Raychem HTC-915 User manual

HTC-915

Universal heat tracing control system

CAUTION: installation, configuration and commissioning

should only be performed by properly trained personnel.

Local regulations regarding the installation & safety must be followed.

APPLICATION

Type Surface sensing/ambient sensing

Area of use Non-hazardous area indoors, typically panel mounted

Approval certification CE marked

PRODUCT SPECIFICATION

Temperature range controller –60°C to 570°C in steps of 1 K

Control algorithms EMR: Line sensing on/off, proportional ambient

SSR: Line sensing on/off, proportional, proportional ambient, power limiting,

Switching accuracy 1 K

ENCLOSURE

Ambient operating temperature range –40°C to +50°C

Ambient storage temperature range –40°C to +85°C

Relative humidity 0% to 90% Non condensing

Ingress protection Housing: IP40, Terminals: IP20

Material ASA-PC, color: green

Flammability class V0 (UL94)

Mounting method Panel mounting on 35 mm DIN rail

WARNING

IEC 60417-5032 (2002-10) Alternating current

IEC 60417-5031 (2002-10) Direct current

ELECTRICAL PROPERTIES

Connection terminals and cabling Screw type terminals. All terminals suitable for stranded and solid core connection

cables having a cross section between 0.5 and 2.5 mm2 (24 to 12 AWG) The

915-HTC and 915-Alarm Relay connector outputs (240V) require ferrules on the

connecting wires if stranded wires are used. The wires shall handle a minimum wire

temperature of 75°C

Supply voltage CE/EAC: 100 Vac to 250 Vac, +10% -10%, 50/60 Hz, 0.15 A to 0.06 A

CSA: 100 Vac to 277 Vac, 50/60 Hz, 0.15

Power consumption Max 20 VA with limiter connected

Control output Contactor control

output

(EMR) Electromechanical relay rated 3 A/250 Vac, 50/60 Hz

Solid-state relay

control output

(SSR) 12 VDC, 75 mA. max. to drive normally open Solid state relays. Depending on

the application, one, two or three phase switching elements have to be used. (Solid

state relays are not included)

Switching capacity Depends on the type of switch element used

(The switch element is external)

nVent.com | 2

(Russia, Kazakhstan, Belarus)

For other countries contact your local nVent representative.

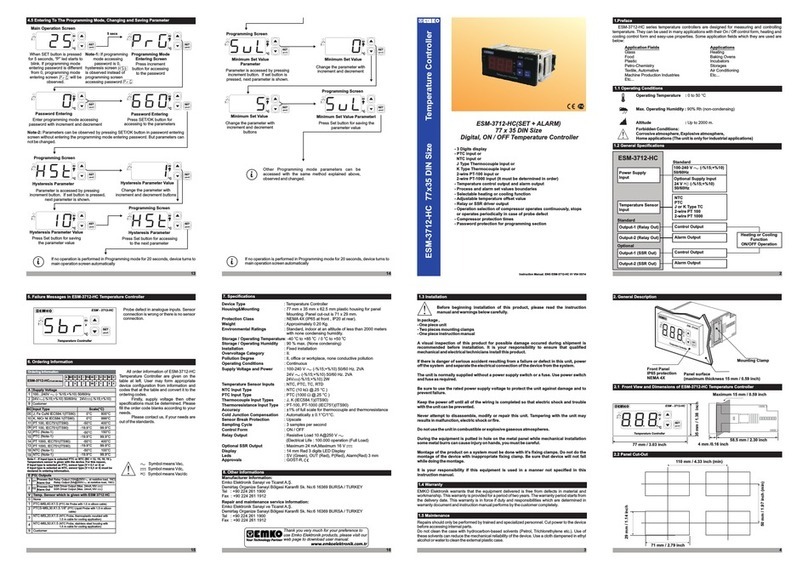

CONNECTION DIAGRAM

TERMINAL ASSIGNMENTS

SHIFT TEST BACK ENTER

MONITO RALARM CONFI G ALAR M

OUTPU T

915 SERIES HEA T-TRACING CONTROLLER

Tx

Rx

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

30 29 28 27 26 25 24 23 22 21 20 19 18 17

Ground fault CT input

1 to 0.001 A

Load CT input 100 to 0.1 A

SSR out

Alarm output

NO or NC

Control relay output

100 to 250 Vac / 277 Vac.

(+10 / –10%)

-

+

Connection to limiter

Ext input

TS2

(optional)

TS1

Alarm output relay CE/EAC: Relay contact rated 3 A/250 Vac, 50/60 Hz

CSA: Relay contact rated 3A/277Vac, 50/60 Hz

Output is user programmable to open or to close on alarm.

Power output 12 Vdc, 200 mA max.

TEMPERATURE SENSOR

Type

Quantity 2 RTD inputs available

COMMUNICATIONS

Protocol Modbus RTU or ASCII

Topology Multidrop/daisychain

Cable Single shielded twisted pair, 0.5 mm2(24 AWG) or larger

Length Typical 2.7 km max @ 9600 Baud

Quantity Up to 32 devices

Address Programmable

FUNCTIONAL OVERVIEW

The nVent RAYCHEM HTC-915 is a full featured temperature control system for

heattracing applications.

Power supply

100 to 250V

±10% at 50/60Hz

(also used

for voltage

measurements)

2 three wire

PT100 inputs

HTC-915

Controller

Digital

communication

Configuration

and set-up

Software (RS485)

Control

Relay output

(250V/277V/3A)

Current

Transformer

Load current

Control

Solid state output

(0 – 12Vdc)

Alarm output

(relay 250V/277V/3A

)

Configurable to open

or to close on alarm

Current

Transformer

Earth leakage current

Scrolling display

Current

Transformer

Load current

3-wire PT100

input

HTC-915

Limiter

Alarm output

(relay 250V/277V/3A)

NC opening on alarm

Tr ip

Relay output

(250V/277V/3A)

nVent.com | 3

Terminal assignments

for the controller

1. RTD 1 source

2. RTD 1 sense

3. RTD 1 common

4. Shield

5. RTD 2 source

6. RTD 2 sense

7. RTD 2 common

(Inhibit/override)

9. External Input –

(Inhibit/override)

10. Communications

11. Communications

12. Shield

13. Digital common (to

Limiter 1)

14. +12Vdc out

(to Limiter 2)

15. TX data (to Limiter 3)

16. RX data

(from Limiter 4)

23. PE

24. SSR control output +

25. SSR control output –

26. Load Current CT input

27. Load Current CT input

29. GF CT input

30. GF CT input

Terminal assignments

of the limiter

1. Digital common

(from HTC 13)

2. +12Vdc in (from HTC

14)

3. RX data (from HTC 15 )

4. TX data (to HTC 16)

5. RTD 1 source

6. RTD 1 sense

7. RTD 1 common

9. Control relay output

10. Control relay output

11. Alarm relay output

12. Alarm relay output

13. Load Current CT input

14. Load Current CT input

17. Mains Input (L1)

neutral)

19. Control relay output

20. Control relay output

21. Alarm relay output

22. Alarm relay output

Alarm availability

An alarm can be generated if the actual measured value is

higher or lower than the value specified in the controller’s

set-up. Alarms are available for:

temperature, voltage, current, power, earth leakage current,

etc… refer to HTC-915 operating manual for details. A copy of

this manual can be downloaded from nVent.com (Doc-2106)

OPERATOR CONSOLE & OPERATION

ALPHA-NUMERIC DISPLAY

The Console incorporates LED display. Messages and

prompts that are greater than 6 characters long are scrolled.

KEYPAD

The local keypad consists of 6 keys that allow you to select

the console mode function. For certain keys, the SHIFT key

selects an alternate function, as shown by the text above

Quick Notes on Operation

Basic rules for efficient Console use:

• use the SHIFT key followed by the appropriate function

key -- ALARM,

MONITOR, or CONFIG -- to select the operating mode

• use Íand to move around in the menu

• use Ëto enter a new menu, enter a new value, or

select a menu item

• use Áto exit the current menu or cancel an edit

Key Function

SHIFT • Press to activate a SHIFT function -- the

next key pressed uses the alternate

(shifted) function.

• The SHIFT LED illuminates, indicating

the next key uses the alternate (shifted)

function pressing SHIFT again cancels the

alternate (shifted) function.

TEST • Turns on tracing for 30 seconds when

prefixed by the SHIFT key, this key

switches the console to the Alarm mode.

ÁBACK

[shift

MONITOR]

• Exits the current menu (or cancels the

new setting when editing a parameter).

• Moves the cursor to the left when editing

an alpha-numeric parameter.

• When prefixed by the SHIFT key, this

key switches the console to the Monitor

mode.

ËENTER

[shift

CONFIG]

• Selects the item in the display (or accepts

the setting when editing a parameter).

• Moves the cursor to the right when editing

an alpha-numeric parameter.

• When prefixed by the SHIFT key, this key

switches the console to the Configure

mode.

• Moves to the previous item in a menu

increments the value when editing.

• Moves to the next item in a menu

decrements the value when editing.

LED INDICATORS

The console includes eight LED indicators:

Four LEDs indicate the Console operating mode.

(SHIFT function, ALARM, MONITOR, or CONFIGure modes).

There are two status LED’s which indicate the alarm and

control output status of the controller:

The output LED, the alarm LED will flash

(approximately once per second) when the controller has

detected an alarm condition. The two additional LEDs are

used to indicate external communications activity.

nVent.com | 4

USE OF THE HTC-915-CONT CONTROLLER WITH

AN OPTIONAL HTC-915-LIM LIMITER

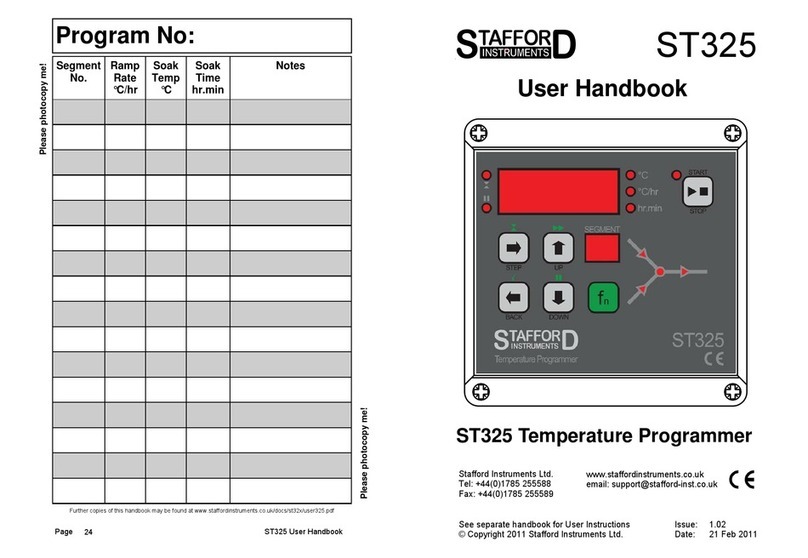

LIMITER CONNECTION DIAGRAM TERMINAL

ASSIGNMENTS

* Wiring for

Communications

with HTC-915-

CONT Controller

ornitted for clarity

** Current sensor

optional and not

included.

12 VDC power supply

can be obtained from

HTC-915-CONT

Heating cable

To external alarm annunciater /

DCS or PLC input Max 3 A 250V

/ 277V

Terminal assignments of the limiter

1. Digital common (from HTC 13)

2. +12Vdc out (from HTC 14)

3. RX data (from HTC 15)

4. TX data (to HTC 16)

5. RTD 1 source

6. RTD 1 sense

7. RTD 2 common

9. Control relay output

10. Control relay output

11. Alarm relay output

12. Alarm relay output

13. Load current CT input

14. Load current CT input

PROGRAMMING THE LIMITER

In order to protect the settings of the limiter for unwanted

changes the user interface provides some special restrictions.

Changing the Limiter set point

The limiter set point is changed through the user interface

of the HTC-915-CONT in exactly the same manner as for the

controller. However, before the new value will be copied in the

limiter memory the user has to press and release the SHIFT

key followed by CONFIG. This additional requirement avoids

unwanted changes of the limiter set point.

Uninstalling the limiter from a HTC-915 control system

Once a limiter is added to the system it can only be removed

(from software) by uninstalling it. This can be done through

the Misc. Setup Sub-menu of the HTC-915-CONT. However,

unlike for installing the limiter the user now will need to hit the

SHIFT key before pressing the CONFIG button to confirm the

removal of the limiter.

Changing the Configuration

To change the Controller configuration:

• Position the desired parameter (menu item) in the display.

• Press the Ëkey to initiate an edit session.

• If the console is “locked” you are prompted to enter the

passcode.

• The present setting will flash on the display to indicate that

you are editing the parameter.

• Use the and Íkeys to change the value.

• The operation of the Ëand Ávaries depends on the type

of data being edited.

Note: Once you have initiated an edit session, you must end

it before switching to another mode or invoking another

function.

Changing a Numeric Parameter

To change a numeric parameter (e.g. the control setpoint):

• Position the appropriate parameter in the display.

• Press the Ëkey to initiate the edit session.

• If the console is “locked” you are prompted to enter the

passcode.

• The present value is displayed and the last (rightmost)

digit blinks.

• The blinking digit identifies the digit that you are editing.

• Use or Íto set the desired value.

• Use Áor Ëto move to a different digit.

• To enter a negative value, scroll to the first (leftmost) digit

until a “-” appears in the display.

• Pressing Ëwhile on the last (rightmost) digit saves the

new value.

• Pressing Áwhile on the first (leftmost) digit ends the edit

session without altering the parameter.

Passcode Protection

The HTC-915 Series Controller provides a passcode for

protection of its configuration. You may view any portion of

the configuration with the

console “locked”, however, when you attempt to initiate an

edit session by pressing Ë, you are prompted to enter the

passcode. A new unit will not be password protected.

nVent.com | 5

Limiter Current sensor input

For specific installations the limiter can be configured such

that it will allow for a temperature overshoot as long as there

is no current flowing to the heating system. This would be the

case when the high temperature is caused by an external heat

source such as steam cleaning, exothermal processes, etc..

Sensors are permanently monitored for short circuit and cable

breakage.

In case an open / short input is detected, the limiter will trip

instantaneously.

LIMITER OUTPUTS

Limiter Control output

The relay output of the limiter is typically used to operate an

external electro mechanical relay (EMR). This relay will in

case of excessive over temperature isolate the load from the

mains supply.

Limiter Alarm output

The limiter alarm output relay will change state (from NC to

NO) if

The limiter is powered up the first time after a power outage.

The limiter set point is exceeded and thus the limiter has

tripped.

An RTD failure is detected.

A limiter current transformer failure (if the limiter CT is being

used) is detected.

Limiter reset

Once the limiter has tripped it has to be reset manually.

Resetting the limiter will only be possible if the actual

temperature measured by the Pt100 is below the limit

temperature minus the unit hysteresis.

The limiter can be reset using one of the following

methods:

1. From the control panel on the HTC-915-CONT by pressing

alarm and SHIFT + RESET (assuming presence of the digital

communication between controller and limiter).

2. Via pushing and holding the RESET key on the limiter unit

for t > 2 seconds.

3. Remotely via the external input of the HTC-915 and a

remote contact.

4. Remotely via DCS system. (5 to 24 Vdc).

5. Remotely via the serial interface and the supervisor

software.

APPENDIX - CONFIGURATION SHEET

915 HTC Configuration - Firmware versions V1.OX

BASIC MODE MENU

(All other parameters are set as shown in the Advanced Mode

Sub-Menus)

CONFIGURATION MODE MENU

Parameter Factory User

Control Setpoint

Lo TS 1 14°F (–10°C)

Lo Load 1.0 A

Switch Control Mode Deadband

Circuit Breaker *n/a (30. A)

Temp. Units °C

Feature Mode Basic

ADVANCED MODE MENUS

CONFIGURATION MODE MENU

Parameter Factory User

Control Setpoint

Lo TS 1 14°F (–10°C)

Lo Load 1.0 A

Switch Control Mode Deadband

Circuit Breaker *n/a (30. A)

Temp. Units °C

Feature Mode Basic

TS ALARMS CONFIGURATION SUB MENU

Parameter Factory User

TS 1 Fail Enable

Lo TS 1 Enable

Lo TS 1 14°F (–10°C)

Hi TS 1 Disable

Hi TS 1 *n/a

212°F (100.0°C)

TS 2 Fail Disable

Lo TS 2 Disable

Lo TS 2 *n/a

14°F (–10°C)

Hi TS 2 Disable

Lo TS 2 *n/a

212°F (100.0°C)

Lo TS Filter 0 min

Hi TS Filter *n/a (0 min)

Latch TS Alarms Yes

CTL TS Fail Enable

nVent.com | 6

POINT SETUP SUB-MENU

Parameter Factory User

Tag TAG-(factory ID)

Switch Control Mode Deadband

Deadband 5°F (3°C)

Prop Band *n/a (4°F (2°C))

Cycle time *n/a (10 min)

Switch Rating *n/a (30.0 A)

Circuit Breaker *n/a (30.0 A)

Outlet Limit Mode Disable

Max. Power *n/a (7200 W)

Max. Current *n/a (30.0 A)

3 Ph Pwr Calc No

TS Fail Mode Off

TS CTL Mode TS1-Fail Off

TS 1 Hi Limit *n/a Disable

TS 2 Hi Limit *n/a Disable

Volt Turns Ratio 1.00 to 1

Current Turns Ratio 1.00 to 1

Auto-cycle Enable

Auto-cycle Interval

Auto-cycle Units Hours

Override Source Remote

Load Shedding *n/a

Limiter Cutout Temp. *n/a (50.0°C)

Limiter Current Sense *n/a (Disable)

MISC. SETUP SUB-MENU

Parameter Factory User

Temp. Units °C n/a

Version V1.0X.XX

Limiter version *n/a (V1.0X.XX)

Ext. Input Not used

Flash Alarm Output Yes

Alarm output N.C.

Language English

Passcode 0

Scroll Delay 0.15 secs

Load Defaults (See user manual)

Limiter Installed No

COMMUNICATION SETUP SUB-MENU

Parameter Factory User

Protocol Modbus RTU

Modbus Addr *n/a (1)

Modbus Sub Addr *n/a (0)

Baud Rate Auto

Parity *n/a (None)

Tx Deley 0.06 secs

* n/a: Parameter may only appear if certain features are

enabled. Values shown in brackets are the Factory defaults

if the settings are enabled.

This information defines the default 915 Series Control

Module configuration as set by the Factory for firmware

V1.0X. These settings are subject to change without notice.

It is the user’s responsibility to verify that all configuration

parameters are chosen appropriately for the intended

application.

OTHER ALARMS CONFIGURATION SUB MENU

Parameter Factory User

Lo Load Enable

Lo Load 1.0 A

Lo Load Filter 0 sec

Hi Load Disable

Hi Load *n/a (30.0 A)

Hi Load Filter *n/a (0 sec)

Hi GFI Enable

Hi GFI 20 mA

Hi GFI Filter 0 sec

GFI Trip Enable

GFI Trip 30 mA

Lo Volt Enable

Lo Volt 90 V

Lo Volt Filter 0 sec

Hi Volt Disable

Hi Volt *n/a (270 V)

Hi Volt Filter *n/a (0 sec)

Lo Resist Disable

Lo Resist *n/a (50%)

Lo Resist Filter *n/a (0 sec)

Hi Resist Disable

Hi Resist *n/a (50%)

Hi Resist Filter *n/a (0 sec)

Nominal Resist

Overcurrent Trip *n/a (Enable)

Switch fail Enable

HTC Reset Disable

C.B. Limiting *n/a (Disable)

Output Limiting *n/a (Disable)

Switch Limiting *n/a (Disable)

Contactor Count Enable

Contactor Count 200,000

EEROM data Fail Enable

nVent.com | 7

PRODUCT DIMENSIONS

Controller Dimensions

Limiter dimensions

INSTALLATION

Ensure all personnel involved in installation, servicing,

and programming are qualified and familiar with electrical

equipment, their ratings and proper practices and codes.

Installation Location

Considerations should include expected atmospheric

conditions, accessibility for maintenance, testing and ambient

temperature. The conditions at the place of installation may

affect load current ratings.

Operator Safety Considerations

Caution: Some wiring configurations will use more than one

power source and all must be de-energized prior to performing

any maintenance on a control circuit.

Warning: The HTC-915 control module must be protected by

external over current and disconnect devices.

Mounting Procedures

The HTC-915-CONT and HTC-915-LIM are designed for

installation on a standard 35 mm x 7.5 mm (EN50022

compatible) DIN rail.

Pollution Degree 2

Altitude 0-2000m

MAINTENANCE

Operator Maintenance

The HTC-915 control system is designed to be a maintenance

free product.

Replaceable Parts

There are no user-serviceable parts in the HTC-915 series

controller or accessories. The unit is designed to be easily

changed out in the field in a matter of minutes.

Any HTC-915 system component appearing inoperative

should be returned to the nearest nVent office.

Cleaning

If the HTC-915 components require cleaning, a damp cloth

may be used to wipe the units. This should only be done while

the units are disconnected from their power source. Do not

use any harsh chemicals or solvents, as this may damage the

housing or finish.

ELECTRICAL CONNECTION

Connections are made via screw connections suitable to

accept cable diameters between 0.5 and 2.5 mm2 (24 to

Do not rely on the controller as a disconnect device!

Installation notes

• If contact with live parts is possible while working on the

unit, it must be completely isolated from the mains supply.

Be aware that the unit might have cables connected to it

which are powered from different sources.

• Magnetic or electric fields, eg: from transformers, mobile

phones or electrostatic discharge must be avoided in the

vicinity of the instrument.

• Route input, output and supply lines separately.

• Arrange sensor cable extensions as twisted and screened

cables. Do not run them close to power cables. The shield,

if any, shall be earthed on the controller’s side only.

• Fluctuations in the supply signals are only permissible

within the specified tolerances.

75

45 105

915 SERIES

LIMITER

POWE R

ALAR M

HEATER

CURRENT

Tx /Rx

RESET TRIP

75

90 105

SHIFT TEST BACK ENTER

MONITO RALARM CONFI G ALARM

OUTPUT

915 SERIES HEAT-TRACING CONTROLLER

Tx

Rx

North America

Tel +...

Fax +...

Europe, Middle East, Africa

Tel +...

Fax +...

Asia Pacific

Tel +...

Fax +...

Latin America

Tel +...

Fax +...

©2018 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its affiliates. All other trademarks are the property of their respective owners. nVent reserves the right to change

specifications without notice.

Raychem-IM-HTC915-INSTALL092-EN-1811

nVent.com

Table of contents

Other Raychem Temperature Controllers manuals