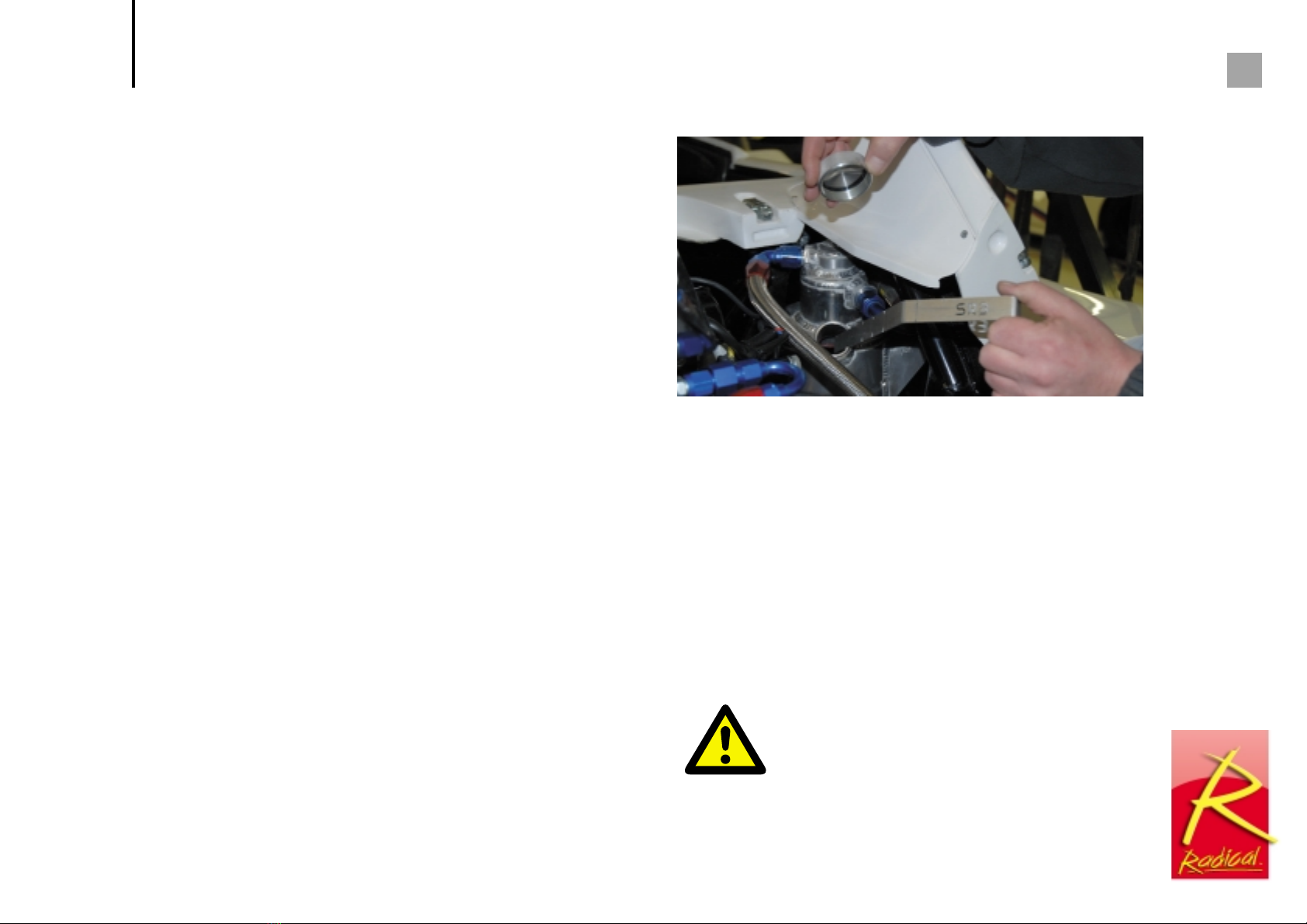

Bedding-in brakes

The car comes fitted with carbon metallic brake pads. To bed in the

brakes and achieve maximum stopping power, a film of carbon must

be transferred to the discs; gently apply brakes six to eight times at

medium speed. Increase speed to simulate race conditions, and

apply brakes hard a further six to eight times.

Allow brakes to cool for 15 minutes. Do not apply brakes

whilst stationary during the cooling down period. Use only

Radical-recommended brake pads, available online.

Brake bias settings

Set central to two turns towards the front (clockwise on the dash

adjuster). Further adjustment can be made to suit individual circuits and

tyre configurations. Adjust bias to the rear in wet conditions.

Manual gear change

If you are unfamiliar with a sequential shift car, it is recommended that

you change gear using the clutch when going both up and down the

gearbox. Once you have become familiar with the technique,

changing gear up the box can be achieved by lifting the

throttle quickly and simultaneously 'snicking' the gear in, without

depressing the clutch. On down changes it is imperative the driver

depresses the clutch and raises the engine speed before engaging

the gear. Smooth gear changes can be best achieved by using the

'heel-and-toe' technique. Only change down one gear at a

Driving your Radical

time, releasing the clutch pedal between gears. As with any

dog-engagement gearbox, aggressive gearchanges will damage the

gear dogs, which will result in gear engagement problems. Only use

a maximum of 7,000-8,000rpm while getting used to driving your SR3.

If you accidentally down-change instead of an up-change, you are less

likely to over-rev the engine. If you do over-rev the engine, make your

way slowly back to the pits. If you have revved the engine over

12,000rpm, switch off and return the engine to Radical for inspection

immediately. The Radical dash will display the maximum rpm.

Paddle-shift gear change

If your SR3 RS is fitted with the Powertec, steering wheel-mounted

paddle-shift system, it is possible to flatshift when you are changing up

the gearbox, and to have clutchless downchanges. You will need to

use the clutch to engage first gear, to pull away from stationary, and

when stopping the car.

To select first gear, depress the clutch and pull the left-hand paddle. To

change to second gear you then use the right hand paddle. It is

recommended to use the clutch when changing up the gearbox, from

first to second, at all times. Once you are on the track, and up to track

speed, then it is just a matter of accelerating, and pulling the right hand

paddle. A very slight delay will be felt as the engine ignition is cut, and

the system selects the next gear.

When changing down the gearbox, simply brake where you need to

and operate the left-hand paddle. The system will blip the throttle for

WARNING If you spin, depress the clutch quickly or

you may damage the starter motor.

NOTE It is also recommended that gearchanges

are not made while experiencing wheelspin, such as

exiting slow speed, hard acceleration corners, as this

can damage the gearbox.

10