LIMITED WARRANTY

Raritan Engineering Company warrants to the original purchaser that this product is free of defects in materials

or workmanship for a period of one year from the product’s date of purchase. Should this product prove defective

byreasonofimproperworkmanshipand/ormaterialswithinthewarrantyperiod,Raritanshall,atitssoleoption,repair

or replace the product.

1. TO OBTAIN WARRANTY SERVICE, Consumer must deliver the product prepaid, together with a detailed

description of the problem, to Raritan at 530 Orange St., Millville, N.J. 08332, or 3101 SW 2nd ave Ft. Lauderdale,

FL33315. Whenrequestingwarrantyservice,purchasermustpresentasalessliporotherdocumentwhichestablishes

proof of purchase. THE RETURN OF THE OWNER REGISTRATION CARD IS NOT A CONDITION PRECE-

DENT OF WARRANTY COVERAGE. However, please complete and return the owner Registration Card so that

Raritan can contact you should a question of safety arise which could affect you.

2. THISWARRANTYDOES NOT COVER defectscausedbymodifications,alterations, repairs or serviceofthis

product by anyone other than Raritan; defects in materials or workmanship supplied by others in the process of

installation of this product; defects caused by installation of this product other than in accordance with the

manufacturer’s recommended installation instructions or standard industry procedures; physical abuse to, or misuse

of, this product. This warranty also does not cover damages to equipment caused by fire, flood, external water,

excessive corrosion or Act of God.

3. ANY EXPRESS WARRANTY NOT PROVIDED HEREIN, AND ANY REMEDY FOR BREACH OF

CONTRACT WHICH BUT FOR THIS PROVISION MIGHT ARISE BY IMPLICATION OR OPERATION OF

LAW, IS HEREBY EXCLUDED AND DISCLAIMED. ALL IMPLIED WARRANTIES SUCH AS THOSE OF

MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE, IF APPLICABLE, AS WELL AS

ANY IMPLIED WARRANTIES WHICH MIGHT ARISE BY IMPLICATION OF LAW, ARE EXPRESSLY

LIMITED TO A TERM OF ONE YEAR. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG A

LIMITED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

4. UNDER NO CIRCUMSTANCES SHALL RARITAN BE LIABLE TO PURCHASER OR ANY OTHER

PERSONS FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH

OFWARRANTY,THEEXCLUSIONORLIMITATIONOFINCIDENTALORCONSEQUENTIALDAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

5. Nootherperson or entity is authorizedtomakeanyexpress warranty, promise oraffirmationoffactor to assume

anyother liability on behalf ofRaritan in connection with its productsexcept as specifically set forth inthis warranty.

6. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

L229 0502wmr Specifications subject to change without notice

Printed in USA

530 Orange Street, P.O. Box 1157, Millville, NJ 08332 USA

Telephone: 856-825-4900 FAX: 856-825-4409

www.raritaneng.com

Southern Office and Plant:

3101 SW Second Avenue, Fort Lauderdale, FL 33315 USA

Telephone: 954-525-0378 FAX: 954-764-4370

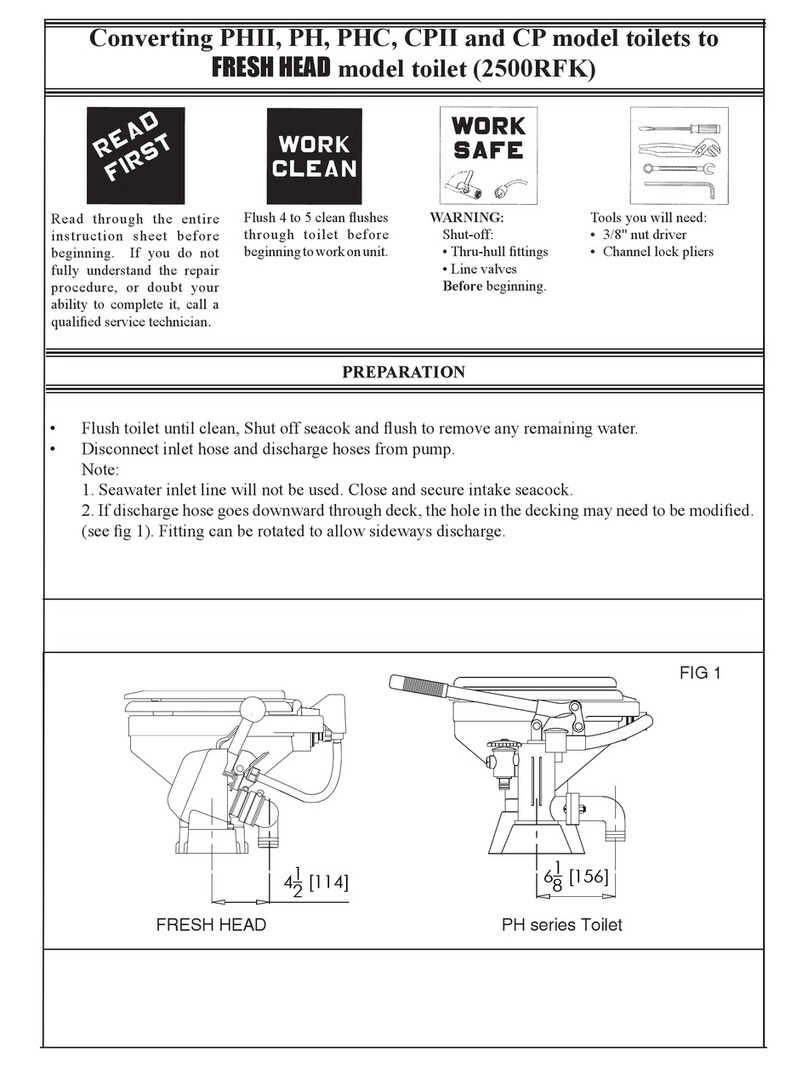

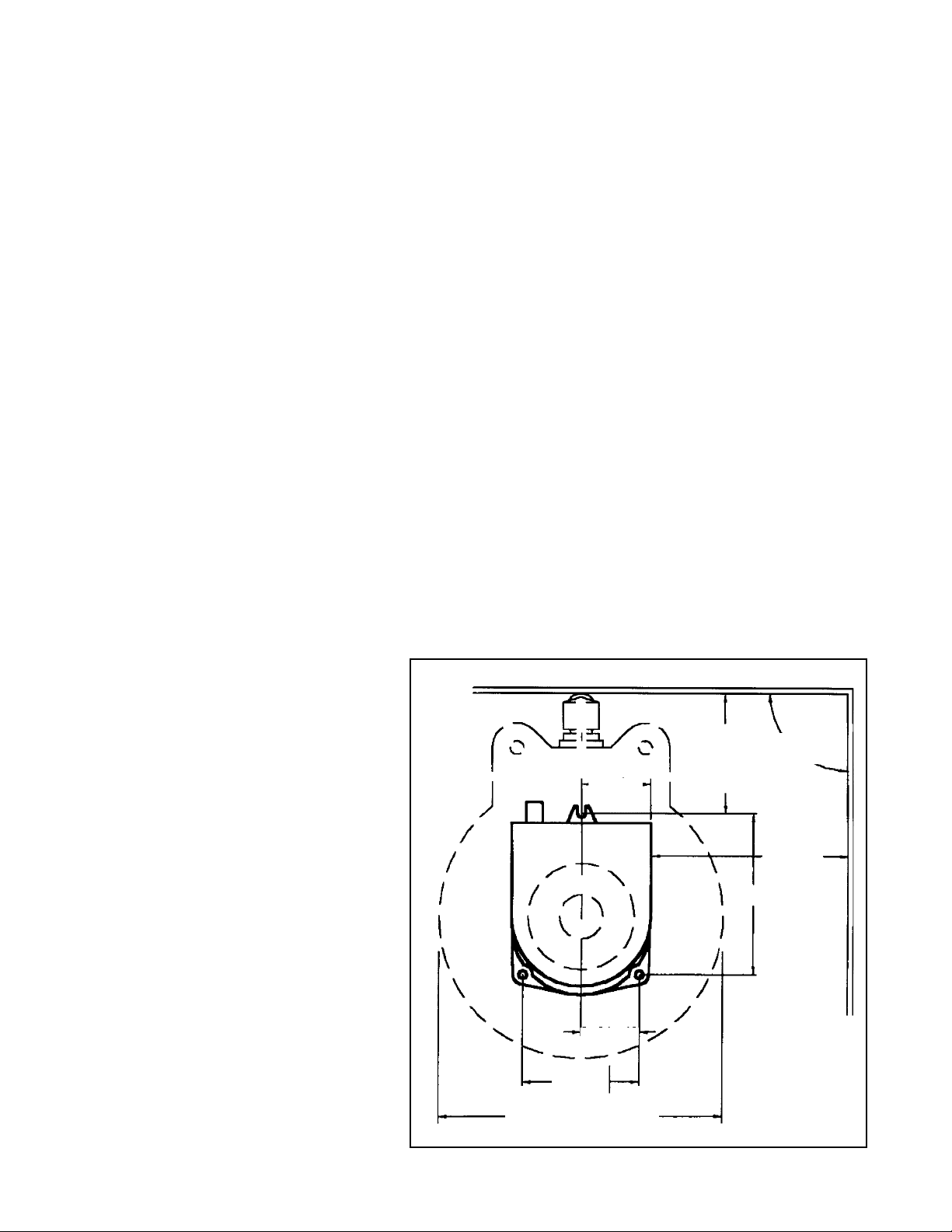

Standard space requirements are:

15 7/8" (40.3 cm) Height,

16 3/4" (42.6 cm) Width and

17" (43.2 cm) Depth.

Hi-Boy space requirements are:

16 1/4" (41.3 cm) Height,

17" (43.2 cm) Width and

20" (50.8 cm) Depth.

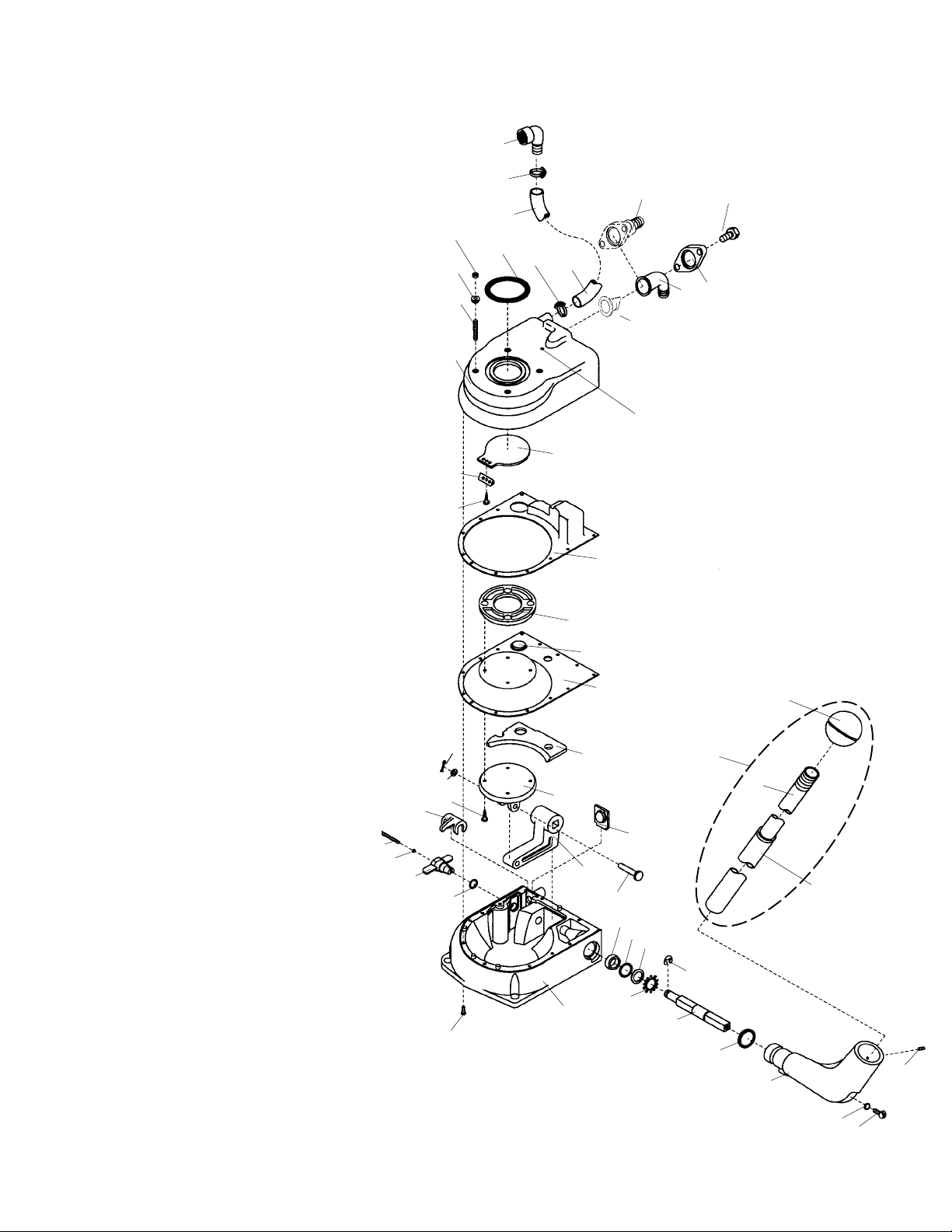

Manually Flushed Toilet: Salt water or fresh water

Fitting Sizes: 3/4" intake and 1 1/2" discharge

Maximum Intake Hose Lift: 36" (1 m)

Maximum Intake Hose Length: 15' (4.6 m)

Maximum Discharge Hose Lift: 5' (1.5 m)

Maximum Discharge Hose Length: 15' (4.6 m)

SPECIFICATIONS