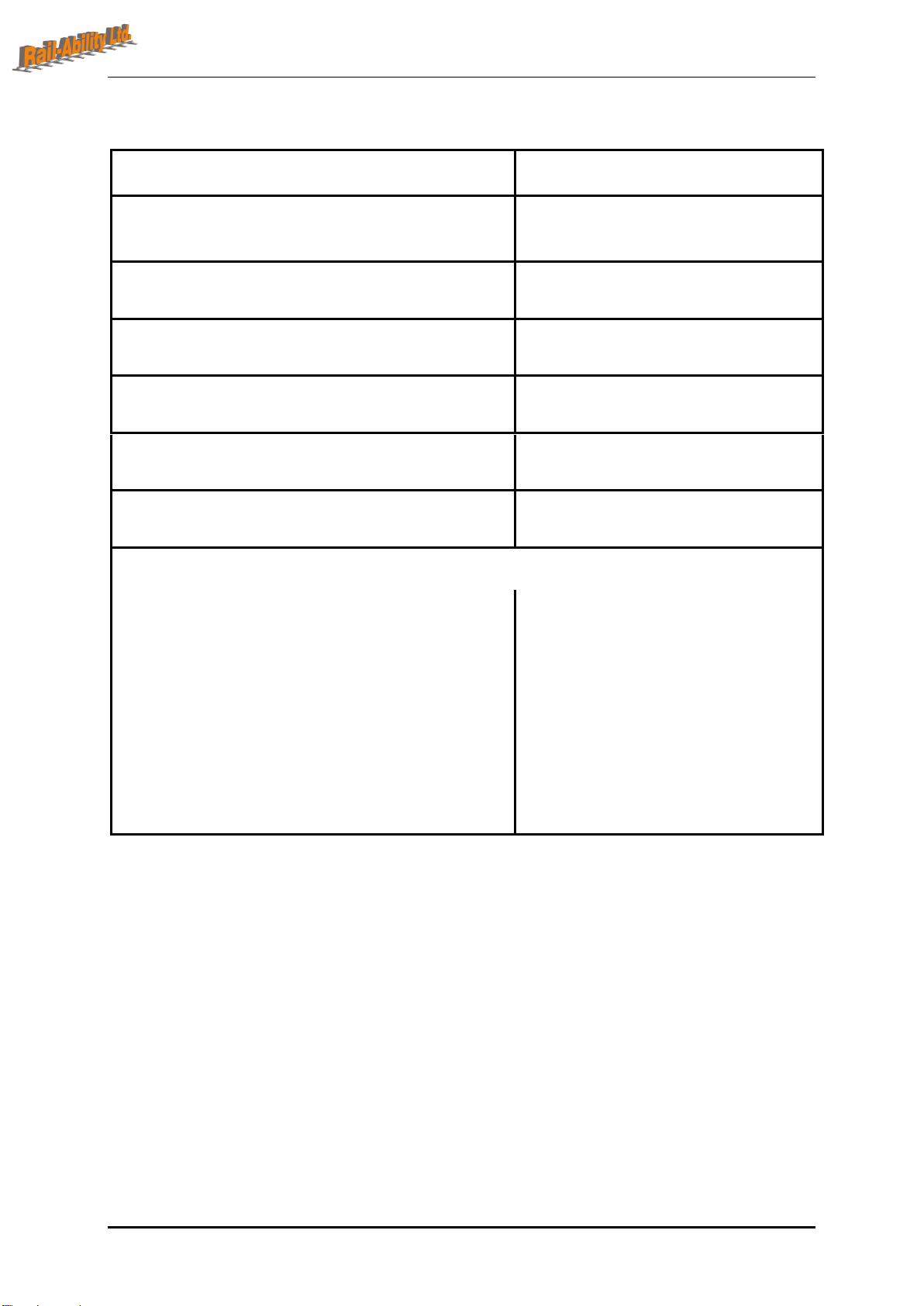

12.6 RCI Display...........................................................................................................33

12.6.1 Screen Surround...........................................................................................33

12.6.2 Travel Control................................................................................................33

12.6.3 Axle-Lock......................................................................................................33

12.6.4 Park Brake ....................................................................................................34

12.6.5 Service Brake................................................................................................34

12.6.6 Rail Axle Control ...........................................................................................34

12.6.7 Axle Selection ...............................................................................................35

12.6.8 Axle Control...................................................................................................35

12.6.9 Travel Mode Gauge Locks ............................................................................35

12.6.10 Data Logger ..................................................................................................36

12.6.11 Trailer Brake Control.....................................................................................36

13 On Tracking and Coupling............................................................................................38

13.1 Air Connections.....................................................................................................38

13.2 Multiple Trailers.....................................................................................................38

14 Towing Procedures.......................................................................................................39

14.1 Brake Status.........................................................................................................39

14.2 Trailer Break Away Detection................................................................................39

15 Coupling and Uncoupling..............................................................................................40

15.1 Coupling/Re-Coupling...........................................................................................40

15.2 Uncoupling............................................................................................................40

15.3 Uncoupling and Off Tracking.................................................................................41

16 Emergency Recovery ...................................................................................................42

17 Pre-Operation Actions ..................................................................................................43

17.1 Requirements .......................................................................................................43

17.2 General.................................................................................................................43

17.3 Inspection .............................................................................................................43

17.4 Completion............................................................................................................44

18 Routine Maintenance....................................................................................................45

18.1 Requirements .......................................................................................................45

18.2 General.................................................................................................................45

18.3 Engine Oil Level....................................................................................................45

18.4 Hydraulic Oil Level................................................................................................45

18.5 Batteries ...............................................................................................................45

18.6 Rail Wheels and Profiles.......................................................................................46

18.7 Fuel Leaks............................................................................................................46

18.8 Completion............................................................................................................46

19 Function Tests..............................................................................................................47

19.1 Requirements .......................................................................................................47

19.2 General.................................................................................................................47

19.3 From the Machine Cab..........................................................................................47

19.3.1 Emergency Stop............................................................................................47

19.3.2 Horn..............................................................................................................47

19.3.3 RCI Sounder .................................................................................................47

19.3.4 RCI Blue Light...............................................................................................48

19.3.5 Crawler Drive Braking ...................................................................................48

19.3.6 Rail Gear Deployment...................................................................................48

19.3.7 Rail Drive and Rail Braking............................................................................48

19.4 Completion............................................................................................................49

20 Workplace Assessment................................................................................................50

20.1 Requirements .......................................................................................................50

20.2 General.................................................................................................................50

20.3 Assessment..........................................................................................................50

20.4 Completion............................................................................................................51

21 Operating Instructions...................................................................................................52

21.1 Requirements .......................................................................................................52