Original instructions

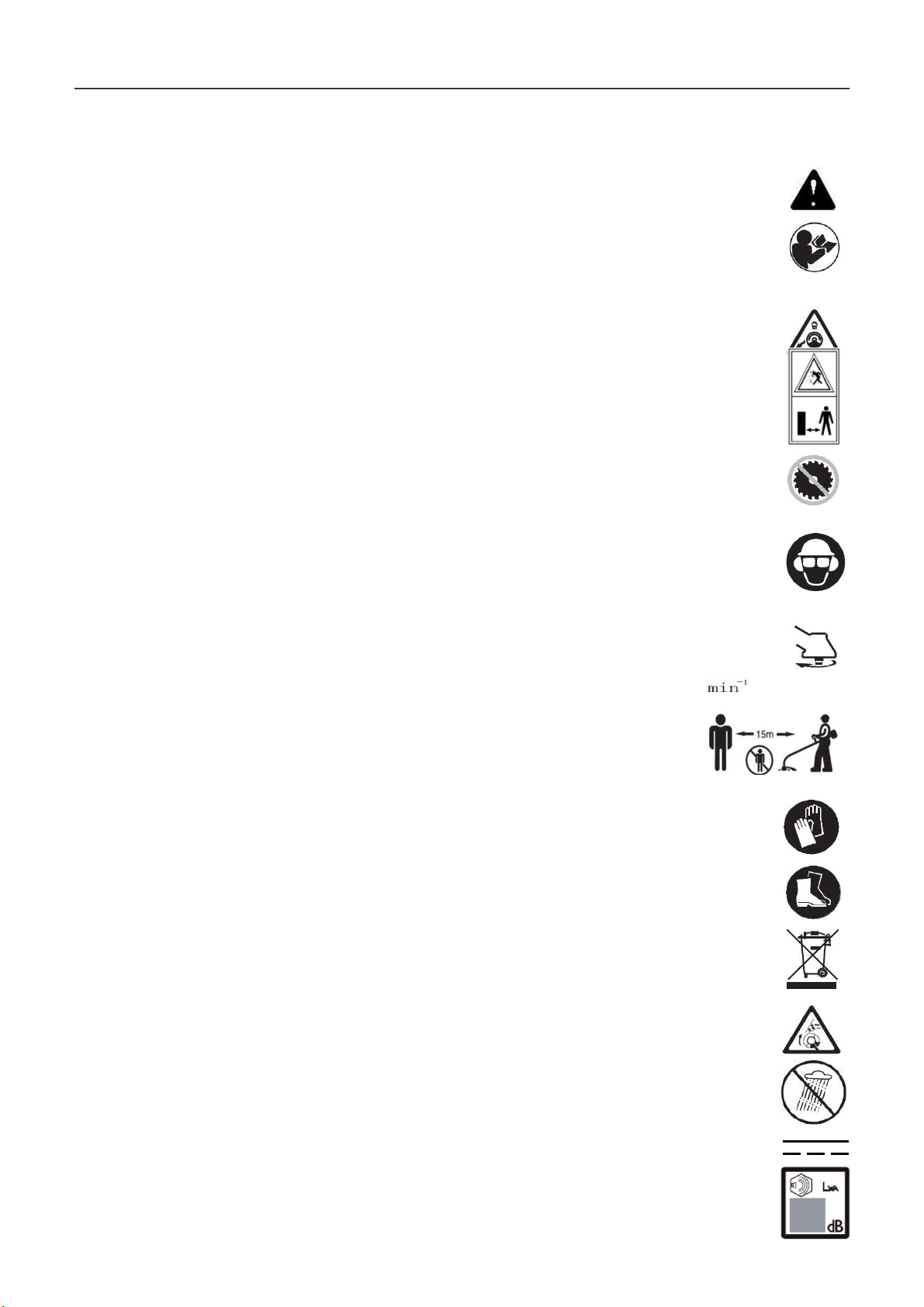

SAFETY INSTRUCTIONS

WARNING!

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

General instructions

1.Do not allow persons unfamiliar with the brush cutter/grass trimmer or these instructions to operate the tool.

Brush cutter and grass trimmers are dangerous in the hands of untrained users.

2.Be sure that anyone who is to operator the brush cutter/grass trimmer has first read the instruction manual.

3.Never allow people unfamiliar with these instruction, people(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge to use the tool. Local regulations can restrict the age of the

operator.

4.Use the tool with the utmost care and attention.

5. Operate the equipment only if you are in good physical condition. Perform all work calmly and carefully. Use

common sense and keep in mind that the operator or user is responsible for accidents or hazards occurring to

other people or their property.

6. Never use the equipment after consumption of alcohol or drugs, or if feeling tired or ill.

7. Avoid Unintentional Starting. Do not carry battery-installed equipment with finger on switch. Be sure switch is

off when installing a battery cartridge.

8. The motor is to be switched off immediately in case that the equipment shows any problem or abnormal sign.

9. Switch off and remove the battery cartridge when resting and when leaving the equipment unattended, and

place it in a safe location to prevent danger to others or damage to the equipment.

10. Don't force the equipment. it will do the job better and with less likelihood of a risk of injury at the rate

for which it was designed.

11. Don't overreach. Keep proper footing and balance at all times.

Check before starting

•Always remove the battery to prevent the machine being started by accident. Always disconnect the

battery before any maintenance on the machine.

•Before using the machine and after any impact, check for signs of wear or damage and repair as necessary.

•Inspect the working area. Remove all loose objects, such as stones, broken glass, nails, steel wire, grass, etc. that

could be thrown out or become wrapped around the cutter or cutter guard.

•The machine operator must ensure that no people or animals come closer than 15 meters(50 ft.)while working.

When several operators are working in the same area the safety distance should be at least 15 meters(50 ft.).

•Do an overall inspection of the machine before use, see maintenance schedules.

Intended use of the tool

1.Use right tool. The cordless brush cutter/grass trimmer is only intended for cutting grass, weeds, brushes and

undergrowth. It should not be used for any other purpose such as edging or hedge cutting as this may cause injury.

Personal safety

•The cutting tool does not stop immediately after the machine is turned off.

•The machine is only design for brush/grass. Do not use the Brush cutter/grass trimmer for any job except that

for which it is intended.

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while

5-English