2

Return Policy–Without soldering anything to the board, please apply power to the

board using alligator clips and make sure the Green LED is on. Contact us immediately

if green LED doesn't turn on! Return and Warranty claims are only considered on units

that have not been soldered and within 30 days of purchase date.

Connecting any external voltages to the RROSD 5V rail will destroy the board and

effectively void warranty

Disclaimer!! - Please understand that quadcopters are potentially dangerous machine.

Use the highest level of precaution when working with hot solder iron, Lipo battery and

motors. Make sure to remove props from motor throughout the entire building process.

Solder equipment –Be sure to use a high quality soldering iron with a large tip

especially when soldering the battery and ESC connections.

Power output on CAM 5V/12V connector –Because a linear regulators are used, limit

the current draw to less than 400mA on 12V and 600mA on 5V rail to prevent

overheating

6S battery –Please make sure VTX solder-bridge is set to RAW to prevent the 12V

regulator from going into thermal shutdown. A low ESR 470uF capacitor might be

needed

Solder Bridge setting –Please make sure the middle pad is only making connection to

either left or right pad. Soldering all 3 pads together will effectively destroy your RROSD

Pro!

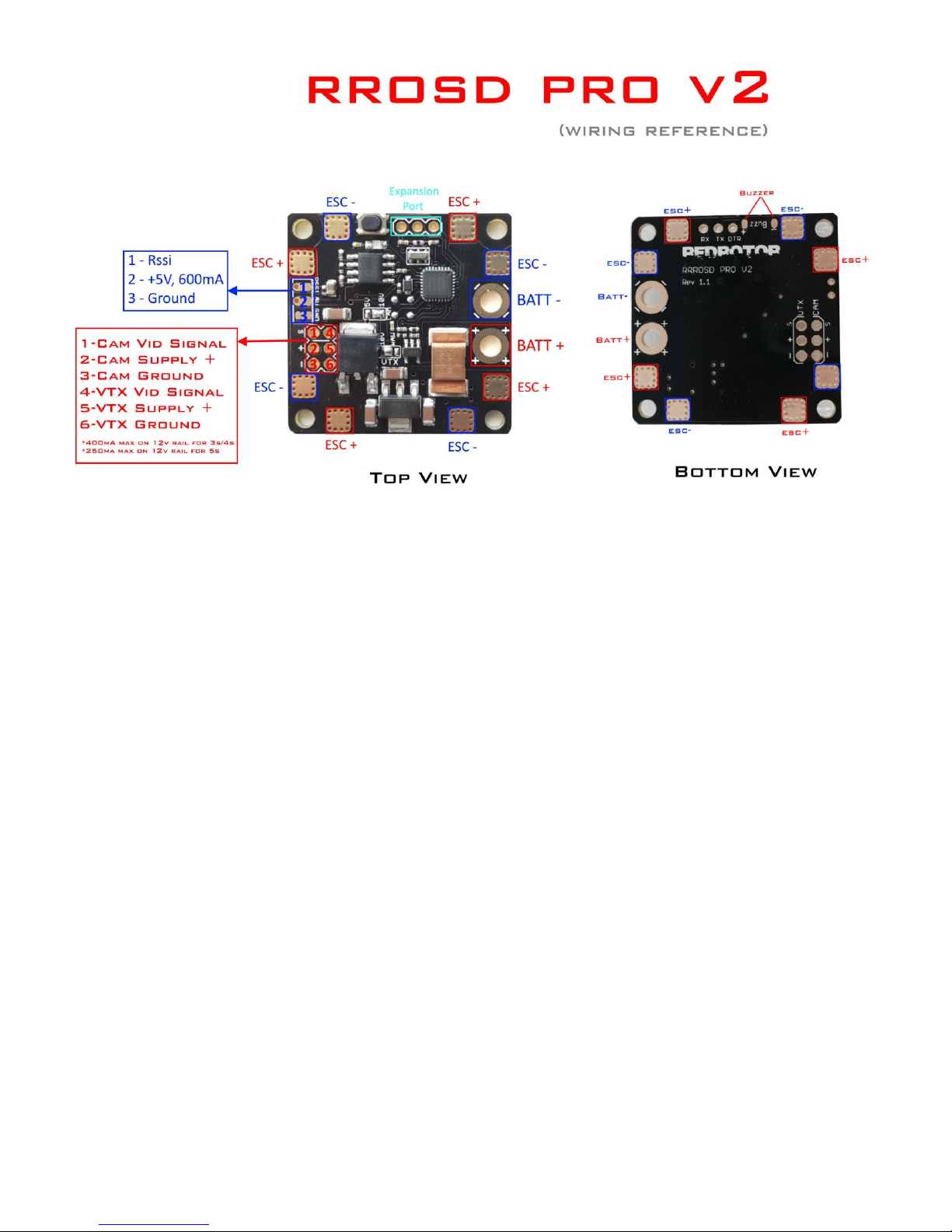

Battery Polarity –Be sure to hook up your battery leads to the proper pads. Positive

lead is clearly marked with ++++ and Negative lead with ----. Reversing this can

potentially damage your board

HEAT!! –This PDB is designed to operate warm to hot. While the heat is not bad

when there’s effective cooling while in flight, do not leave the unit plugged in on the

bench for too long to avoid over heating