FOX DHX2 / Float X2 / DPX2 Setup for the RAAW Madonna

Here are a few basics about spring-rate, sag and parameters that determine the spring rate

you need.

•The rate of the spring you use in your DHX2 shock defines the amount of sag. The air

pressure you use in your Float X2 or DPX2 defines the amount of sag.

•Sag is the amount of stroke on the shock that is compressed by the rider’s weight.

•A higher spring rate, or more air pressure will result in less sag.

Defining the spring rate or the air pressure that fits you, depends on a few factors.

•The spring rate or air pressure depends on the design of the suspension. The same

rider will need different spring rates on different bikes. You cannot simply transfer

the spring rate or air pressure from bike A to bike B.

•The spring rate or amount of air pressure mainly depends on the rider’s weight. The

weight should include all gear you wear.

•Your riding style also influences the spring rate or air pressure that fits you best.

Choosing a firmer spring (higher rate) or more air pressure will result in less sag,

which means:

•You will effectively use less travel

•The geometry of the bike will be a bit more ‘up-right’, with a little higher BB

•The chance to bottom out is smaller

Choosing a softer spring (lower rate) or less air pressure will result in more sag, which

means:

•You will effectively use more travel

•The geometry of the bike will be a bit more ‘slack’, with a little lower BB

•The chance to bottom out is bigger

The compression damping and the rebound damping are also very important in setting up

the shock correctly. If for example you are a racer and have a very aggressive/ efficient riding

style, you might want to go up in spring rate or air pressure, but you can also play with the

high speed and low speed compression.

If you have the FOX DHX2, it is recommendable to have a few different spring rates in your

toolbox. This way you can change your sag depending on the gear you wear, the type of

terrain you ride and simply how you feel.

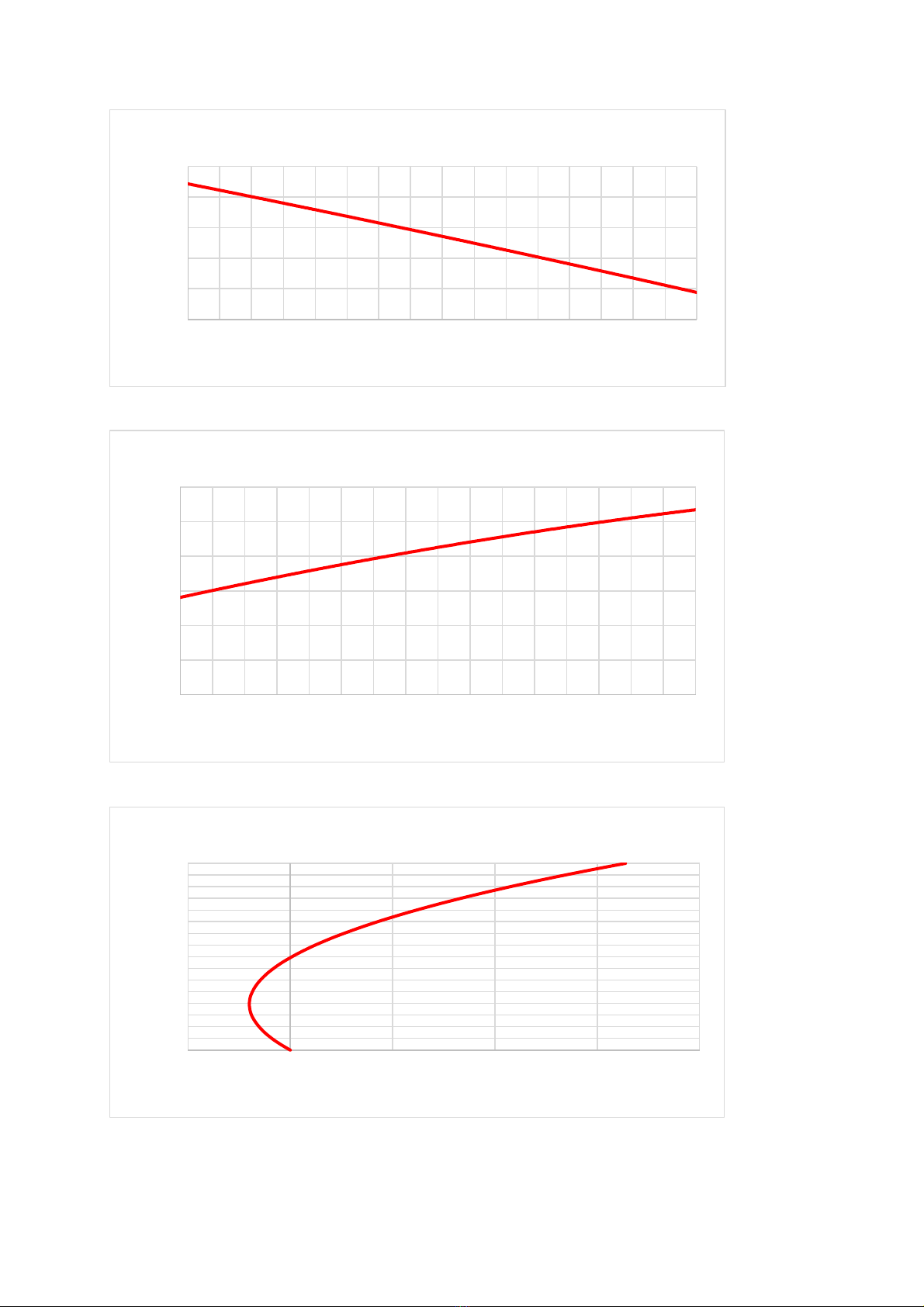

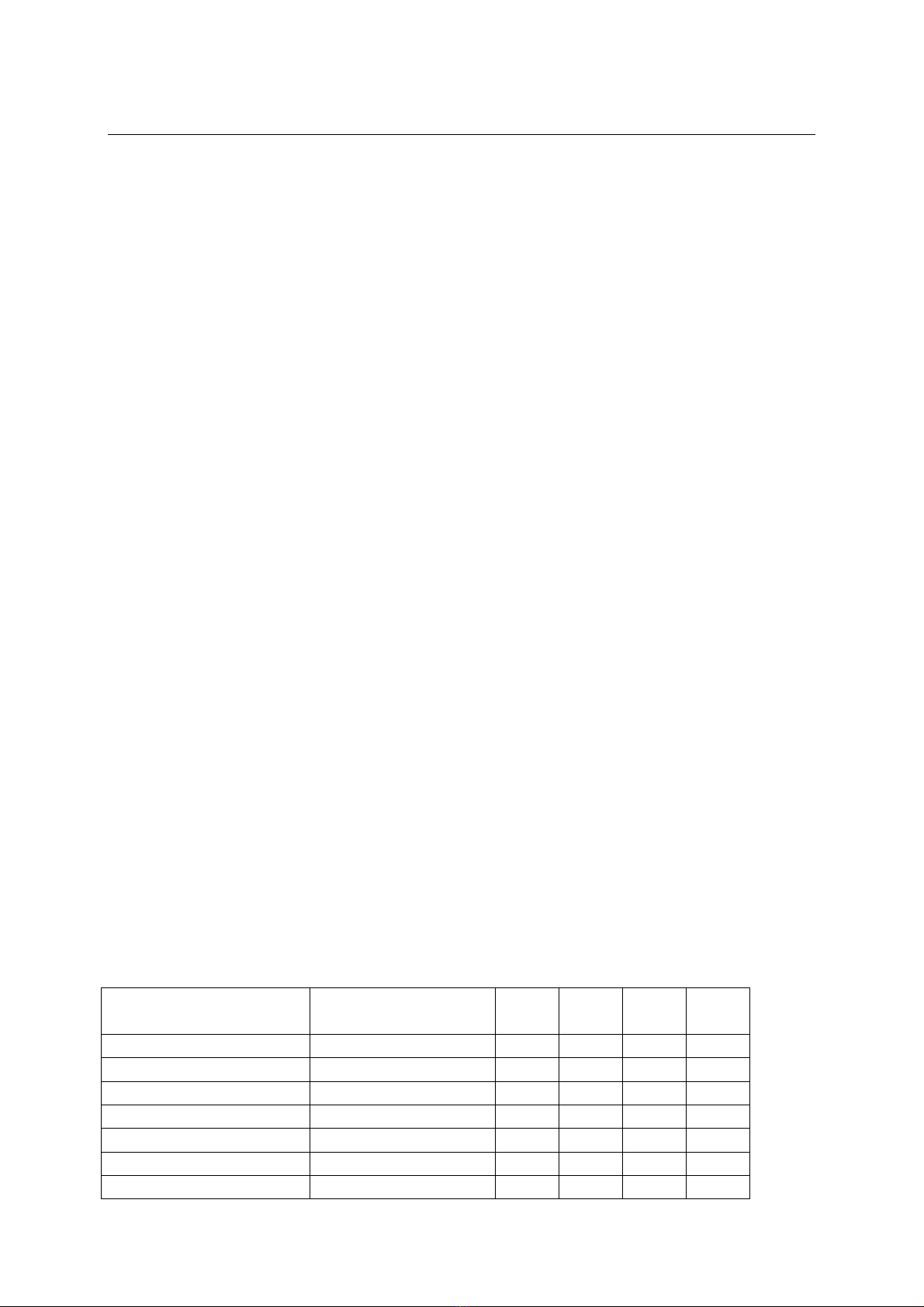

These are spring rates we recommend for the DHX2, with a basic setting for the four

damping settings. The number of clicks is counted from fully closed. The damping settings

can also be taken for the Float X2.