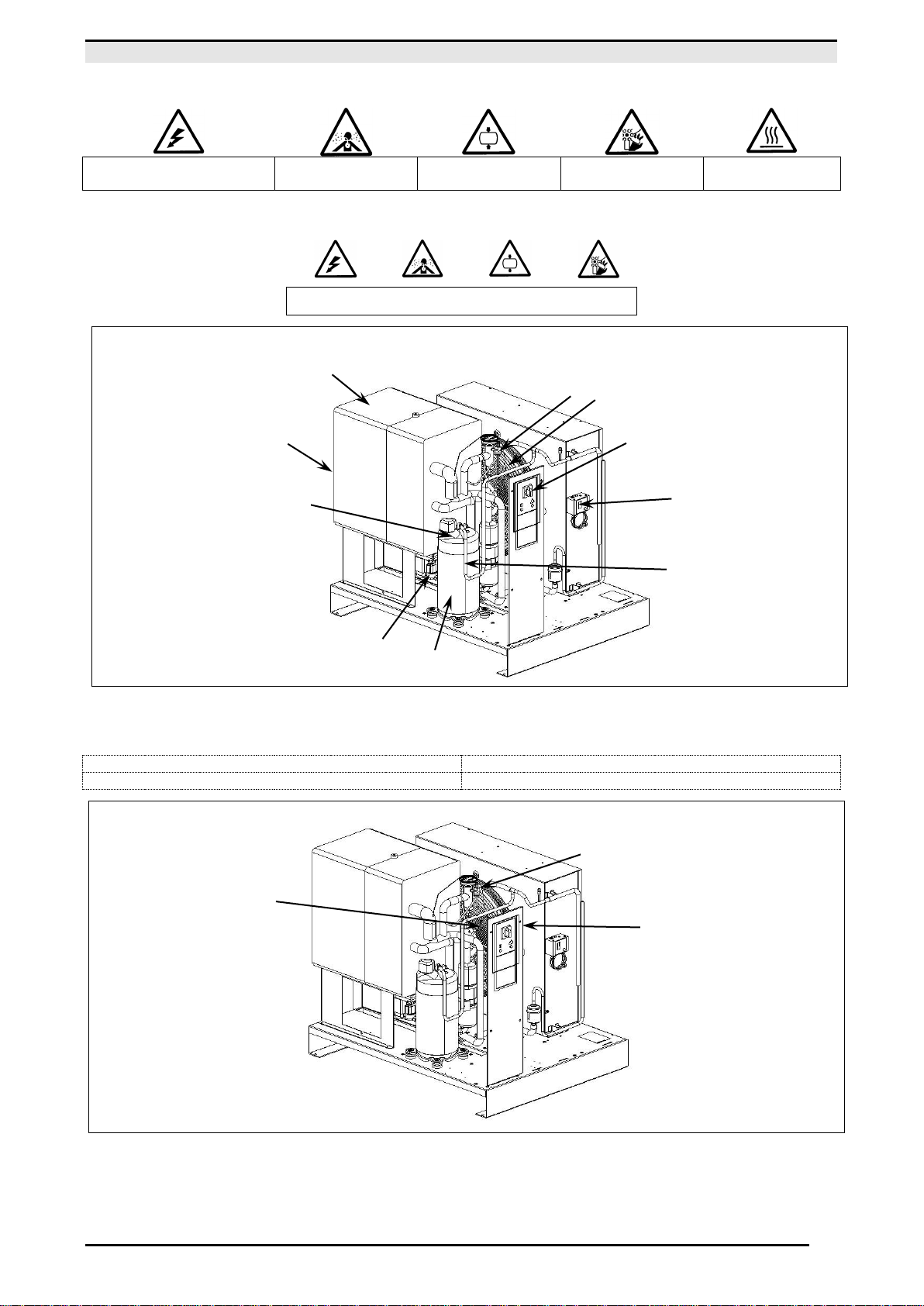

14.0 MACHINE ILLUSTRATION

15.0 SCRAPPING THE DRYERS

PART B: INFORMATION RESERVED FOR TECHNICALLY SKILLED PERSONNEL

16.0 PARTIAL ROUTINE MAINTENANCE

17.0 TROUBLE-SHOOTING AND EMERGENCY REMEDIES

18.0 STARTING UP, FREE CONTACT FEATURES

ATTENTION: THERE IS A COPY OF THE WIRING DIAGRAM INSIDE THE ELECTRIC PANEL

ADDRESSES OF ASSISTANCE CENTRES

In the event of breakdown or malfunction of the dryer, switch it off and do not tamper with it. If repairs are needed, apply

only to a technical assistance centre approved by the manufacturer and insist on the use of original spare parts. Failure

to comply with the above may endanger the safety of the machine.

INTRODUCTION

Keep this manual with care for future consultation; the use and maintenance manual is an integral part on the

dryer. Read this manual carefully before carrying out any operations on the dryer.

The installation of the dryer and all operations involving it must be performed in conformity with the regulations

in force concerning electric plants and personal safety.

CHARACTERISTICS AND SAFETY PRECAUTIONS

BEFORE REMOVING THE PROTECTIVE GUARDS TO CARRY OUT ANY MAINTENANCE ON THE MACHINE, SWITCH OFF THE ELECTRIC

POWER SUPPLY AND DISCHARGE THE RESIDUAL PRESSURE INSIDE THE UNIT.

ALL WORK ON THE ELECTRIC PLANT, HOWEVER SLIGHT, MUST BE CARRIED OUT BY PROFESSIONALLY SKILLED PERSONNEL.

The manufacturer does not accept responsibility for damage caused as a result of negligence of failure to abide by the

instructions given above.

THIS MACHINE IS NOT SUITABLE FOR EXTERNAL INSTALLATION

THIS MACHINE CORRESPOND TO THE ESSENTIAL SAFETY REQUIREMENTS FORESEEN FROM THE

EUROPEAN STANDARD (2006/42 CE).

THE LUBRICATING LIQUIDS AND OTHER EVENTUAL FLUIDS MUST NOT BE DISCHARGED IN THE

ENVIRONMENT. THESE POLLUTING AND HAZARDOUS PRODUCTS MUST COMPULSORY BE DISPOSED BY

CHARGING AUTHORISED AND SPECIALISED FIRMS ACCORDING TO THE DIFFERENT TYPOLOGY OF

PRODUCT.

DIFFERENTIATE THE COMPRESSOR COMPONENTS ACCORDING TO THE DIFFERENT CONSTRUCTION

MATERIALS (PLASTIC, COPPER, IRON, OIL FILTER, AIR FILTER ECC…)