Raychem HWAT-ECO User manual

HWAT-ECO (Version 2)

R

Electronic Temperature Control Unit

For energy saving operation of HWAT-R/-M/-L heating cable

Mikroprozessorgesteuerter Temperatursteller

Für den energiesparenden Betrieb der

Temperaturhaltebänder HWAT-R/-M/-L

Modulateur de puissance électronique

Pour une utilisation économique des rubans HWAT-R/-M/-L

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 1

3

148 mm

1

2

A

B

C

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 2

10 20 30 40 50 60 70 80 90

0

HWAT-ECO

!

esc

5

4

3

2

7

1

6

B

A

22-08-2001 09:30

Maintain *8

2x

2x

HWAT 230V

HWAT-ECO

!

esc

11

12

13

9

10

14

HWAT-ECO-10

R

Electronic TemperatureControl Unit

For energy saving operation of HWATheating cable

Mikroprozessorgesteuerter Temperatursteller

Zum energiesparenden Betrieb der TemperaturhaltebänderHWAT

Modulateur de Températureelectronique

Pour l'application economique des rubans HWAT

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 3

0100 110 120 130 140 150 160 170 180

mm

7

6

3

2

1

4

5

8

Description of indicator lights, buttons and display

See diagram in flip-out coverpage

Indication lights

1(green LED) Power supply ON.

(green LED) Power to heater on.

(green LED) Legionella prevention.

100% power to the heating cable. (Increased risk of scalding)

(green LED) Temperature limit warning: boiler temperature too

low.

(red LED) Error, see chapter 4.

Key Esc: Escape from current menu without changing actual

selection or value.

Key Enter : Use to confirm selected choice, menu or value.

Arrow Keys : to change menu selection or positioning

the cursor.

Display functions6

The display has two lines with

16 characters each. The display shows the

following text on start up:

After finishing quick install the display

shows date, time, temperature mode and

a star to indicate that the unit is unlocked.

Packaging content

See diagram in flip-out coverpage

The box contains the following parts:

HWAT-ECO unit

Manual

Two screws

Two washers

Temperature sensor with 4 metre cable

Aluminium tape for sensor mounting

B

A

Quick install

Any key to start

22-6-2001 09:13

Maintain *

9

10

11

12

13

14

!

esc

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 4

ENGLISH

Description of indicator lights, buttons and display.............................. 4

Contents .............................................................................................. 6

1. Description ...................................................................................... 8

2. Installation ........................................................................................ 10

3. Operation .......................................................................................... 14

4. Error/ Alarms and Troubleshooting .................................................. 22

5. Appendix .......................................................................................... 24

DEUTSCH

Beschreibung der Anzeigeleuchten, Tasten und Anzeige ...................... 37

Inhalt .................................................................................................... 38

1. Beschreibung .................................................................................. 40

2. Installation ........................................................................................ 42

3. Betrieb .............................................................................................. 46

4. Fehler/Alarme und Fehlerbehebung .................................................. 56

5. Anhang ............................................................................................ 58

FRANCAIS

Description des témoins, boutons et écrans ........................................ 72

Table des matières ................................................................................ 73

1. Description ...................................................................................... 75

2. Installation ........................................................................................ 77

3. Utilisation ........................................................................................ 81

4. Erreurs, alarmes et guide de dépannage .......................................... 91

5. Annexes ............................................................................................ 93

RHWAT-ECO

5

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 5

6

1. DESCRIPTION...................................................................................... 8

1.1 Purpose ........................................................................................ 8

1.2 Technical data .............................................................................. 8

1.3 Care and maintenance .................................................................. 9

2. INSTALLATION .................................................................................... 10

2.1 Disassembling the unit ................................................................ 11

2.2 Wall mounting instructions .......................................................... 11

2.3 Installation of cables and sensors ................................................ 11

2.3.1 Wiring diagrams .................................................................. 11

2.3.2 Minimum power cable sizing .............................................. 12

2.3.3 Heating cable ...................................................................... 12

2.3.4 Sensor cable........................................................................ 12

2.3.5 Alarm wiring ........................................................................ 13

2.3.6 Network .............................................................................. 13

2.3.7 Building Management System (BMS).................................. 13

3. OPERATION ........................................................................................ 14

3.1 Quick install .................................................................................. 14

3.1.1 Language ............................................................................ 14

3.1.2 Year/ Month/ Day /Hour/ Minutes ........................................ 14

3.1.3 Cable type............................................................................ 14

3.1.4 Cable length ........................................................................ 14

3.1.5 Ambient temperature .......................................................... 14

3.1.6 Country................................................................................ 15

3.1.7 Maintain temperature .......................................................... 15

3.1.8 Economy temperature.......................................................... 15

3.1.9 Pre-Programs ...................................................................... 15

3.1.10 Trace boiler ........................................................................ 16

3.2 Menu overview.............................................................................. 17

3.3 Menu explanation.......................................................................... 18

3.3.1 Language ............................................................................ 18

3.3.2 Time and Date...................................................................... 18

3.3.3 Setup .................................................................................. 18

3.3.4 Timer program and legionella prevention............................ 20

3.3.5 Holiday ................................................................................ 22

3.3.6 Info ...................................................................................... 22

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 6

7

4. ERROR/ALARMS and TROUBLESHOOTING ...................................... 22

5. APPENDIX .......................................................................................... 24

5.1 Country code ................................................................................ 24

5.2 Pipe size, Insulation and Temperature .......................................... 24

5.3 Legionella prevention by temperature shock ................................ 26

5.4 Checklist for problem-free installation and safe operation............ 30

5.4.1 Typical installation schedule for the HWAT-Plus system...... 30

5.4.2 Circuit protection, Testing and Operation for all systems .... 30

5.5 Diagrams ...................................................................................... 32

5.5.1 Diagrams A, B, C, D, E, F, G and H, Installation .................. 32

5.5.2 Diagram I, Pre-programs .................................................... 34

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 7

8

1. DESCRIPTION

1.1 Purpose

The HWAT-ECO control unit has been developed for operation with the fol-

lowing self-regulating heater range: HWAT-R, HWAT-M and HWAT-L. The

hot water temperature maintenance system is a comfort system providing

instant hot water at the tap.

A self-regulating heating cable is positioned on the pipe and compensates

for any temperature loss of the warm water.

The HWAT-ECO control unit combines the following features:

•The operating temperature of the heater can be limited to a desired tem-

perature. Combined with the integrated power off timer function, this

offers important energy savings.

•Energy can be saved, upon activation of the “trace boiler”function and

installation of the boiler sensor. The maintain temperature of the heater

will automatically be lowered in case the boiler temperature is reduced,

preventing the heater from using too much energy for heating the boiler

water.

•On big warm water systems it is sufficient to program one HWAT-ECO

(= MASTER). The other ECOs (= SLAVES) will automatically copy the

MASTER settings when connected to it.

•HWAT-ECO can be connected to a BMS. The input of a remote DC volt-

age will set the desired maintain temperature.

•An alarm terminal makes errors remotely readable.

1.2 Technical data

Switching capacity 20 A / 230 VAC

Use Only for HWAT-R/-M/-L heating cables

Off- power 2,5 VA max.

Power cable section entry 1,5 - 4 mm2for fixed wiring only

Auxiliary cable section entry up to 1,3 mm2(16 AWG)

Automatic switching Type 1 action, according to EN60730

Weight 880 g

Size 165 mm x 85 mm x 71 mm

Mounting options Wall mount with two screws or DIN rail.

Cable glands (entries) 2 x M20 and 1 x PG13.5 with 3 inputs

for external wires of 3-5mm

Master/slave cable 2-wire twisted pair, max. 1,3mm2core

and insulation of 500V

Alarm contacts Max. 24VDC, or 24 VAC, 1A, SPST,

Voltage free

Protection level IP 54

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 8

9

Selectable temperature 41˚C up to 65˚C in 48 blocks per day.

Pre-programs 9 editable built-in building specific

pre-programs

BMS interface 0 –10 V DC

Master/Slave Master is selectable in the unit, up to

8 slaves can be connected

Approval VDE according to EN60730

EMC According to EN 50081-1/2 for emission

and EN50082 - 1/2 for immunity

Circuit breaker max. 20 A, C-Characteristic

Real Time Clock Automatic Summer/Winter time and

Leap year correction

Clock backup time 8 hours ±10%

Clock accuracy ±10 minutes per year

Settings All settings are stored in non-volatile

memory.

Operating temperature 0˚C to 40˚C ambient

Housing material ABS

1.3 Care and maintenance

To clean the HWAT-ECO use a soft cloth, water and soap, do not use sol-

vents. Do not pour water directly on the device. Do not use a water hose or

high pressure cleaner.

In case of defect please return the unit to a qualified repair service or to

the local Tyco Thermal Controls representative.

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 9

10

2. INSTALLATION

This chapter is for installation purposes only, it contains no operational

information. The installation and, if necessary the maintenance and the

disassembling, must be carried out by a qualified electrical installer. The

installation must be compatible with local regulations.

Check the maximum circuit length for your circuit breaker in the next

table:

Fig. 1

Maximum circuit length at 230 VAC and for 20°C start-up temperature

C-characteristic HWAT-L HWAT-M HWAT-R

circuit breaker (Yellow) (Orange) (Red)

10A 80 m 50 m 50 m

13A 110 m 65 m 65 m

16A 140 m 80 m 80 m

20A 180 m 100 m 100 m

Multiple units on multiple power point can be used if longer heating cables

are required. Up to 9 units can be connected on three phase systems via

the network configuration.

2.1 Disassembling the unit

Always switch off the mains supply (circuit breaker) before opening the

unit. Several touchable parts inside the unit are directly connected to

the mains voltage.

The HWAT-ECO has a removable top lid. Both top and bottom of the box

have electronic parts and are connected to each other by a 14-pin connec-

tor. First unscrew the four screws in the lid. Pull the lid carefully upwards,

not sideways! Inside the unit an ABS separation sheet will help to guide

the connector when disconnecting. See 5.5 Diagrams and .

Closing the box

Position the lid in front of the wall-mounted bottom unit. The separation

sheet inside the unit will help to guide the lid and the connector. Push the

lid gently towards the bottom unit, the last part will offer some resistance

because of the connector pins.

2.2 Wall mounting instructions

The unit has two mounting options.

1. Inside the bottom part there are two holes, with the two supplied

screws and sealing rings the unit can be mounted to a wall.

HG

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 10

11

2. The second mounting option is DIN-rail mounting.

For both options see the diagram with ruler on the flip-out cover page.

2.3 Installation of cables and sensors

Tyco Thermal Controls insists on the use of a 30 mA residual current

device and a C-characteristic circuit breaker to provide maximum safety

and protection from fire.

2.3.1 Wiring diagrams

There are three wiring diagrams: C, D and E (see 5.5 Diagrams).

For connection of a single unit: Diagram pag. 32

F1: Circuit breaker 20 A max. (C-Characteristic).

F2: Residual current device 30 mA.

For multiple unit connection on one phase system: Diagram pag. 33

F1, F3, F5: Circuit breaker 20 A max. (C-Characteristic).

F2, F4, F6: Residual current device 30 mA

For multiple unit connection on a three phase system: Diagram pag. 33

F1: Circuit breaker 3 x 20 A max. (C-Characteristic)

F2: Residual current device 3 x 30 mA

Double-pole electrical protection might be needed to comply with local

electrical standards.

2.3.2 Minimum power cable sizing

Fig. 2

C - Characteristic circuit breaker

10A 13A 16A 20A

Minimum cable size 3 x 1,5 mm23 x 1,5 mm23 x 1,5 mm23 x 2,5 mm2

Use solid core wires for 1,5 mm2diameters.

Ensure that the installation is compatible with applicable local electrical

requirements.

E

D

C

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 11

2.3.3 Heating cable

Fig. 3

Achievable Ambient temperature

temperature

Heating cable 10°C 15°C 20°C 25°C

HWAT-L (Yellow) 41 - 44˚C 41 - 46˚C 41 - 50˚C 41 - 52˚C

HWAT-M (Orange) 41 - 50˚C 41 - 52˚C 41 - 56˚C 41 - 58˚C

HWAT-R (Red 41 - 64˚C41-66˚C41-68˚C41-70˚C

Above values are indications and depend on the insulation thickness.

Complete the heating cable tests (including the insulation resistance test)

in accordance with 5.4 (Checklist for problem-free installation and safe

operation).

2.3.4 Sensor cable

The temperature sensor should be connected to a single or master unit

only. Connect both wires of the sensor to the TEMP terminal in the unit

(PL4), see Fig. 4. The sensor wires do not have a special polarity. To con-

nect a wire use a screwdriver to push down the orange tab on the side of

the terminal. Put the wire into the hole and release the orange tab. The

sensor should be connected as near as possible to the boiler (5.5

Diagrams, ).

The metal tabs can be folded around the hot water output pipe. Use the

aluminium tape (included) to attach the sensor to the pipe. The sensor and

at least 200 mm of the sensor cable should be covered by insulation.

Be careful not to install the heating cable too close to the sensor, keep a

clearance of at least 20 cm.

The temperature sensor cable can be extended up to 100 meter. The wire

used to connect the temperature sensor to the HWAT-ECO should have a

basic insulation of 500 V and a solid core of at least 0,75 mm2.

2.3.5 Alarm wiring

The alarm contact (24 VAC, 24 VDC, 1A) inside the unit can be used to

switch an external device. The contact is open during an alarm. Normally it

is closed. In a network all alarm contacts should be connected in series.

The alarm terminal (PL6), see Fig. 4, is located in the upper right corner of

the unit and has the text “alarm contact”next to it. To connect a wire use a

screwdriver to push down the orange tab on the side of the terminal. Put

the wire into the hole and release the orange tab. The wires used for the

alarm contact should have a dielectric strength of 500 V. See Chapter 4 for

A

12

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 12

alarm relay conditions.

Note: For master/slave combination with alarm function, the alarms need

to be connected in series by a RS485 wire. Due to the limited amount of

holes in the sealing ring of the cable gland, the alarm wire and BMS wire

can be combined in a 4 wire cable.

2.3.6 Network

See 5.5 Diagrams, diagram . The HWAT-ECO unit can be used in a sys-

tem with up to 9 units. All units should be connected to each other on the

A and B inputs in parallel on terminal (PL3), see Fig. 4. This means that

several units will have two wires together in one hole. Twist the two wires

together before putting two wires into one hole. The wire should be a

twisted pair and have a dielectric strength of 500V. The total maximum

length of this cable between all units is 100 m. Be careful not to mix A and

B connections. To connect a wire use a screwdriver to push down the

orange tab on the side of the terminal. Put the wire into the hole and

release the orange tab.

2.3.7 Building Management system (BMS)

See 5.5 Diagrams, diagram . The BMS input of the HWAT-ECO is an

analogue 0 to 10 Volt input. If the unit is programmed to have a BMS

connection, this will override any time program-

ming (see BMS page 19). Connect both wires of

the 0-10 V output to the BMS terminal (PL5)

inside the HWAT-ECO. Connect the ground wire

to the “–” and the

0-10 V output to the “+”terminal. To connect

a wire use a screwdriver to push down the

orange tab on the side of the terminal Put the

wire into the hole and release the orange tab.

The wires used to connect BMS to the HWAT-ECO

should have a dielectric strength of 500 V.

To connect a wire use a screwdriver to push

down the orange tab on the side of the terminal.

Note: Due to the limited amount of holes in the

sealing ring of the cable gland, the alarm wire

and BMS wire can be combined in a 4 wire cable.

B

B

B A TEMP BMS

+ -

PL3 PL5PL4

PL6

Alarm contact

Terminals

inside the

HWAT-ECO.

Fig. 4

13

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 13

14

3. OPERATION

The HWAT-ECO version 2 has six buttons: Up/Down/Left/Right arrows,

Enter and Escape.

In the table on the next page is an overview of all menu items. Press any

button, except ESC, to enter the menu. When ESC is pressed the unit

shows the current requested water temperature. The unit will exit the

menu automatically after five minutes of key inactivity.

3.1 Quick install

When the unit is powered up for the first time, a quick setup must be exe-

cuted before the unit is ready to start. The quickstart helps to set all

important settings, the unit will start automatically when done. Quickstart

is sufficient for normal operations. More settings are available in the Setup

menu for special installations.

During the quick start the ESC button can be used to go back to a previous

menu. On startup the display will show the following text:

Press a key to start, and the following menus appear:

3.1.1 Language

With the up/down arrow keys you can choose between 5 languages,

English, German, French, Danish or Italian. Press Enter to confirm your

choice.

3.1.2 Year/ Month/ Day /Hour/ Minutes

Select the year with the up/down arrow keys and press Enter to confirm.

Then select and enter the Month, Day, Hour and Minutes.

3.1.3 Cable type

Use the up/down arrow keys to select the HWAT-R, HWAT-M or HWAT-L

cable. Select the type of cable used in your installation. Press Enter to con-

firm your choice.

3.1.4 Cable length

The minimum cable length is 1 m. The maximum cable length depends on

cable type and circuit breaker capacity (See installation). Use the up/down

arrow keys to select from 1 to the maximum length (see page 10 for max.

length). Press Enter to confirm your choice.

3.1.5 Ambient temperature

The ambient temperature is the temperature inside the room where the

heating cable is installed. Use the up/down arrow keys to select from 0˚C

to 25˚C. Press Enter to confirm.

Quick install

Any key to start

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 14

15

3.1.6 Country

Select a country in this menu. This is used to set the default values for

pipe diameter and insulation thickness. For more information see

Appendix 5.1, page 24.

3.1.7 Maintain temperature

The maintain temperature is the water temperature that you set for normal

use. The temperature can be selected using the up/down arrow keys.

The minimum temperature is 41˚C or the economy temperature, whichever

is higher. The maximum temperature depends on cable type, pipe thick-

ness, insulation thickness and ambient temperature (see Fig. 3, page 12).

The programmed maintain temperature can be displayed by pushing the

escape key once the system is in operation.

3.1.8 Economy temperature

The economy temperature is the water temperature for periods during

which hot water is not usually tapped (at night) or when lots of hot water

is tapped (peak period). The temperature can be selected using the

up/down arrow keys. The minimum temperature is 41˚C and the maximum

temperature is the selected maintain temperature.

3.1.9 Pre-Programs

The HWAT-ECO has 8 default timer programs. See 5.5.2 Diagrams,

page 35 for more information. A pre-program can be selected using the

up/down arrow keys. Press Enter to confirm your choice. HWAT-ECO takes

a few seconds to copy the default program to the internal memory. During

this time a row of dots will show in the display.

Fig. 5

Program name Diagram number Building type

Constant I - 0 Constant temperature

Apartments I - 1 Apartment block

Family Home I - 2 Family home

Prison I - 3 Prison / Barracks

Hospital I - 4 Hospital

Nursing Home I - 5 Nursing home

Hotel I - 6 Hotel

Sport Centre I - 7 Sport centre / Swimming pool

Convalesc. Home I - 8 Convalescent home

esc

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 15

16

3.1.10 Trace boiler

The trace boiler setting is included to ensure that the heating cable temper-

ature does not exceed the boiler temperature. The boiler temperature is

measured with the external temperature sensor. The HWAT-ECO memo-

rizes the highest measured temperature over the last 24 hours. With the

up/down arrow keys the setting can be altered between OFF and ON with a

selected temperature difference from 5°C to max 15°C between boiler tem-

perature and maintain temperature. Press Enter to confirm your choice. If

the boiler temperature is too low the maximum temperature is lowered to

the boiler temperature minus the trace temperature. In this case the trace

boiler LED will be on.

Finishing “Quick install”

Press Enter to start the unit.

With ESC it is possible to retrace all menu items to check the settings.

After starting the unit the display shows date, time, temperature setting

and a * to indicate that the unit is unlocked.

Back to “Quick install”

The Setup menu (see next chapter) has a Reinitialise menu to start over

again.

Previous settings are returned to default factory settings, except time and

date.

Note:

A menu can be consulted if further detailed settings (eg. Master/slave,

BMS, etc.) are required. You must press a key to access the menu inside

the HWAT-ECO. (Pressing ESC shows the current preferred cable tempera-

ture.) Pressing another key shows the main menu. There are 6 main

menus: Language, Time and Date, Setup, Timer program, Holiday and Info.

22-6-2001 09:13

Maintain *

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 16

17

3.2 Menu overview

1 Language English

Deutsch

Francais

Dansk

Italiano

2 Time and Date 1 Year Select Year

2 Month Select Month

3 Day Select Day

4 Hour Select Hour

5 Minutes Select Minutes

3 Setup 1 Maintain Temp "Enter maintain temp."

2 Economy Temp "Enter economy temp."

3 Cable Length "Enter cable length"

4 Ambient Temp. "Enter ambient temp."

5 Pipe Diameter Select 15 mm up to 100 mm

6 Insulation Select 9 mm up to 100 mm

7 Power Corr Select 60% up to 140%

8 Trace Boiler Select Off or On_5 up to On_15 degrees

9 Lock Lock/unlock Setup and Timer menus

10 BMS Select Yes/No

11 NetworkMaster Select Yes/No

12 Reinitialise Select Yes/No

4 Timer program 1 Default program Constant

(password check Apartements

if Lock is On) Family home

Prison

Hospital

Nursing home

Hotel

SportsCentre

Convalesc.Home

2 Edit program Monday Edit timer for Monday

Tuesday Edit timer for Tuesday

Wednesday Edit timer for Wednesday

Thursday Edit timer for Thursday

Friday Edit timer for Friday

Saturday Edit timer for Saturday

Sunday Edit timer for Sunday

5 Holiday setting 1 xx Days off

2 Off

3 On

6 Info Show firmware version nr. + Cable type + Sensor temp.

(password check

if Lock is On)

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 17

18

3.3 Menu explanation

3.3.1 Language

Select one of 5 languages using the up/down arrow keys: English, German,

French, Danish or Italian. Press Enter to confirm your choice.

3.3.2 Time and Date

Select Year to set the year using the up/down arrow keys and press Enter

to confirm. Then select and set the Month, Day, Hour and Minutes.

3.3.3 Setup

When Lock is on (No star in the lower right corner) a password is needed

to access the following menus. After the correct password is entered the

setup menu is accessable. The unit locks again after 60 seconds timeout

(no keys pressed).

When lock is off the following menus are directly accessable.

1. Maintain Temperature

The maintain temperature is the water temperature that you set for normal

use. The temperature can be selected using the up/down arrow keys. The

minimum temperature is 41˚C or the economy temperature, whichever is

higher. The maximum temperature depends on cable type, pipe thickness,

insulation thickness and ambient temperature.

2. Economy Temperature

The economy temperature is the water temperature for periods during

which hot water is not usually tapped (at night) or when lots of hot water

is tapped (peak period). The temperature can be selected using the

up/down arrow keys. The minimum temperature is 41˚C and the maximum

temperature is the selected maintain temperature.

3. Cable Length

The minimum cable length is 1m. The maximum cable length depends on

cable type and circuit breaker capacity (see Fig. 1, page 10). Select from 1

to the maximum length for the selected cable type using the up/down

arrow keys. Press Enter to confirm your choice.

4. Ambient Temperature

The ambient temperature is the temperature inside the room where the

heating cable is installed. Select from 0˚C to 25˚C using the up/down arrow

keys. Press Enter to confirm.

5. Pipe Diameter

Set the pipe diameter using the arrow keys The value can be changed from

15 mm up to 100 mm. See Appendix 5.2, page 24 for more information.

6. Insulation

Set the insulation thickness with the arrow keys. The value can be changed

from 9 to 100 mm, but is limited by the pipe diameter. See appendix 5.2,

page 24 (‘Pipe size, Insulation and Temperature’) for more information.

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 18

19

7. Power correction

Adjust the power setting for fine tuning the temperature.

See appendix 5.2, page 24 (‘Pipe size, Insulation and Temperature’) for

more information.

8. Trace Boiler

The trace boiler setting is included to ensure that the heating cable temper-

ature does not exceed the boiler temperature. The external temperature

sensor is used to measure the boiler temperature. See page 16 for more

information.

9. Lock

Lock On/Off can be selected using the up/down arrows and Enter to con-

firm. If ‘On’is selected a password must be entered using the left/right and

up/down arrow keys. Enter to confirm.

If lock is On, the Setup and timer menus are protected by the password.

After the password is entered the unit remains unlocked until five minutes

of key inactivity or the Lock ‘On’is selected again.

10. BMS

The Building Management System option is activated using this menu.

When set to “Yes”the unit responds only to the voltage applied to the

BMS terminal. For voltages ≤4 VDC: heater is OFF. For voltages between

4,1 VDC and 6,4 VDC: maintain temperatures as indicated in Diagram F,

Chapter 5.5. For voltages > 6,4 VDC: 100% power to the heater for

legionella prevention (in case HWAT-R). See page 13 for installation.

If Trace Boiler is ON, it overrules the BMS temperature setting if necessary.

11. Network Master

In large installations where more than 1 HWAT-ECOs are connected to

each other, one unit must be selected as Master. This unit should be fully

programmed and all slave units will use the Master settings.

The master unit sends commands to all slave units to switch them ON or

OFF. The timer program of the master unit will be used for all units in the

following way: Slave units on the same phase (max. three units) will have

a delayed ON and OFF. This way the start-up current of the cable will never

occur at the same moment for these units (A, B and C). Slave units con-

nected to a different phase will switch at the same time (1, 2 and 3).

After selecting Master: Yes the slave units will inilialise and show:

“Slave: x y”x= phase number (1 to 3) y= slave identification (A, B and C)

The master unit is always 1 A, the slave units will get their number and

identification automatically. Always check afterwards if all units have

unique id-numbers, if not check the RS485 cables and repeat this proce-

dure.

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 19

20

12. Reinitialize

If “Yes”is selected the Quick install menu is activated and all settings are

returned to factory settings.

3.3.4 Timer program and legionella prevention

When Lock is ON a password is needed to access the following menus.

When lock is OFF the following menus are directly accessable (The display

shows a * in the lower right corner).

1. Default program

These programs are selected based on the typical water usage at the tap of

the concerned building. For example: a large amount of hot water will be

tapped in the morning around 7.00 am. Due to the continuous flow of hot

water in the pipes, the heat loss will be minimum and the heater can be off

power in order to save energy. Similar behaviour can occur during night

time. The choice of the optimum timer program for the application ensures

that the hot water temperature maintenance system works even more effi-

ciently. Any timer program can be edited to suit personnel requirements

(See 2 Edit program).

The following pre-programs are available.

Fig. 6

Program name Diagram number Building type

Constant I - 0 Constant temperature

Apartments I - 1 Apartment block

Family Home I - 2 Family home

Prison I - 3 Prison / Barracks

Hospital I - 4 Hospital

Nursing Home I - 5 Nursing home

Hotel I - 6 Hotel

Sport Centre I - 7 Sport centre / Swimming pool

Convalesc. Home I - 8 Convalescent home

The time tables of all pre-programs are given in appendix 5.2 diagram I,

page 35. After selecting a pre-program the HWAT-ECO shows a row of

dots on the display. This is because it takes a few seconds to program the

internal memory.

2. Edit program (incl. legionella prevention)

Timer programming is done graphically in 1/2 hour time blocks.

A block can be set to Off, Economy temp, Maintain temp, or 100% power

(100% only if HWAT-R cable is used).

Tyco C 9278e HWAT-ECO 22.02.2002 14:12 Page 20

Table of contents

Languages:

Other Raychem Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD RFF Series Operating Instructions, Mounting & Installation

Calex

Calex PyroSigma Series Operator's guide

SMA

SMA SUNNY VIEW user manual

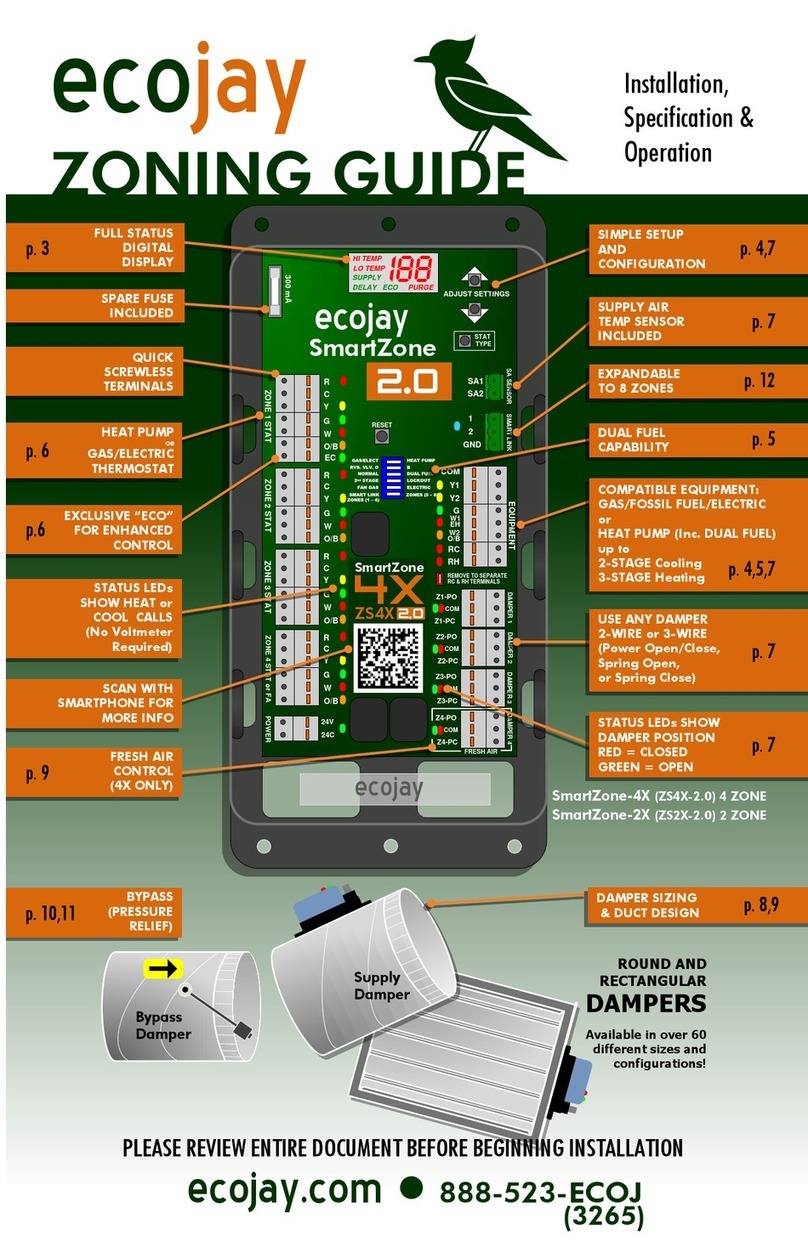

Ecojay

Ecojay SMartZone-2X Installation, Specification & Operation

Danfoss

Danfoss FHV-A datasheet

MCC

MCC 68AC353-102 MICROMAX Operation and service

Hukseflux

Hukseflux HF03 / LI19 user manual

ABB

ABB i-bus KNX Yucus YUB/U1.0.1 Series Technical reference manual

Lubing

Lubing Pad-Climate-System Assembly instruction and manual

iT+

iT+ 30.3009.54.IT instruction manual

Siemens

Siemens REA23.03RF user manual

Domotec

Domotec Therm-Control DHB 370 C Installation notes