R&M CMX 007 Operation instructions

English

Original Instruction

INSTALLATION INSTRUCTION

TMU Upgrade Kit

020131en / Revision C

2013-03-20

TABLE OF CONTENTS

1 INTRODUCTION................................................................................................................................... 3

1.1 About this manual......................................................................................................................... 3

1.2 About the upgrade kit usage......................................................................................................... 3

1.3 Waste treatment and recycling of removed material...................................................................... 3

2SAFETY................................................................................................................................................. 4

2.1 Before starting to work at the site.................................................................................................. 4

2.2 Main switch and emergency stop buttons...................................................................................... 4

2.3 After working at the site................................................................................................................. 4

3DESCRIPTION OF THE UPGRADE KIT............................................................................................... 5

3.1 Parts included in the kit................................................................................................................. 5

3.2 Required tools............................................................................................................................... 6

3.3 Terminal connections.................................................................................................................... 6

3.4 DIP switches................................................................................................................................. 7

3.5 EMC filter...................................................................................................................................... 8

4INSTALLATION..................................................................................................................................... 9

4.1 Old frequency converter removal.................................................................................................. 9

4.2 Control voltage front resistors....................................................................................................... 12

4.3 New frequency converter installation............................................................................................. 12

5 COMMISSIONING................................................................................................................................. 17

5.1 Old inverter parameter settings..................................................................................................... 17

5.2 Driving frequency table selection................................................................................................... 17

5.3 S1 Maximum driving frequency..................................................................................................... 18

5.4 S2 Minimum driving frequency...................................................................................................... 20

5.5 S3 Acceleration and deceleration ramp time................................................................................. 23

5.6 S4 Control mode and slowdown mode.......................................................................................... 24

5.7 S5–S10 Motor parameters............................................................................................................ 25

5.8 Testing the trolley functions........................................................................................................... 26

6 TROUBLESHOOTING........................................................................................................................... 27

6.1 Purpose of troubleshooting........................................................................................................... 27

6.2 Problems and solutions................................................................................................................. 27

7 ELECTRICAL DRAWING...................................................................................................................... 28

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

2/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

1 INTRODUCTION

1.1 About this manual

This manual offers installation and commissioning instructions of CMX 007 frequency converter replacement to

ControlMaster®NXT 003 .

As a maintenance technician, taking the time to read this manual will help you easily adopt the replacement

procedures. Note that this manual is not intended as a substitute for proper training.

1.2 About the upgrade kit usage

This upgrade kit is designed only for CMX 007 frequency converter which is mounted in a

TROLLEY MOTOR UNIT (TMU) in chain hoist crane. It is not designed for wire rope hoist

application. There is a different replacement kit available for the Wire Rope Hoist application.

There is no replacement kit available for chain hoist hoisting application. In case of brake

down, the complete chain hoist must be replaced with a new one.

Parameters for the new ControlMaster®NXT 003 frequency converter have NOT BEEN SET

UP at the factory. Please make sure that you SET UP the DIP switches according the

following instructions before start-up.

1.3 Waste treatment and recycling of removed material

The removed parts and packaging material shall be recycled according to local regulations. We recommend

recycling the frequency converter’s aluminum heat sink separately.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

3/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

2 SAFETY

2.1 Before starting to work at the site

Before starting any work on the crane:

• Familiarize yourself with the equipment and its user instructions.

• Find out the location of the main switch and the emergency stop buttons.

•Evaluate the risks of the site and try to minimize them.

• Inform the site responsible that you will be working on the crane.

• Restrict access to the working area, if possible.

• Prevent unintentional use of the crane.

• Ensure that you have all the appropriate personal protection equipment. Use them as required.

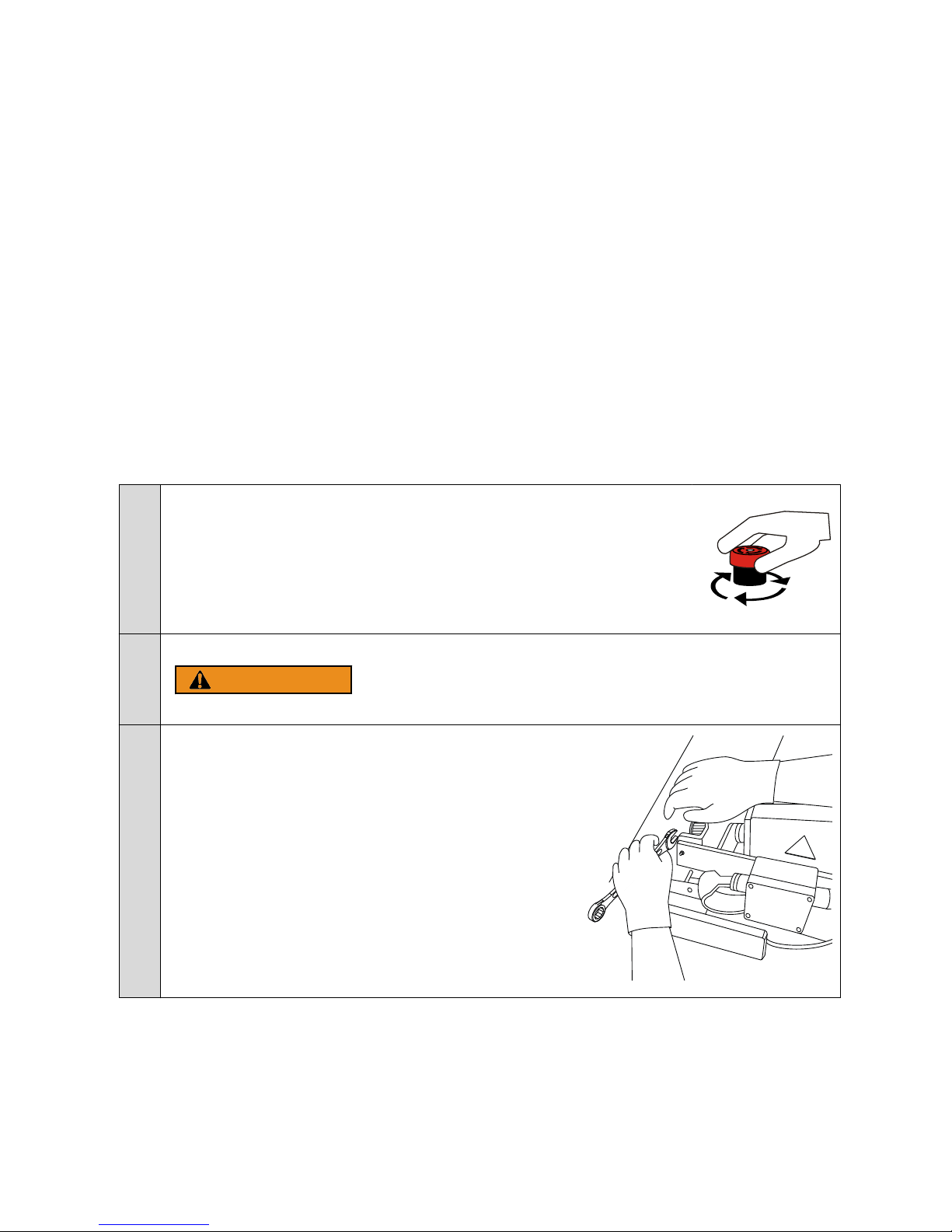

2.2 Main switch and emergency stop buttons

Lock and tag the main switch when you need to switch it off during your work.

WARNING Be aware of the main isolation switch functionality.

Even though one switch is turned off, there may still be voltage in some

parts of the product.

2.3 After working at the site

Ensure that you leave the site in a safe condition:

• Ensure that the work area is clean.

• Remove any locks/tags from switches.

•Ensure that the crane functions normally.

• Inform the site responsible that you have finished the work.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

4/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

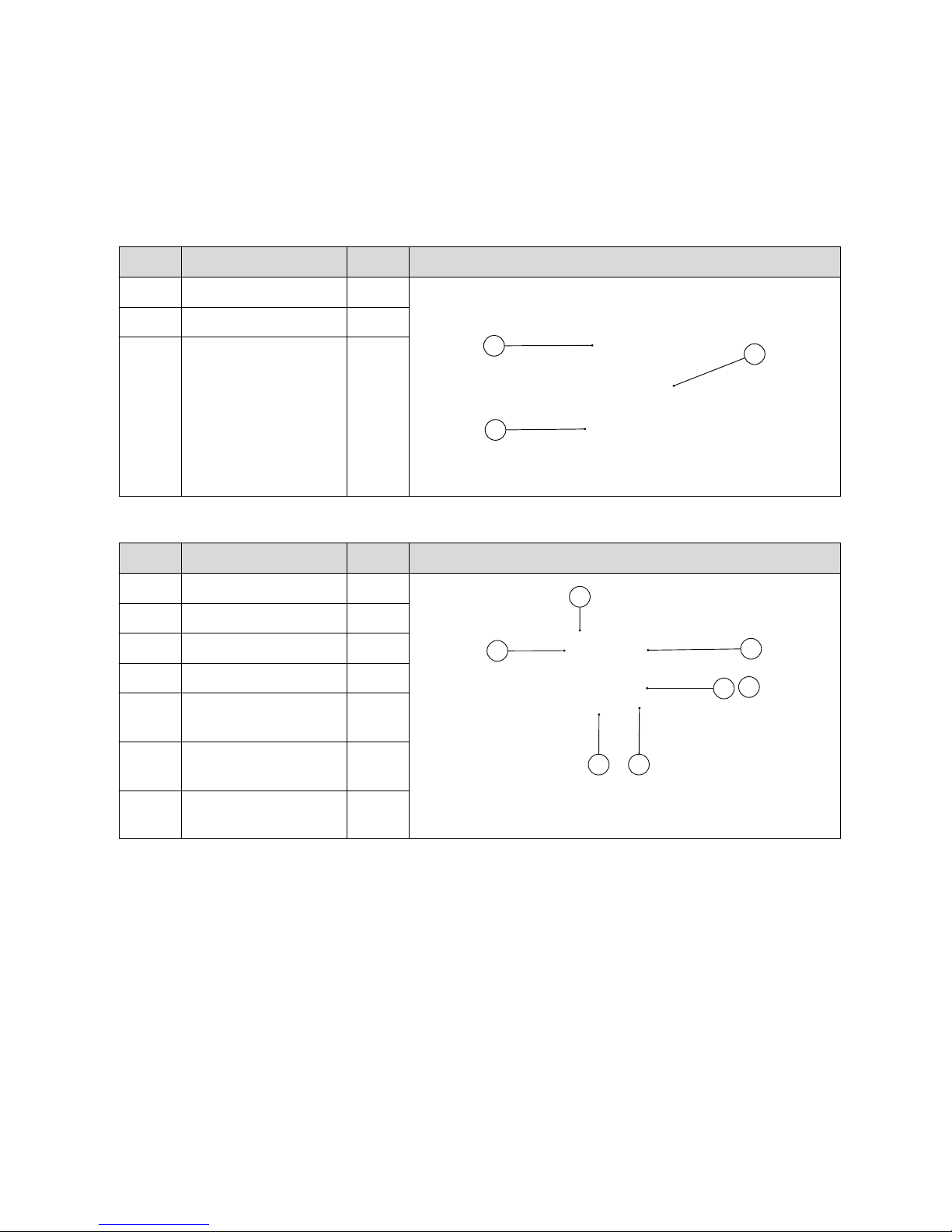

3 DESCRIPTION OF THE UPGRADE KIT

3.1 Parts included in the kit

Part Name Qty. Image

Part 1 Frequency converter 1 pcs

1

2

3

Part 2 Mounting rack 1 pcs

Part 3 Installation accessory 1 pcs

INSTALLATION ACCESSORY

Part Name Qty. Image

Part 4 Cable tie 3 pcs

47

5

6 10

89

Part 5 Wire marker set 1 pcs

Part 6 Allen key 1 pcs

Part 7 Cleaning pad 1 pcs

Part 8 Wire end ferrule 1.5

mm2

5 pcs

Part 9 Wire end ferrule 2.5

mm2

5 pcs

Part 10 Counter sunk flathead

screw M5 x 8

3 pcs

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

5/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

3.2 Required tools

Item

No

Name Image

1 Screwdriver, slot-head 3.5 x 0.6 mm

3

12

4

65

2 Screwdriver, Phillips No. 2 (PH2)

3 Wire cutters

4 Socket wrench, 8 mm

5 Crimping tool for wire end ferrules

6 Wire strippers

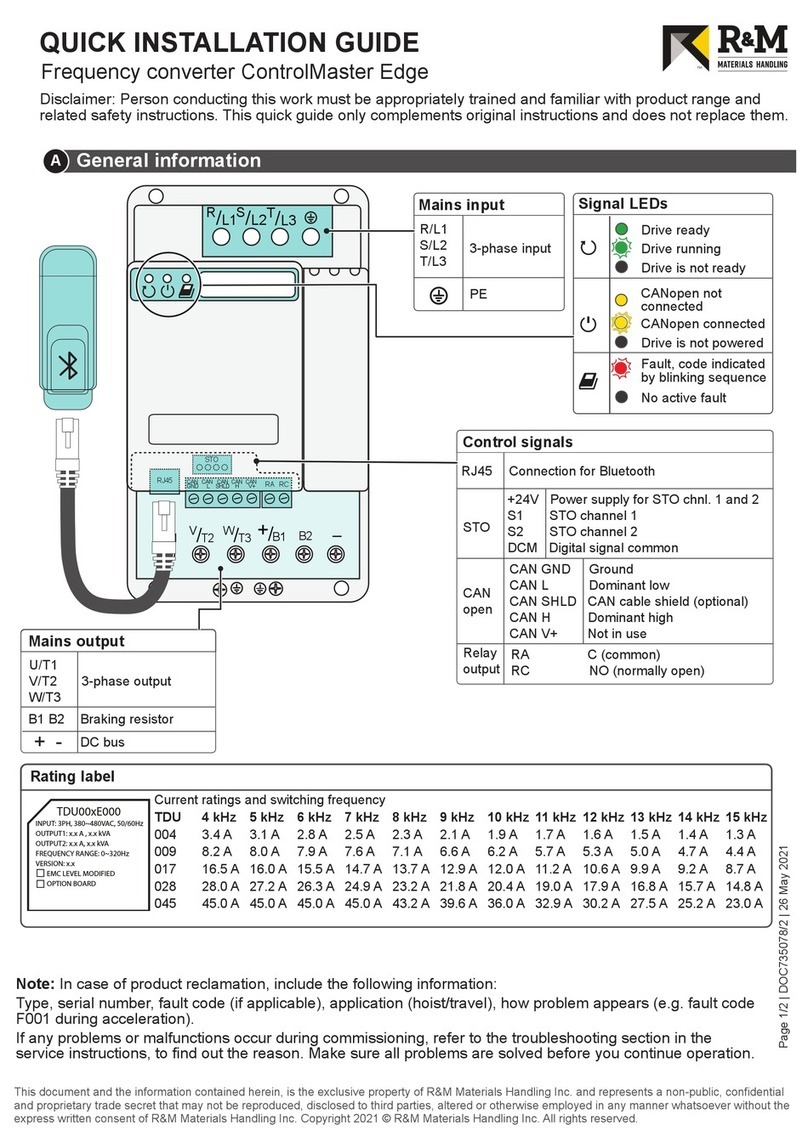

3.3 Terminal connections

The following table describes the differences between the terminals of CMX 007 and ControlMaster®NXT

003 .

Description of terminal CMX

007 Terminal X1

ControlMaster®NXT

003 Power terminals

Protective earth 1 PE

Power supply, phase 1 2 L1

Power supply, phase 2 3 L2

Power supply, phase 3 4 L3

Motor supply, phase 1 5 U

Motor supply, phase 2 6 V

Motor supply, phase 3 7 W

Control board terminals

Drive command, direction1 8 1

Drive command, direction 2 9 2

Speed 2 / Acceleration command 10 3

Control voltage, common 11 7

Terminals 4, 5 and 6 in ControlMaster®NXT 003 control board are not used.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

6/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

3.4 DIP switches

CMX 007 has 4 groups of DIP switches (S1-S4), whereas ControlMaster®NXT has 10 groups of DIP switches

(S1-S10).

The correct DIP switch settings for ControlMaster®NXT 003 can be found in Chapter 5: “Commissioning”.

CMX 007 ControlMaster®NXT 003

Switch Description Description Switch

S1

S2

S3

S4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

DIP DIP DIP

DIP

1212

12

1231 231 23

1231 231 2312

S1 S2 S3 S4 S5

S6 S7 S8 S9 S10

10

10

S1 Maximum driving frequency Maximum driving frequency S1

S2 Minimum driving frequency Minimum driving frequency S2

S3 Acceleration and deceleration ramp times Acceleration and deceleration ramp times S3

S4 Control mode and motor type Control method and slowdown mode S4

Limit operations S5

Voltage at low frequencies (U/f curve) S6

Current limit S7

Start and stop current S8

Motor nominal frequency S9

Terminal DI6 operation S10

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

7/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

3.5 EMC filter

CMX 007 has an external EMC filter package (KC310 / KC330), whereas ControlMaster®NXT 003 has an

internal EMC filter in the power supply. By default, the EMC level of the frequency converter is set to N by the

manufacturer.

If the mains network is non-grounded (IT-network), the ControlMaster®NXT 003 frequency converter’s EMC

level must be changed to 0 by removing the filter capacitor disconnection screw.

Verify the type of electrical supply network from original electrical drawings.

DANGER

5 MIN

1 2 3 4 5 6 7 8 9 10 11

OK

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

8/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

4 INSTALLATION

Before installation. After installation.

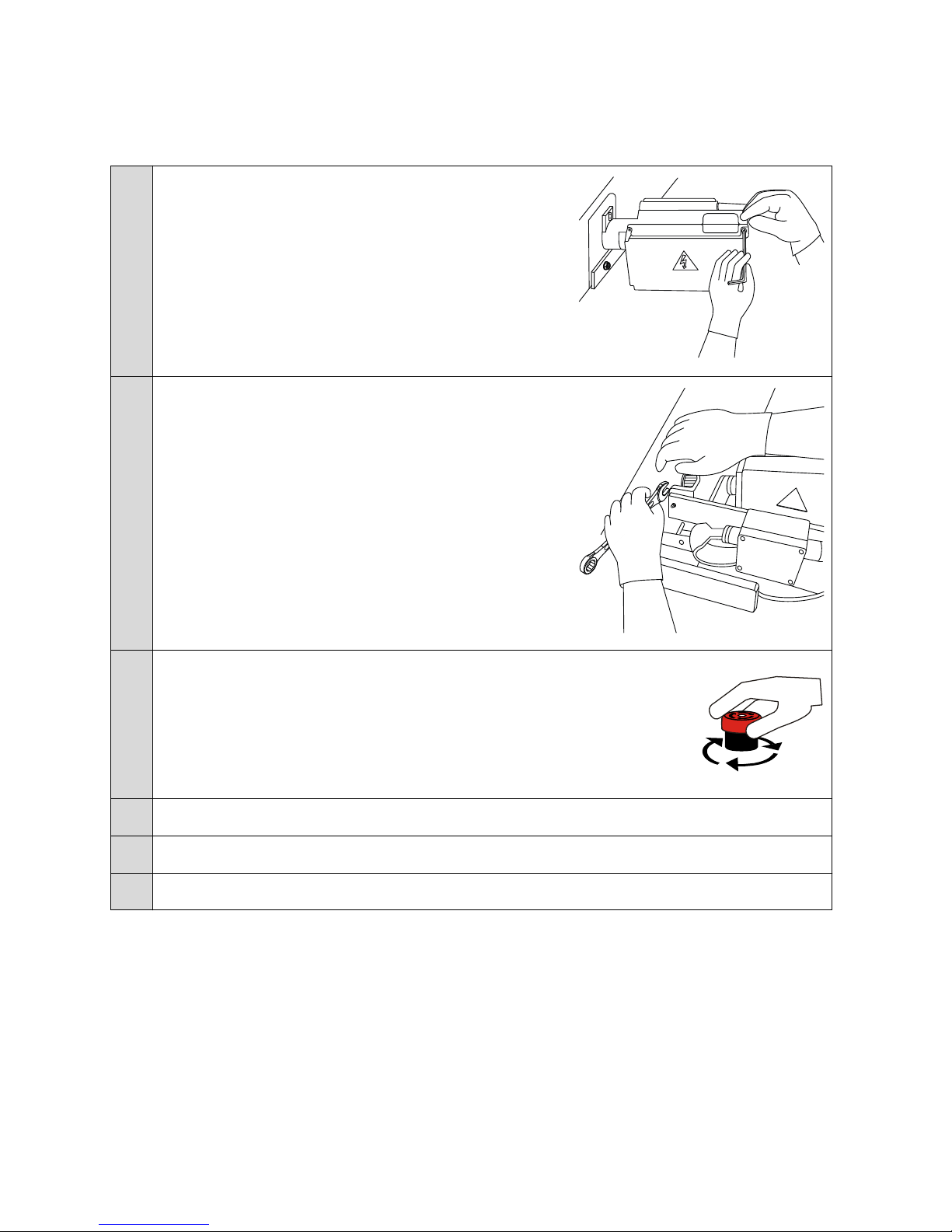

4.1 Old frequency converter removal

1If the trolley is operable (not broken), record the trolley driving directions.

2Push the main power off from the pendant or radio controller.

WARNING High voltage inside the Frequency converter.

Wait for at least five minutes after the voltage supply has been

switched of before taking any service actions.

3Remove the festoon electric connection box (if installed)

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

9/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

4Remove the motor connection box lid.

5Record the dip-switch settings from the CMX 007 frequency

converter.

On pageOld inverter parameter settings (page 17) you can

find an empty table where to write the settings.

6Remove the wire terminal by pulling. Remove the CMX 007 .

7Remove wires from the terminal one at the time.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

10/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

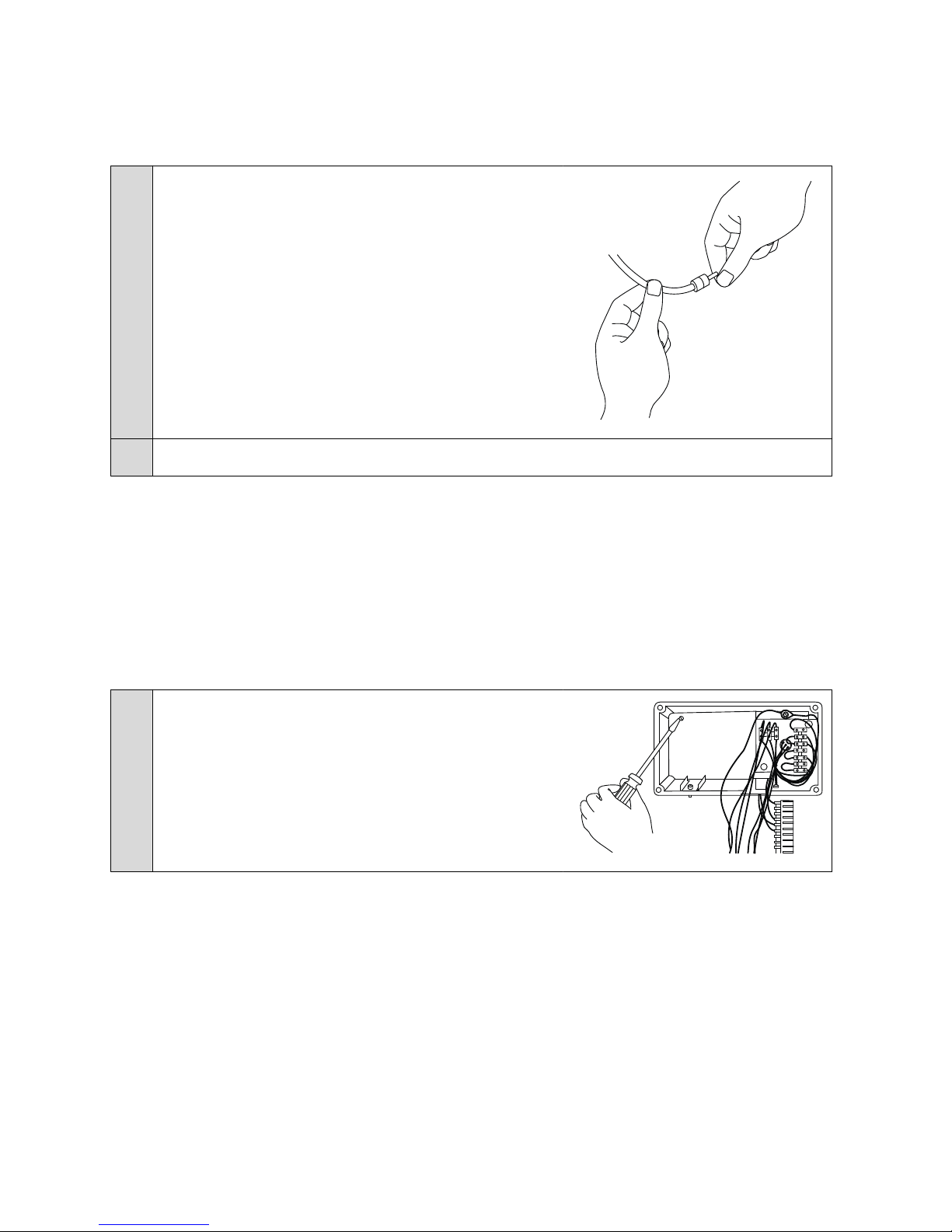

8Cut the wire. Make sure you leave as much length for the

wire as you can.

9Strip the wire end from the length of 10 mm.

10 Connect the end ferrule to the wire end.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

11/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

11 Mark the wire with markers. Use installation mandrel for easy

installation.

12 Do steps 5-9 to the rest of the wires.

4.2 Control voltage front resistors

The TMU should not have front resistors. However, if they are present, they must be removed. Do not mix the

order of the wires.

If the front resistors are not removed or by-passed, the control inputs on the

ControlMaster®NXT 003 frequency converter will not be activated, even though voltage can

be measured with a multimeter.

4.3 New frequency converter installation

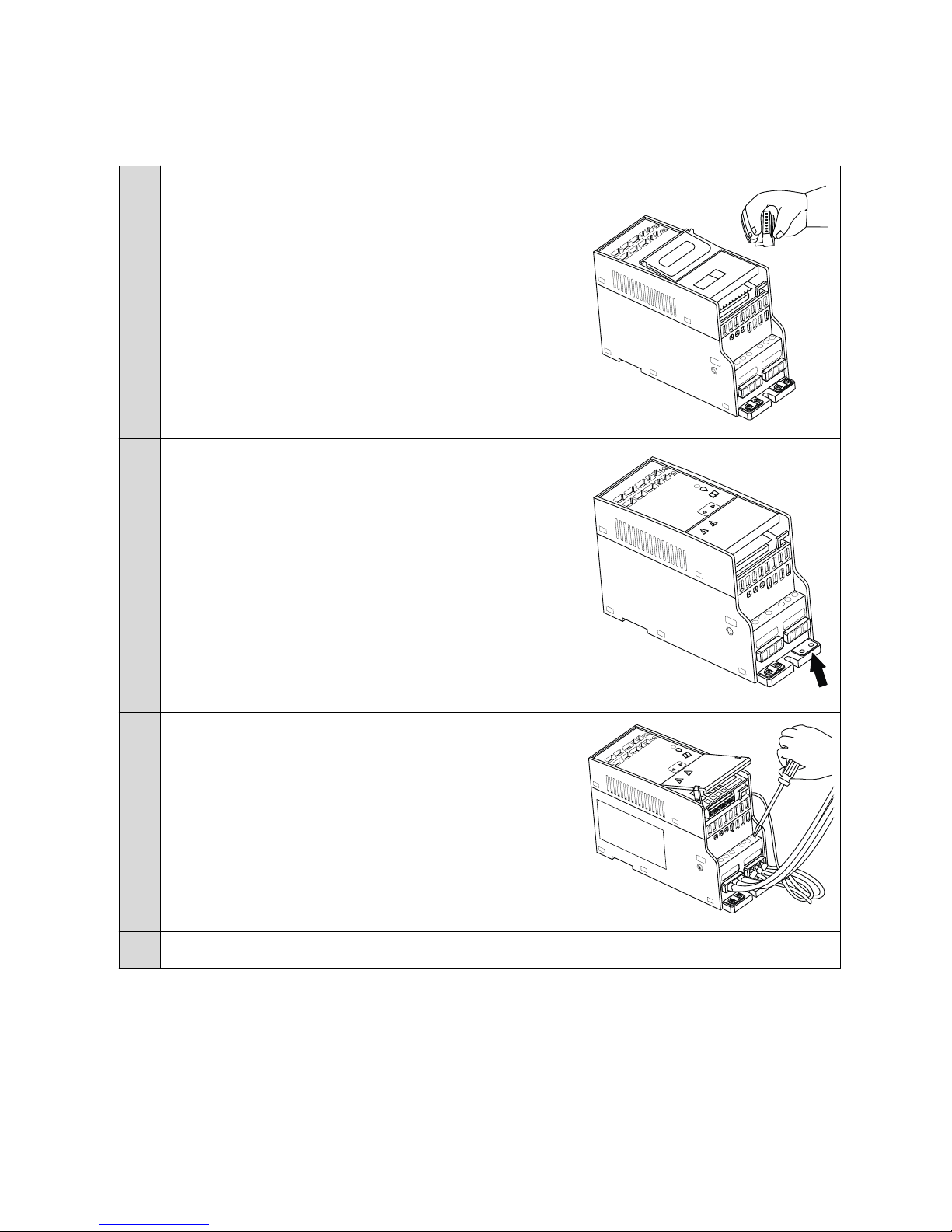

1Install the bottom plate. Use the 2 flat head screws delivered

with the package.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

12/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

2Remove the input wire terminal from the ControlMaster®NXT

003 frequency converter.

S6 S7 S8 S9 S10

S1 S5

S4

S3

S2 10

10

3Remove the grounding wire connector. See image. Leave the

other in place. The inverter doesn't fit into the motor

connection box otherwise.

S6 S7 S8 S9 S10

S1 S5

S4

S3

S2 10

10

OK

4Connect the frequency converter power supply wires; L1, L2,

L3 and motor power supply wires; U,V,W.

S6 S7 S8 S9 S10

S1 S5

S4

S3

S2 10

10

OK

DANGER

5Set the correct dip switch settings according to commissioning tables.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

13/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

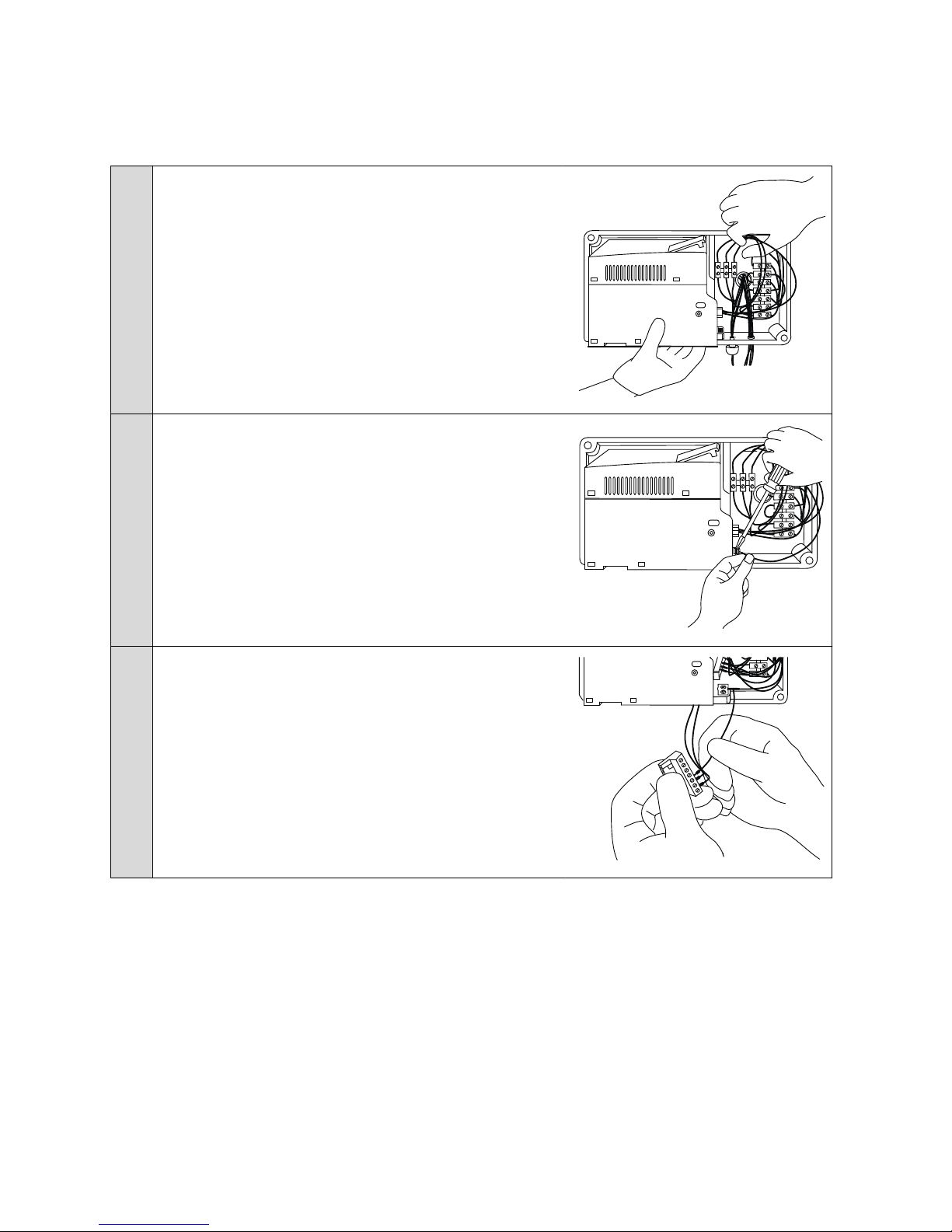

6Push the new frequency converter into the c-rail. Leave the

input lid open.

7Install the ground wire.

8Install the control wires (1,2,3 and 7) into the input terminal.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

14/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

9Push the input terminal into ControlMaster®NXT 003 . And

close the lid.

10 Fold the wires inside the box. Secure the wires with cable

ties. The image on the right shows how the final assembly

should look alike.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

15/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

11 Install the motor connection box lid.

12 Install the festoon electric connection box (if installed).

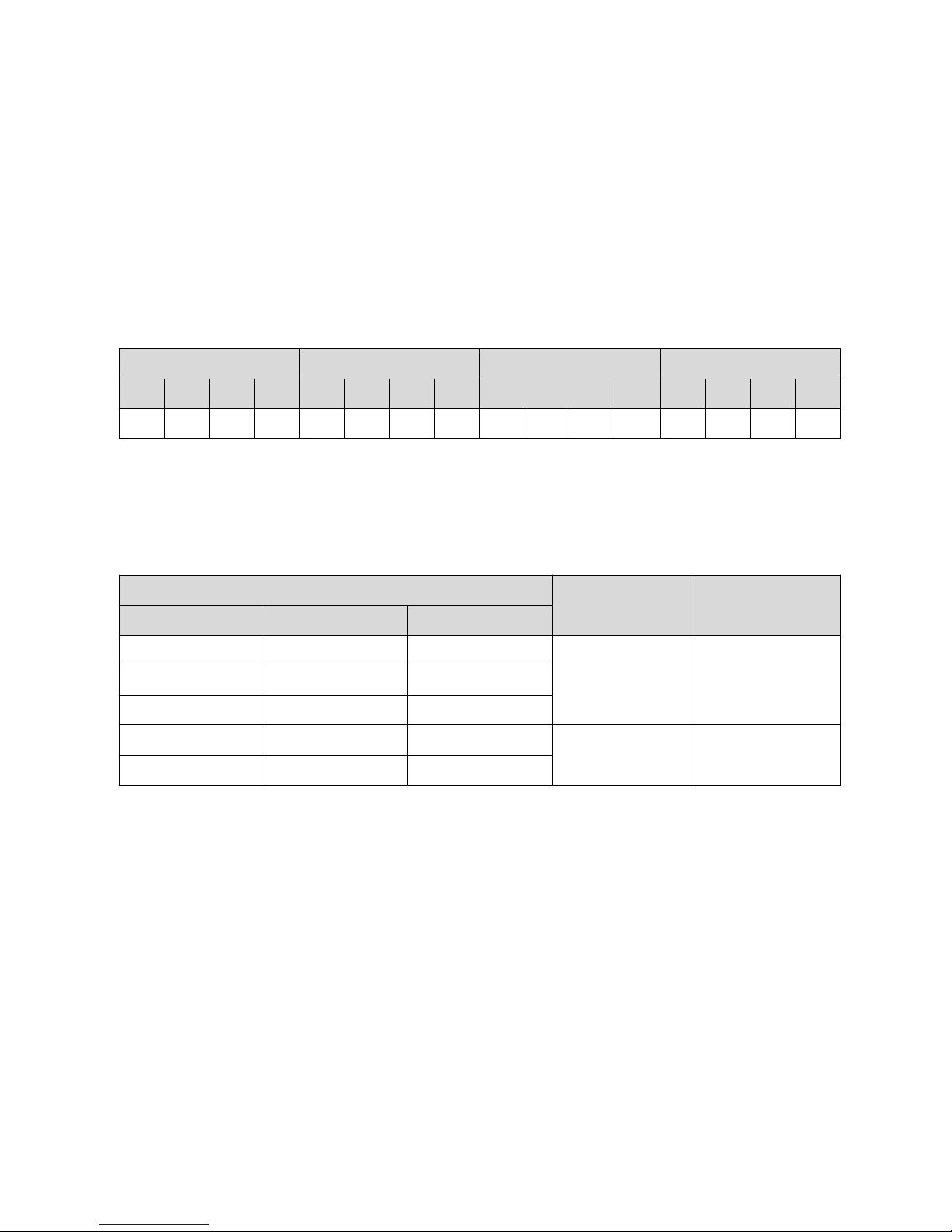

13 Release the main power button up from the pendant or radio controller.

14 Make sure that the trolley move's into correct directions by operating the trolley.

15 Make sure that the traveling speeds are suitable for customer needs by operating the trolley.

16 Make sure that the trolley slow-down ramps are suitable for customer needs by operating the trolley.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

16/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5 COMMISSIONING

Compare the DIP switch settings of the CMX 007 with the following tables and find the correct settings for the

ControlMaster®NXT 003 DIP switches.

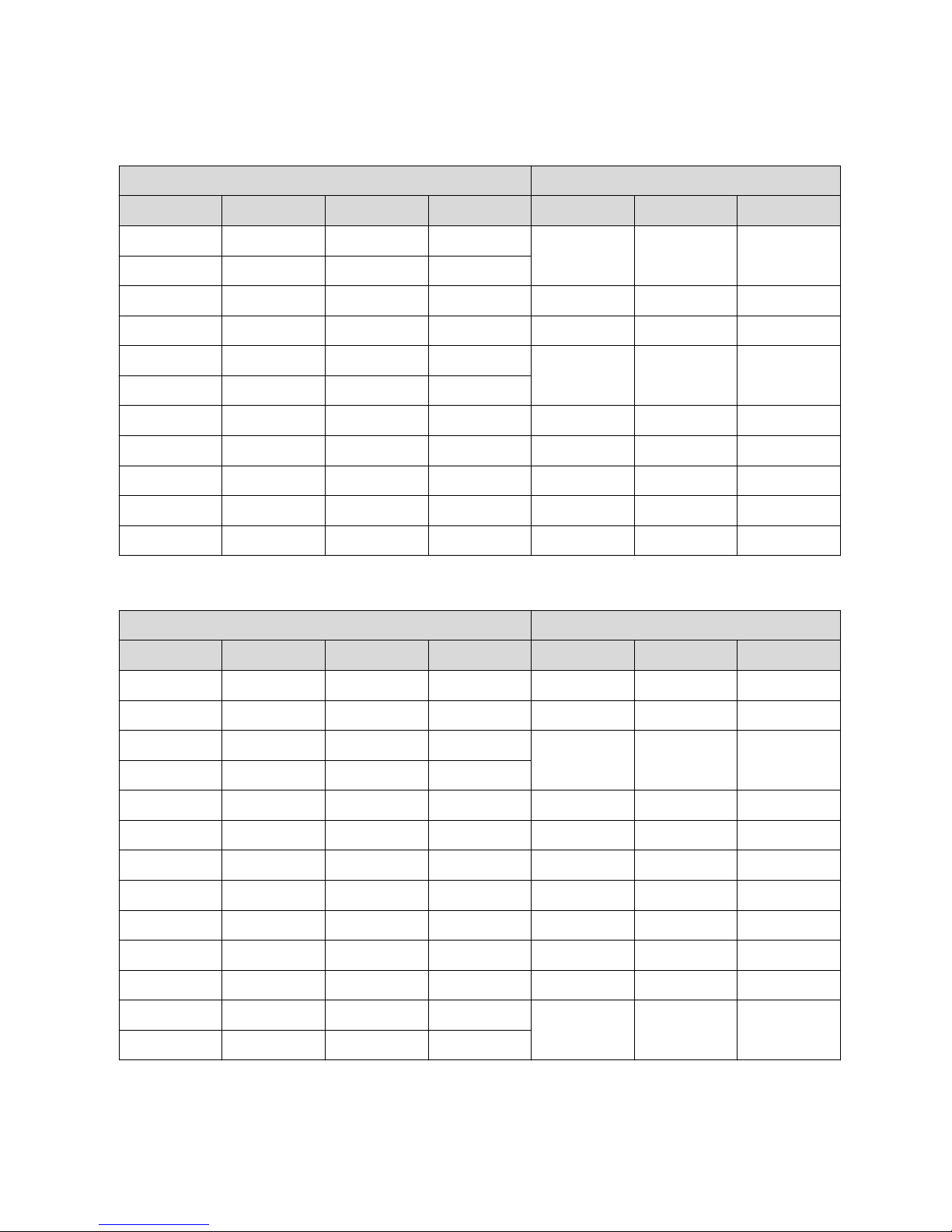

5.1 Old inverter parameter settings

Write in the table below the old frequency converter DIP switch settings.

Table 1. CMX 007 parameter settings.

Switch S1 Switch S2 Switch S3 Switch S4

-1 -2 -3 -4 -1 -2 -3 -4 -1 -2 -3 -4 -1 -2 -3 -4

5.2 Driving frequency table selection

The maximum and minimum driving frequencies depend on the nominal frequency of the motor. Use the

following table to determine which table should be used to set

Table 2. Driving Frequency table selection

CMX 007 Switch S4 Maximum Driving

Frequency Table

Minimum Driving

Frequency Table

-2 -3 -4

00035

010

001

10046

110

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

17/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5.3 S1 Maximum driving frequency

Set the maximum driving frequency according to the following tables

Table 3. Motor nominal frequency = 100/120 Hz

CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1

-1 -2 -3 -4 -1 -2 -3

0000000

0001111

0010110

0011111

0100100

0101110

0110101

0111

1000001

1001101

1010100

1011010

1100

1101011

1110

1111001

Table 4. Motor nominal frequency = 80 Hz

CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1

-1 -2 -3 -4 -1 -2 -3

0000010

0001011

0010001

0011011

0100110

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

18/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1

-1 -2 -3 -4 -1 -2 -3

0101011

0110

0111001

1000000

1001111

1010

1011110

1100101

1101100

1110100

1111010

Table 5. Motor nominal frequency = 35 Hz

CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1

-1 -2 -3 -4 -1 -2 -3

0000010

0001000

0010011

0011

0100110

0101011

0110001

0111111

1000010

1001111

1010101

1011100

1100

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

19/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1

-1 -2 -3 -4 -1 -2 -3

1101010

1110

1111

5.4 S2 Minimum driving frequency

Set the minimum driving frequency according to the following tables:

Table 6. Motor nominal frequency = 100/120 Hz

CMX 007 Switch S2 ControlMaster®NXT 003 Switch S2

-1 -2 -3 -4 -1 -2 -3

0000110

0001000

0010100

0011000

0100111

0101000

0110001

0111101

1000111

1001101

1010010

1011111

1100

1101

1110

1111

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

20/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Table of contents

Other R&M Media Converter manuals