INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

SYDNEY | MELBOURNE | BRISBANE | PERTH | AUCKLAND

Australia 1300 788 778 www.rba.com.au | New Zealand 0800 722 111 www.rbagroup.co.nz2 of 4

Components Supplied

• P-trap stainless steel pan

• S-trap converter

• Security bit

Components Supplied By Others

• 12mm xing rod

• Wall anchors

• M12 ground anchors

Pre-installation

Installation must be undertaken in accordance with the PCA (Plumbing Code of Australia) , AS/NZS3500.1 and AS/

NZS3500.2. Where multiple WC’s may be installed, correct hydraulic water supply sizing must be undertaken to ensure

that each ushing device servicing each WC is able to operate correctly under probable simultaneous demand. A minimum

water supply pressure of 300kPa is required for ushing device installation along with a minimum 25mm Cu or equivalent

water supply line size for single ushing device installation only.

Pan is wall faced and should preferably be xed to a masonry wall with suitable wall anchors provided by others.

Flushing device should be:

Fowler Tasman Mk 2 [or Stylus Symphony] cistern

Caroma Invisi II [inceiling mount recommended]

RBA’s ‘Nautilus’ Dual Flush Valve Incl Large Mounting Plate [see RBA1882-100-001]

Installation

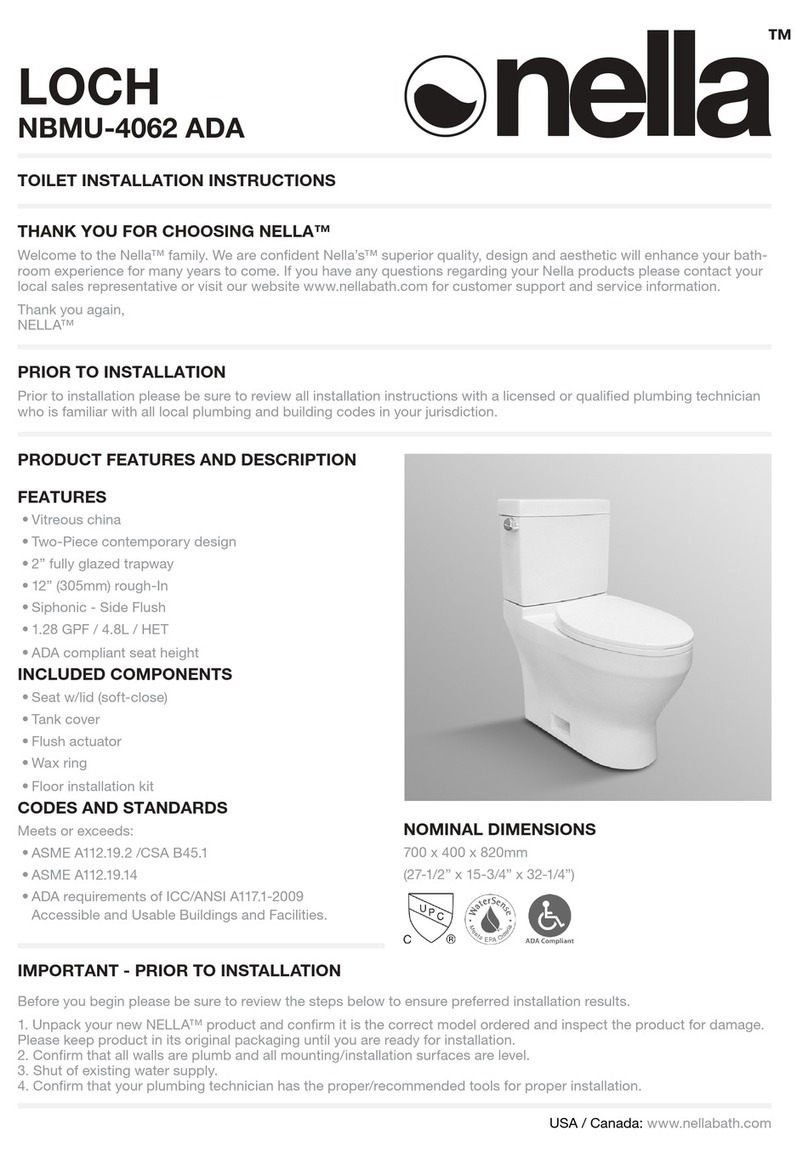

1. Check supplied toilet against rough-ins provided in the installation instructions.

2. Remove access panels and place them in a safe area. Make sure to identify the access panels to the toilet they are

removed from.

3. If not pre-formed, make sufcient penetrations through the wall and/or oor, as determined from the drawing, to allow

for the 100mm waste pipe and ush pipe as provided by the cistern or ush valve manufacturer.

a. If rear xed, M12 xing rods [by others] to pass through.

b. If front xed, use suitable wall anchors [by others] in the rear and oor of the toilet.

4. Determine oor mounting location by mocking up.

5. For P-trap congurations, t a 100mm pan collar to the outlet with sufcient 100mm pipe to extend through the wall.

Alternatively the waste and ush pipes may be pre-plumbed and the pan pushed onto the pipework.

6. For S-trap congurations, location of oor penetration should be centred 220mm from nished wall.

7. Similarly t a 55mm Kee seal [by others] to the pan inlet with sufcient pipe, as provided by the cistern manufacturer,

to extend through the wall.

8. Push the pan into position and secure the pan to the wall & oor [xings by others].

9. Make the necessary connections to the waste and install the cistern and connect according to the manufacturer’s

instructions.

10. Check for leaks and correct ush volumes, 6 litres full ush and 3 litres half ush.

11. Unscrew plug bolts and t the seat to pre-drilled holes and replace the access panels.