Raider Operators Manual R40ES-001-15-1

Contents

1. Your Raider 40 Outboard Motor .....................................................................................................1

a. Limited Warranty ............................................................................................................. 1

b. Serial Number ................................................................................................................... 1

c. Safety/Danger/Warnings/Cautions..................................................................................... 1

d. Features of Raider Outboard............................................................................................. 1

e. Specification Table............................................................................................................. 2

f. Raider Engine Overview.................................................................................................... 3

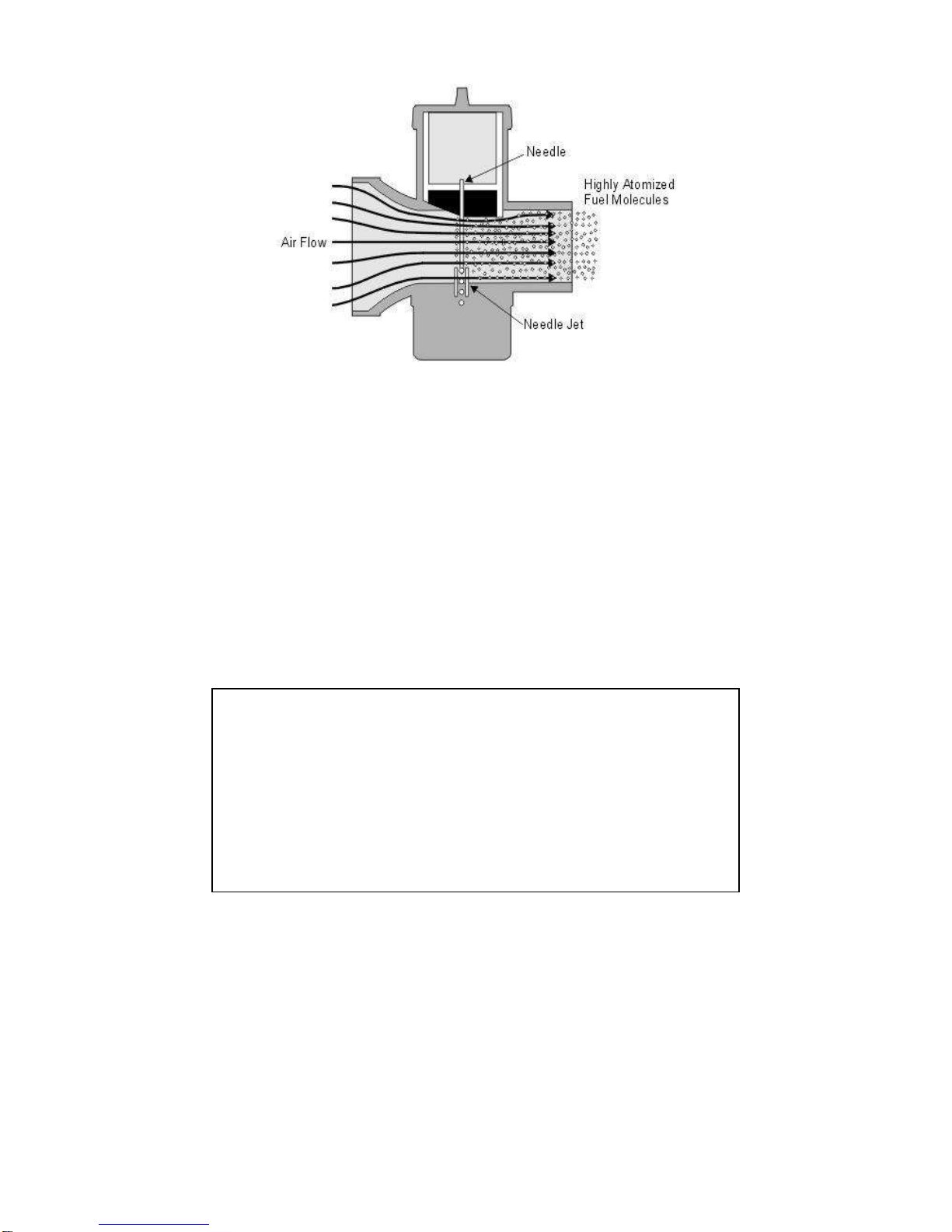

g. Fuel Induction System - How to change from Gasoline to Heavy Fuels ....................... 4

2. Raider Installation ............................................................................................................................5

a. Handling Engine................................................................................................................ 5

b. Installation of single Engine............................................................................................... 5

c. Installation of Twin Engines................................................................................................ 6

d. Installation of Safety Wire ................................................................................................. 6

e. Transom Height................................................................................................................. 6

f. Propeller............................................................................................................................ 7

3. Raider Running ..............................................................................................................................8

3. Raider Running.................................................................................................................................8

a. Fuels (Multi-fuel)................................................................................................................ 8

b. Raider Break in.................................................................................................................. 8

c. Normal Starting Procedure................................................................................................. 9

d. After Raider Starts/Warm Up.............................................................................................. 9

e. Throttle Friction.................................................................................................................10

f. Shifting .............................................................................................................................10

g. Stopping Raider................................................................................................................11

h. Trim Angle ........................................................................................................................11

i. Trailering...........................................................................................................................11

j. Tilting................................................................................................................................11

k. Trim Tab Adjustment .........................................................................................................12

l. Shallow Water Drive .........................................................................................................12

m. Shallow Water Operation..................................................................................................12

n. Impact Damage................................................................................................................13

o. Special Operating Conditions............................................................................................13

p. Overheating......................................................................................................................14

q. Emergency Starting..........................................................................................................14

r. Pre-Submersion Procedure ..............................................................................................15

s. Dewatering Procedure.......................................................................................................16

t. Post Submersion Procedure..............................................................................................16

4. General Maintenance.....................................................................................................................17

a. Fuel/Oil Requirements......................................................................................................17

b. Removing and Carrying the Raider...................................................................................18

b. Emergency Kit and spare parts ........................................................................................19

d. Corrosion Protection.........................................................................................................19

e. Optional Accessories........................................................................................................19

f. Trouble shooting...............................................................................................................20

g. Storage.............................................................................................................................20

h. Out of Storage Service......................................................................................................21

i. After Submersion Maintenance.........................................................................................22