3 QD163-1

TABLE OF CONTENTS

Introduction ........................................................................................................................................5

1. Introduction To Your Car..................................................................................................................6

1.1 Cockpit Layout...........................................................................................................................6

1.2 Steering wheel Layout ................................................................................................................6

1.3 Engine Bay Layout .....................................................................................................................7

1.4 Front Suspension Layout..............................................................................................................7

1.5 Rear Suspension Layout..............................................................................................................8

1.6 Electrical Hardware Location.......................................................................................................8

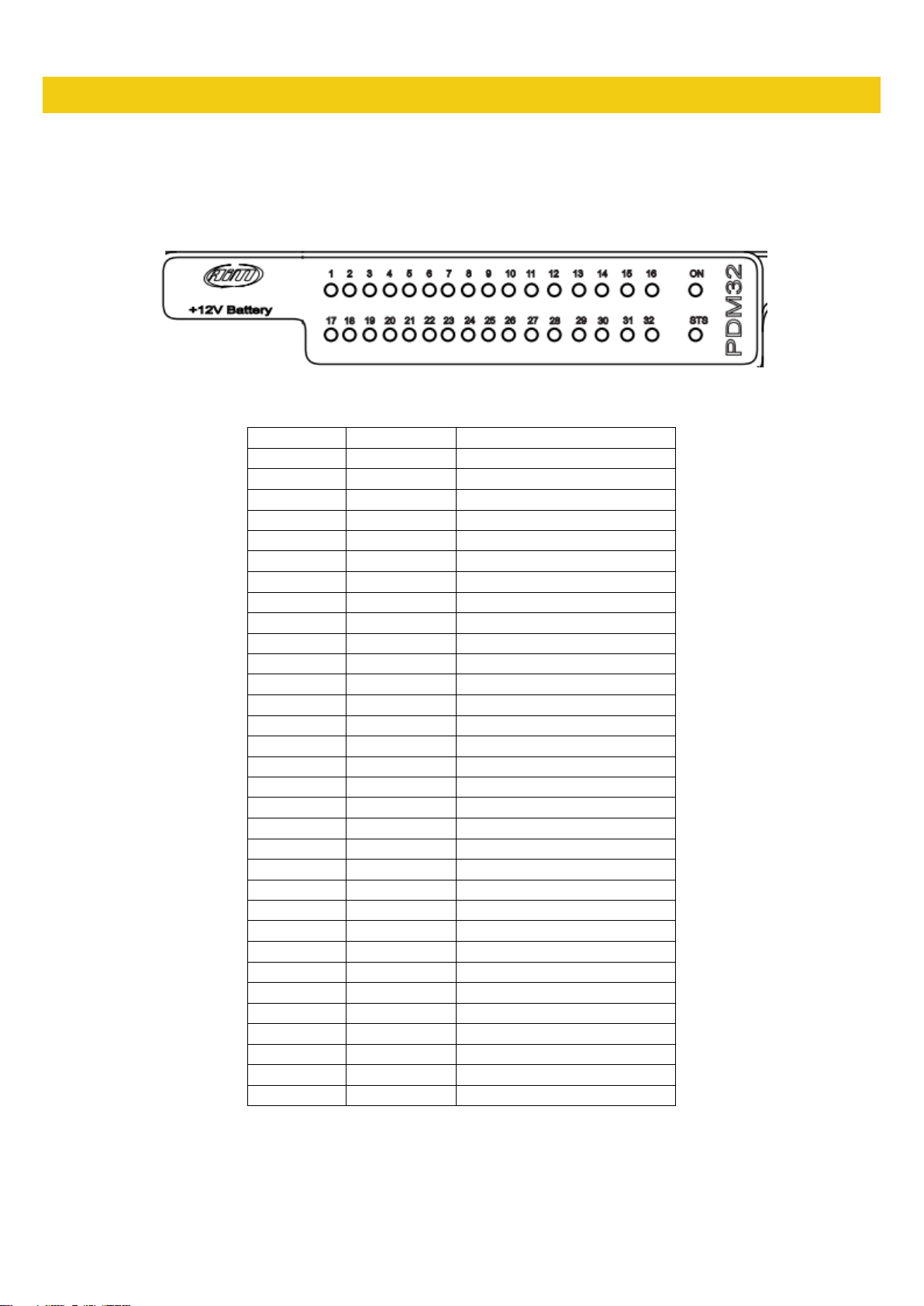

1.7 PDM status window..................................................................................................................10

1.8 Reverse Lever Location..............................................................................................................11

2. Running Your Car .........................................................................................................................12

2.1 Pre-Session Checks...................................................................................................................13

2.2 Driver controls.........................................................................................................................14

2.3 Adjusting the Seat and Pedals...................................................................................................16

3. New Car Shakedown....................................................................................................................17

3.1 Shakedown Guide...................................................................................................................17

3.2 Bedding In The Brakes..............................................................................................................19

4. Tyre Management.........................................................................................................................20

5. Workshop Car Maintenance..........................................................................................................21

5.1 Lifting Your Car .......................................................................................................................21

6. Car Setup.....................................................................................................................................23

6.1 How To Set Up The Car............................................................................................................23

6.2 Corner Weights.......................................................................................................................23

6.4 Hankook Setup Sheet...............................................................................................................24

6.6 Hankook Drop Heights.............................................................................................................25

6.7 Dampers.................................................................................................................................26

6.8 Wet Weather Set-up ................................................................................................................27

7. Car Servicing ...............................................................................................................................28

7.1 Filter Servicing.........................................................................................................................28

7.2 Gearshift Actuator Setup...........................................................................................................28

7.3 Wheel Speed Sensor Setup.......................................................................................................29

7.5 Balancing The Throttle Bodies....................................................................................................29

7.8 Coil Plug Order.......................................................................................................................29

7.6 Servicing The Gear Drive Unit...................................................................................................30

7.7 Filling THe Gear Drive Unit With Oil..........................................................................................31

7.8 Radical Spin Safe Clutch Setup (if fitted)....................................................................................32

7.9 Checking The Starter Motor After A Spin....................................................................................33

7.10 TPMS setup...........................................................................................................................34

8. Troubleshooting ............................................................................................................................35