2

www.DentalEZ.com 866-DTE-INFO (opt 4)

2

www.DentalEZ.com

Badger LF User Manual

This manual contains installation, operation,

care, and repair instructions and user service

information for the RAMVAC® Utility Badger LF

dental vacuum system.

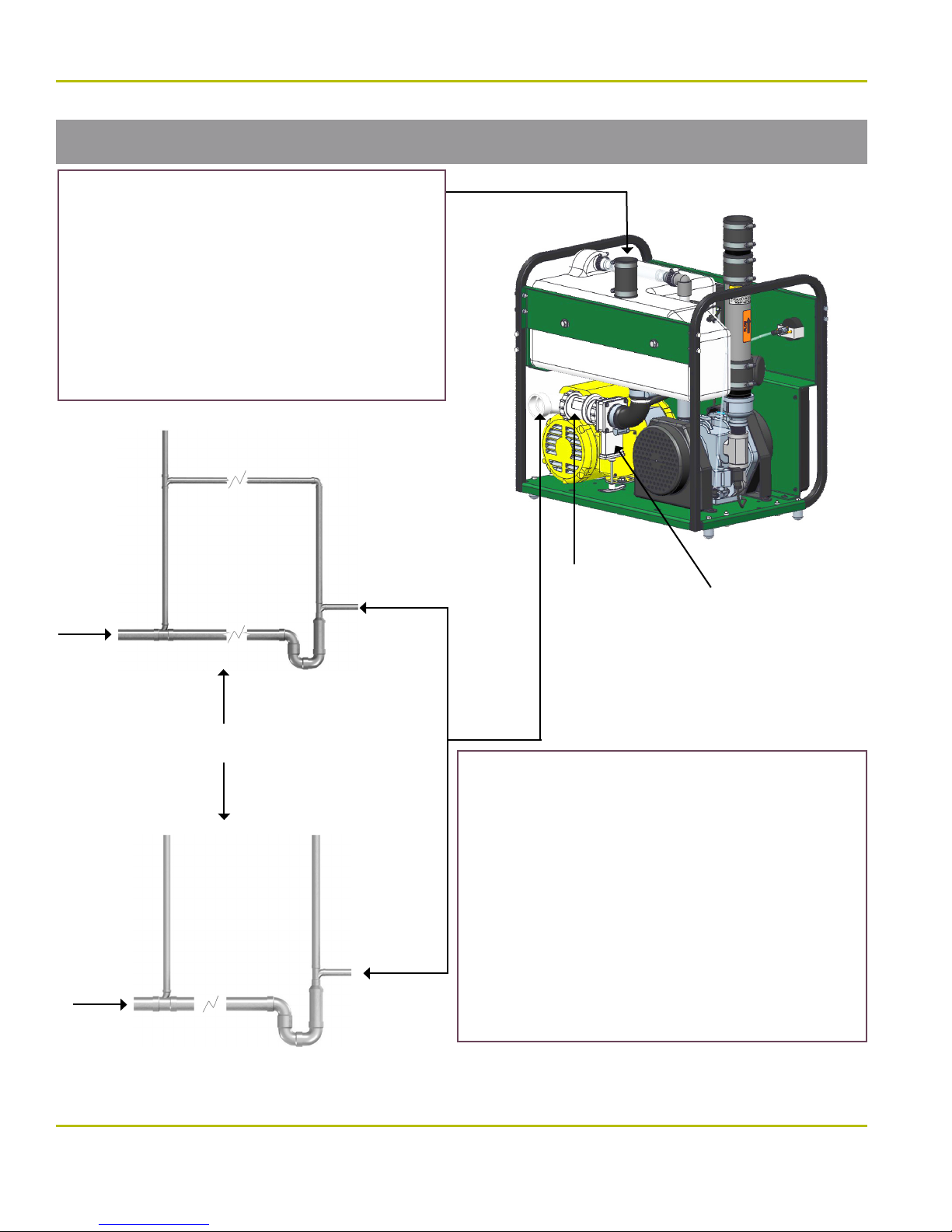

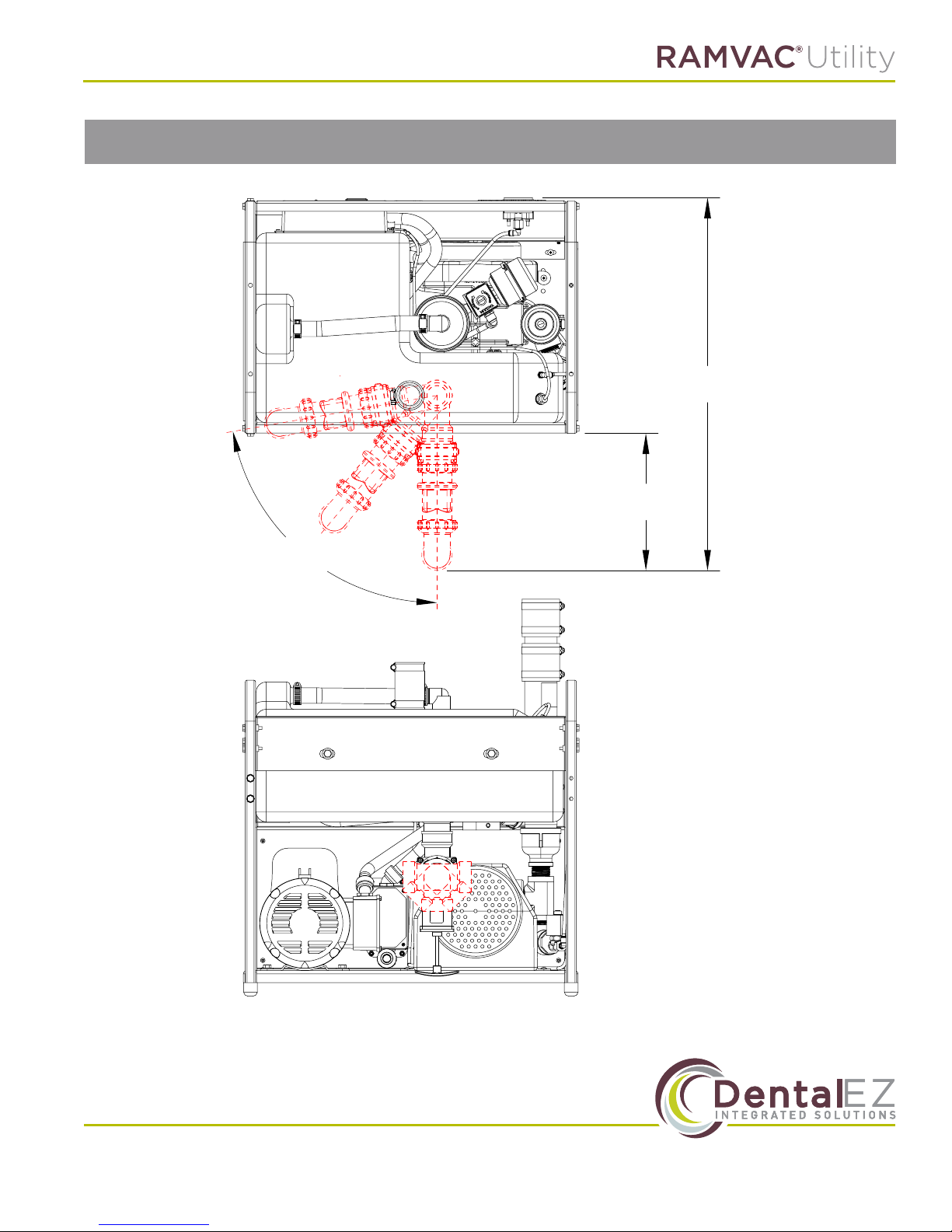

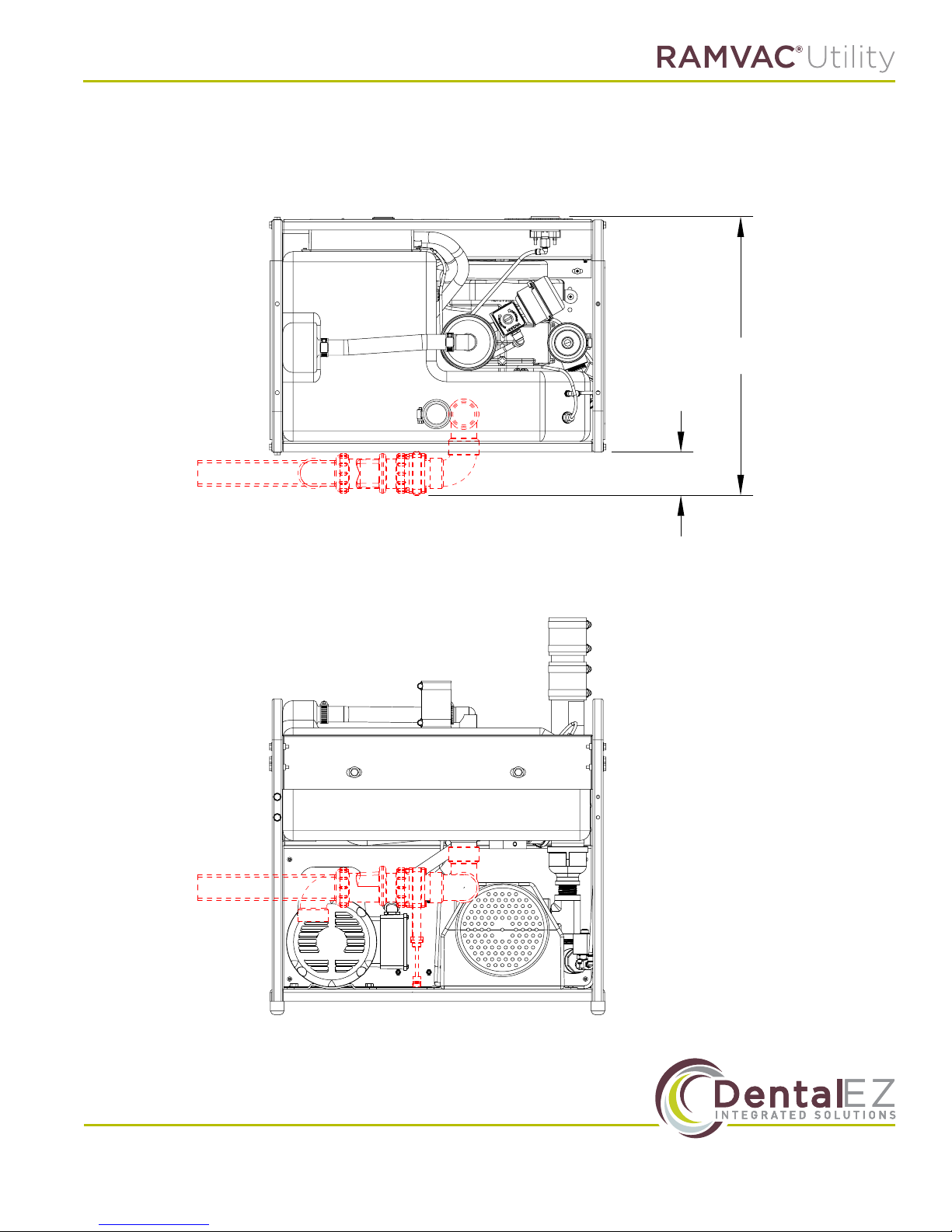

The main purpose of the Badger LF is to provide

a positive displacement, oil-less dry vacuum

system intended for use in a dental facility and

to be used by trained professional dental care

personnel only.

Badger LF is designed to provide trouble-free service

when installed, operated and cared for according to

the procedures set forth in this User Manual.

Vacuum is supplied to the system by a durable oil-

less rotary vane pump. A space-saving integrated

separation tank keeps liquid and foam out of the

pump. The E2 control provides precise electrical

control over run-time and shutdown operations

while vacuum is maintained at a uniform level by

the RAMVAC vacuum level control valve.

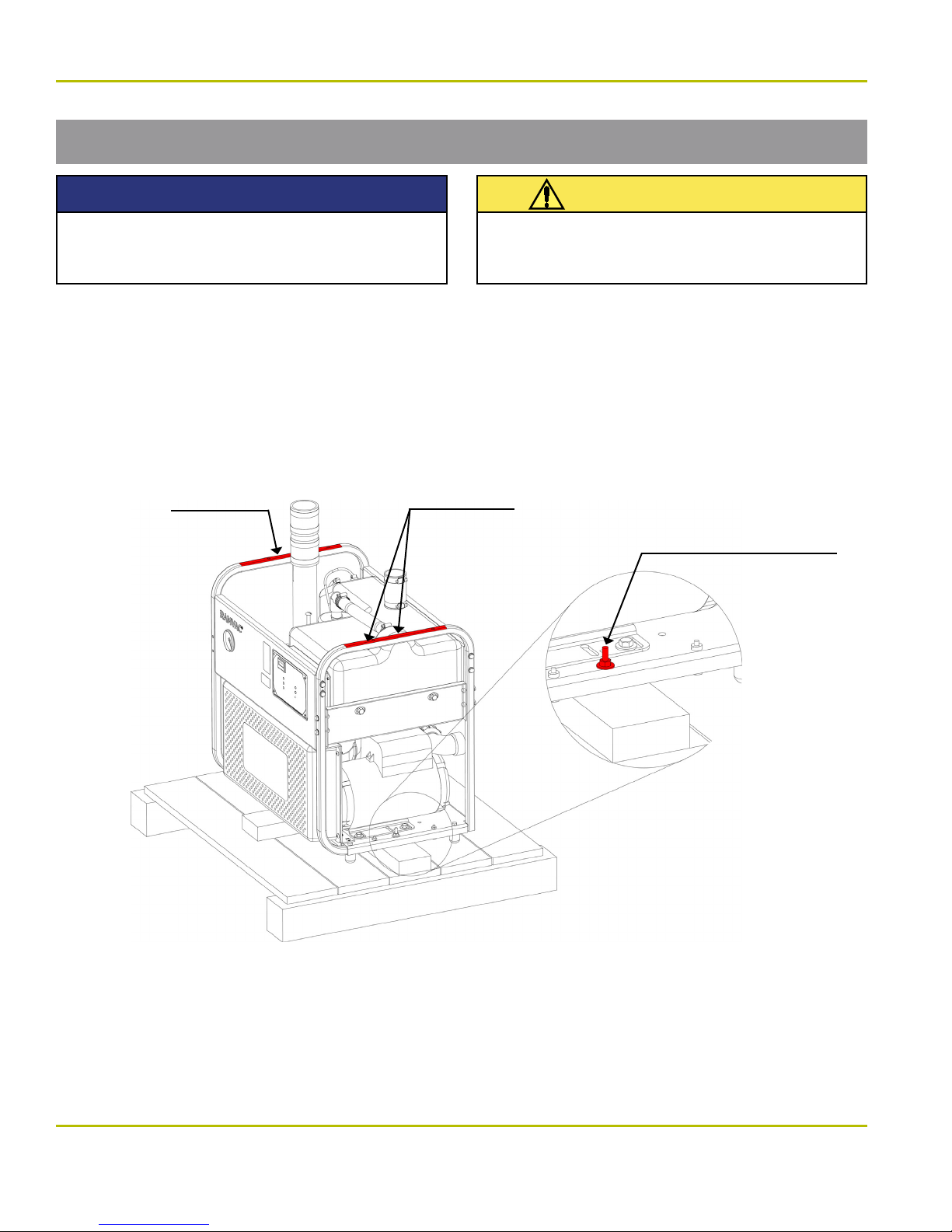

To ensure proper installation of the Badger

LF, carefully read all instructions contained

in this manual prior to installing, operating,

and servicing. For safety, pay close attention

to all notices, warnings, cautions and notes.

Section I Introduction

Safety Information

Classications

After the Badger LF is installed, please review the

features, operation procedures and care guide-

lines with the doctor's sta. Leave this manual in

the doctor's oice for future reference.

RAMVAC vacuum units are certied to ANSI/AAMI,

EX606-0-1:2005(R2012) and certied to CAN/CSA

Standard C22.2 No. 60601-11:08, and comply with

NFPA 99c Level 3 vacuum requirements, and are

manufactured in a FDA Registered ISO 13485:2003

certied facility.

– Type of protection against electric shock:

Class 1 Equipment

– Degree of protection against the ingress of

water: Ordinary

Here’s what you need to do to insure the safety

potential of this equipment is achieved:

• Make sure your equipment is installed ac-

cording to our written instructions and the

Installation Checklist is completed. If you have

purchased your RAMVAC from an authorized

dealer, the dealer is responsible for presenting

you with the completed checklist.

• Exhaust from dental vacuum systems can be

hazardous. Make sure the exhaust pipe is ter-

minated outside your building according to our

written instructions.

• Nitrous oxide and oxygen can be safely scav-

enged in the small concentrations typically

encountered in dental analgesia. The additional

air drawn into a properly installed and operated

Vacuum Unit will dilute these agents.

• Never use your RAMVAC to remove pure nitrous

oxide, oxygen or other oxidizing agents directly

from storage vessels or supply hoses. Large

concentrations may cause a re in the Vacuum

Unit and may cause an exhaust hazard.

• Never use this equipment in an OXYGEN RICH

ENVIRONMENT. Large concentrations may

cause a re in the Vacuum Unit and may cause

an exhaust hazard.

• Never use your RAMVAC for housekeeping

functions.

• Never use your RAMVAC to collect lab dust.