R&M ControlMaster Edge User manual

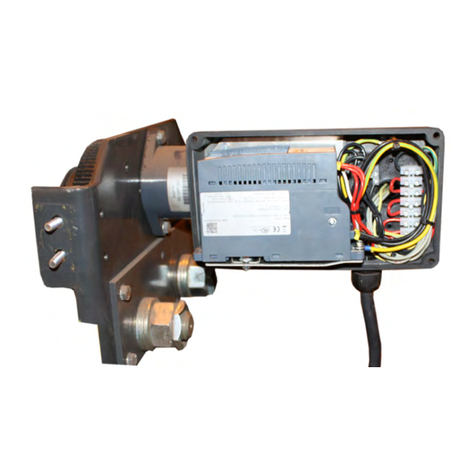

V/T2 W/T3 +/B1 B2

R/

L1

S/

L2

T/

L3

U/T1

RJ45

CAN

GND

STO

CAN

L

CAN

SHLD

CAN

H

CAN

V+

RA RC

Signal LEDs

Drive ready

Drive running

Drive is not ready

CANopen not

connected

CANopen connected

Drive is not powered

Fault, code indicated

by blinking sequence

No active fault

Mains output

U/T1

V/T2

W/T3

3-phase output

B1 B2 Braking resistor

+ - DC bus

Control signals

RJ45 Connection for Bluetooth

STO

+24V Power supply for STO chnl. 1 and 2

S1 STO channel 1

S2 STO channel 2

DCM Digital signal common

CAN

open

CAN GND Ground

CAN L Dominant low

CAN SHLD CAN cable shield (optional)

CAN H Dominant high

CAN V+ Not in use

Relay

output

RA C (common)

RC NO (normally open)

A

General information

R/L1

S/L2

T/L3

3-phase input

PE

Mains input

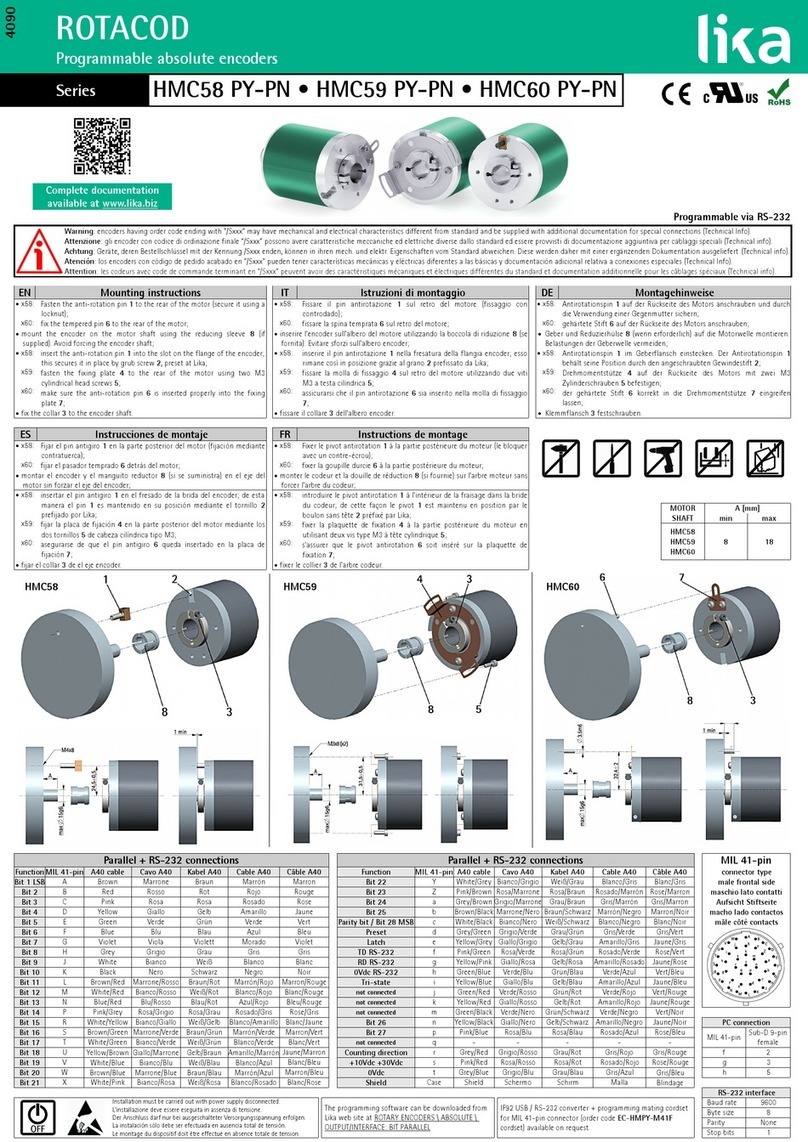

TDU00xE000

INPUT: 3PH, 380~480VAC, 50/60Hz

OUTPUT1: x.x A , x.x kVA

OUTPUT2: x.x A, x.x kVA

FREQUENCY RANGE: 0~320Hz

VERSION: x.x

EMC LEVEL MODIFIED

OPTION BOARD

Current ratings and switching frequency

TDU 4 kHz 5 kHz 6 kHz 7 kHz 8 kHz 9 kHz 10 kHz 11 kHz 12 kHz 13 kHz 14 kHz 15 kHz

004 3.4 A 3.1 A 2.8 A 2.5 A 2.3 A 2.1 A 1.9 A 1.7 A 1.6 A 1.5 A 1.4 A 1.3 A

009 8.2 A 8.0 A 7.9 A 7.6 A 7.1 A 6.6 A 6.2 A 5.7 A 5.3 A 5.0 A 4.7 A 4.4 A

017 16.5 A 16.0 A 15.5 A 14.7 A 13.7 A 12.9 A 12.0 A 11.2 A 10.6 A 9.9 A 9.2 A 8.7 A

028 28.0 A 27.2 A 26.3 A 24.9 A 23.2 A 21.8 A 20.4 A 19.0 A 17.9 A 16.8 A 15.7 A 14.8 A

045 45.0 A 45.0 A 45.0 A 45.0 A 43.2 A 39.6 A 36.0 A 32.9 A 30.2 A 27.5 A 25.2 A 23.0 A

Rating label

Note: In case of product reclamation, include the following information:

Type, serial number, fault code (if applicable), application (hoist/travel), how problem appears (e.g. fault code

F001 during acceleration).

If any problems or malfunctions occur during commissioning, refer to the troubleshooting section in the

service instructions, to find out the reason. Make sure all problems are solved before you continue operation.

This document and the information contained herein, is the exclusive property of R&M Materials Handling Inc. and represents a non-public, confidential

and proprietary trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the

express written consent of R&M Materials Handling Inc. Copyright 2021 © R&M Materials Handling Inc. All rights reserved.

Frequency converter ControlMaster Edge

QUICK INSTALLATION GUIDE

Disclaimer: Person conducting this work must be appropriately trained and familiar with product range and

related safety instructions. This quick guide only complements original instructions and does not replace them.

Page 1/2 | DOC735078/2 | 26 May 2021

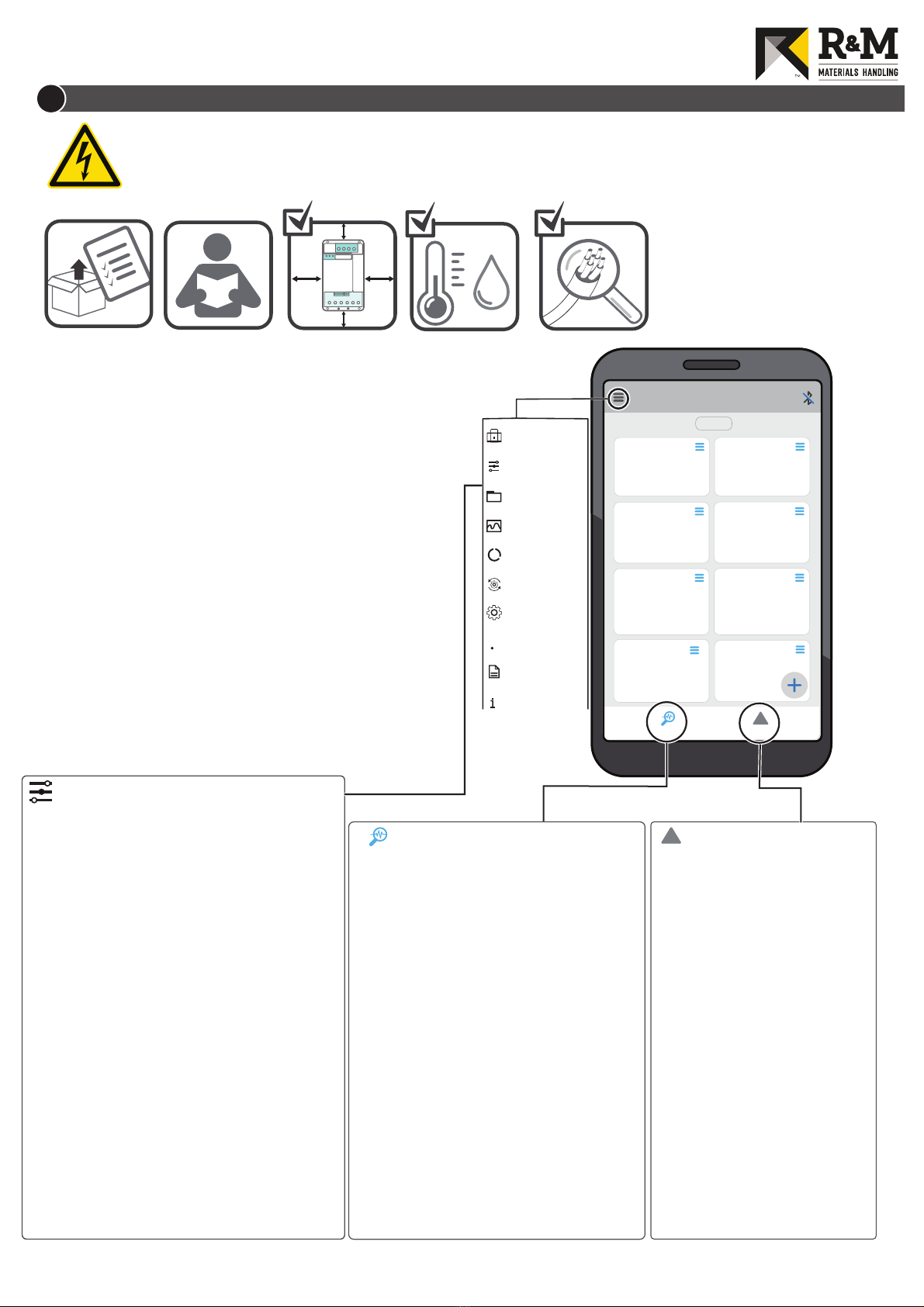

Preparations

1. Check that the delivery corresponds to the order.

2. Read the safety instructions.

3. Check the clearances around device carefully.

4. Check ambient conditions.

5. Check sizes of motor cable, the control wires etc.

6. Check control wirings.

Parameters and commissioning

1. Switch on mains power, release emergency stop

button, and press start pushbutton.

2. To check parameters establish connection between

device and TD DriveTool app.

NOTE: Usually, the parameters are properly set after factory

tests and no adjustments are needed.

• Compact brake motors for traveling (MF06MA, MF06LA)

See the motor parameter values from Service Instruction.

• Other motors for traveling

1. Check parameters 01-00...01-06, and 00-01.

2. Perform automatic tuning with TD Drive Tool

• All motors for lifting

See the motor parameter values from Service Instruction.

NOTE: Use only pre-defined motors with factory tested

parameter values.

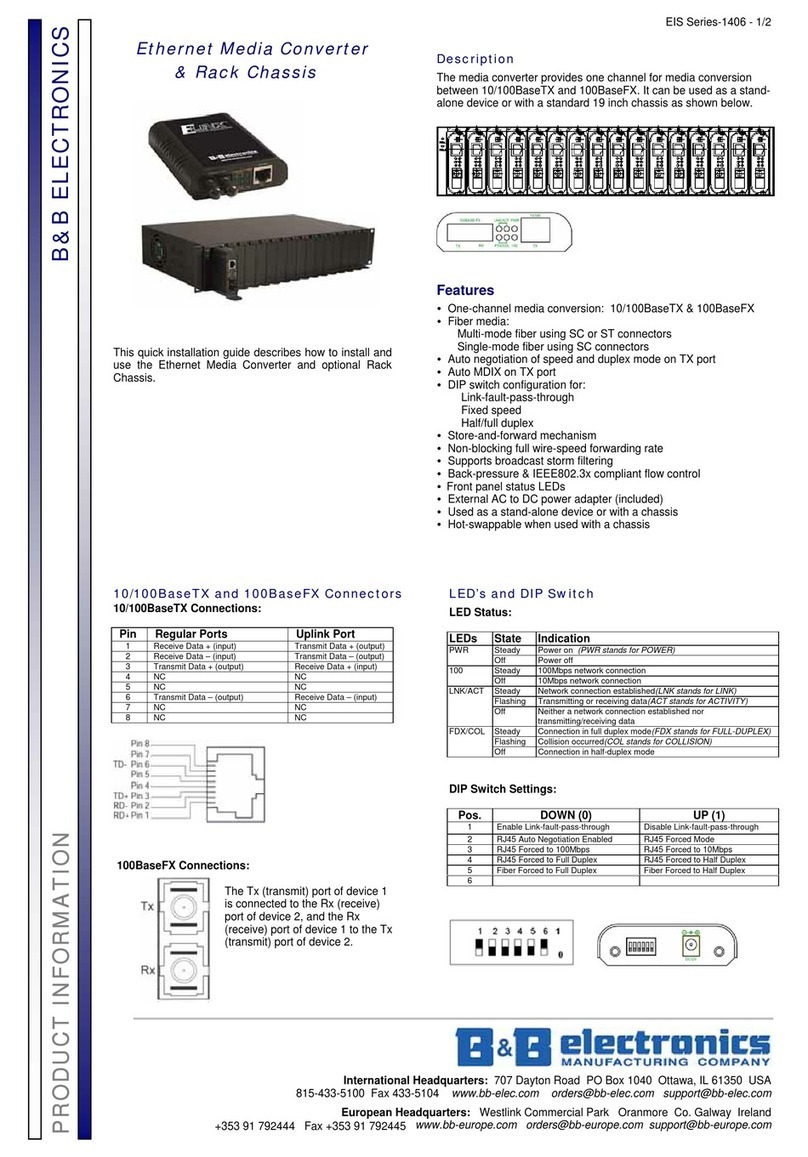

Dashboard

Disconnected

RESET

Drive Label

...

Model

...

Output Frequency

...

Hz

Motor Current

...

A

Motor Voltage

V

... ...

IGBT Temperature

oC

Monitor

!

Events

DC Voltage

V

...

Active Warning

...

BInstallation

High voltages inside the device.

Wait at least 5 min after the mains input voltage has been switched off before service actions.

When signal LEDs are on there is dangerous voltage on the DC bus.

When signal LEDs turns off, the DC bus voltage is about 100 V.

Note that there is a dangerous voltage in the braking resistor when DC bus is charged.

RH

°C °F

Device info

Parameters

File manager

Trend

Autotuning

Settings

Support Package

Documentation

About

Datalogger

?

Parameters

!

Events

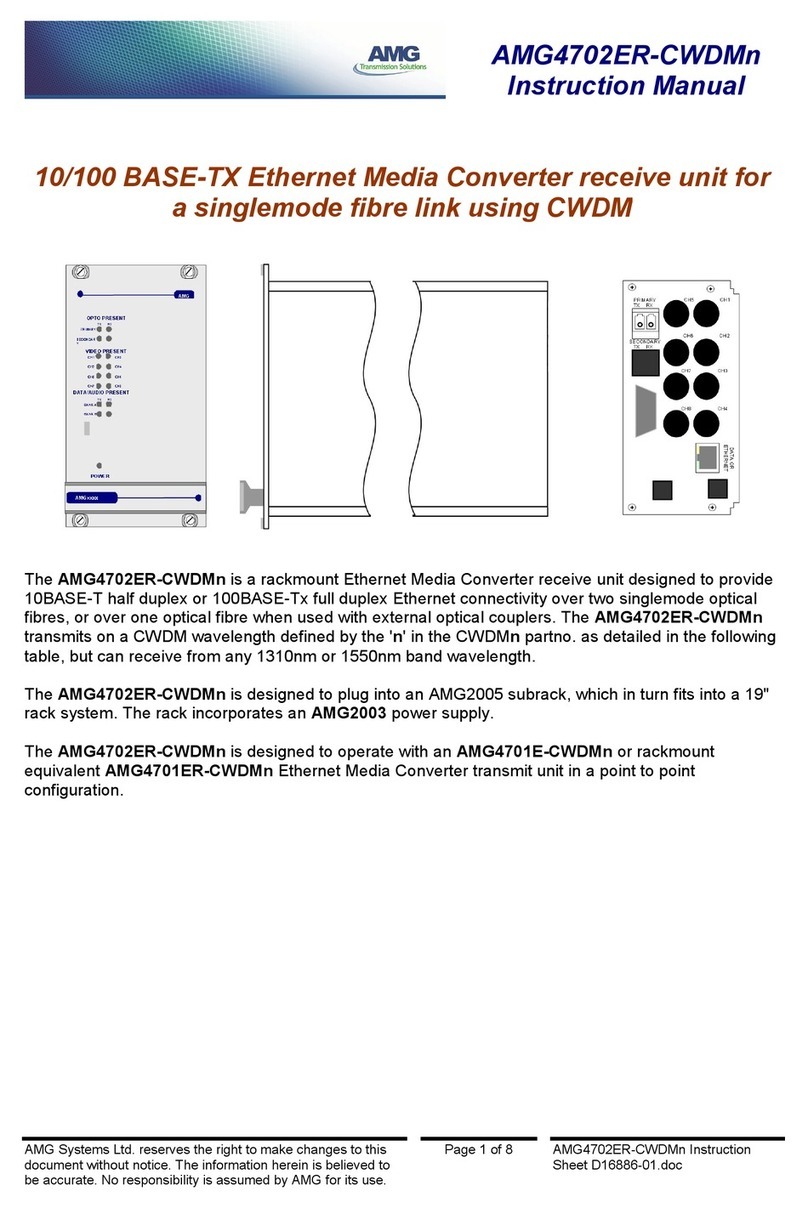

F001... Over current

F003 Over current

F006 Over current

F007... Overvoltage

F010 Overvoltage

F011... Undervoltage

F014 Undervoltage

F140 Ground fault

F141 Ground fault

F200 CANopen communication

F201 Motor overtemperature

F202 Both directions fault

F203 Ramp supervision

F204 Parameter fault

F205 Parameter fault

Common fault codes

Monitoring values

Output frequency

Motor current

Motor voltage

IGBT

temperature

DC voltage

Freq reference

Freq command

STO input

RO status

DI status

CANopen SW

CANopen CW

Active Warning

Active Fault

Drive Label

Output frequency to the

motor

Output current to the induction

motor

Output voltage to the motor

Internal temperature of IGBT

module

Inverter DC-link voltage

Frequency reference

Frequency command from a

radio or a pendant controller

Safe torque off input status

Status of relay output

Status of digital input

Status word of CANopen

Control word of CANopen

Code of active warning

Code of active fault

Drive label code of the

connected frequency converter

Monitor

00-00 User Role Key 03-06 Motor Rs

00-01 Drive Selection 03-07 Motor Rr

00-02 Accel Time 03-08 Motor Lm

00-03 Decel Time 03-09 Motor Lx

00-04 Min Frequency 03-10 System Inertia

00-05 Max Frequency 03-11 ASR1/2 Switch F

01-00 Motor Nom Volt 03-12 ASR Zero-Speed

01-01 Motor Nom Freq 03-13 ASR1 Low-Speed

01-02 Motor Nom Curr 03-14 ASR2 High-Speed

01-03 No-Load Current 04-00 DI1 Function…

01-04 Motor Cos Phi 04-05 DI6 Function

01-05 Motor Nom Power 05-00 Ramp Stretching

01-06 Motor Nom Speed 05-01 Flux Brake

01-08 Start Current 05-02 Slowdown Mode

02-00 Brake Open Delay 05-03 Brake Chopper

02-01 Start DC Time 06-00 Node ID

02-02 Start Frequency 06-01 CAN Speed

02-03 Load Floating Time 06-02 Control Place

03-00 ESR mode 06-03 Process Data 1…

03-01 ESR Max Freq 06-09 Process Data 7

03-02 Ramp Scale Freq 07-00 Switching Freq

03-03 U/f Zero Freq Volt 08-00 F#1 Fault Record…

03-04 U/f Mid Voltage 08-09 F#10 Fault Record

03-05 U/f Mid Freq

Loremipsum

This document and the information contained herein, is the exclusive property of R&M Materials Handling Inc. and represents a non-public, confidential

and proprietary trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the

express written consent of R&M Materials Handling Inc. Copyright 2021 © R&M Materials Handling Inc. All rights

Page 2/2 | DOC735078/2 | 26 May 2021

Other R&M Media Converter manuals