5

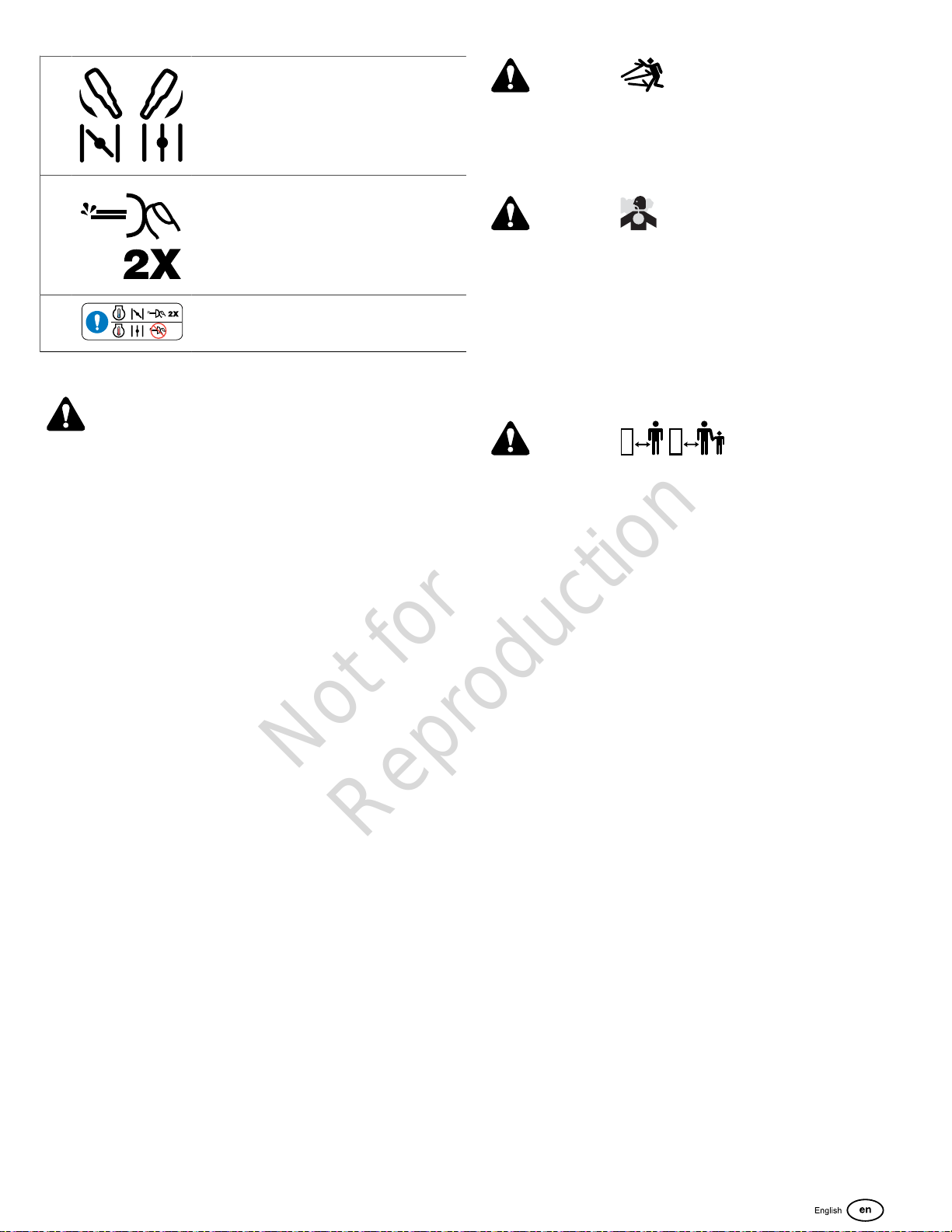

M Choke CLOSED / Choke OPEN

N Primer Button

O Alternate Choke-Prime Instructions

Operation

WARNING

This snowthrower is only as safe as the operator. If it is

misused, or not maintained correctly, it can be dangerous.

Remember you are responsible for your safety and those

around you.

• When leaving the operating position always disengage

the auger, STOP the engine, and remove the key. DO

NOT leave a running machine unattended.

• DO NOT operate the snowthrower without the correct

guards, and other safety protective devices in place and

working.

• Be careful when you operate the unit on gravel

driveways, walkways, or roads. Stay alert for hidden

hazards or traffic.

• DO NOToperate the snowthrower without good

visibility or light. Always be sure of your footing, and

keep a firm hold on the handles. Walk; never run.

• Be careful to avoid slipping or falling, especially when

you operate the snowthrower in reverse.

• Be careful when you operate the snowthrower on

slopes.

• If you strike a foreign object, stop the engine, remove

the wire from the spark plug, thoroughly inspect the

snowthrower for damage, and repair the damage before

you start and operate the snowthrower.

• DO NOT operate the equipment without wearing

adequate winter garments. Avoid loose fitting clothing

that can get caught in moving parts. Wear footwear that

will improve footing on slippery surfaces.

• DO NOT touch a hot muffler or engine. Let the muffler

and engine cylinder to cool before touching.

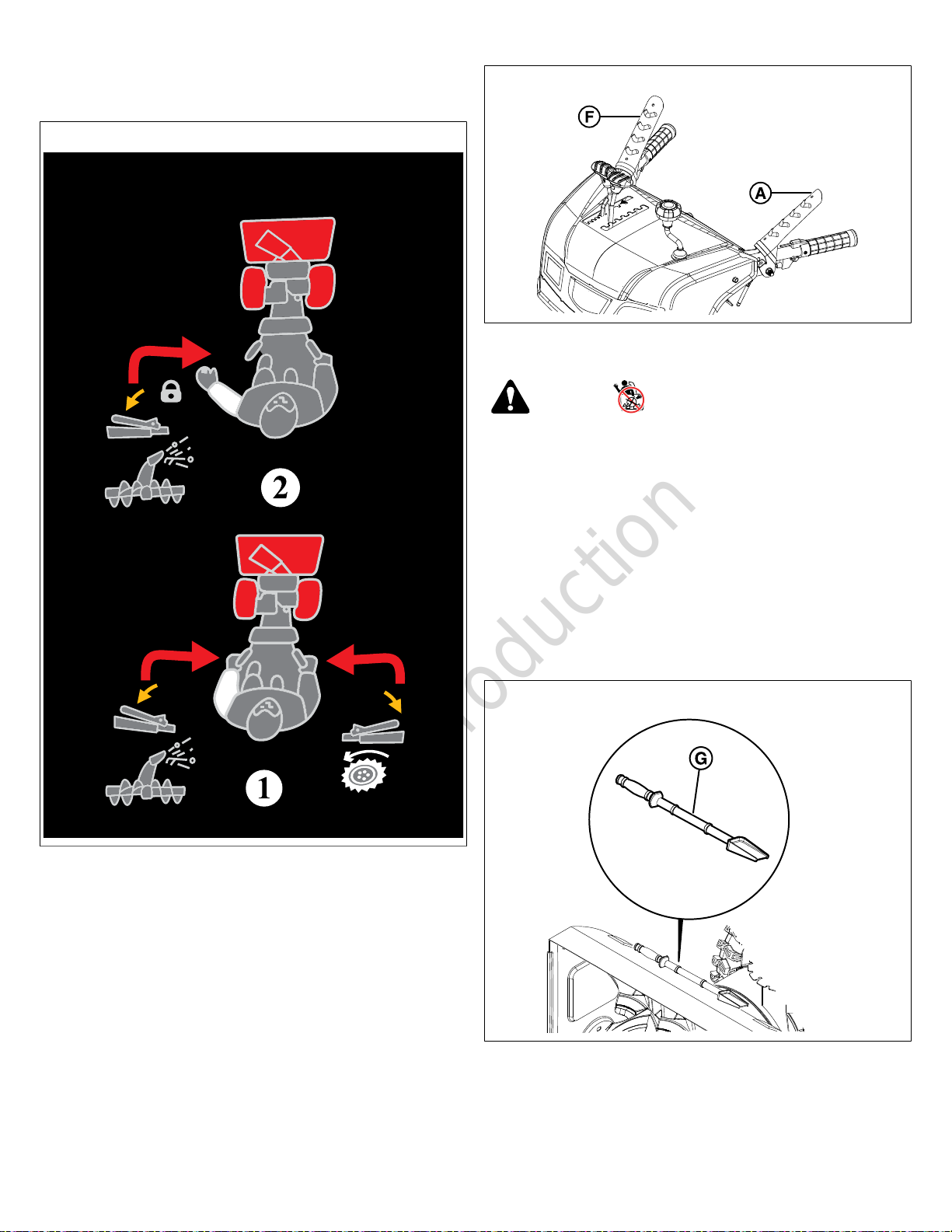

Operating Area

1. Identify the walkways and driveways where you plan to

operate the snowthrower.

2. Make sure that the area is free of debris or objects that

the auger could pick-up and throw from the chute.

WARNING

This machine is capable of throwing objects that could

injure bystanders or cause damage to buildings.

3. Before you start the engine, move the snowthrower

outdoors and away from windows and doors.

WARNING

Engines give off carbon monoxide, an ordorless, colorless,

poison gas. Breathing carbon monoxide can cause nausea,

fainting, or death.

• Start and operate the engine outdoors.

• Do not operatethe engine in an enclosed area, even

if doors or windows are open.

4. Make sure that the operating area is clear of bystanders,

especially children.

WARNING

This snowthrower is capable of amputating hands and feet,

and throwing objects. Read and obey the safety instructions

in this manual. Failure to do so could result in death or

serious injury.

• Keep children out of the area during operation.

• Children are often attracted to the equipment. Be

mindful of all persons present.

• Be alert and turn the unit off if bystanders enter the

area.

• Use extra care when you approach blind corners,

shrubs, trees, or other objects that can obscure vision.

Engine

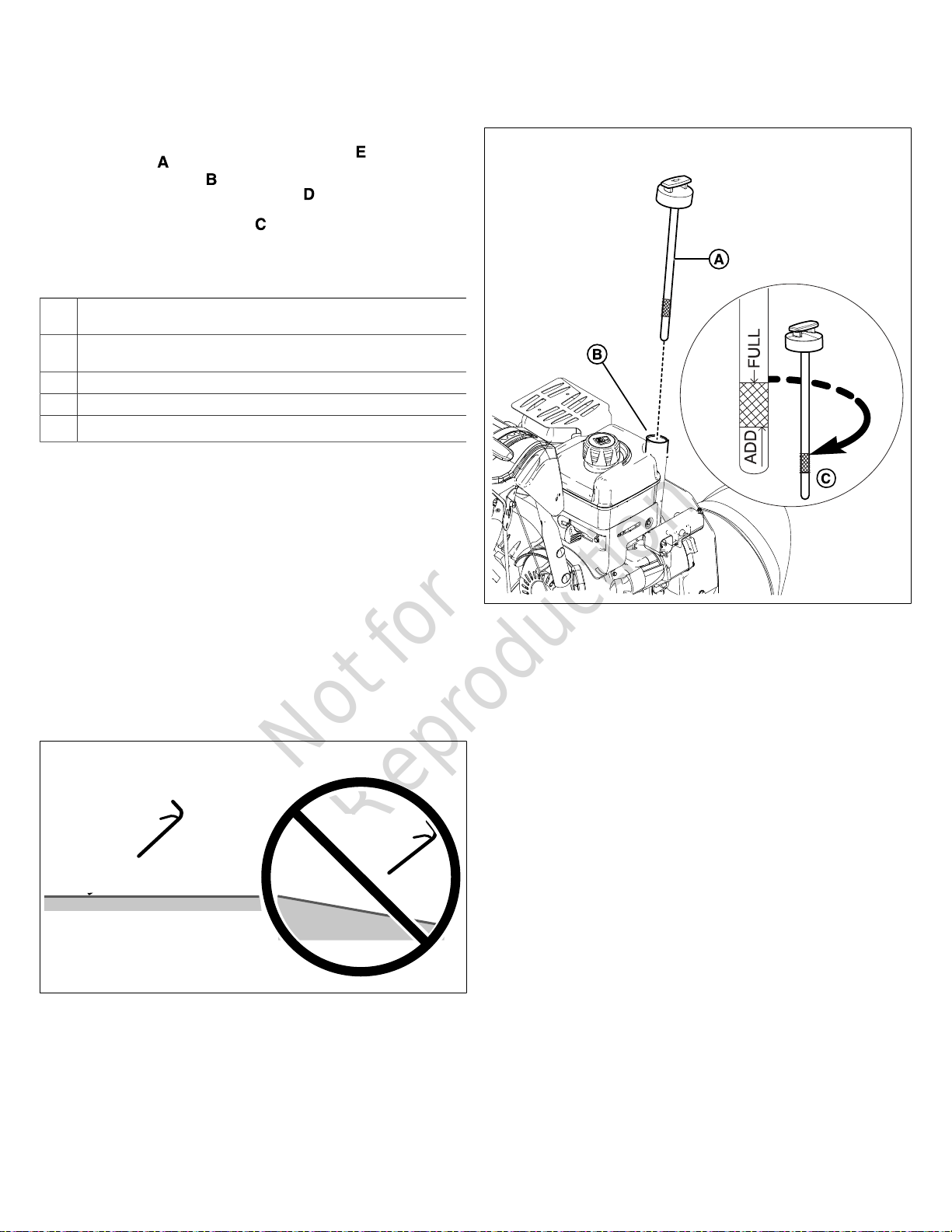

Oil Recommendations

Oil Capacity:See theSpecificationssection.

NOTICE

This engine was shipped from Briggs & Stratton without oil.

Equipment manufacturers or dealers may have added oil

to the engine. Before you start the engine for the first time,

make sure to check the oil level and add oil as specified

by the instructions in this manual. If you start the engine

without oil, it will be damaged beyond repair and will not be

covered under warranty.

We recommend the use of Briggs & Stratton®Warranty

Certified oils for best performance. Other high-quality

detergent oils are permitted if classified for service SF, SG,

SH, SJ or higher. Do not use special additives.

Outdoor temperatures determine the correct oil viscosity

for the engine. Use the chart to select the best viscosity

for the outdoor temperature range expected. Engines on

most outdoor power equipment operate well with 5W-30

Synthetic oil. For equipment operated in hot temperatures,

Vanguard®15W-50 Synthetic oil gives the best protection.