Raider 40 Manual Military version

Raider Parts and Assembly Manual R40ES-001-15-2 describes part numbers and

illustrates how the Raider subassembly is put together. This manual is a

supplement to the Raider Service Manual R40ES-001-15-3 that describes in

detail all steps required to repair the Raider 40.

Raider Outboard makes no warranty, express or implied, regarding the use of

this data. Raider

Inc. assumes no responsibility for errors or omissions nor

assumes any liability for damages

resulting from the use of the information

contained herein. In some cases a part design may have

changed since this

manual was published or may not apply to your particular engine serial number, or

a service/parts bulletin may have been issued containing important information

pertaining to this

model and/or a particular part. Some parts may be serial

number and/or model number specific.

You are strongly advised to contact Raider

for all up to date information (321) 403-3585

.

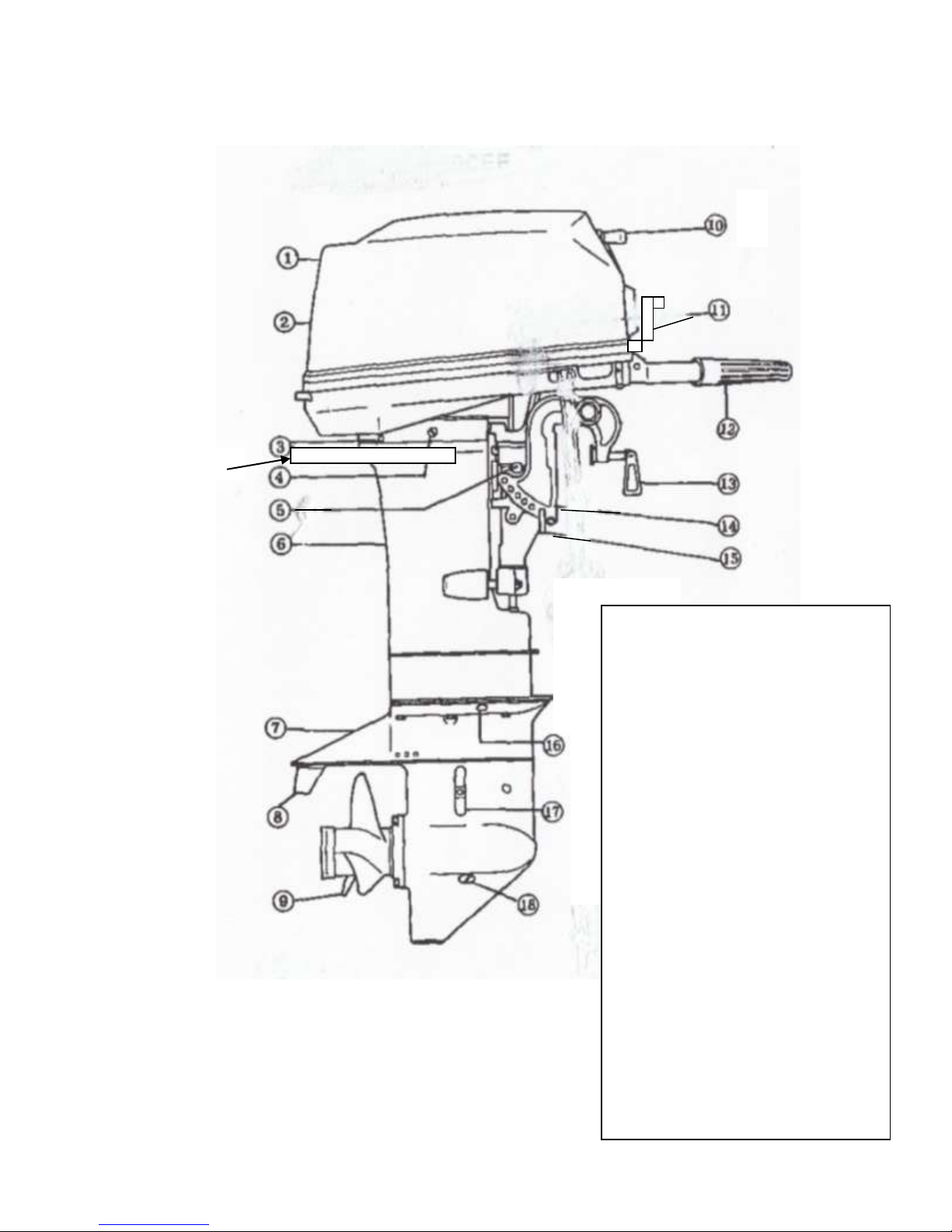

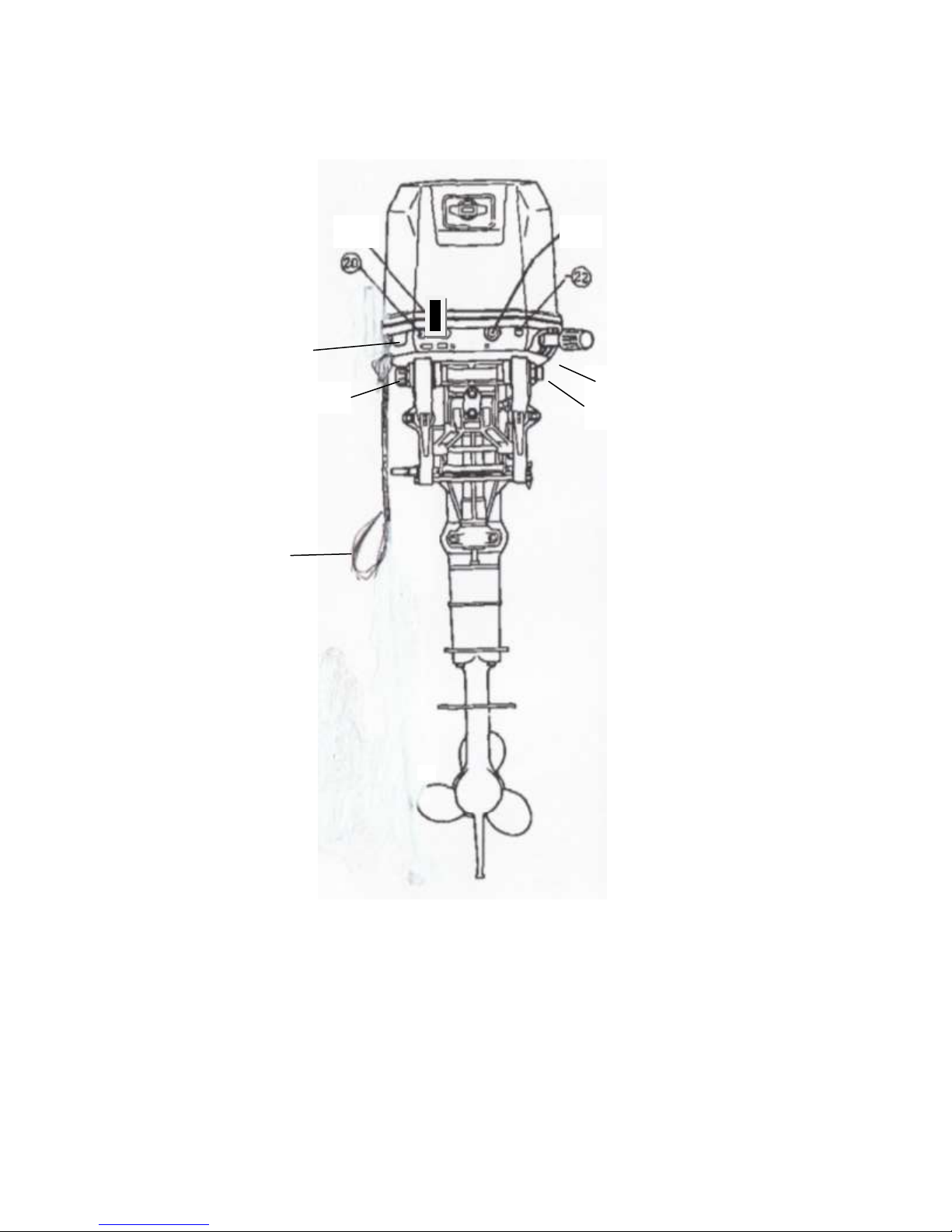

This Raider 40 manual has all parts and assembly data contained herein. It has been

presented to help the user identify parts, identify part numbers, how that part has

been assembled and tools required to repair the part or secure a new part if required.

The Raider is a military only engine and will not be sold to commercial market. It is

submersible and runs multiple fuels. An additive must be placed into JP-5/JP-8 to be

in compliance with EPA.

This manual, Parts/Assembly Manual 40 ES-001-15-2 provides detailed drawings and

part numbers for the Raider outboard motor. This is a supplement to the Service

Manual No. R40ES-001-15-3 that describes in detail how to remove; repair and the

Raider 40.

For background purpose’s the Raider 40 comes from a family of motors that have an

extensive history of reliability and performance and are identical in parts except for

the branding and pricing. These motors are Mercury; Nissan; and Tohatsu.

Supporting Raider with common parts available at local dealers supports a low life

cycle cost for the Government –with worldwide support.

The Mercury, Nissan and Tohatsu outboards are Commercial Off The Shelf (COTS)

engines with a long history of performance and reliability. Raider takes the basic

COTS and modifies the outboards specifically for the military. We have eliminated as

many electrical components as possible and use only the highest reliable mechanical

parts.

Key components of the Raider features a fuel induction system (FIS) which allows

burning of multiple fuels. To go from gasoline to heavy fuels three knobs are turned

on the FIS unit. Second key component is the dewatering system. New heads were

developed with special valves that allows water to be quickly eliminated between the

heads and the pistons. Another key component is a high performance spark plug,

made of stainless steel with a robust spark. This spark plug was developed to allow

submersion without the need to replace spark plugs after submersion. A secondary

start system has been installed that uses a battery to provide quicker starts. The

battery is located under the cowling. A grab rail has been installed to easily carry the

motor and the second is protection of the Raider outboard when dropped. A new

slide plate has been installed in the COTS engine to allow for easier placement on the

rubber inflatable boat, especially in higher sea states.