TABLE

OF

CONTENTS

....................................................

Interface

••••••••••••••••••••••••••••••••••••••••••

I

NSTAlLATI

ON

•.•.•.••••••••••••••••••••••••••••••••••••.••••.•••

I

NTRODUCTI

ON

•••••••••••••••••••••••••••••••••••••••••••••••••••

Page

1

1

1

2

3

3

3

3

3

3

4

5

5

7

7

7

8

8

8

9

9

9

9

9

10

10

10

10

10

11

11

11

12

13

13

13

15

15

17

17

18

18

18

18

iii

Interface

••••••••••••••••••••••••••••••••••••••••

....................................................

Input Lines

.....•.........•.•...........•........•..........

Drive Select 1-4

••••••••••••••••••••••••••••••••••••••••

Direction .

Step

............................•.......................

Write

Data

••••••••••••••••••••••••••••••••••••••••••••••

Write

Gate

•••.•..•••.••••••••••.•.••••••••.••.•.••••••••

Side Select

•••••••••••••••••••••••••••••••••••••••••••••

Low

Current/Switch

Filter

•••••••••••••••••••••••••••••••

Head

Load

•••••••

·

••••••••••••••••••••••••••••••••••••••••

In

Use

••••••••••••••••••••••••••••••••••••••••••••••••••

Output

Lines

••••••••••••••••••••••••••••••••••••••••••••••••

Index .

Rea

dy

•••••••••••••••••••••••••••••••••••••••••••••••••••

Track

OO

•••••••••••••••••••••••••••••

~

••••••••••••••••••

Write Protect

•••••••••••••••••••••••••••••••••••••••••••

Read

Data

••.••••••••••••••••.•••••••••••••••••••.•••.••.

Disk

Change

•••••••••••••••••••••••••••••••••••••••••••••

Two-S

i

ded

•••••••••••••••••••••••••••••••••••••••••••••••

Alternate

I/O

Pins

••••••••••••••••••••••••••••••••••••••••••

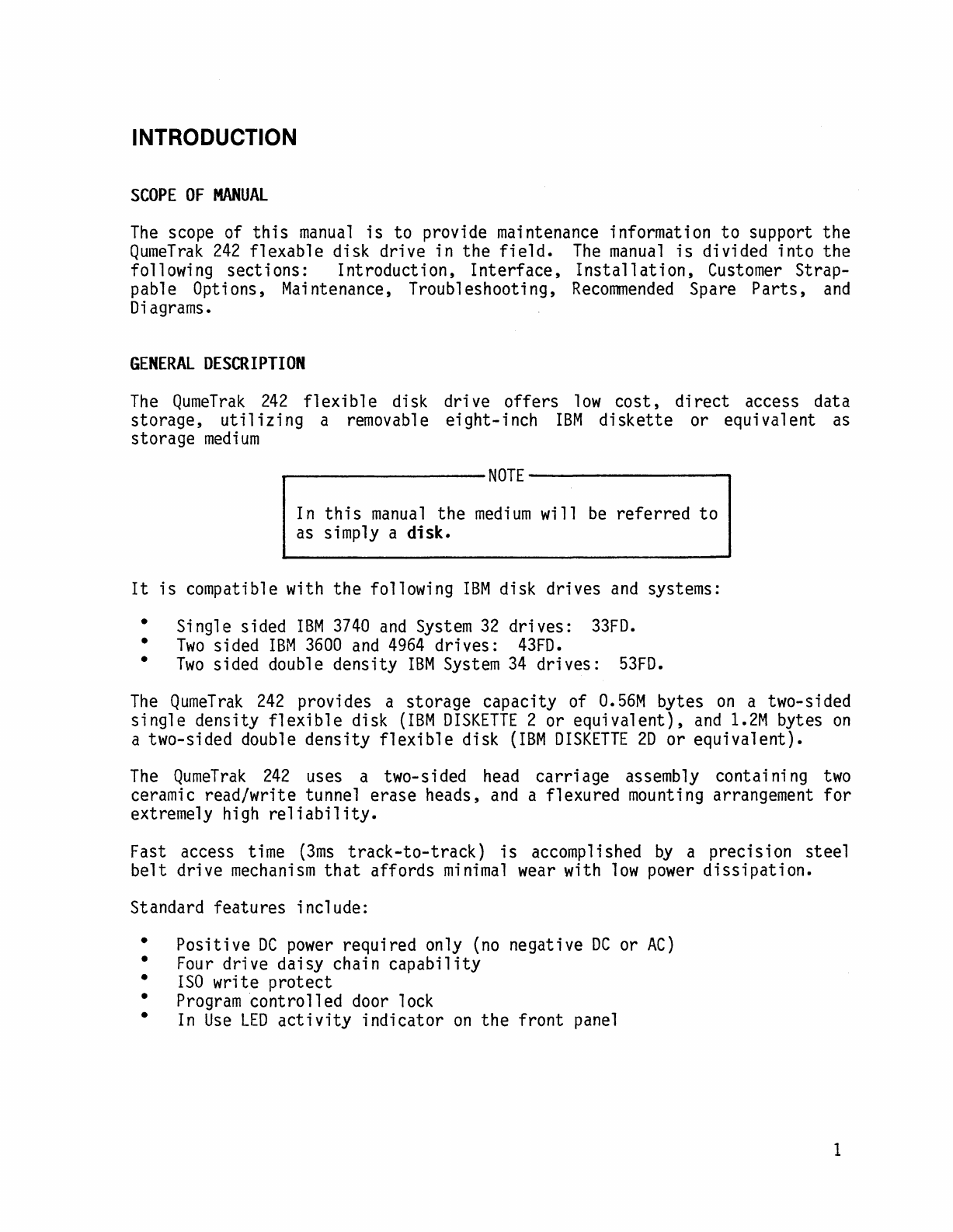

Scope

of

Manual

•••••••••••••••••••••••••••••••••••••••••••••

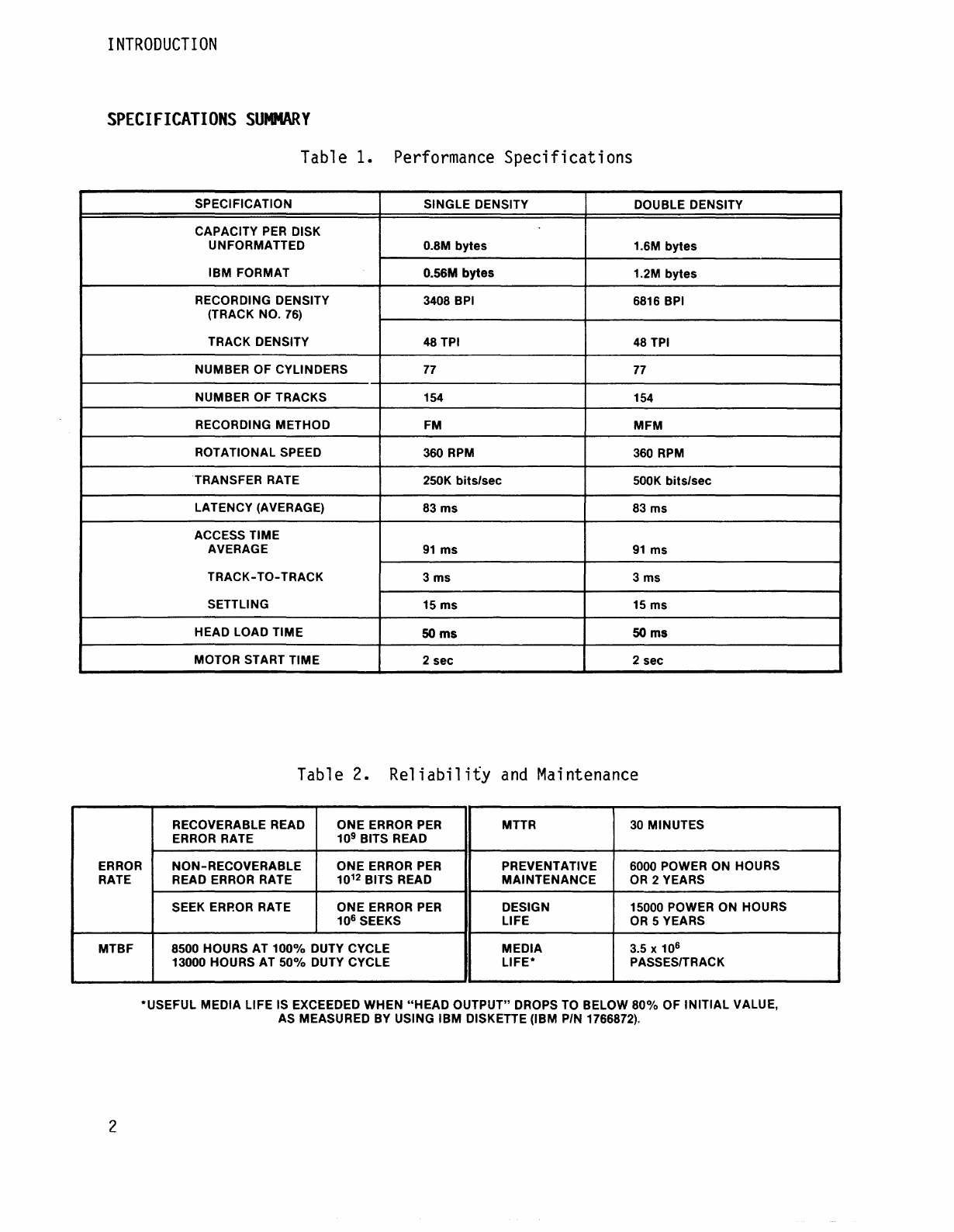

General Description

•••••••••••••••••••••••••••••••••••••••••

Specifications

Summary

••••••••••••••••••••••••••••••••••••••

Compati

bi

1

ity

•••••••••••••••••••••••••••••••••••••••••••••••

Read/Write/Erase

Head

•••••••••••••••••••••••••••••••••••

Read

Output

Level

•••••••••••••••••••••••••••••••••••••••

Write Current

•••••••••••••••••••••••••••••••••••••••••••

Switch

Filter

•••••••••••••••••••••••••••••••••••••••••••

Track

Positioning

•••••••••••••••••••••••••••••••••••••••••••

Index Positioning

•••••••••••••••••••••••••••••••••••••••••••

Receiving

and

Inspection

••••••••••••••••••••••••••••••••••••

Mou

nt

in

g

....•.•••••••••••••••••••.•.••••••••••••••.•..••••••

Mechanical

Dimensions

•••••••••••••••••••••••••••••••••••

Recommendations

•••••••••••••••••••••••••••••••••••••••••

Installation

Requirements

•••••••••••••••••••••••••••••••••••

Timing

Physical

Connectors

and

Cables

•••••••••••••••••••••••••••••••••••••••

I/O

Signals

(Pl/Jl)

•••••••••••••••••••••••••••••••••••••

Power

(P5/J5)

•••••••••••••••••••••••••••••••••••••••••••

T

ermi

nators

•••••••••••••••••••••••••••••••••••••••••••••••••

INTERFACE

El

ectri

cal