SPRAYMASTER 200

2

Contents

1. Installation - Overview ____________________________3

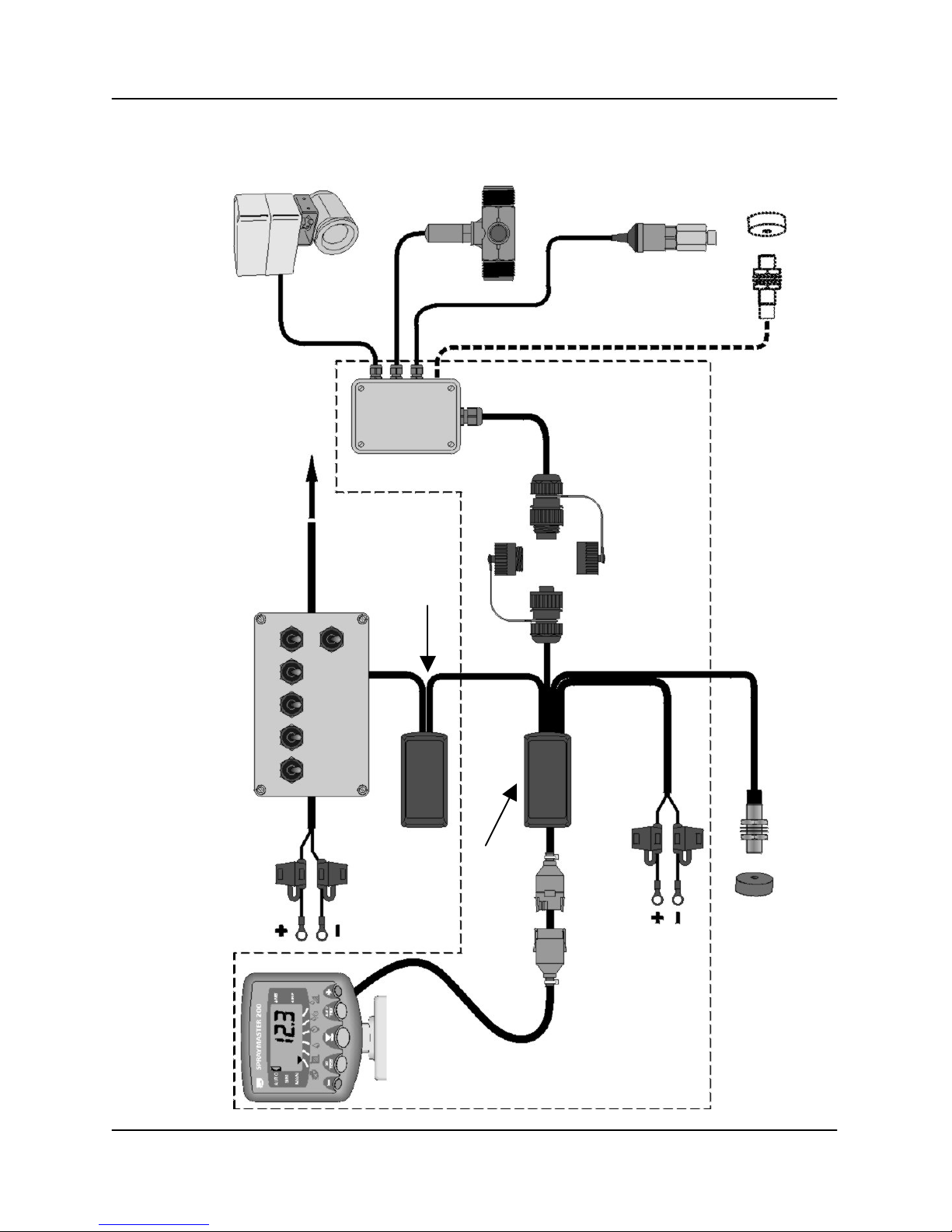

1.1 Base Kit ............................................................................................................4

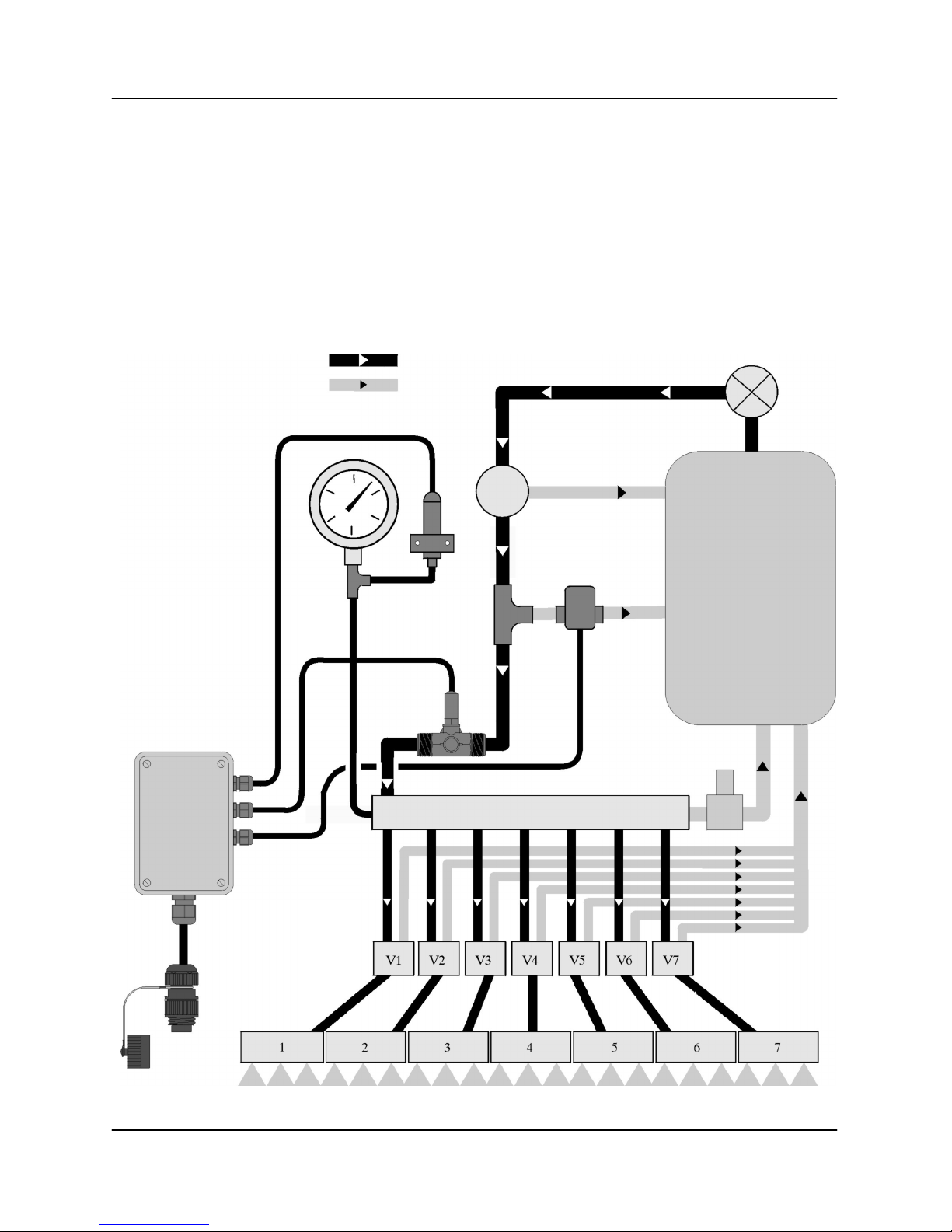

1.2 Flow-and/or Press re-based Pl mbing...........................................................5

1.3 Terminator ........................................................................................................6

1.4 C to t Switch/ACI............................................................................................7

2. Calibration _______________________________________8

2.1 Boom/C to t Switch Set p .............................................................................8

2.1.1 Enable Single Boom Configuration (Standard) .................................

2.1.2 Enable Multiple Boom Configuration.................................................

2.1.3 Select Default Boom..........................................................................

2.1.4 Set No. of Nozzles per Section ..........................................................9

2.1.5 Nozzle Spacing ..................................................................................9

2.2 Select Press re or Flow-based Reg lation .....................................................9

2.3 Press re-based Set p ...................................................................................10

2.3.1 Pressure Sensor Auto Calibration....................................................10

2.3.2 Manually adjust the Pressure Sensor Gain Factor...........................11

2.3.3 Adjust Nozzle Flow Rate and Reference Pressure ..........................12

2.4 Flow-based Set p ..........................................................................................13

2.4.1 Enable / Adjust Flow Sensor Cal Factor ..........................................13

2.4.2 Select Default Flow Sensor..............................................................13

2.4.3 Set No. of Sensed Nozzles ..............................................................14

2.4.4 Valve Type........................................................................................14

2.5 Control Valve Settings....................................................................................14

2.5.1 Response Factor..............................................................................14

2.5.2 Minimum Pulse Width ......................................................................15

2.5.3 Deadband ........................................................................................15

2.5.4 Startup Delay....................................................................................15

2.6 Speed Sensor Set p......................................................................................16

2.6.1 'AutoCal' ...........................................................................................16

2.6.2 Manually calculating the Factor.......................................................16

Number of Sensor magnets ...........................................................................17

Example Calculation 1....................................................................................1

Example Calculation 2....................................................................................1

Manually setting the Factor ............................................................................1

2.7 Other Settings ................................................................................................19

2.7.1 Set Step % in Automatic Mode ........................................................19

2.7.2 Units.................................................................................................19

F nctions s mmary ..................................................................................................20