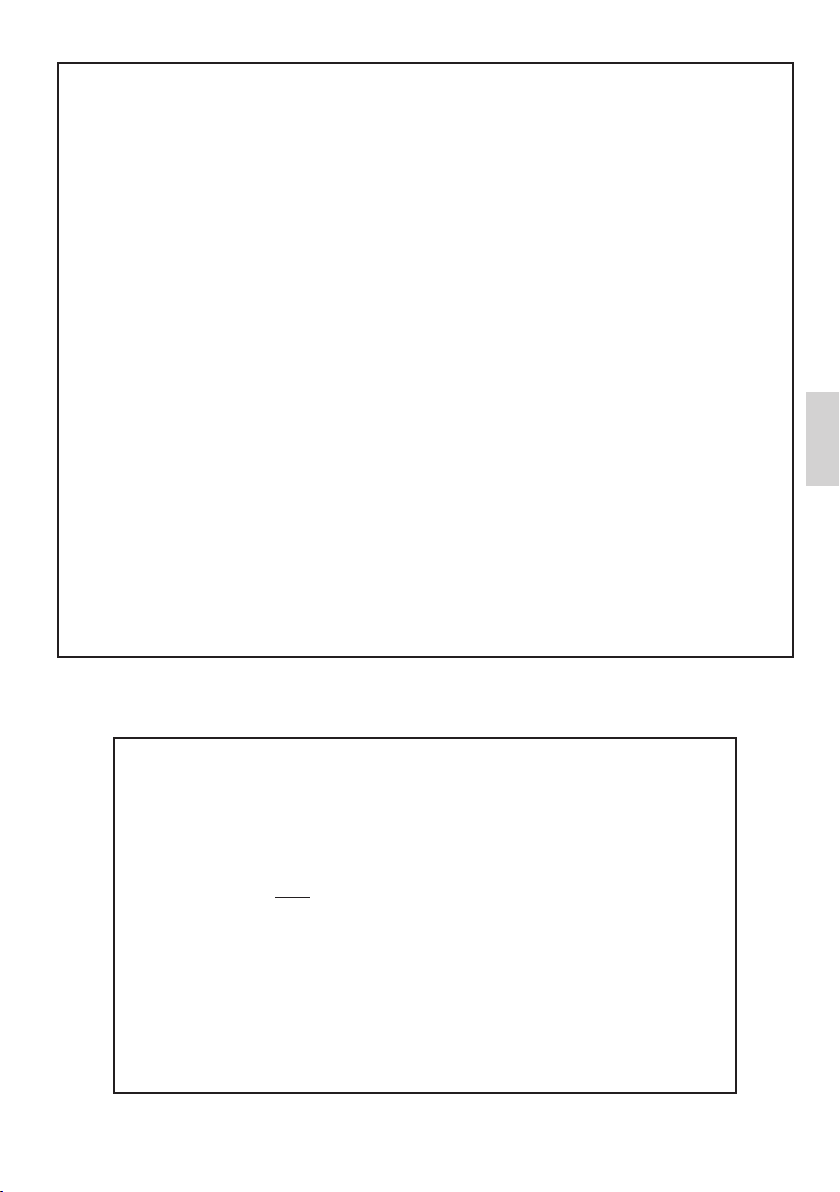

RAIS/attika VISIO L

EN 13229:2001+A1:2003+A2:2004 Raumheizer für feste Brennstoffe

Appliance fired by wood

Poêle pour combustibles solides

Produced at:

RAIS A/S, Industrivej 20, 9900 Frederikshavn, Danmark

15a B-VG

EC.NO: 224

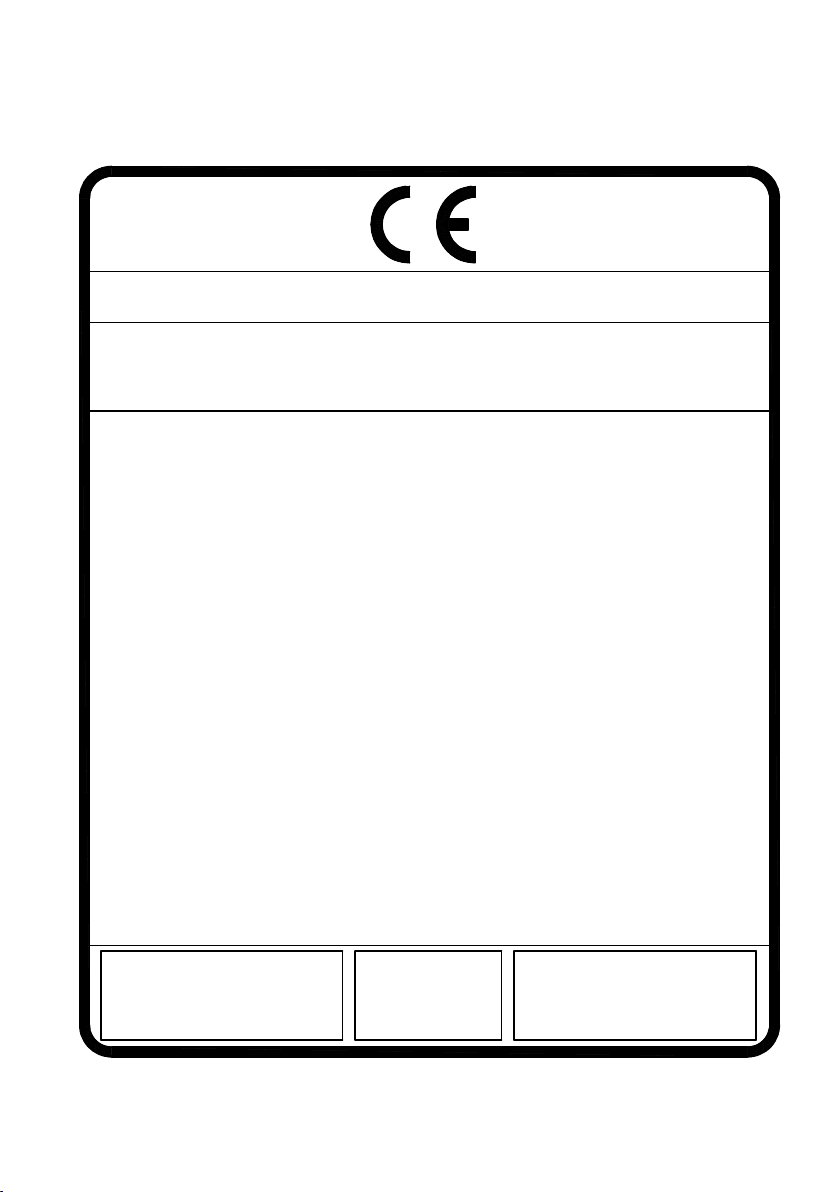

AFSTAND TIL BRÆNDBART, BAGVÆG

ABSTAND ZU BRENNBAREN BAUTEILEN, HINTEN

DISTANCE TO COMBUSTIBLE BACK WALL

DIST. ENTRE COMPOSANTS COMBUSTIBLES, ARRIÈRE

AFSTAND TIL BRÆNDBART, SIDEVÆG

ABSTAND ZU BRENNBAREN BAUTEILEN, SEITE

DISTANCE TO COMBUSTIBLE SIDE WALL

DISTANCE ENTRE COMPOSANTS COMBUSTIBLES, COTÉ

AFSTAND TIL BRÆNDBART, MØBLERING

ABSTAND VORNE ZU BRENNBAREN MÖBELN

DISTANCE TO FURNITURE AT THE FRONT

DISTANCE ENTRE COMPOSANTS COMBUSTIBLES, DEVANT

CO EMISSION (REL. 13% O2)

CO EMISSION IN DEN VERBRENNUNGSPRODUKTEN (BEI 13%O2)

EMISSION OF CO IN COMBUSTION PRODUCTS (AT 13%O2)

EMISSION CO DANS LES PRODUITS COMBUSTIBLES (À 13%O2)

NOMINEL EFFEKT / HEIZLEISTUNG /

THERMAL OUTPUT / PUISSANCE CALORIFIQUE:

RØGGASTEMPERATUR / ABGASTEMPERATUR /

FLUE GAS TEMPERATURE / TEMPÉRATURE DES GAZ DE FUMÉE:

VIRKNINGSGRAD / ENERGIEEFFIZIENZ /

ENERGY EFFIENCY /EFFICACITÉ ÉNERGÉTIQUE:

DK: Brug kun anbefalede brændsler. Følg instrukserne i

brugermanualen. Anordningen er egnet til røggassamleledning og intervalfyring.

DE: Lesen und befolgen Sie die Bedienungsanleitung.

Zeitbrandfeuerstätte. Nur empfohlene Brennstoffe einsetzen.

UK: Fuel types (only recommended). Follow the installation and

operating instruction manual. Intermittent operation.

F: Veuillez lire et observer les instructions du mode d'emploi.

Foyer à durèe de combustion limitèe, homologué pour cheminée à

connexions multiples. Utiliser seulement les combustibles recommandés.

Hergestellt für /Produced for:

ATTIKA FEUER AG, Brunnmatt 16, CH-6330 Cham / RAIS A/S, Industrivej 20, DK-9900 Frederikshavn

STØV / STAUB /

DUST / POUSSIÈRES: DK: 28 mg/Nm3 / DE: 28 mg/Nm3

UK: 28 mg/Nm3 / FR: 28 mg/Nm3

DK: 225°C / DE: 225°C

UK: 225°C / FR: 225°C

DK: 10,3 kW / DE: 10,3 kW

UK: 10,3 kW / FR: 10,3 kW

DK: 81% / DE: 81%

UK: 81% / FR: 81%

DK: BRÆNDE

DE: HOLZ

UK: WOOD

FR: BOIS

DK: SE BRUGERVEJLEDNING

DE: SIEHE BEDIENUNGSANLEITUNG

UK: SEE USER MANUAL

FR: CONSULTEZ LE GUIDE DE L'UTILISATEUR

DK: SE BRUGERVEJLEDNING

DE: SIEHE BEDIENUNGSANLEITUNG

UK: SEE USER MANUAL

FR: CONSULTEZ LE GUIDE DE L'UTILISATEUR

DK: 1100 mm/SE BRUGERVEJLEDNING

DE: 1100 mm/SIEHE BEDIENUNGSANLEITUNG

UK: 1100 mm/SEE USER MANUAL

FR: 1100 mm/CONSULTEZ LE GUIDE DE L'UTILISATEUR

DK: 0,098%

DE: 0,098% / 1226 mg/Nm3

UK: 0,098%

FR: 0,098%

CE Label:

Visio 2 L Left / Visio 2 L Right

Visio 3 L

19

Visio 2 L Left / Visio 2 L Right

Visio 3 L

Notified Body: 1235

Mærkeplade/CE Zeichen/Manufacturer’s plate/Plaque signalétique/Merkeplate/Märkplät