USE COMMON SENSE AND PLENTY OF IT

1) DO NOT allowanyperson to operate the rotary hoe withoutfirst readingandunderstanding the

safety precautionsandoperatinginstructions. Readandunderstand the enginemanual.KNOW

THE CONTROLS AND HOW TO STOP THE ROTARY HOE QUICKLY IN AN EMERGENCY.

2) NEVER allow children or untrained adults to operate the rotary hoe.

3) ALWAYSwearprotectiveclothingwhenoperating the rotary hoe.

This includes, but is not limited to: safety glasses, loose fitting gloves,

steel capped boots and hearing protection. NEVER wear loose fitting

clothing or jewellery when operating the rotary hoe. Keep all clothing away from moving parts. Items

could become caught in the machine, resulting in injury.

4) ALWAYS operate the rotary hoe in a well lighted area.

5) ALWAYSmakecertainthat the tyne engagement control lever is in the “neutral”positionprior to

starting the engine. The TYNE ENGAGEMENT CONTROL LEVER on the left handlebar is for the

6) ALWAYS operate rotary hoe on level groundonly. Police the area before

rotary hoeing. Remove anyforeignobjects in the diggingarea(egbricks, rocks,

wire and sticks). Locate andmarkanysprinklerheads, water pipes, gaslines,

electrical and telephone cables or any other hazard either below or above ground.

7) DO NOT allow otherpersonsnear the rotary hoe. It is the responsibility of the operator to keep

bystanders and animals a minimum of 6 metres (18ft) away from the machine while it is in operation.

9) NEVERoperate the rotary hoe when fatigued.ALWAYS BE ALERT! If youbecometiredwhile

operating the rotary hoe, takeabreak. If youhaveanyphysical or mental conditionthatmay be

aggravated by strenuous work, consult your physician before you operate this equipment.

NEVER operate the rotary hoe under the influence of medication, alcohol or drugs.

10) ALWAYSKEEP YOUR HANDS,FEETAND BODY AWAY FROM THE DIGGING

AREA WHILE ENGINE IS RUNNING.

11) NEVER operate the unit without the safety guards in place and in working order.

Keep the unit well maintained and in good working order

12) DO NOT leave the machine unattended while the engine is running.

13) DO NOT overspeed the engine or alter the governor settings. Excessive speed is dangerous and will

shorten engine life.

14) NEVERoperate the rotary hoe in an enclosedarea.Engineexhaustcontainscarbon

monoxide, an odourless and tasteless poison.

15) STOP the engine, disconnect the spark plug lead and allow engine to cool before inspecting or

performing maintenance on the rotary hoe.

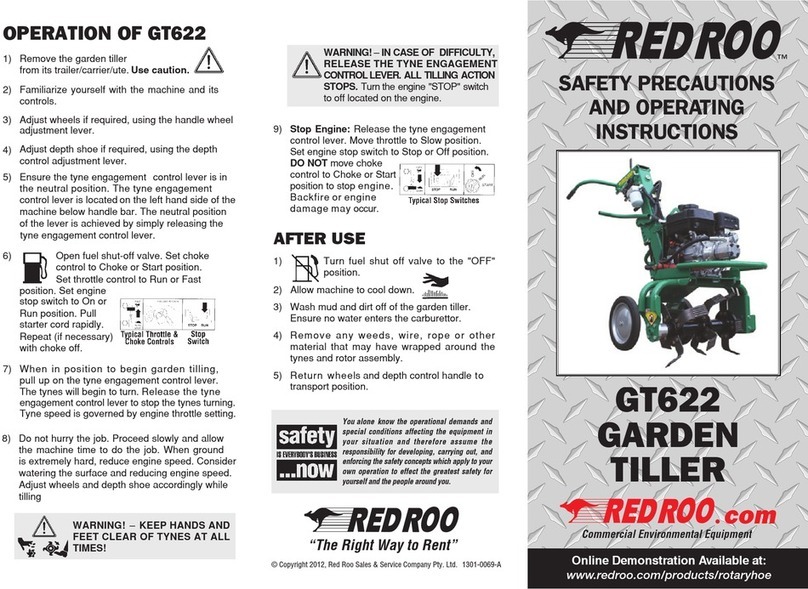

16) REFUELLING

*SHUT OFF ENGINE. DO NOT REFUEL AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes.

*USE UNLEADED FUEL ONLY. Use clean, fresh unleaded fuel.

*Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space for fuel expansion.

* Do not smoke near equipment.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels. Remember, fuel is a potential hazard.

* Refer to engine owners manual for full details.

SAFETY INSTRUCTIONS FOR RH918 USERS

Outdoor Power Equipment Institute Recommendations

WARNING TO PURCHASERS OF INTERNAL COMBUSTION

ENGINE EQUIPPED MACHINERY OR DEVICES:

The equipmentwhich you have purchased doesnothave a spark arrester muffler. If thisequipment

is to be used on any forest and brush covered land or grass covered unimproved land, the law may

requirethatasparkarrester muffler be installedand be in effectiveworkingorder. The spark

arrester must be attached tothe exhaust system and comply with local authorities by-laws.

Hydraulic oil is under extreme pressure and can get under skin and burn or poison. Check for

leaks with cardboard.

8)

operator’s protection. All motion stops when the control lever’s released!

DO NOT TAPE THE CONTROL LEVER UP or otherwise by-pass this safety feature!

6

MAXIMUM ANGLE

OF OPERATION

DO NOT EXCEED

15º ANGLE

USE COMMON SENSE

AND PLENTY OF IT

SAFETY INSTRUCTIONS FOR HT912USERS

INSTRUCTIONS

DO NOT allow any person to operate the

hydraulic trencher without first reading and

understanding the safety instructions and

NEVER allow children to operate the hydraulic trencher.

ALWAYS use hydraulic trencher in a well lighted area.

ALWAYS make certain that all control clutches are in

the “disengaged” position prior to starting the engine.

The safety clutch lever/Operator Presence Control on

the left handlebar is for operator protection. DO NOT

tape down or otherwise bypass this Safety Device.

NEVER wear loose fitting clothing or jewellery when

operating the hydraulic trencher. Keep all clothing

away from moving parts. Item could become

caught in the machine, resulting in injury.

ALWAYS wear protective

clothing when operating

the hydraulic trencher.

This includes, but is not limited to, safety glasses, hard hat

loose fitting gloves, steel capped boots and hearing protection.

operating instructions. KNOW THE CONTROLS AND

HOW TO STOP THE HYDRAULIC TRENCHER QUICKLY

IN AN EMERGENCY.

1)

2)

3)

4)

Police the area before trenching. Remove any foreign

objects in the digging area eg bricks, rocks, wire and

sticks. Locate and mark any sprinkler heads, water

pipes, gas lines, electrical and telephone cables or any

other hazard either below or above ground.

5)

DO NOT leave the machine unattended while the engine

is running. DO NOT park on incline or park

perpendicular to slope. DO NOT freewheel down incline.

7)

DO NOT overspeed the engine or alter the governor

settings. Excessive speed is dangerous and will

shorten engine life

8)

NEVER operate the hydraulic trencher when fatigued.

ALWAYS BE ALERT! If you get tired while operating

the hydraulic trencher, take a break. If you have any

type of physical or mental condition that may be

aggravated by strenuous work, consult with your

physician before you operate this equipment. NEVER

operate the hydraulic trencher under the influence of

medication, alcohol or drugs.

9)

NEVER operate the unit without the safety

guards in place and in working order. Keep

the unit well maintained and in good working order

Remove the hydraulic trencher from its

trailer. Use caution.

Police the area. Remove any

foreign objects from the area.

Identify and mark the location of sprinkler heads,

gas pipes, telephone cables, etc.

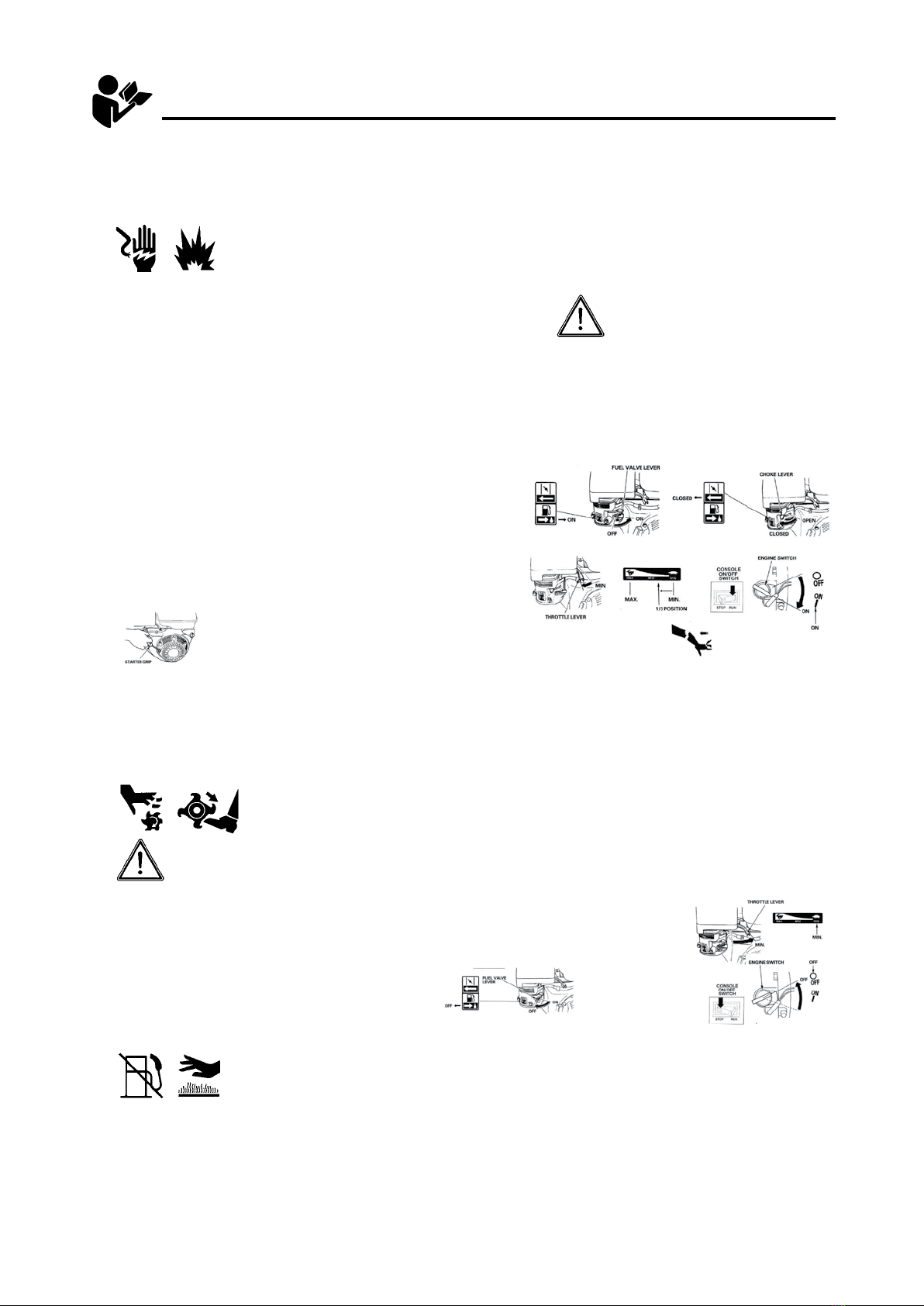

IGNITION: Must be in “ON” position to start. “OFF”

to stop.

ENGINE: Throttle cable controls engine speed.

Operate at full throttle (all the way forward).

WHEEL DRIVE CONTROL LEVER: Controls wheel

speed forward or reverse after clutch lever is engaged.

DIGGING BOOM CONTROL LEVER: Raises and lowers

the digging boom.

DIGGING CHAIN CONTROL LEVER: must be in “ON”

position BEFORE clutch lever is depressed in order

to start chain in motion. Chain moves in a forward

direction after clutch lever is engaged.

SAFETY CLUTCH LEVER/OPERATOR PRESENCE

CONTROL: (At left handle grip) Activates WHEEL

DRIVE and DIGGING CHAIN controls when depressed.

Stops all motion when released.

FORWARD/REVERSE DIGGING CHAIN CONTROL

LEVER: Allows manual operation of chain in forward

or reverse rotation to dislodge objects or dig difficult

terrain. (This control can be used with the clutch lever

released.) To reverse chain, DIGGING CHAIN control

must be in “OFF” position.

Familiarize yourself with the hydraulic

trencher and its controls.

10)

1)

1)

2)

1)

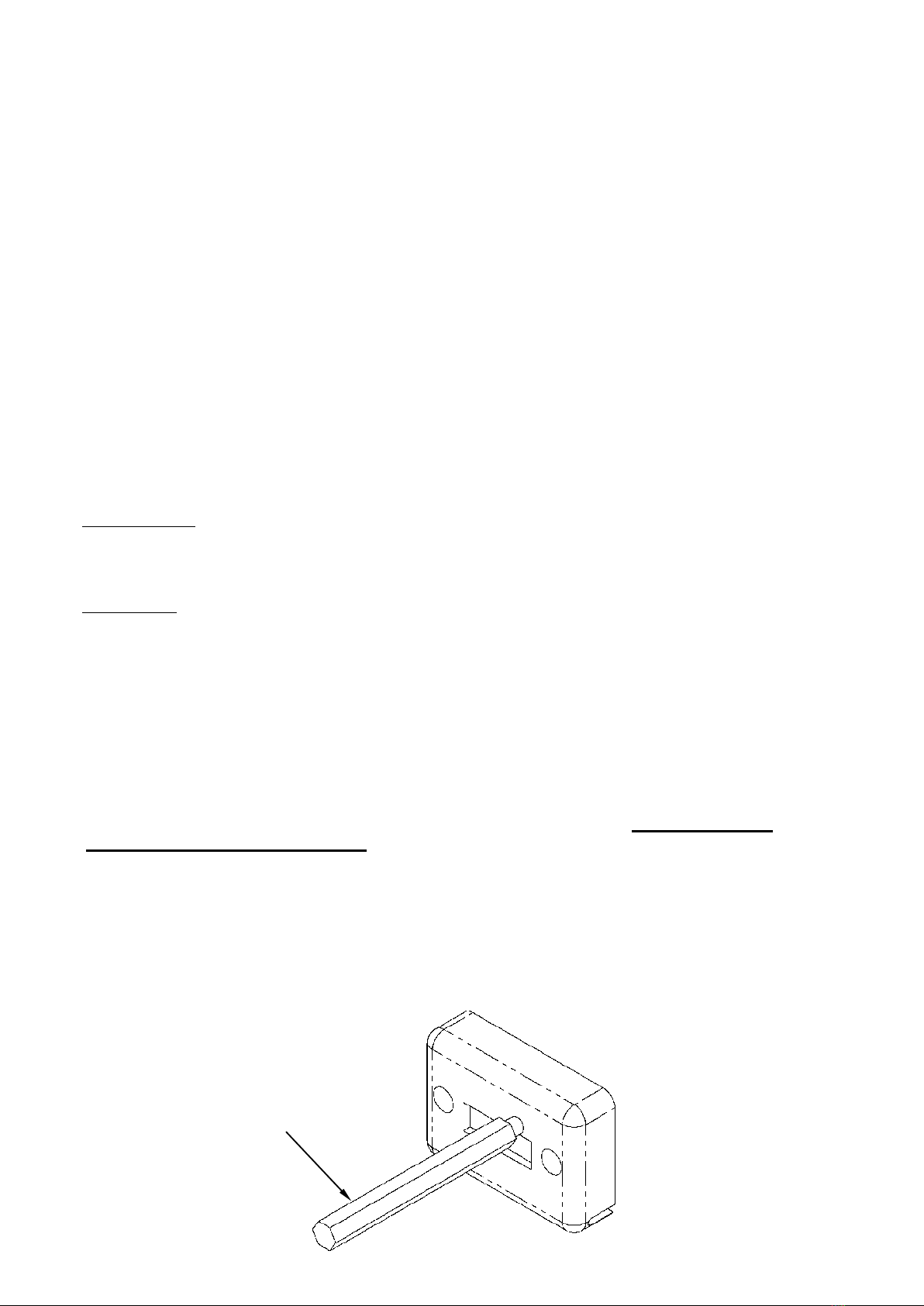

Free Wheel Hub Feature - Operation:

Pull one free wheeling pin slightly, using the split

ring. Rotate the pin until the 3mm (1/8”) diameter roll

pin aligns with the slot in the mounting plate. Allow

the pin to slide through the slot. Repeat for the other

wheel. Roll the trencher until each pin drops into a

hole in the hub. The wheel hubs are now locked.

Reverse the procedure to unlock the wheels.

2)

DO NOT allow other persons near the hydraulic

trencher. It is up to the operator to keep

bystanders and animals a minimum of 6 metres

(20ft) away from the machine while in operation.

12)

NEVER operate the hydraulic trencher in an

enclosed area. Engine exhaust contains carbon

monoxide, an odourless and tasteless poison.

13)

WARNING: Hydraulic oil is under extreme

pressure and can get under skin and burn

or poison. Check for leaks with cardboard.

14)

STOP the engine and disconnect the spark

plug lead(s) and allow engine to cool before

inspecting or performing maintenance on

the hydraulic trencher.

15)

REFUELLING

* Shut off engine. DO NOT REFUEL AN ENGINE

WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes

* Do not smoke. *Allow no naked flame

or hot material in refuelling area.

* Use only approved fuel containers and funnels.

Remember, fuel is a potential hazard.

* Do not over-fill fuel tank. Allow space for

fuel expansion.

* USE UNLEADED FUEL ONLY. Use clean,

fresh unleaded fuel.

* Do not mix oil with unleaded fuel.

16)

ALWAYS KEEP YOUR HANDS, FEET AND BODY

AWAY FROM THE DIGGING CHAIN AND OTHER

MOVING PARTS WHILE ENGINE IS RUNNING.

11)

ALWAYS operate

hydraulic trencher

on level ground only.

6) MAXIMUM

ANGLE OF

OPERATION

DO NOT EXCEED 15ºANGLE

BEFORE USE

OPERATION

TRANSPORT