Razor eLEG User manual

www.Razorinternational.com Page 1 of 8

eLEG Owners Manual

Specifications

eLEG www.Razorinternational.com Page 2 of 8

Supply Voltage

9 to 30 Volt DC

Lift Capacity

25 Tonnes (60,000lb)

Leg Speed

34cm/min (13.5”/min) on high gear

eLEG Kit Weight

135~145Kg (dependant of foot Configuration)

Environmental

Fully weather & waterproof

Temperature

-30oC to 60oC (-22oF to 140 oF) (reduced performace at extremes)

eLEG Installation Instructions

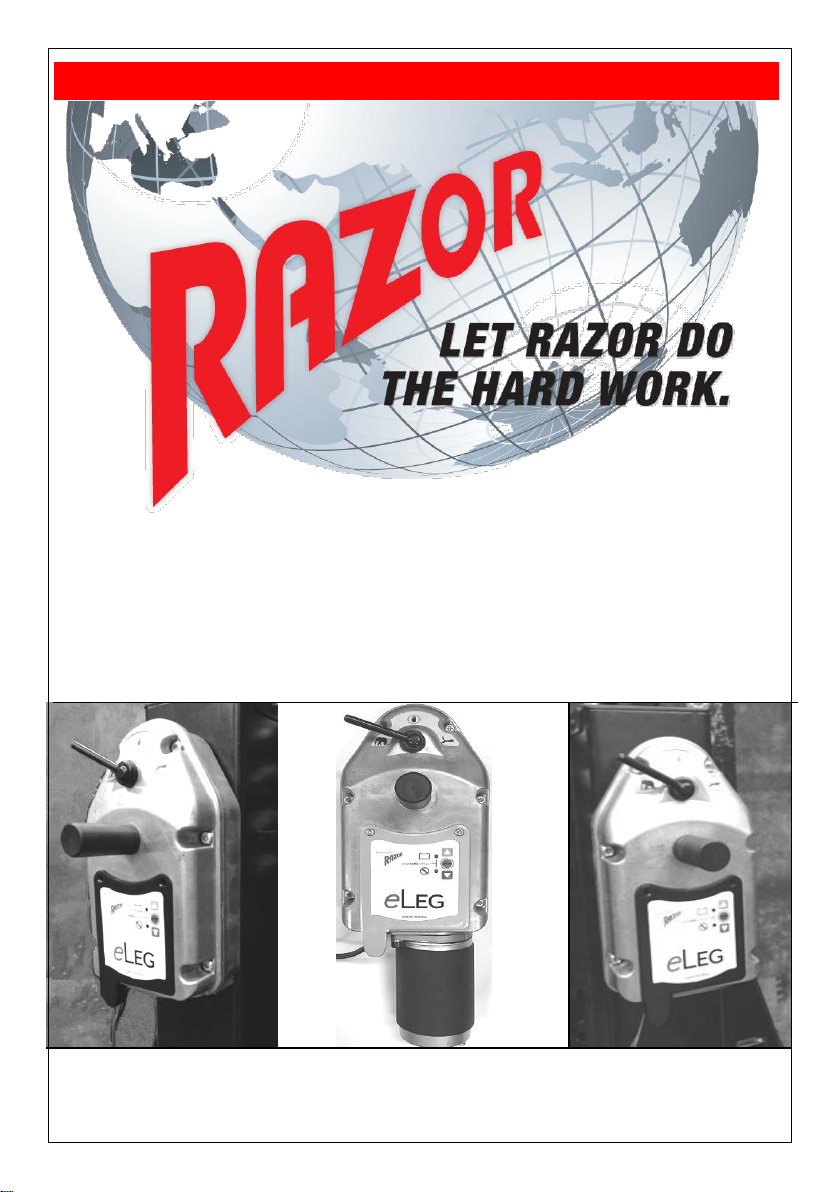

PARTS LIST FOR eLEG

POWER KIT, consisting of:

•Battery (12volt)

•Battery Harness with 30 amp fuse (not shown)

•Battery Bracket

•Charge Harness(not shown)

•Battery Strap

•2 x M8 Clamp bolts, Spring washers and plates

•Charger (12 volt @ 2 amps)

•4 x M8 Bolt, Spring, Flat Washers & Nuts

•Battery Cover

•Rubber Pad(not shown)

POWER KIT - ALTERNATIVE

•Extension Harness

•Offside Leg

•Square hollow

connecting shaft

•Drive Leg complete with

electric drive (gearbox

and motor) and controller

•Power Kit (as per below)

Note: This kit must be

used to supply the drive

leg power

•eLEG manual handle

with mounting hardware

CAUTION: DO NOT WELD TO TRAILER WITHOUT DISCONNNECTION NEGATIVE.

Installation Instructions

eLEG www.Razorinternational.com Page 3 of 8

•Read the entire instructions through prior to starting the installation to

ensure you have all the tools and equipment necessary to carry out the work.

•Unpack the eLEG parts and power kit and check components.

eLEG Installation Instructions

1. Mount the landing legs as per normal landing leg fitment, ensuring to cut the

square hollow shaft to the correct length and fitted between the legs so that

the offside leg is driven from the drive leg. The correct length must ensure

that no lateral pressure is applied to the drive shafts of the geared and slave

leg in the fully installed position(no bolts required)

2. Locate a solid point on the trailer chassis to mount the power kit, taking due

note of the size required for the battery (approximately 24cm wide, 21cm

high and 13cm deep (9 1/2'' x 8 1/4 '' x 5''). It must also be mounted in close

proximity to the drive leg as it will need to be connected to via the harness

supplied. The battery should be mounted in the orientation shown.

3. Using the supplied Template supplied to

mark hole locations is the trailer chassis.

(21cm x 6.5cm hole centres, 8.25'' x 2.5'')

Drill 4 off 9mm (3/8'') diameter holes.

4. Bolt the battery bracket to the trailer chassis with the bolts supplied,

ensuring to fit the spring washers.

5. The charge harness now needs to be connected to a power source on the

trailer. (9 to 30 Volts DC). There are three wires available to be connected to

keep the eLEG battery charged. The negative or common is and must

be connected to the trailer negative, there is a blue and brown wire available

that can be connected to a power source on the trailer. Typically the brown

can be connected to the running or clearance lights the blue wire could be

connected to either an auxiliary or even the stop lights on the trailer. You only

need one but two is an advantage. Refer to the wiring schematic shown.

Ensure the electrical connections to the trailer harness are robust and sealed.

Note: Make sure a proper earth is established between battery negative and

the trailer electrical circuit. (Experience has shown that electrical problems

caused by bad earth or low trailer voltage is responsible for most problems

associated with the installation of the eLEG. This affects the ability to keep

the battery charged. A test of the charge circuit is to connect the blue (or

brown) charge wire to the battery positive; a solid yellow LED light indicates

charger is operating as it should)

Installation Instructions

eLEG www.Razorinternational.com Page 4 of 8

6. Then connect the drive unit to the battery harness via the harness supplied.

Secure and protect the wiring as appropriate to minimise damage

7. Finally, locate a solid point

on the trailer chassis to

mount the eLEG manual handle

with hardware. Drill two

off 9mm (3/8'') diameter holes

using the bracket as a template

and bolt the handle bracket to

the trailer chassis.

Then lock manual handle with L bolt and clip into the hanger clip.

-ve

+ve

Brown Wire Trailer +ve (clearance

light)

Blue Wire Trailer +ve (auxillary)

White Wire Trailer –ve (earth)

Charger

Leg

Drive

12V Battery

Electrical Schematic

30 amp fuse

hanger

clip

L bolt

handle

bracket

eLEG

manual

handle

Operating Instructions

eLEG www.Razorinternational.com Page 5 of 8

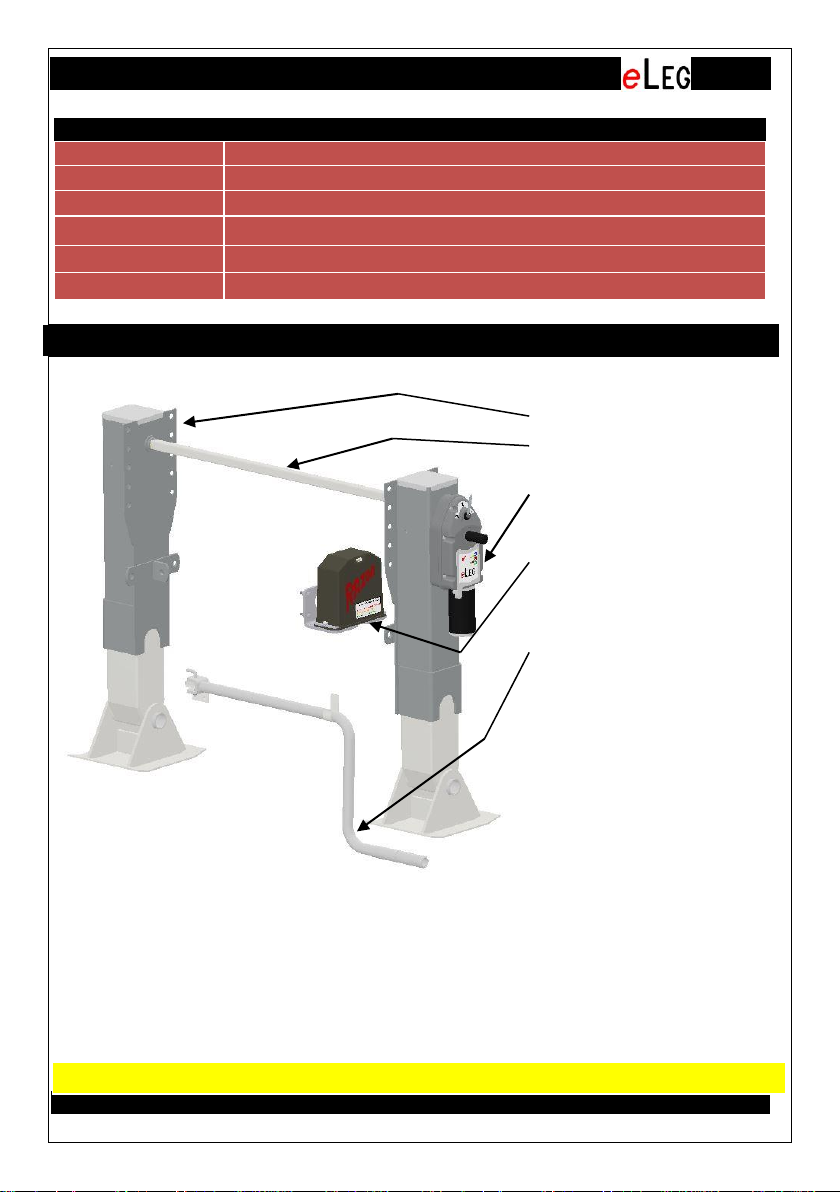

eLEG Operating Instructions

Installed correctly your eLEG will give you years of trouble free service.

The electric drive and its associated battery are sealed maintenance free

items.

Your eLEG comes with a battery

charger. It is located inside the

battery cover. It will charge your

battery to the correct voltage if

connected to the trailer electrics as

described above. This is vital for the

longevity of the battery and to

ensure the eLEG landing legs

function correctly

Raise Button - Blue

Stop Button - Red

Lower Button - Green

Gear Change Lever

Elephant –Heavy lift

Central –Neutral

Cheetah–Fast Speed

Red LED

Yellow LED

Red LED

Yellow LED

Green LED

CAUTION: STOP MOTOR

BEFORE CHANGE GEAR

Operating Instructions

eLEG www.Razorinternational.com Page 6 of 8

CHARGER

The battery charger has three LED lights. For indication of the condition of the

battery and of power supply from the trailer their functions is as per the table

below:

CONTROLLER

To operate the legs you must first initiate (or wake up) the controller. This is

required to prevent the inadvertent or accidental operation of the legs which

could lead to hazardous and even dangerous situations.

You should also select the gear position you require. The high speed gear,

which is indicated by a , is generally used to get the legs to the ground fast

and also return them to their home position (fully up) once they have cleared

the ground. The high load gear, which is indicated by n,is generally used to

lift a loaded trailer once the legs are on the ground. The neutral position,

indicated by , is only used if there is a problem and it allows you to still

manually wind the leg. (refer below)

To initiate the controller press and hold the Stop button for 2 seconds. The

Red LED and Yellow LED will flash twice to acknowledge the controller has

been activated. It is noted that if the gear selection is in neutral you cannot

initiated the unit and you will get four Red LED flashes to indicate this

condition. First change the gear selection away from the neutral position

You may now operate in the legs in either direction by pressing the down

(green) button or the up (blue) button.

The legs will continue to travel in the direction selected until the preset load

condition is met. If the legs are travelling down in high speed this will be when

the legs first hit the ground, if they are going up it will be when the legs reach

the end of their travel and are fully home. (Note: The Maximum run time is 2

minutes)

The gear selection lever is simple operated by rotating it by hand either to the

left or right. If the legs are operating and the gear selector is changed it will

stop the motor and the Red LED will illuminate while in the neutral position.

The drive can be restarted once either high load or high speed is selected.

The Controller has two LED lights for indication of the operation and the

battery condition their functions is as per the table below:

Red LED

This indicates that supply is connected

Yellow LED

This indicates that the battery is charging.

Green LED

This indicates that the battery is fully charged

Operating Instructions

eLEG www.Razorinternational.com Page 7 of 8

Manual Operation.

In the event that there is a problem and the drive will not operate. You can still

operate the legs manually.

To do this first remove the plastic protective sleeve from the drive shaft that

protrudes out from the gearbox (shown below). Put the gear selector in the

neutral position. This will disengage the motor from the legs. Attach the

eLEG manual handle supplied to the shaft( locked with 10mm L bolt) and wind

as per a normal manual set of landing legs.(Refer page 4 for detailed parts

breakdown).

Red LED

One Flash

A button activation is acknowledged by one flash.

Note: this is only once the controller is initiated as

elsewhere described.

One flash also indicates that the pre-set maximum

increase in load has been exceeded and the

motor has been stopped.

It will flash once again if the button is pressed for the

same direction indicating this is an inhibited operation.

Two Flashes

Indicates that the pre-set maximum load has been

reached and the motor has been stopped

It will flash twice again if the button is pressed for the

same direction indicating this is an inhibited operation.

Three Flashes

This indicates a locked mechanical condition such

as gear failure or motor failure

(Check motor and gearbox)

Four Flashes

An over temperature condition has been reached.

Allow time to cool down before operating again.

Continuous

Indicates that the gear lever is in the neutral

position and you cannot operate the eLEG in that

condition. You must change the lever to a gear

setting before you can operate the eLEG.

Note: this will only occur once the controller is initiated.

Yellow LED

Five Flashes

This indicates that the battery is low and requires

to be charged.

Note: this will only flash once the controller is initiated.

Red LED &

Yellow LED

Two Flashes

Both LED’s will flash twice upon controller

initiation. Refer operation instructions

Service and Maintenance

eLEG www.Razorinternational.com Page 8 of 8

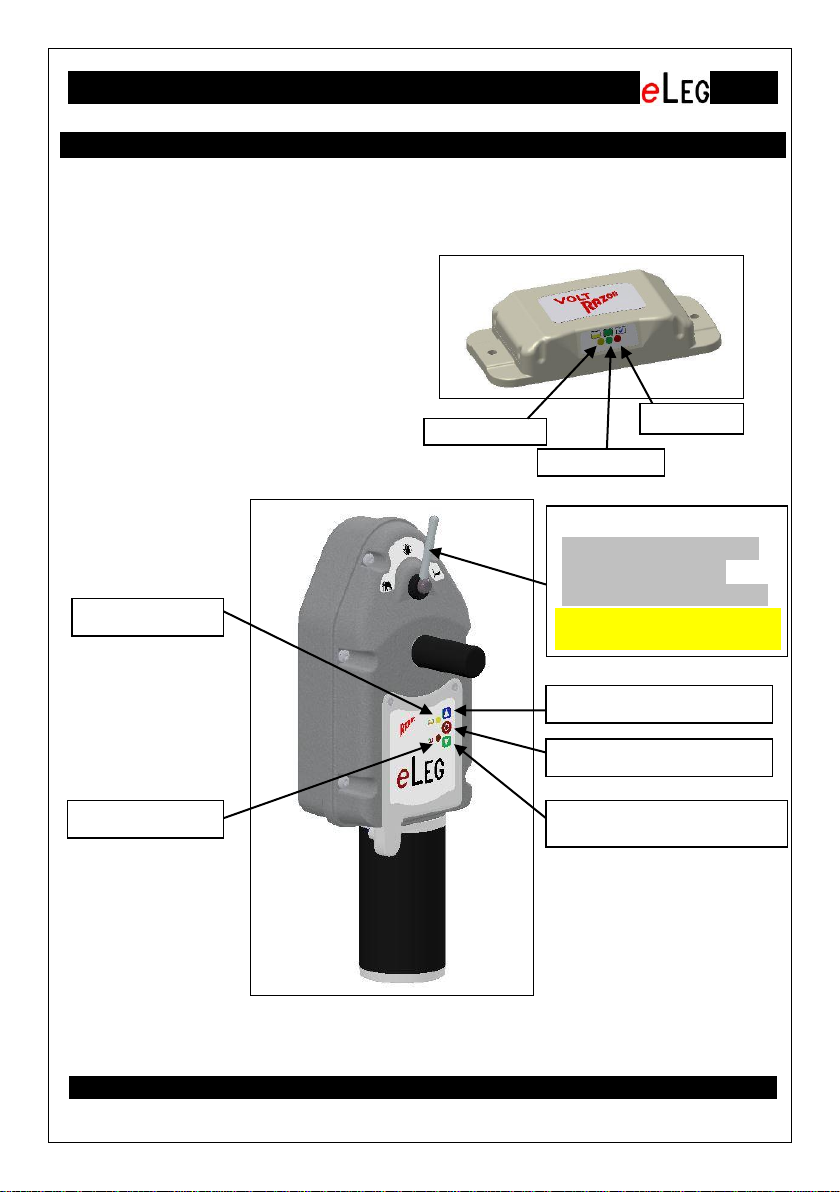

eLEG Service

The eLEG power drive gearbox is designed to be maintenance free. There is

no serviceable parts. The gearbox is a sealed pre-lubricated unit, as is the

battery, the charger and controller.

Should any of the components have an issue, the drive system has been

designed to be modular so that each component can be readily replaced in

minutes. These components are the battery and its associated charger, the

electric motor and the electronic controller. Please refer to the illustration

below for change out of each component.

To remove electric motor first

remove the two M8 bolts and the

motor can then be pulled out

from the gear box(Note: The

longer M8 screw is bolted to the

left hole of the controller).

Electric

Motor

Motor retaining bolts &

spring washers

(6mm Hex Key

required,Max Torque

20N.m/14.75ft.lb)

Note: Long M8 bolt must

go in the left side

To remove the controller,

first disconnect the

harness and remove the

motor then remove the two

M4 screws and the

controller can be lifted out.

Controller

Controller

retaining screws

(T20 Torx key

required, Max

Torque 2N,m/

/1.47ft.lb

CAUTION: DO NOT ATTEMPT TO REMOVE BEFORE

FIRST DISCONNECTING BATTERY POWER

Drive Shaft protective cover.

Remove to operated gearbox

manually with standard crank

handle

Refer page 2 for

detailed parts

breakdown

Table of contents