R. Lang Company Roll Away R6500 Series User manual

Revison: 1.0 Date: 12/01/2010 Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 1 of 6

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

R6500 Series

Installation Instructions

(For Surface Mount Doors)

IMPORTANT:

REVIEW ALL INSTRUCTIONS

THOROUGHLY

BEFORE STARTING STEP 1

TOOLS REQUIRED:

Tape Measure•

Standard Screwdriver•

Phillips Head Screwdriver•

Drill Motor•

1/8” Drill Bit•

3/16” Drill Bit•

Hack or Chop Saw•

Framing Square•

Level•

Step 1

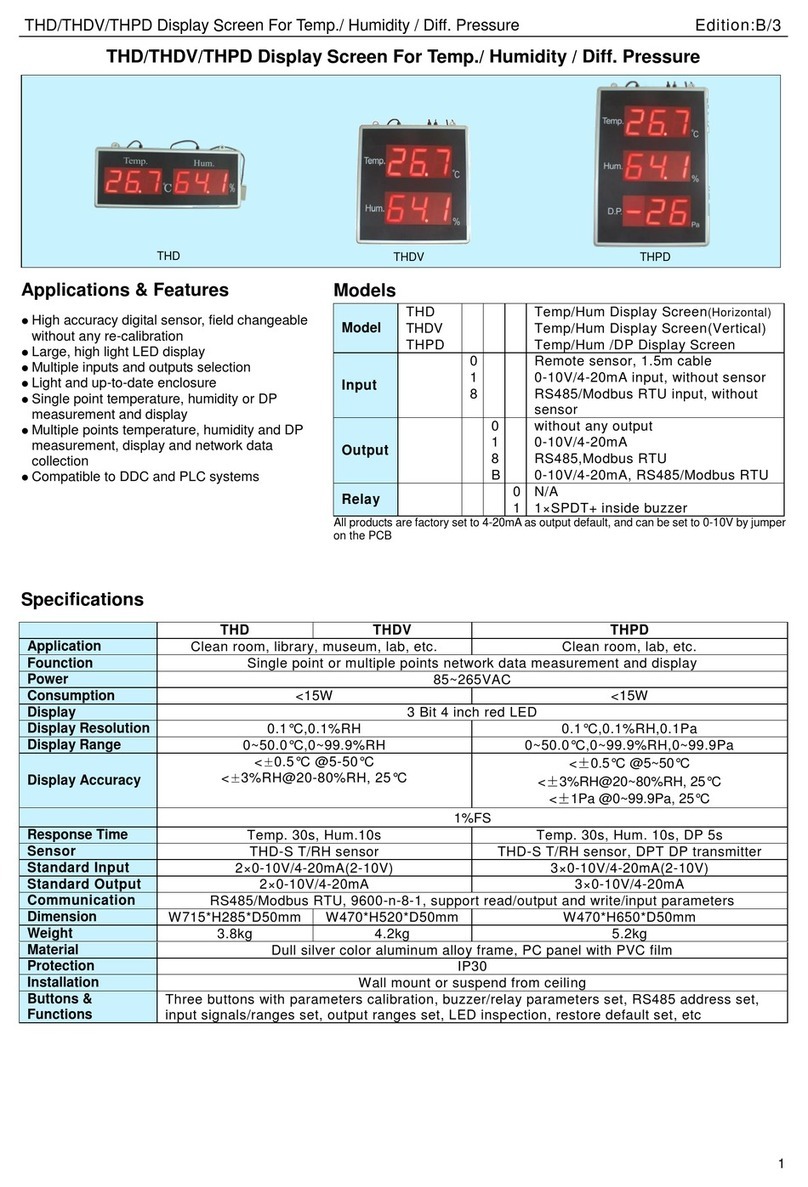

PARTS INCLUDED:

Head Track

#R6046

Sill Track

#R6041

Closer

#R8021

Strike

#D2160

Flat Head Screws

#6 x 3/4”

Pan Head Screws

#4-40 x 1/2”

#8 x 1”

Fabricate / Verify Part Lengths Required

Note:

Assembled Roll-• Away® screens have already been cut to size. Verify cut size below and proceed to Step 2

Closer (#R8021)

Opening Height minus 1-1/8”

Track (#R6041 & #R6046)

Opening Width minus 3-1/16 ”

Hinge/Housing assembly opening height 1-1/8”.

KD “Kit” Roll-• Away® screens. Please refer to Page 1 of the Fabrication Instructions.

#4-40

Lock Nut

Partially

Assembled Unit

Revison: 1.0 Date: 12/01/2010Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 2 of 6

Install Tracks

Track correctly

pocketed in the housing

end cap.

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

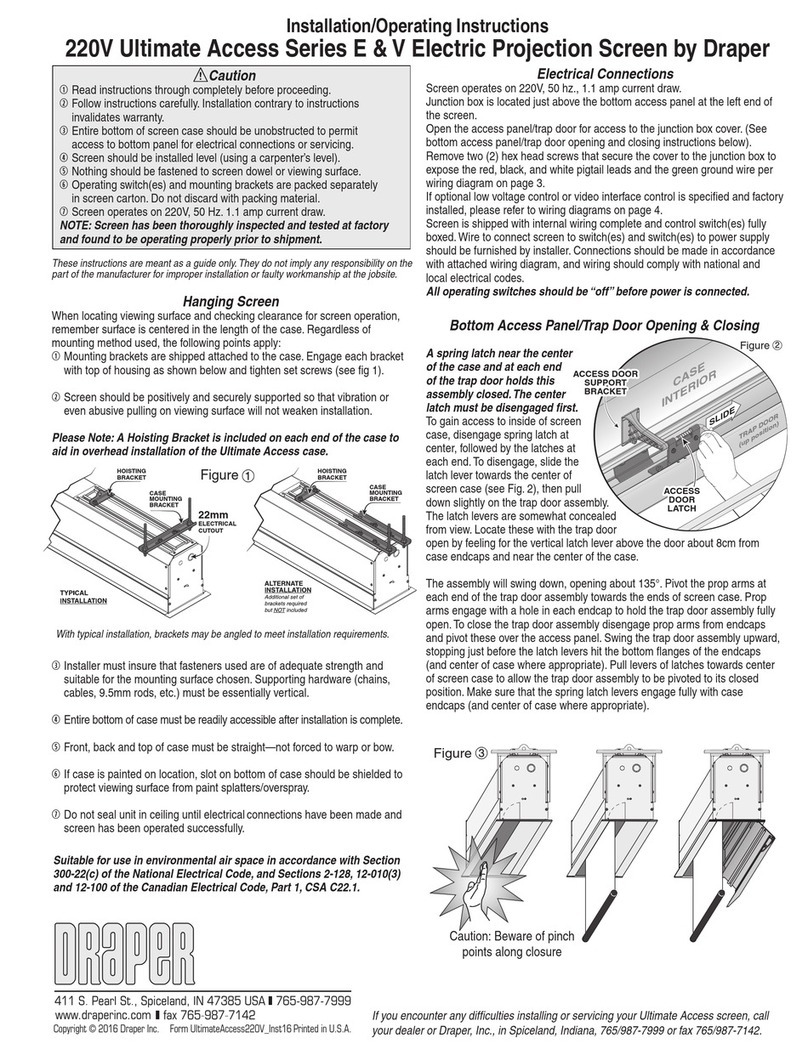

Step 2 Install Housing/Hinge

Figure 1

Figure 2

Drill three (3) 3/16” clearance holes in the housing hinge, one approximately 2” from each end,

oneapproximatelyinthemiddle.Locatetheholesusingthegrooveinthehingeange(Figure1).

Note: These hole locations may be pre-drilled from the factory.

Carefully, making sure not to damage the screen, install the Housing Hinge against the stop in the

jamb using three (3) #8 x 1” pan-head screws provided. The hinge should extend past the opening

1/2” on both the header and sill.

Step 3

Figure 3

Figure 6

Drill three (3) 3/16” clearance holes in each track, one approximately 2” from each end, one approximately

in the middle. Note: These hole locations may be pre-drilled from the factory. Locate the holes using the

grooveinthetrackange(Figure3).Inserttheheadtrackintothedrawbarwheelhousing,andslideit

into the pocket in the housing end cap. Carefully align the track with the housing, using a framing square

(Figure 4) to insure accuracy. Make sure the track is fully seated in the housing end cap pocket (Figure 5)

and attach the track to the opening using the #8 x 1 pan head screws provided. Repeat this process for the

sill track (Figure 6).

NOTE:

It is the responsibility of the installer to insure the installation screws are rmly xed in a suitable wall or frame. R. Lang

Company makes no implication that the screws provided are suitable for every application, and will not be responsible

for damage, poor operation, or failure that result from improper installation. Pilot holes are recommended for all screw

fastening applications. Sill Track attached.

(Note its relation to the opening edge.)

Use a square

to align the

track.

Figure 4 Figure 5

Screw Hole

Groove

Screw Hole

Groove

A #6 x 3/8 pan head screw has been installed to lock

the hinge to the housing.

Place the hinge against the jamb as shown (Figure 2)

and screw it into place. Make sure the housing is fully

seated on the hinge.

Hinge Lock

Screw

Revison: 1.0 Date: 12/01/2010 Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 3 of 6

Figure 8

Screw hole groove locknut

This distance

should be

approximately

1/8”

Latch

Nose of strike

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

Step 4 Install Closer

Step 5 Strike Installation

Installation Complete

Make sure all components are properly installed. Check the overall operation of the door. Drawbar guides should move freely over

both the bottom and top tracks and connect squarely with the closer. If properly installed, the door will want to return to the housing

quickly after breaking contact with the strike.

Drill three (3) 3/16” clearance holes in the closer (#R8021), two

approximately 4” from each end, one approximately in the middle

using the groove in the closer ange. The closer is designed to

pocket the tracks. It may be installed without modifying the tracks,

leaving a small gap.

Install Closer over the ends of the tracks using #8 x 1” pan head

screws provided, on the jamb opposite the housing (Figure 7).

The strike (D2160) is mounted nose down (Figure 8), using the #4-40 x 1/2 screws and lock nuts provided. The mounting holes

for the strike must be located along the alignment groove (Figure 9) provided inside the closer. The nose of the strike should be

approximately 1/8” below the latch, as measured from the sill track (Figure 10). The strike holes will locate 3/4” and 1 1/4” above

this point. Adjust the strike up or down as needed to get a secure latch. Use a 1/8” drill for #4 screw pilot holes.

WARNING!

Adjusting the strike too far down will not allow the latch to engage the strike.

Figure 7

Installed Closer, Top View.

Note its relation to the opening edge.

Strike #4-40

Lock Nut

Figure 10Figure 9

Track

Measure for strike

from this point.

Revison: 1.0 Date: 12/01/2010Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 4 of 6

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

French Door Instructions

R5180

Astragal

R5490

Astragal Pin

Amendments To Installation Instructions For French Door Opening

Inactive Door

The astragal and astragal pins are installed on the inactive door. The

strike is pre-installed in the astragal center pocket of the inactive door.

Install Head Track

Both doors in a French set will travel along the same tracks. Locate the Head Track (R6046) and feed it on to

the top roller guide of the inactive door (See Figure 5 on Page 2). Now take the opposite end of the Head Track

and align it into the Housing end cap notch on the active door. The Head Track on the inactive side should now

beinthehousingnotchlocation.FastentheTracktotheheaderusingthe#8x1”atheadscrewsprovided.

ADDITIONAL PARTS

INCLUDED:

“Snapping” in the Active Door

Carefully... and while making sure the screen is properly

guided within the top and bottom tracks, pull on the center

of the drawbar until approximately two (2) feet of screen is

exposed. Line up the top drawbar guide with the top track,

and the bottom drawbar guide with the bottom track (this will

require the drawbar to be at a slight angle) and “snap” into

place (Figure 11). Allow the screen to retract back into the

housing. Test for smooth operation.

Install Housing / Hinge

Install both Housing/hinge assemblies in the jambs directly opposite

of each other. The active door will have a latch projecting from the

drawbar at the handle center.

Step 2

Step 3

Step 4

Note: It is necessary to keep the drawbar guides aligned with the tracks

during this process to prevent damage to the guide assemblies!

Step 6

Pan Head

#4-40 x 1/2”

Lock Nut

#4-40

(See Page 1 for Step 1)

Step 1

Step 5

Install Bottom Sill Track

Repeat Step 4 for installing the Sill Track. After this step the

drawbar and screen for the inactive door will operate on the

track. The active door will not.

Inactive

Door

Figure 11

Revison: 1.0 Date: 12/01/2010 Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 5 of 6

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

Install Astragal Stops

Install Astragal Stops (#R6490/R6495) into head and sill track.

Fasten using one (1) #6 x 3/4”

atheadscrewthroughholeand

intotrack.Theastragalblocksarekeyedonthebottomtotin

the screw groove in the track, and the stop upright will point at the

active door. Make sure stops are evenly placed, top and bottom,

and hold stationary door in required position. The stop upright

should be placed at that position in the track. The active door

Step 7

Adjust Strike

Follow the instructions in Step 6, Page 3 for adjustment of the strike if necessary.

Installation Complete

Make sure all components are properly installed. Check the overall operation of the door. Drawbar guides should move freely over

both the bottom and top tracks and connect squarely with the closer. If properly installed, the door will want to return to the housing

quickly after breaking contact with the strike.

should easily open and close, latching at the inactive door when required. If more depth for the astragal pins are desired, a 7/32” drill

bit can be used to drill through the astragal stops into the track. Be careful here, that this process does not compromise the integrity of

the building structure or weather barrier. R. Lang Company will not be responsible for any damage as a result of improper application

of this process.

Step 8

R6490 (RH)

R6495 (LH)

Astragal Block

Location Drawbar with

Astragal Pin.

(Pin is in

slot in drawbar)

Roll-Away® LIMITED WARRANTY

To the original purchaser, R. Lang Company warrants this product and its components parts to be free of defects on materials and workmanship for a period

of one year from the date of purchase.

Damagecausedbyaccident,improperinstallationorabuse,isspecicallyexcludedfromthiswarranty.Manufacturer’sliabilityonanyclaimshallnot

exceed the cost of the product. In no instance shall manufacturer be responsible for consequential damage from the use of this product, including damage

to existing door during installation or operation.

For a period of one (1) year from the date of purchase, any defective product or part may be sent, freight prepaid, to R. Lang Company, 8240 West Doe

Avenue, Visalia, California (93291) for replacement or repair at no charge. Proof of purchase date and a pre-approved Return Materials Authorization must

accompany any returned item. For further information about this warranty, write to Consumer Affairs Manager at R. Lang Company.

This warranty replaces any and all previous warranties, either written, oral, or implied, and is the only warranty made on this product by the R. Lang

Company.Thiswarrantygivesyouspeciclegalrights.Rightsmayvaryfromstatetostate.

Active Door

Stop upright

Revison: 1.0 Date: 12/01/2010Tel: 800-677-5264 | Fax: 888-526-4329

Installation

Page 6 of 6

www.rollaway.com

Manufactured &Manufactured &

made in theU.S.A.

Series 6500

Parts List

R6171R

R6041

R8021

R6100

R6161

R5170

R5636/37

R5120

R6171L

R6075

R6110

R6010

R6021

R6046

R6465

D2160

SCREEN HEIGHT

SCREEN WIDTH

HEAD

JAMB

JAMB

15/16”

1-7/8”

2-5/8”

1-3/8”

1-1/16”

1-1/8”

1-1/8”

1-1

/

16”

SILL

R. Lang Company

Tel 800-677-5264 | Fax 888-526-4329

Tel 800-677-5264 | Fax 888-526-4329

R. Lang Company

Series 6500 Surface Mount

Parts List

R5120## Drawbar

R5636MFTube with Screen 82”

R5637MFTube with Screen 96”

R5170 Spring Roller Assembly

R8021## Facemount Closer

D2160 Die Cast Strike & Screw Assembly

R6465BL/WH Handle Assembly with Strike

R6010## Housing

R6021## Surface Mount Hinge

R6041## Sill Track

R6046## Head Track

R6075 PVC Cushion

R6110BL/WH Housing End Cap - LH

R6100BL/WH Housing End Cap - RH

R6161BL/WH Bushing with Pan

R6171(BL/WH)LDrawbar End Cap Assembly - LH

R6171(BL/WH)RDrawbar End Cap Assembly - RH

## - Door color

Table of contents

Popular Projection Screen manuals by other brands

SI

SI Dynamic 2 XL installation manual

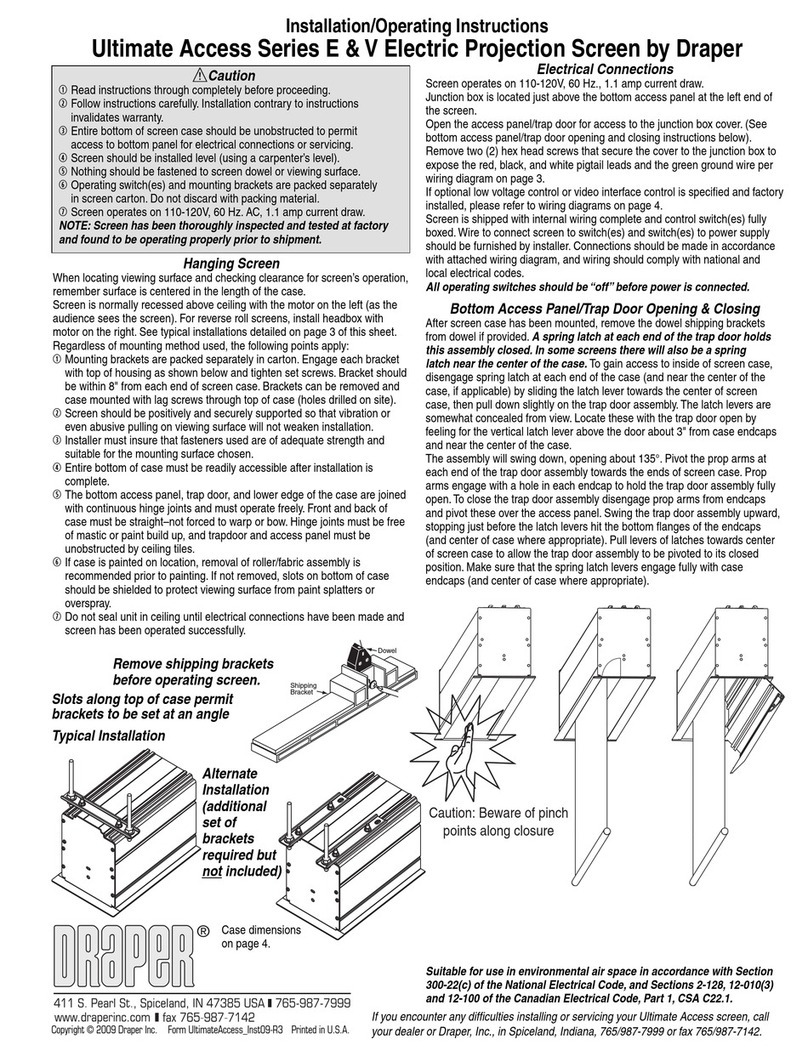

Draper

Draper E series Installation and operating instructions

Draper

Draper Envoy Installation & operating instructions

Remaco

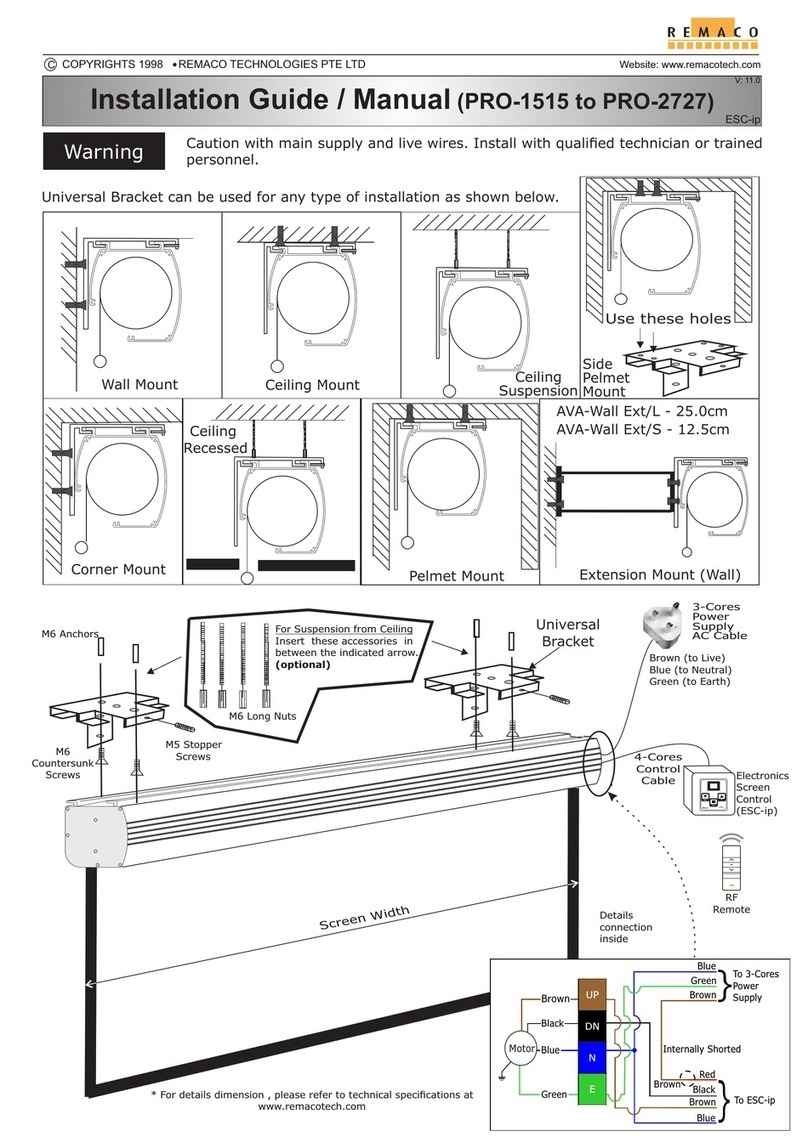

Remaco PRO-1515 Installation guide & manual

Elite Screens

Elite Screens isf CineWhite UHD-B Sable Frame B2 Series user guide

Shenzhen HONY Optical

Shenzhen HONY Optical FDT05 user manual

Draper

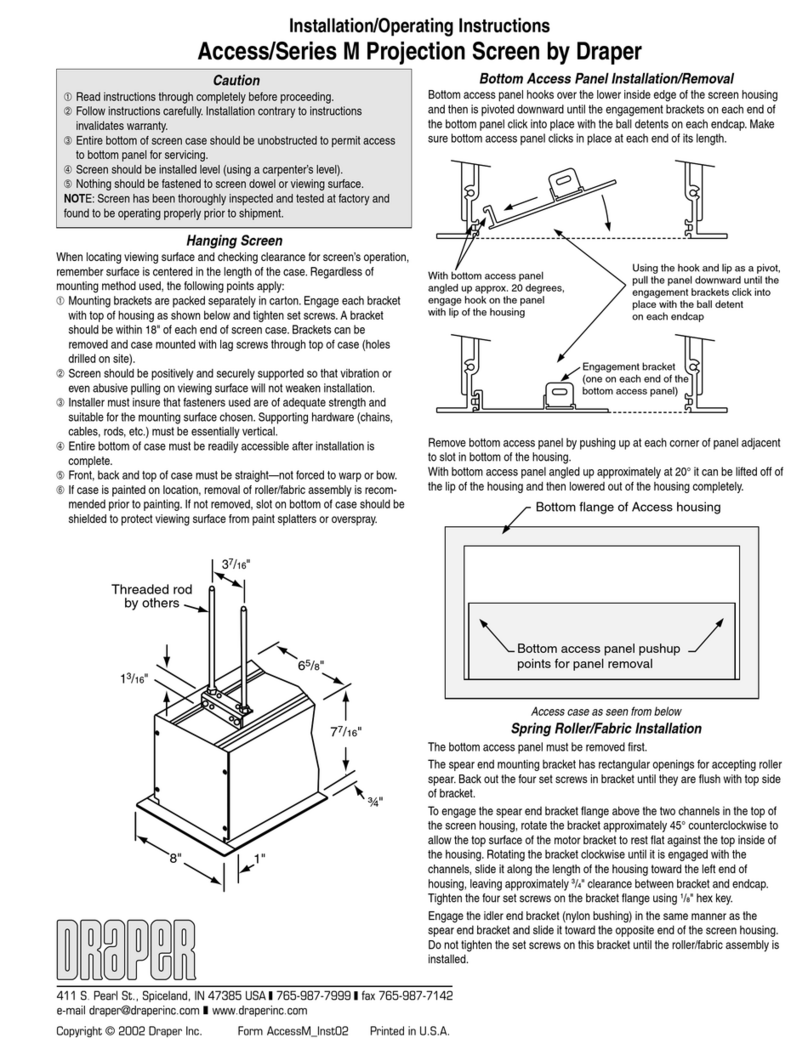

Draper M Series Installation & operating instructions

Da-Lite

Da-Lite Deluxe Insta-theater Instruction book

Draper

Draper Ultimate Access Series E Installation & operating instructions

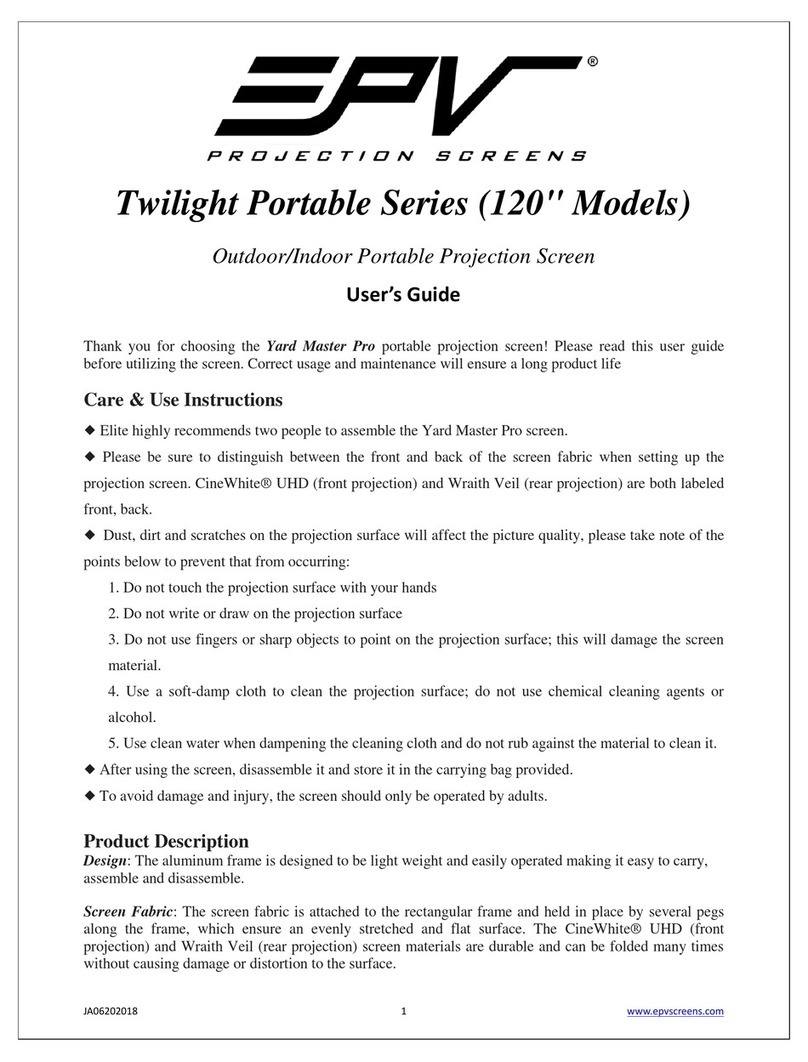

EPV

EPV Twilight Portable Series user guide

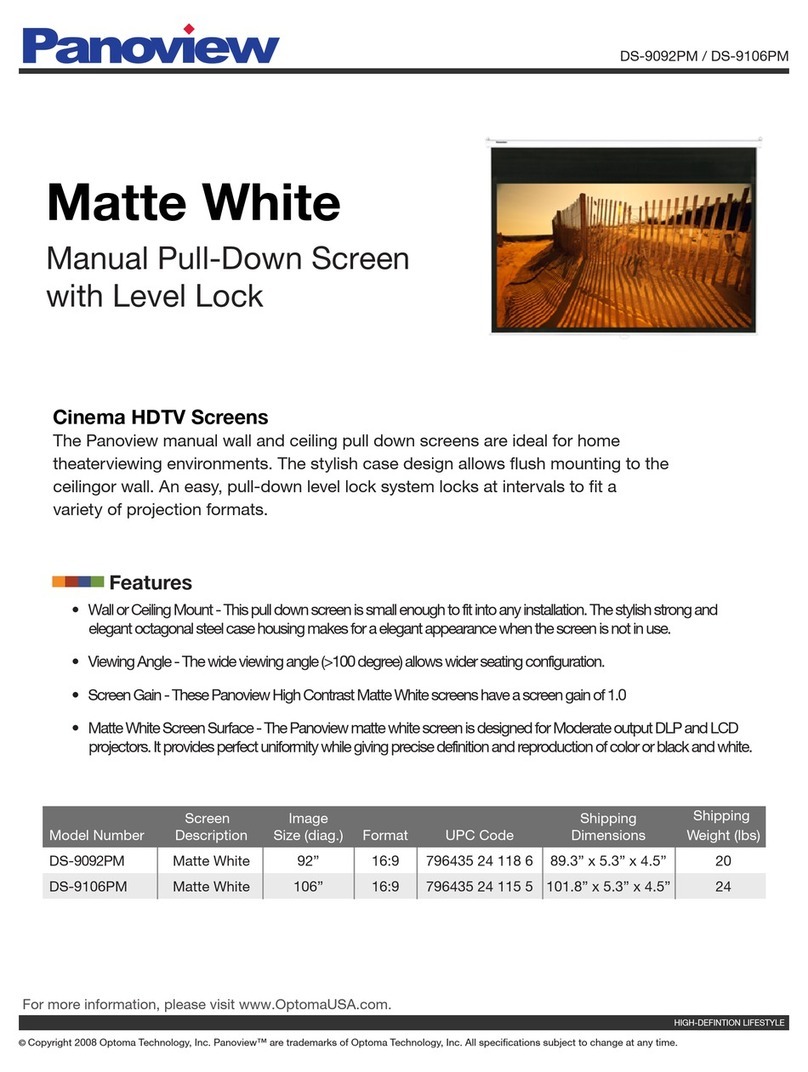

Panoview

Panoview Panoview DS-9092PM datasheet

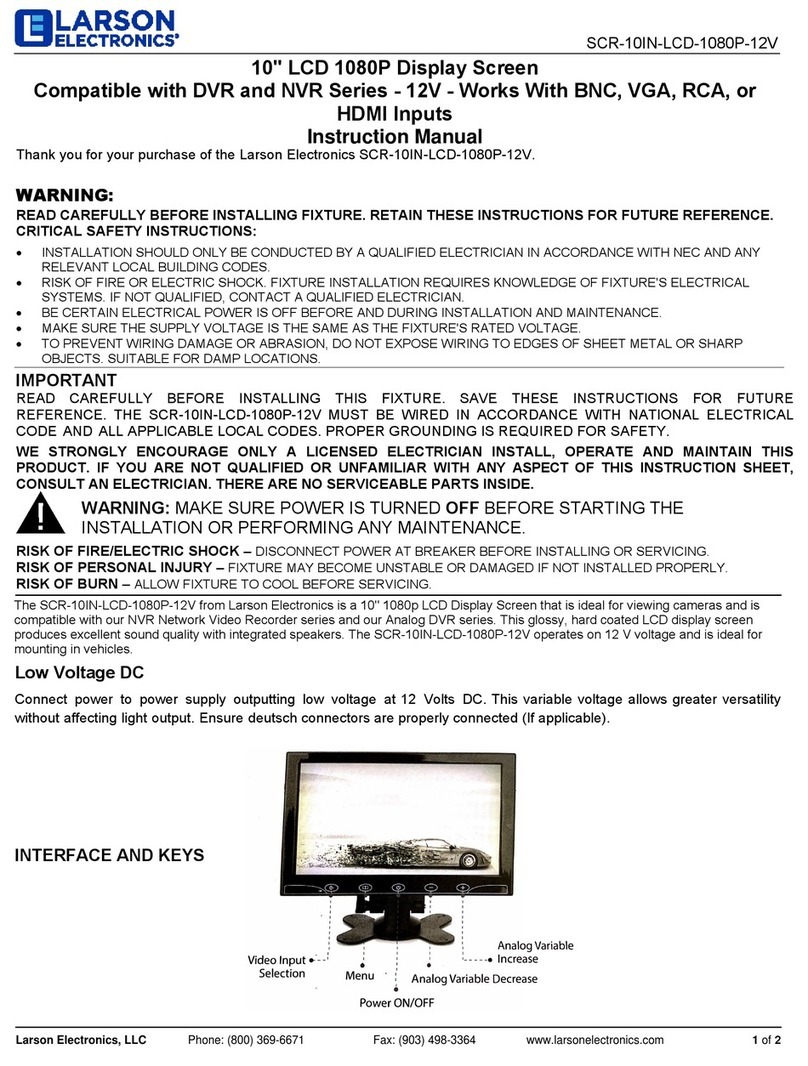

Larson Electronics

Larson Electronics SCR-10IN-LCD-1080P-12V instruction manual