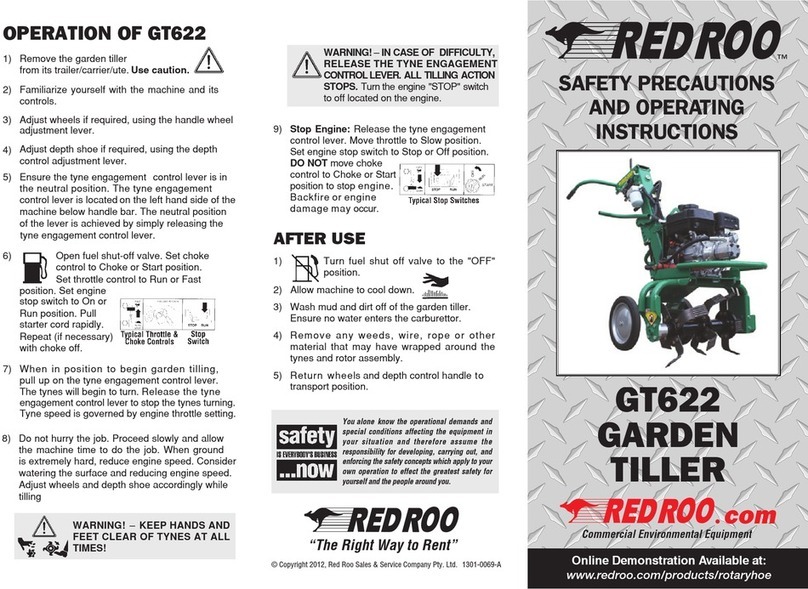

USE COMMON SENSE AND PLENTY OF IT

1) DO NOT allowanyperson to operate the garden tillerwithout first readingandunderstanding the

safety precautionsandoperatinginstructions. Readandunderstand the engine manual.KNOW

THE CONTROLS AND HOW TO STOP THE GARDEN TILLERQUICKLY IN ANEMERGENCY.

2) NEVER allow children or untrained adults to operate the garden tiller.

3) ALWAYSwearprotectiveclothingwhenoperating the garden tiller.

This includes, but is not limited to: safety glasses, loose fitting gloves,

steel capped boots and hearing protection. NEVER wear loose fitting

clothing or jewellery when operating the garden tiller. Keep all clothing away from moving parts. Items

could become caught in the machine, resulting in injury.

4) ALWAYS operate the garden tiller in a well lighted area.

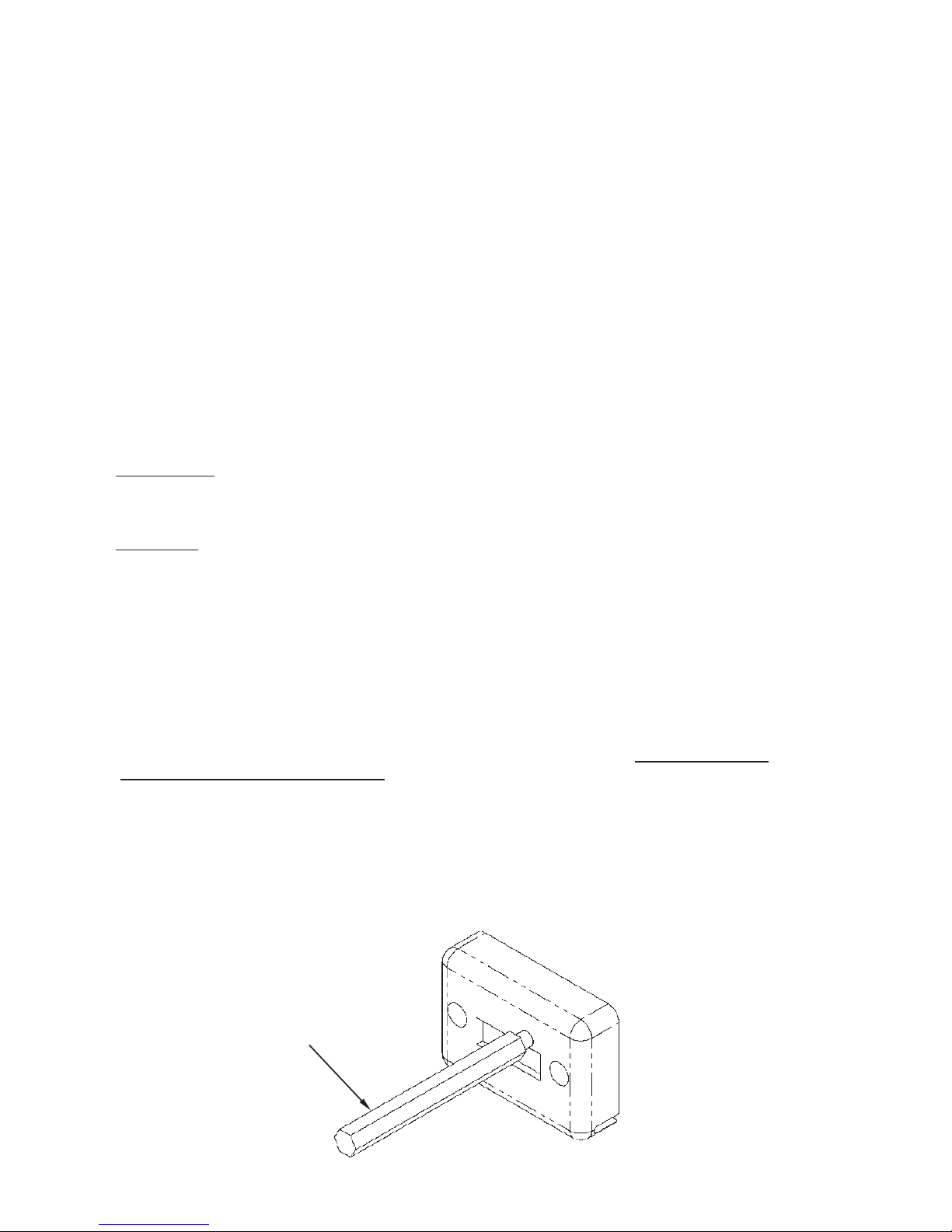

5) ALWAYSmakecertain that the tyne engagement control lever is in the “neutral”positionprior to

starting the engine. The TYNE ENGAGEMENT CONTROL LEVER on the left handlebar is for the

6) ALWAYS operate garden tilleronlevel groundonly. Police the areabeforegarden tilling.

Remove any foreignobjects in the diggingarea(egbricks,rocks,wireandsticks). Locate

andmarkany sprinklerheads, water pipes, gaslines, electrical and telephone cables or

any other hazard either below or above ground.

7) DO NOT allow otherpersonsnear the garden tiller. It is the responsibility of the operator to keep

bystanders and animals a minimum of 6 metres (18ft) away from the machine while it is in operation.

9) NEVERoperate the garden tillerwhen fatigued.ALWAYS BE ALERT! If youbecome tiredwhile

operating the garden tiller, take a break. If youhaveanyphysical or mental condition thatmay be

aggravated by strenuous work, consult your physician before you operate this equipment.

NEVER operate the garden tiller under the influence of medication, alcohol or drugs.

10) ALWAYSKEEP YOUR HANDS, FEETAND BODY AWAY FROM THE DIGGING

AREA WHILE ENGINE IS RUNNING.

11) NEVER operate the unit without the safety guards in place and in working order.

Keep the unit well maintained and in good working order

12) DO NOT leave the machine unattended while the engine is running.

13) DO NOT overspeed the engine or alter the governor settings. Excessive speed is dangerous and will

shorten engine life.

14) NEVERoperate the garden tiller in an enclosedarea.Engineexhaustcontainscarbon

monoxide, an odourless and tasteless poison.

15) STOP the engine, disconnect the spark plug lead and allow engine to cool before inspecting or

performing maintenance on the garden tiller.

16) REFUELLING

*SHUT OFF ENGINE. DO NOT REFUEL AN ENGINE WHILE OPERATING!

* Allow engine to cool. Minimum 5 minutes.

*USE UNLEADED FUEL ONLY. Use clean, fresh unleaded fuel.

*Do not mix oil with unleaded fuel.

* Do not over-fill fuel tank. Allow space for fuel expansion.

* Do not smoke near equipment.

* Allow no naked flame or hot material in refuelling area.

* Use only approved fuel containers and funnels. Remember, fuel is a potential hazard.

* Refer to engine owners manual for full details.

SAFETY PRECAUTIONS FOR GT622 USERS

Outdoor Power Equipment Institute Recommendations

WARNING TO PURCHASERS OF INTERNAL COMBUSTION

ENGINE EQUIPPED MACHINERY OR DEVICES:

The equipmentwhich you have purchased doesnothave a spark arrester muffler. If thisequipment

is to be used on any forest and brush covered land or grass covered unimproved land, the law may

require that a sparkarrester muffler be installedand be in effectiveworkingorder. The spark

arrester must be attached tothe exhaust system and comply with local authorities by-laws.

5

Hydraulic oil is under extreme pressure and can get under skin and burn or poison. Check for

leaks with cardboard.

8)

operator’s protection. All motion stops when the control lever’s released!

DO NOT TAPE THE CONTROL LEVER UP or otherwise by-pass this safety feature!