Re S.p.A. TL01-A

03/07/12 1/13

Warnings

The present manual is for device fitters and operators. It provides indications on the intended use of the

device, technical specifications and instructions for installation, adjustment and use.

This manual is an integral part of the device and must be kept until the device is decommissioned. It

reflects the technical state of the device at the time of its sale.

The plant builder may include the present manual in the documentation for plant use.

Re S.p.A. reserves the right to update its production and/or manuals without updating products already

sold and previous manuals.

Since the device forms part of a plant, the plant builder is responsible for ensuring that all parts comply

with the laws in force in the country in which it is installed.

The device must be fitted and adjusted by qualified technical personnel.

It may be moved manually.

Information about device recovery

- In European Union member states

The device falls within the electrical and electronic equipment category, which must be disposed of

not amongst undifferentiated urban waste, but through separate collection. Therefore, at the end of

the device’s lifetime, it must be disposed of in conformity with the European standards adopted in the

member state in which it was installed.

WEEE (Waste Electrical and Electronic Equipment) may be intended for individual, collective or

mixed collection and recovery systems at designated centres (for more information contact the

relevant local authorities) or may be returned to the distributor when a new item of equipment is

purchased. This eliminates or reduces potentially negative effects on the environment deriving from

improper use of the equipment or parts of it.

For correct waste management, the relevant authorities promote the reduction of final waste disposal

by means of re-use, recycling and other forms of recovery to obtain raw materials from waste.

In the event of illegal disposal of WEEE, offenders will be punished in accordance with the sanctions

established by the member state in which it was installed.

- In non-EU countries

Recovery and final disposal of the device must be carried out in conformity with the standards in

force in the country in which it was installed. It may be advisable to take into account the information

provided regarding European Union member states.

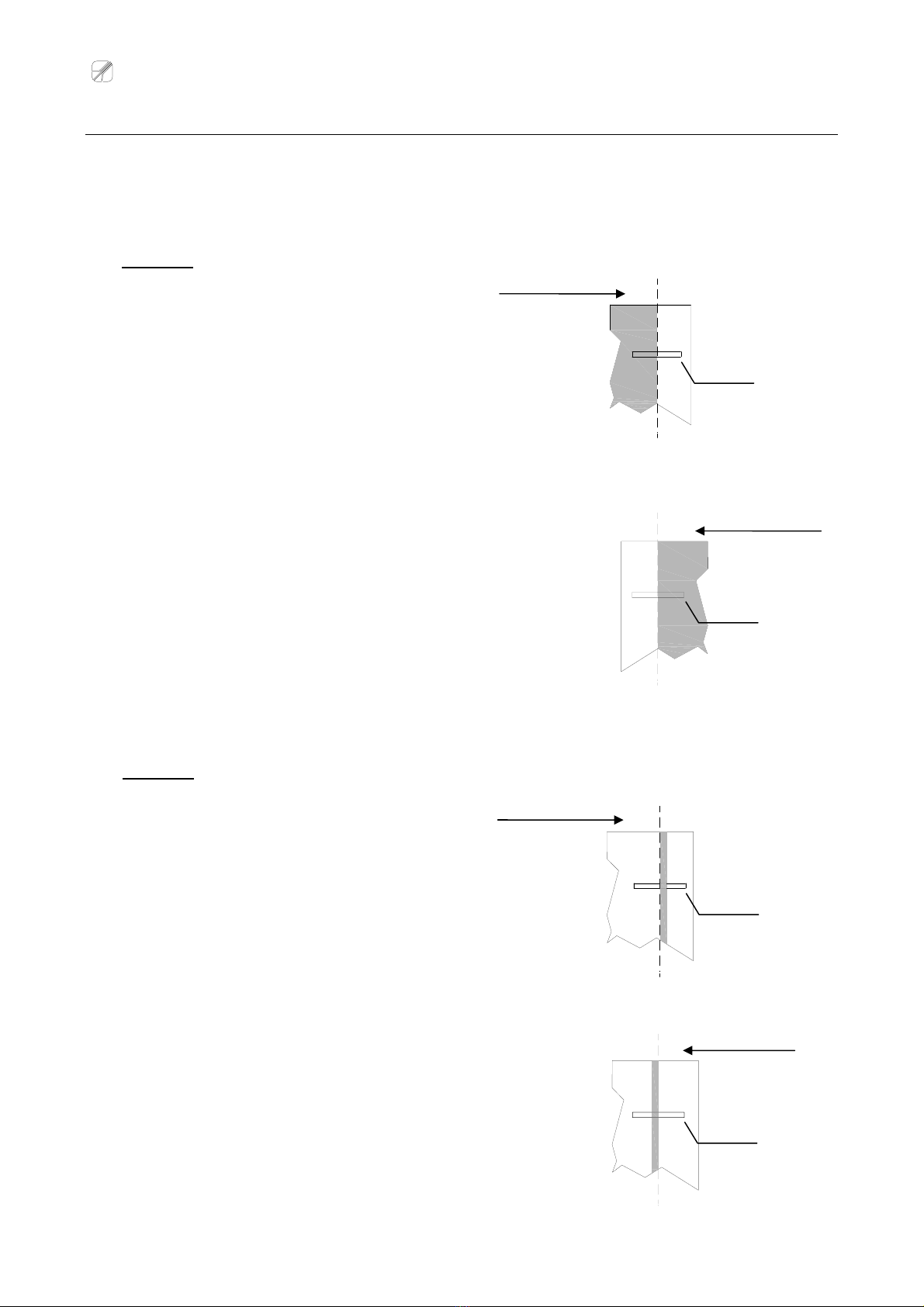

The device bears a clear, visible and indelible indication allowing identification of the

manufacturer and the separate collection symbol (symbol on side).

This symbol, showing a wheelie bin with a cross through it, unequivocally indicates that

the device was released after 13.08.2005 and that it must be subject to separate

collection.