Re S.p.A. US3

I

Contents

Warnings ........................................................................................................................................... 1

Ultrasonic sensor advantages........................................................................................................ 2

Ultrasonic sensor limitations.......................................................................................................... 2

Typical applications......................................................................................................................... 2

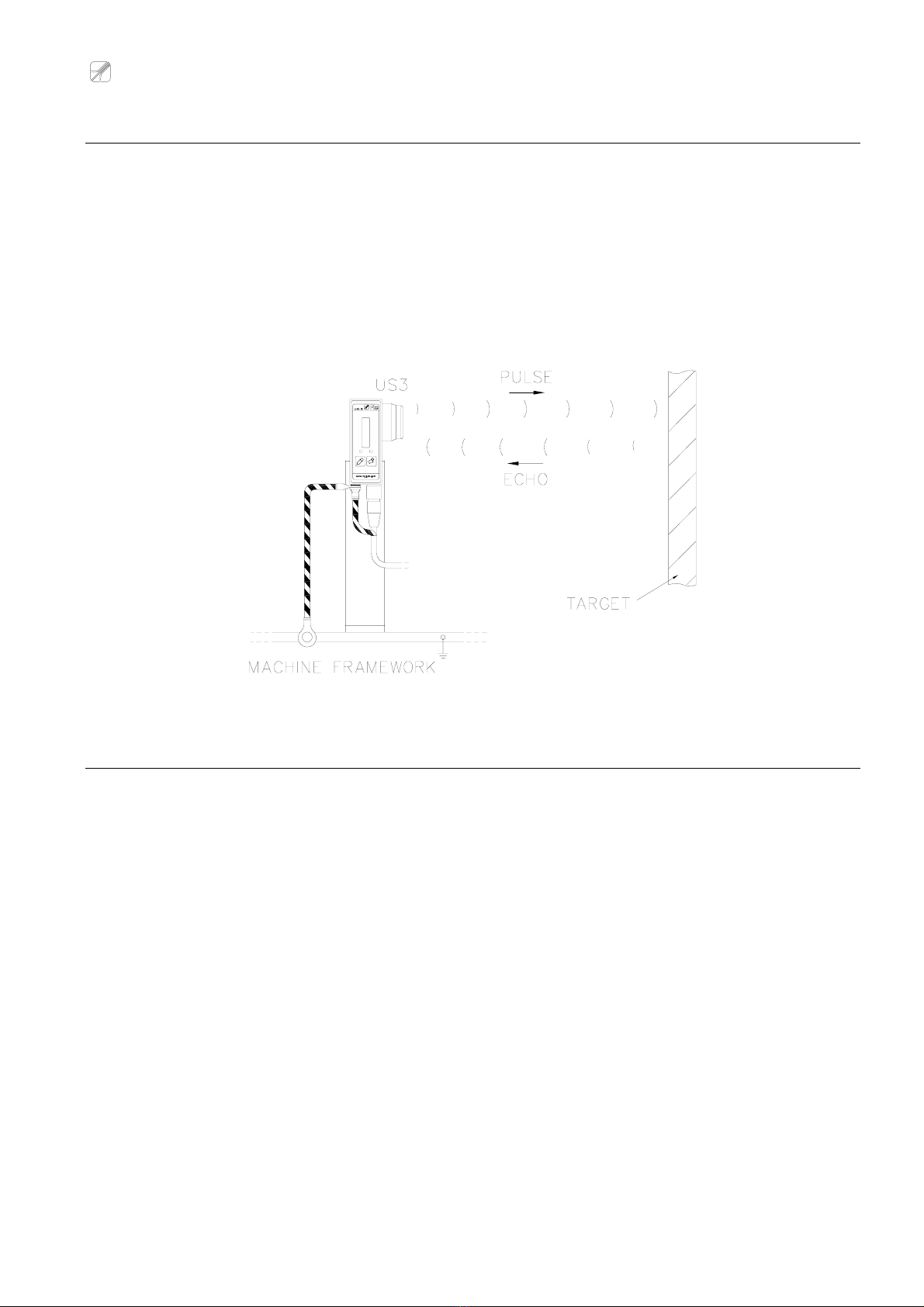

“Pulse-echo” measuring method ...................................................................................................3

Factors which influence measurement.......................................................................................... 3

Technical characteristics ................................................................................................................ 4

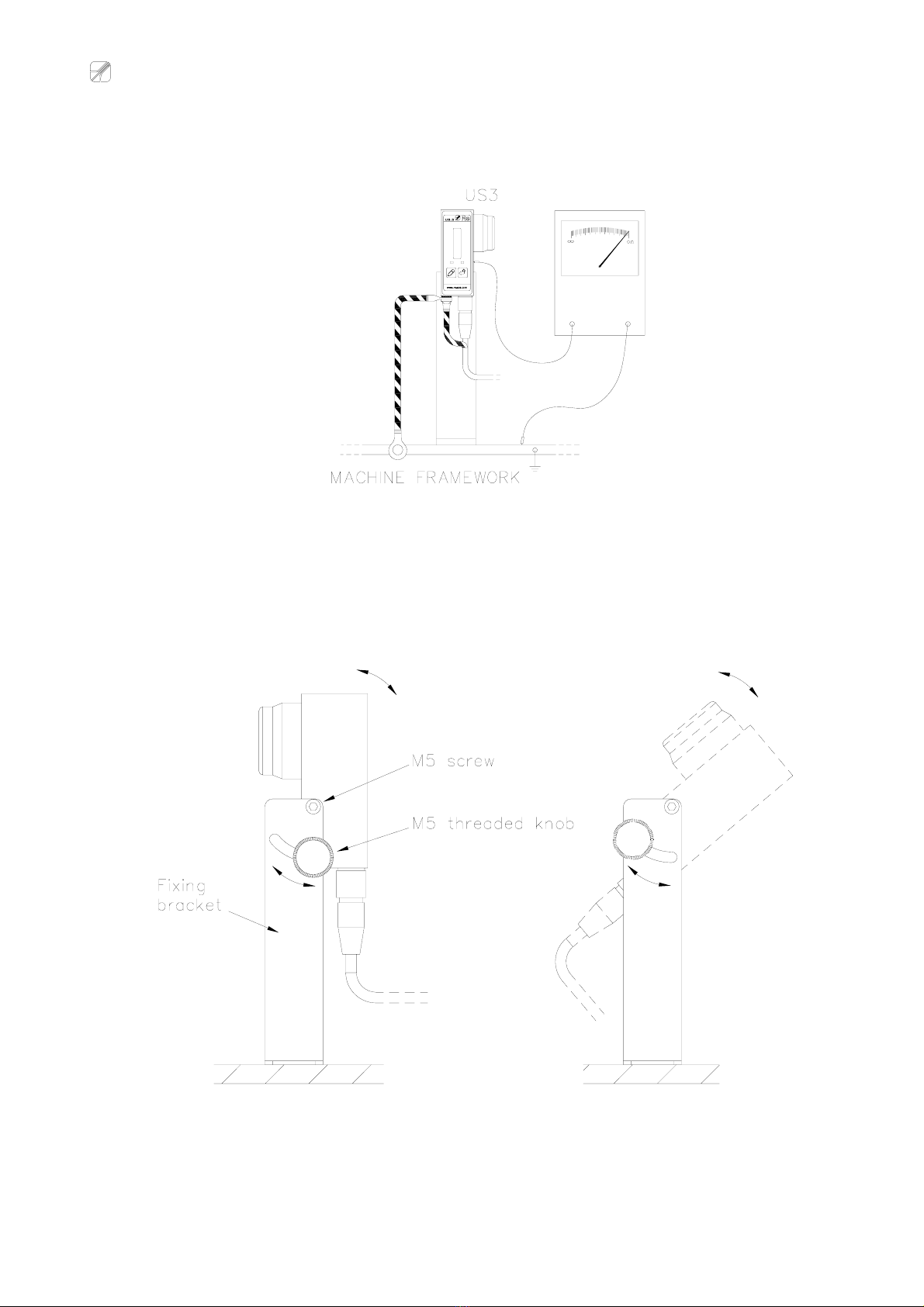

Installation ........................................................................................................................................ 4

Functioning of the device................................................................................................................ 8

General ....................................................................................................................................................8

Control panel...........................................................................................................................................8

LED bar ...............................................................................................................................................9

Status LED (green)..............................................................................................................................9

“Out of range” LED (red)......................................................................................................................9

Keys ....................................................................................................................................................9

Programming menu ....................................................................................................................... 10

Calibration....................................................................................................................................... 11

“Field” calibration by maximum and middle diameter.........................................................................12

“Lab” calibration by maximum diameter and axis...............................................................................13

Configuration of the sensor as distance reader ......................................................................... 14

Detailed description of the functions...........................................................................................15

F1 - Regulated output type selection (Volt o mA) ..............................................................................15

F2 - Minimum distance calibration (maximum diameter) ...................................................................15

F3 - Middle diameter calibration - only for field calibration................................................................16

F4 - Maximum distance calibration (axis calibration) - only for lab calibration ...................................16

F5 - Setting 1st alarm threshold..........................................................................................................17

F6 - Setting 2nd alarm threshold.........................................................................................................17

F7 - Regulated output inversion.........................................................................................................17

F8 - Led bar mode .............................................................................................................................18

F9 - Thermal probe exclusion ............................................................................................................18

F10 - Exit menu saving the data ........................................................................................................18

Reset .................................................................................................................................................18

Setpoint ........................................................................................................................................... 19

Electrical and mechanical characteristics................................................................................... 20

Mechanical dimensions................................................................................................................. 21

Electrical connection diagrams.................................................................................................... 22

Guarantee........................................................................................................................................ 23