6

About related Radisys products

TheRTMispartoftheRadisysproductfamily.Forinformationonthisproductfamilyand

otherRadisysproducts,seetheRadisysWebsiteatwww.Radisys.com.

Standards information

ForinformationaboutthePCIIndustrialComputerManufacturersGroup(PICMG®)andthe

AdvancedTCAstandard,consultthePICMGWebsiteatthisURL:http://www.picmg.org.

Related documents

CAN/CSAC22.2No.60950‐1‐03SafetyforInformationTechnologyEquipment,Version2,

CanadianStandardsAssociation(www.csa.ca),April1,2003

EN60950‐1:2002InformationTechnologyEquipment.Safety.GeneralRequirements,

EuropeanCommitteeforElectrotechnicalStandardization(CENELEC)(www.cenelec.eu),

February22,2002

IEC60950‐1InformationTechnologyEquipment‐Safety‐Part1:GeneralRequirements,1st

Edition,InternationalElectrotechnicalCommission(www.iec.ch),October25,2001

InformationTechnology‐SerialAttachedSCSI‐1.1(SAS‐1.1),ANSI/INCITS417‐2006

IntegratedRAIDforSASUser’sGuide,LSILogic®Corporation

LSISAS1064EPCIExpressto4‐PortSerialAttachedSCSI,LSISAS1064ERevision2.3,LSILogic

Corporation,November2007

IntelligentPlatformManagementInterfaceSpecificationv1.5,Revision2.0,IntelCorporation;

HewlettPackardCompany,NECCorporation,andDellComputerCorporation

PICMG3.0AdvancedTelecommunicationsComputingArchitectureR3.0,PCIIndustrial

ComputerManufacturersGroup,March24,2008

PICMG3.1R1.0Specification,Ethernet/FibreChannelforAdvancedTCASystems,PICMG,

January22,2003

PICMGAMC.0R2.0AdvancedMezzanineCardBaseSpecification,PCIIndustrialComputer

ManufacturersGroup,November15,2006

PM8380QuadSMX3GQuadSATA/SASMux/Demuxfor3G,PMC‐2031101,Issue8,PMC‐

Sierra,April2005

SerialATARevision2.5,SerialATAInternationalOrganization,October27,2005

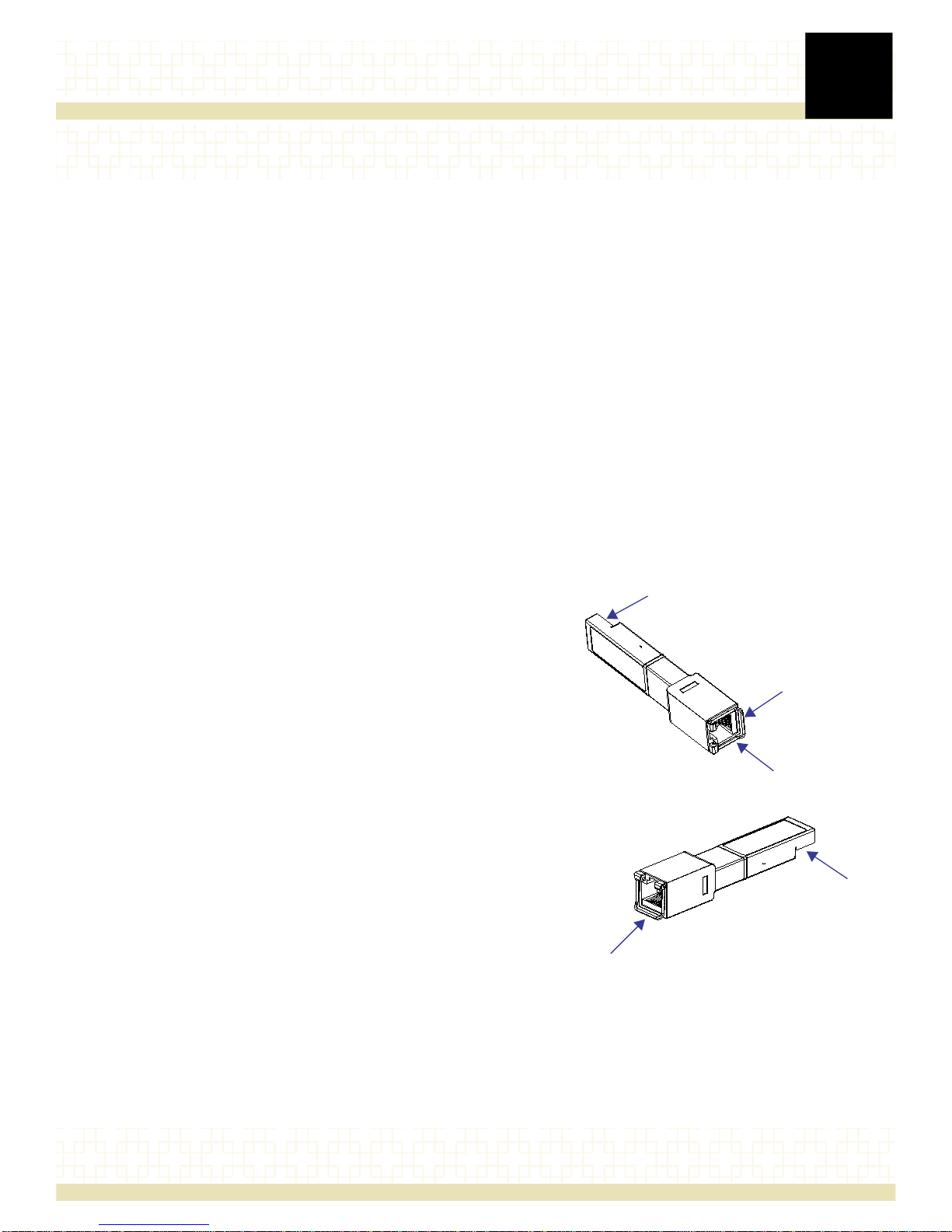

SmallForm‐factorPluggable(SFP)TransceiverMultisourceAgreement(MSA),Cooperation

AgreementforSmallForm‐FactorPluggableTransceivers,AgilentTec hnologies,Blaze

NetworkProducts,E2OCommunications,Inc.,ExceLightCommunications,Finisar

Corporation,FujikuraTechnologyAmericaCorp.,HitachiCable,InfineonTechnologi esCorp.,

IBMCorp.,LucentTechnologies,Molex,Inc.,OpticalCommunicationProducts,Inc.,Picolight,

Inc.,StratosLightwave,andTycoElectronics,September14,2000