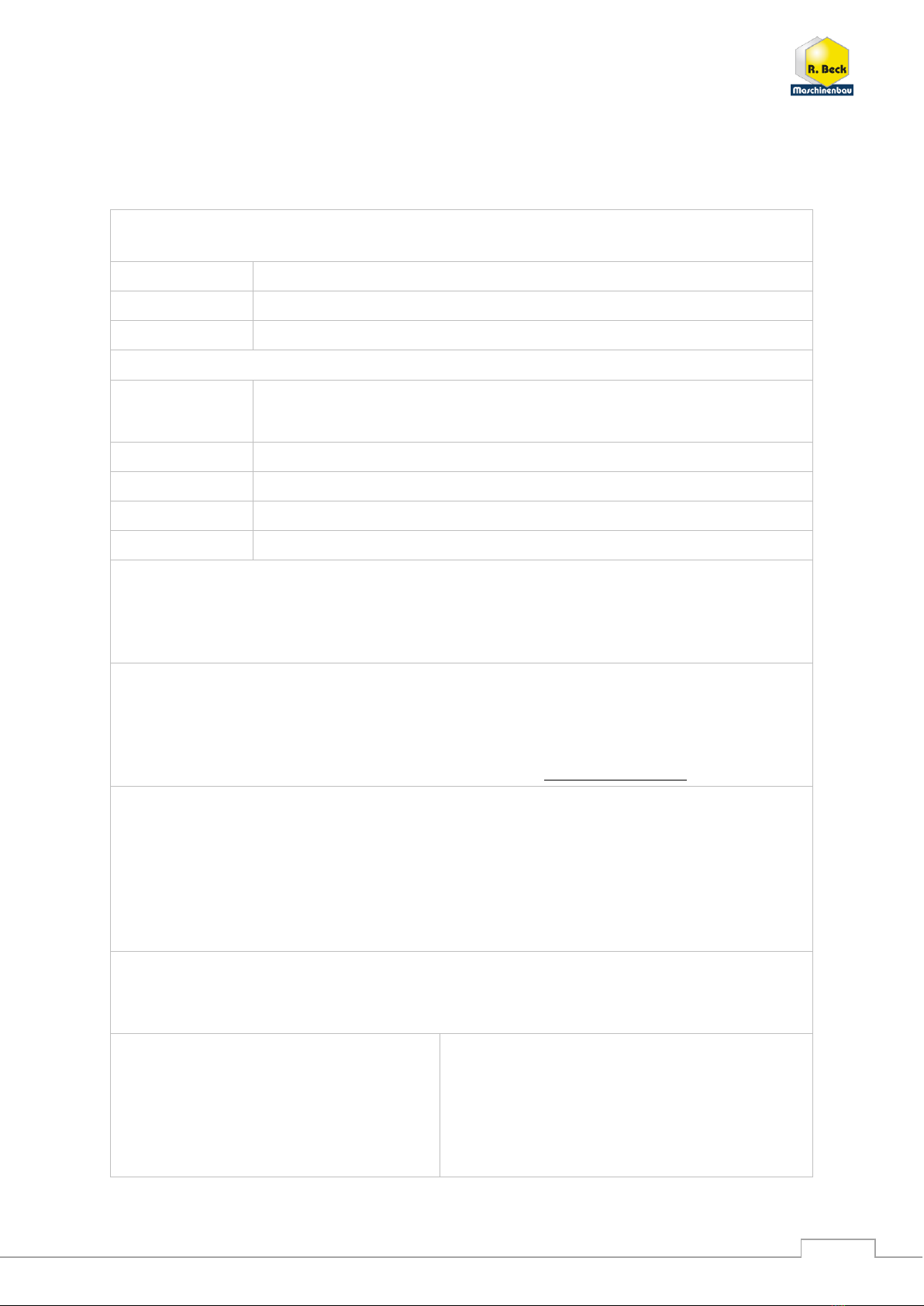

List of figures

Figure 1: machining process on the UTK..............................................................................................................................................13

Figure 2: permissible workpiece cross-sections UTK 350..................................................................................................................... 17

Figure 3: permissible workpiece cross-sections UTK 450..................................................................................................................... 17

Figure 4: permissible workpiece cross-sections UTK 500..................................................................................................................... 17

Figure 5: permissible workpiece cross-sections UTK 600..................................................................................................................... 17

Figure 6: danger zones on the under-table cross-cut saw................................................................................................................... 25

Figure 7: name plate............................................................................................................................................................................26

Figure 8: UTK 350 dimensions ............................................................................................................................................................. 28

Figure 9: UTK 450 dimensions ............................................................................................................................................................. 28

Figure 10: UTK 500 dimensions ...........................................................................................................................................................29

Figure 11: UTK 600 dimensions ...........................................................................................................................................................29

Figure 12: transport on pallet.............................................................................................................................................................. 30

Figure 13: lifting off the pallet .............................................................................................................................................................30

Figure 14: levelling via the feet............................................................................................................................................................31

Figure 15: working positions................................................................................................................................................................33

Figure 16: terminal box........................................................................................................................................................................ 34

Figure 17: direction of rotation............................................................................................................................................................34

Figure 18: suction nozzles UTK 500 and 600........................................................................................................................................35

Figure 19: earthing example for suction hose .....................................................................................................................................35

Figure 20: connector............................................................................................................................................................................35

Figure 21: maintenance unit................................................................................................................................................................ 36

Figure 22: components and controls ...................................................................................................................................................37

Figure 23: control panel with switches and signal lamps..................................................................................................................... 38

Figure 24: two-hand safety control......................................................................................................................................................39

Figure 25: adjusting knob for lifting speed ..........................................................................................................................................39

Figure 26: safety switch UTK 600 - door unlocked............................................................................................................................... 40

Figure 27: safety switch UTK 600 - door locked...................................................................................................................................40

Figure 28: vertically mounted safety switch........................................................................................................................................ 40

Figure 29: saw blade disassembly via expansion cone flange.............................................................................................................. 41

Figure 30: direction of rotation of the saw blade ................................................................................................................................41

Figure 31: clamping guard for model UTK 600.....................................................................................................................................42

Figure 32: clamping guard for model UTK 350.....................................................................................................................................42

Figure 33: protective shield (standard version)................................................................................................................................... 42

Figure 34: optional pneumatic protective shield................................................................................................................................. 43

Figure 35: full protection cover with viewing window.........................................................................................................................43

Figure 36: workpiece fence..................................................................................................................................................................43

Figure 37: inclined machine design......................................................................................................................................................44

Figure 38: pneumatic horizontal clamping device ...............................................................................................................................44

Figure 39: roller conveyor mounted on one side.................................................................................................................................44

Figure 40: saw blade access door ........................................................................................................................................................45

Figure 41: adjustment knob for lifting speed.......................................................................................................................................45

Figure 42: manual positioning system with flip stop ...........................................................................................................................45

Figure 43: cut triggering via two-hand control ....................................................................................................................................46

Figure 44: laser unit to indicate the cutting line..................................................................................................................................47

Figure 45: visualisation of the cutting line on the workpiece ..............................................................................................................47

Figure 46: wear rail in the state of delivery (example UTK 600).......................................................................................................... 52

Figure 47: wear rail in the fitted state, still without slot (example UTK 600).......................................................................................52

Figure 48: ready-to-use wear rail with sawn slot (example UTK 600)..................................................................................................52

Figure 49: motor cover plate removed................................................................................................................................................53

Figure 50: V-belt tensioning nuts UTK 350...........................................................................................................................................53

Figure 51: V-belt tensioning nuts UTK 450...........................................................................................................................................53

Figure 52: V-belt tensioning nuts UTK 500...........................................................................................................................................54

Figure 53: V-belt tensioning nuts UTK 600...........................................................................................................................................54

Figure 54: brake adjustment screw 2.2 / 3.0 / 4.0 kW......................................................................................................................... 56

Figure 55: brake adjustment screw 5.5 / 7.5 kW .................................................................................................................................56

Revisions: