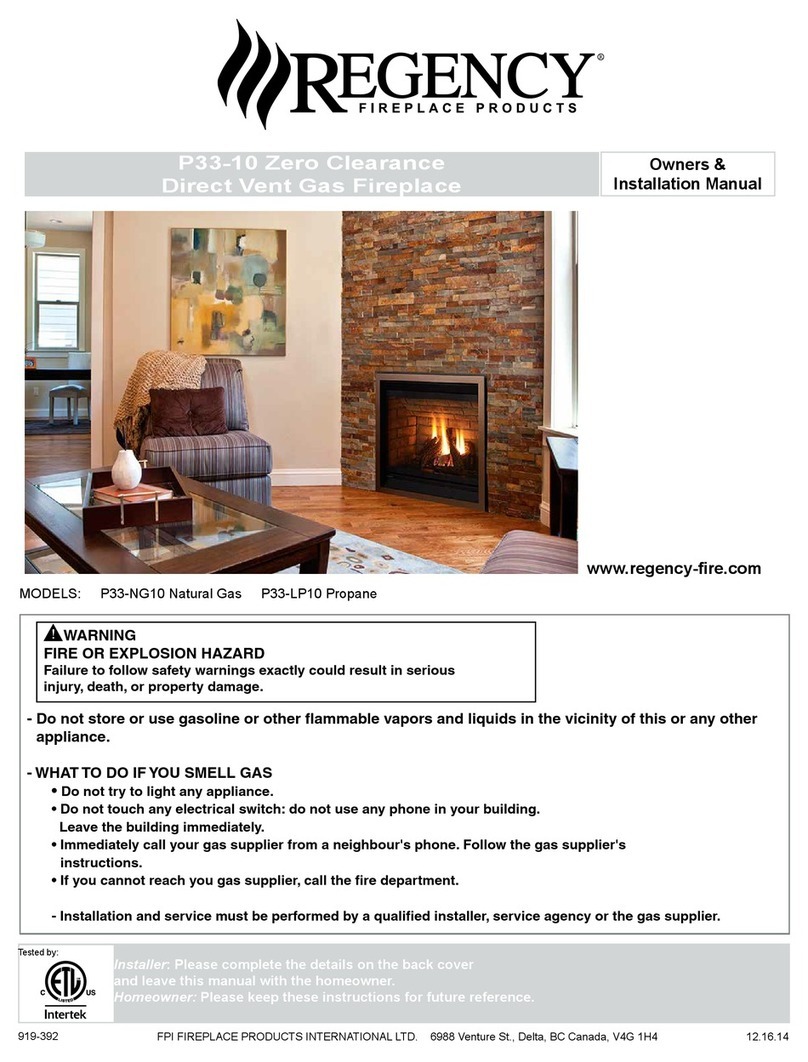

Regency P33R-LP2 Quick start guide

Other Regency Indoor Fireplace manuals

Regency

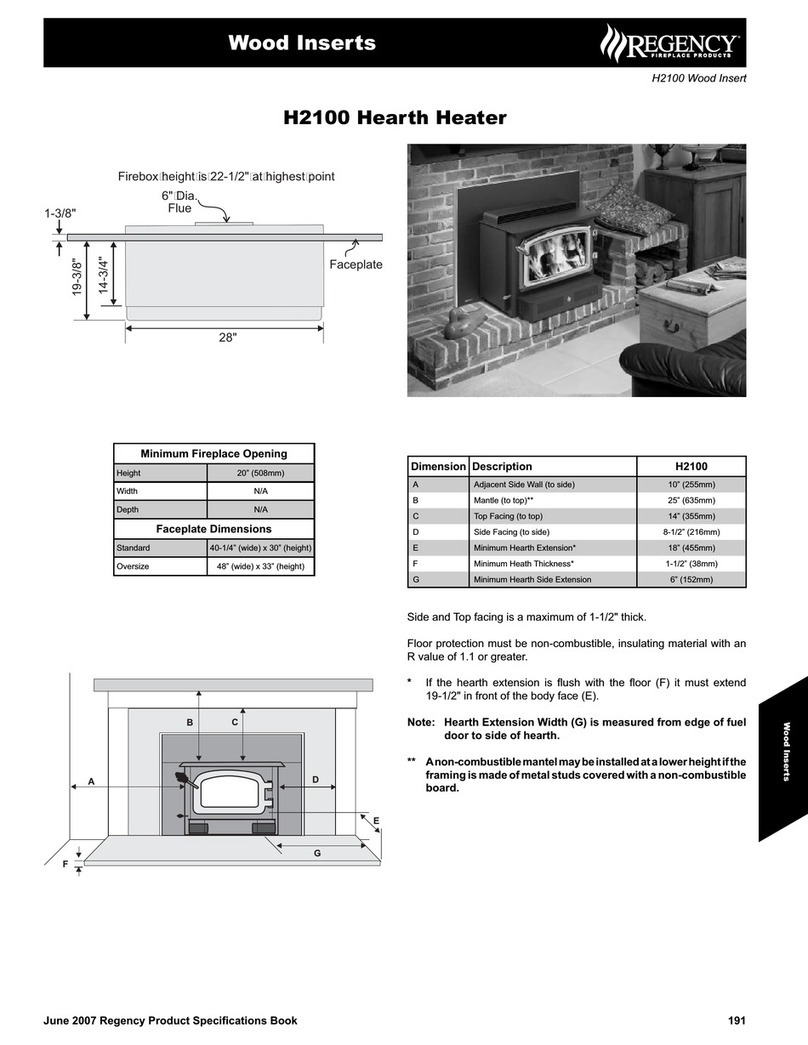

Regency H2100 User manual

Regency

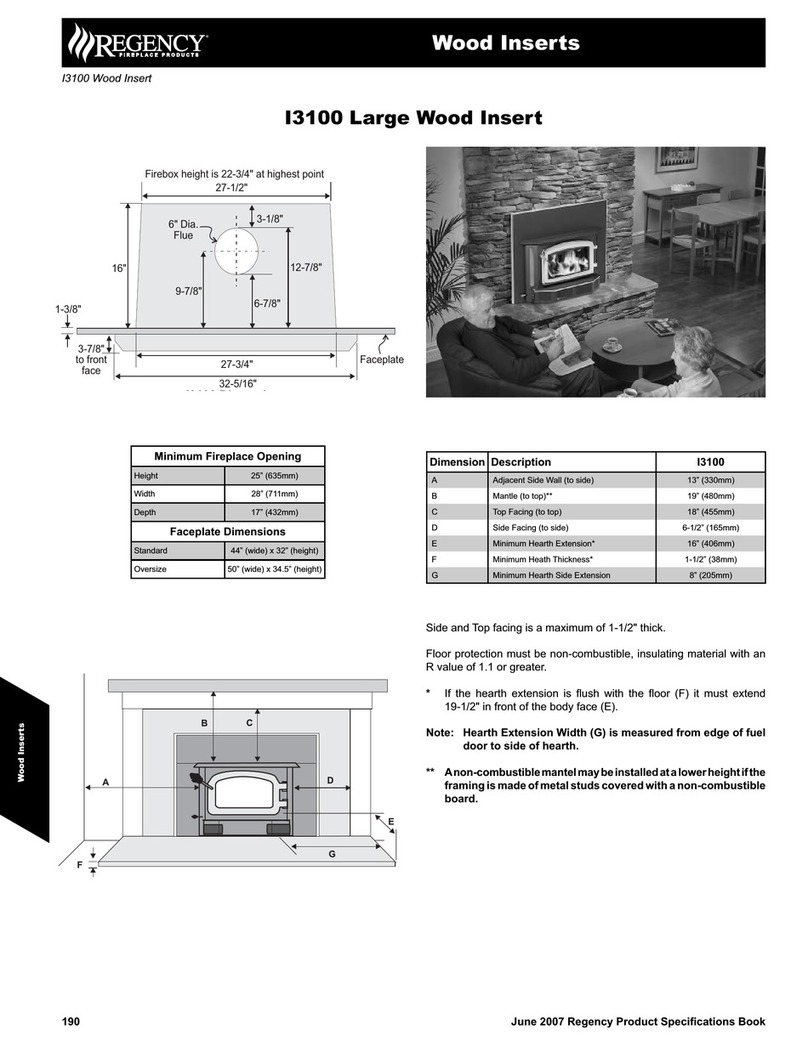

Regency I3100 Installation instructions

Regency

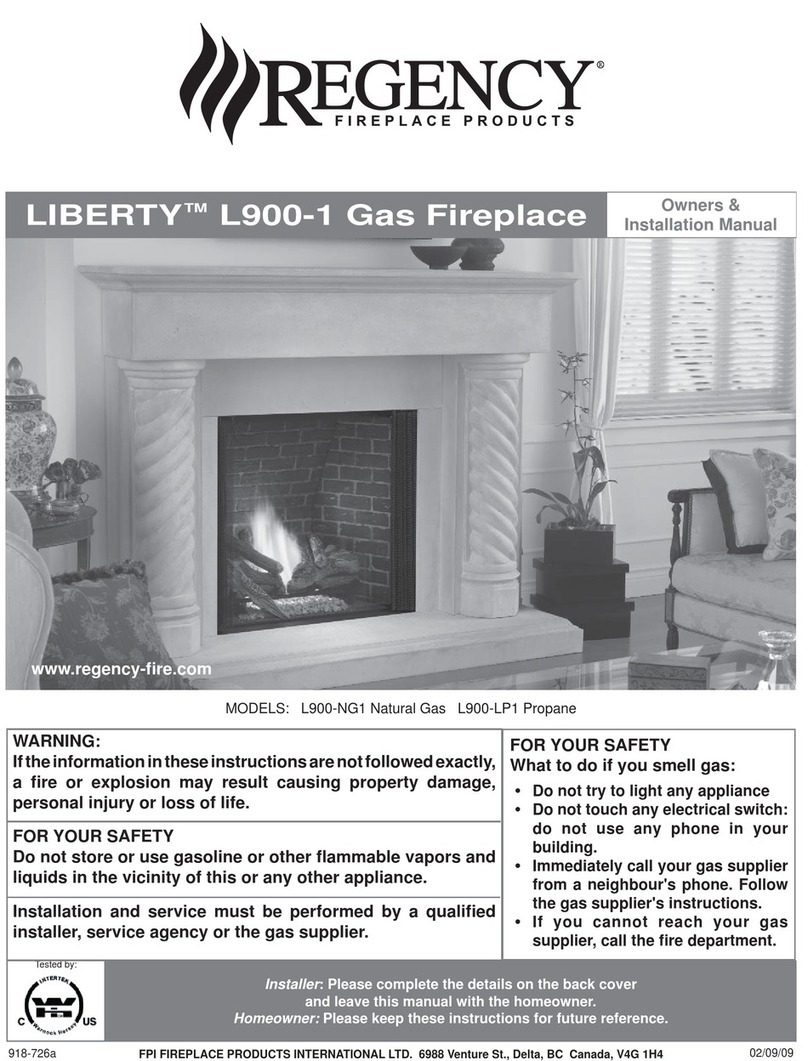

Regency Liberty L900 Gas Fireplace L900-NG1 Quick start guide

Regency

Regency 944-072 User manual

Regency

Regency Panorama PG33NG4-R Quick start guide

Regency

Regency U31-NG10 Quick start guide

Regency

Regency Grandview G600C Quick start guide

Regency

Regency IG35-NG Quick start guide

Regency

Regency classic fp90 Quick start guide

Regency

Regency HZ54E-NG10 Quick start guide

Regency

Regency E18-NG Quick start guide

Regency

Regency HZI234E-NG Quick start guide

Regency

Regency Cascades I1500 Quick start guide

Regency

Regency IG35-NG Quick start guide

Regency

Regency 510-994 User manual

Regency

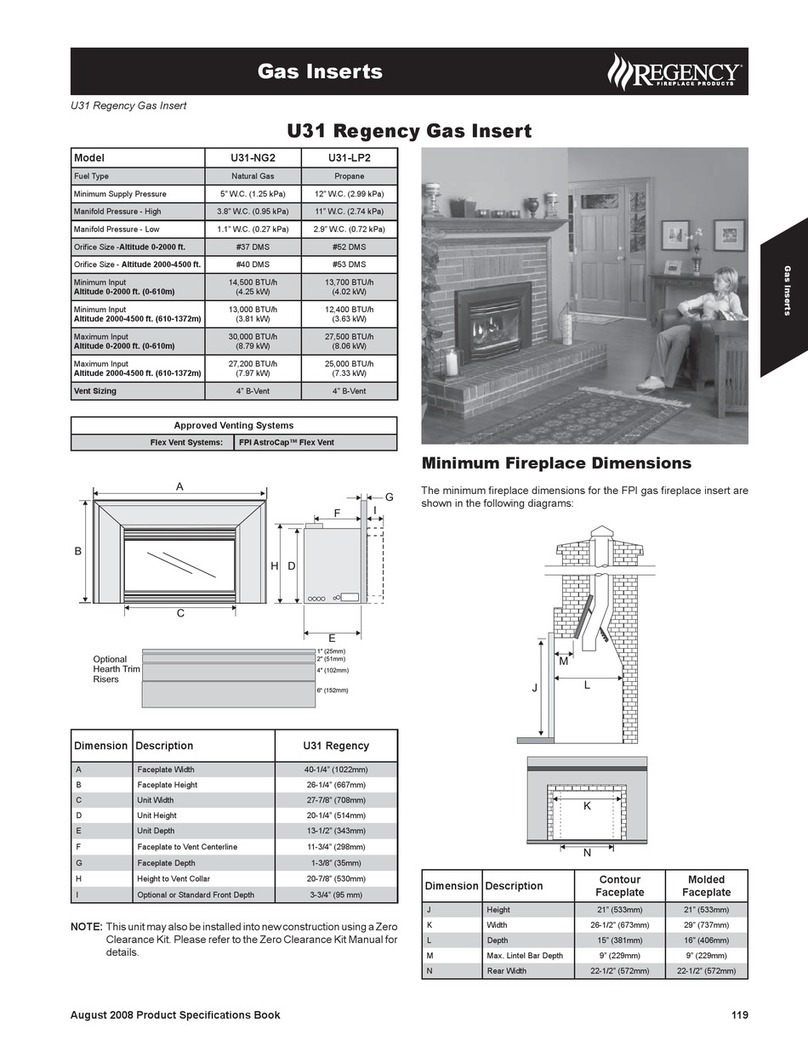

Regency Energy U31 User manual

Regency

Regency GF900L-NG Quick start guide

Regency

Regency L390PB Quick start guide

Regency

Regency U32E-NG5 Quick start guide

Regency

Regency HZ33CE-NG10 Quick start guide

Popular Indoor Fireplace manuals by other brands

Brigantia

Brigantia 35-DVRS31N-2 User's installation, operation and maintenance manual

Nordpeis

Nordpeis Bergen Installation and user manual

Superior

Superior BCT2536TMN Installation and operation instructions

Quadra-Fire

Quadra-Fire 5100I-GD-B owner's manual

Renaissance

Renaissance RUMFORD 1000 user manual

Lacunza

Lacunza IV-800 Instruction book

Baxi

Baxi 940 Installer and owner guide

Dru

Dru Maestro 60/2 Tall RCH installation manual

Diamond Fireglass

Diamond Fireglass SS-O22 General assembly, installation, and operation instructions

HearthStone

HearthStone Windsor Bay 8830 Owner's manual and installation guide

Napoleon

Napoleon ASCENT B42 quick start guide

Enviro

Enviro E33GI owner's manual

Smeg

Smeg L30 FABE Installation & user's instructions

KEDDY

KEDDY K700 Installation instructions care and firing instructions

Godin

Godin 3451 manual

Jøtul

Jøtul Jotul GI 535 DV IPI New Harbor Installation and operation instructions

Desa

Desa CCFPDFT Owner's operating & installation manual

Miles Industries

Miles Industries Vogue 1300IRN Installation & operating instructions