2

WARNING

• The installation must conform with local codes or, in the absences of local codes, with the National

Fuel Code, ANSI Z223.1/NFPA54, or CAN/CGA-B149.1, National Gas and Propane Installation Code.

• All installation and repair should be done by a qualied installer, service agency, or the gas suppler.

• THIS UNIT IS INTENDED FOR OUTDOOR USE ONLY! This product shall be used outdoors, in a well

ventilated space and shall not be used in any enclosed area.

• Never use natural gas in a unit designed for liquid propane gas.

• Do not use solid fuel or charcoal for this unit.

• When lighting this unit, stay away from the burner as the ame will light up and may cause injury.

• The rst time the unit is ignited, keep away form the unit for the rst 20 minutes, as lava rock could

pop out and cause injury. Discard any lava rock that pops out.

• Always ensure lava rocks are completely dry before use. Failure to do so will cause them to crack and

pop.

• LP GAS WARNING: Do not use any more than 1/2 inch depth of lava rock above the burner holes.

Doing so may suffocate the ame.

• If the propane gas cylinder is leaking gas, you may hear, see or smell a leak. Do the following:

• Disconnect the propane cylinder.

• Do not attempt to x the problem yourself.

• Contact your gas supplier or re department for help.

• Do not use a ame to check for leaks.

• The maximum manifold inlet supply pressure: LP 11.0”WC; NG 7.0” WC.

• The LP cylinder supply pressure is: Max 250 PSI; Min 5 PSI.

• The NG supply pressure is: Max 10.5” WC; Min 3.5” WC.

• The pressure regulator and hose assembly provided with the re pit must be used. If they are

damaged, they must be replaced by the specied ones of manufacturer.

• The appliance should be inspected prior to each use and at least annually by a qualied service

person. Do not operate the unit if there is a gas leak.

• Inspect the hose assembly and burner prior to each use. If there is evidence of any kind of damage,

do not operate the appliance. For assistance with repair or replacement parts, call Even Embers at

1-855-735-9922.

• Check for leaks after not using the appliance for long periods of time.

• LP gas supply cylinder to be used must be constructed and marked in accordance with the

specications for LP gas cylinders of the U.S. Department of Transportation (DOT) or the National

Standard of Canada CAN/CSA-B339, LP gas tanks, spheres and tubes for Transportation of

Dangerous Goods; and Commission.

• The cylinder supply system must have a listed overlling prevention device and a QCCI or Type 1, LP

tank connection. The cylinder must include a collar to protect the cylinder valve.

• DO NOT ll propane cylinder over 80% full.

• Discontinue use if any part of the propane cylinder is damaged. Rust and dents may be hazardous

and should be inspected by a qualied gas supplier.

• Do not operate unit until all parts are fully assembled.

• Do not disconnect any part while unit is in use.

• Do not store a spare propane cylinder on or near this unit.

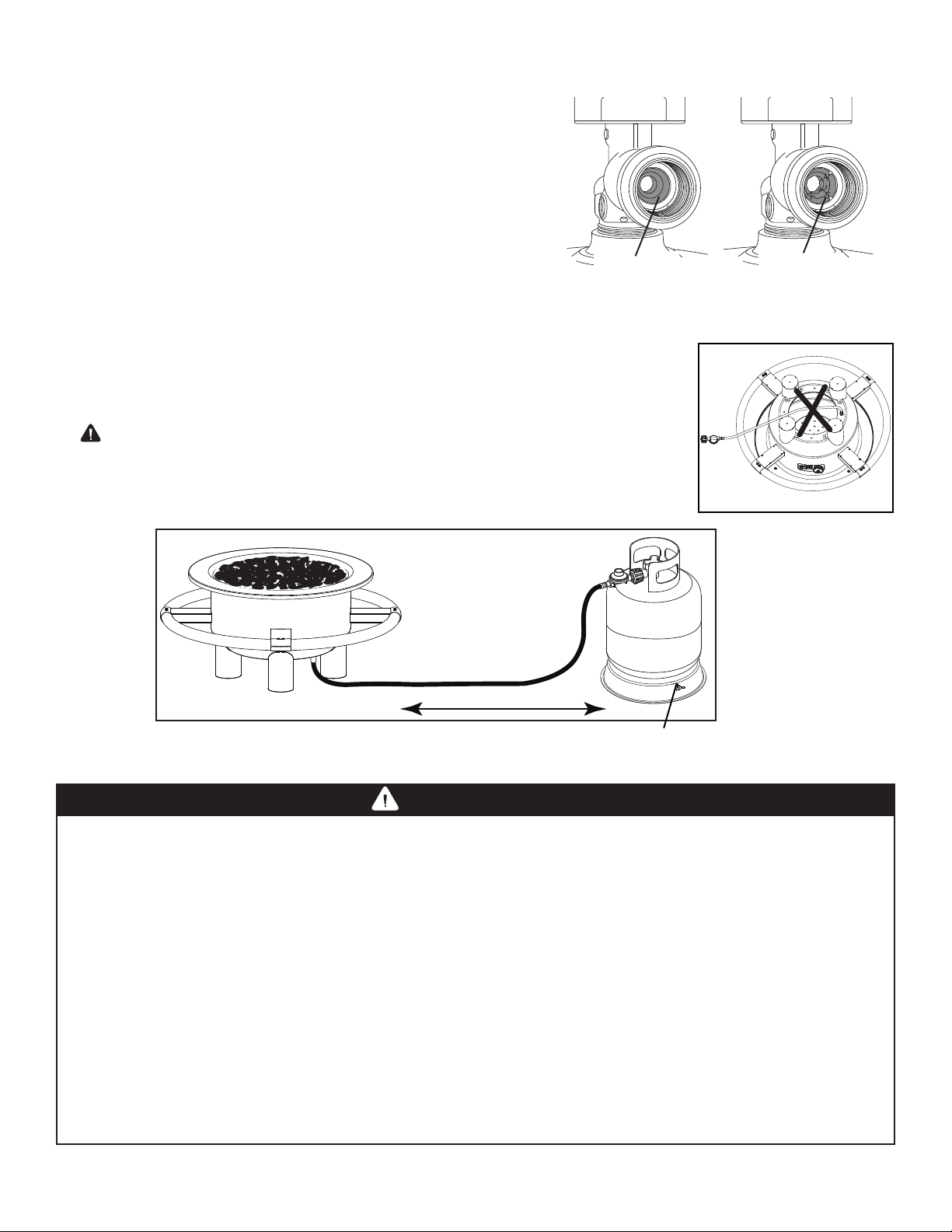

• Keep propane cylinder at least 72 inches away from unit while in use.

• Keep hose out from any pathways to eliminate any accidental damage and avoid a trip hazard.

• Keep all electrical cords and fuel supply hose away from heated surfaces.

• Never leave this unit unattended while in use.

• It is imperative that the control compartment, burner and circulating air passageways of the appliance

are kept clean.

GENERAL WARNINGS: