1 SAFETY

1.1 Used symbols and important safety instructions

Electrical voltage! Danger to life! Safety instructions are

marked with this symbol.

Note

1.2 Intended use

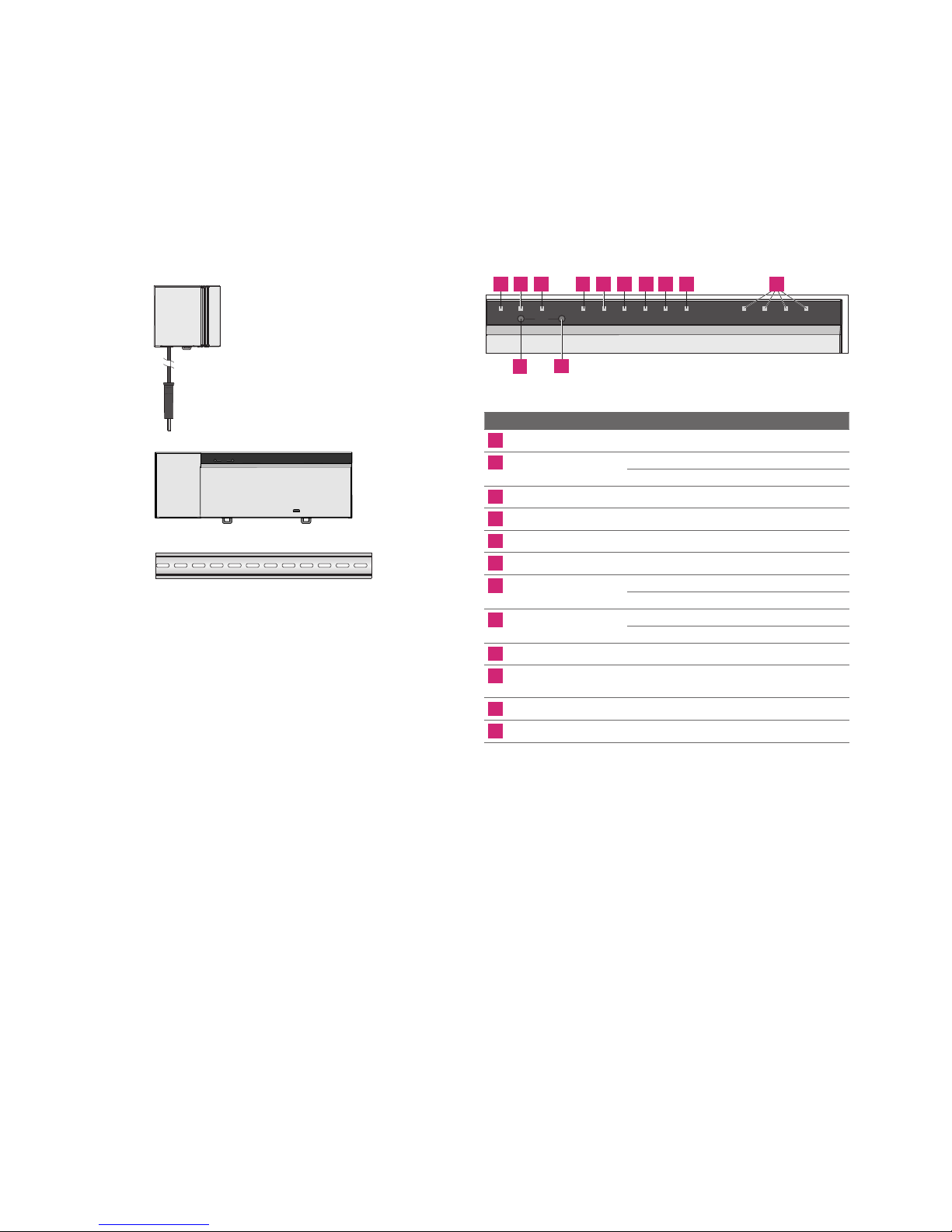

The NEA Smart base station 24 V is intended

- for a single room regulation system with a maximum of 8 zones for

heating and cooling systems,

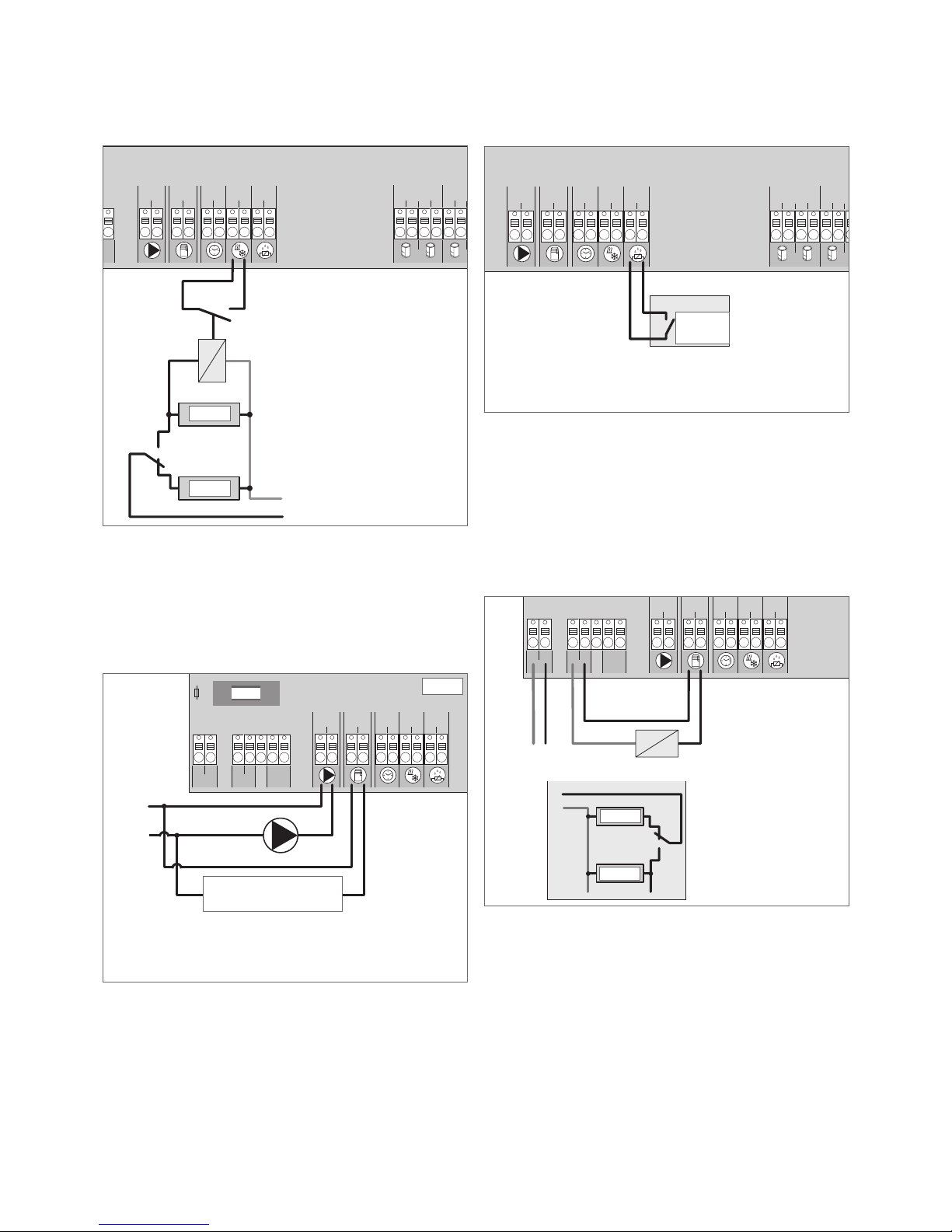

- for the connection of a maximum of 12 actuators UNI 24 V and any

combination of 8 NEA Smart R room control units, a pump, a CO

signalling unit, a humidity sensor with potential-free contact as well

as an external timer.

- for a fixed installation.

Every other use outside its intended use, the manufacturer cannot be

held liable for.

Modifications and conversions are expressively forbidden and lead to

dangers the manufacturer cannot be held liable for.

1.3 General safety warnings

Electrical voltage! Danger to life! The base station is live.

- Prior to opening always disconnect from the mains and

secure in such a way that it cannot accidentally be switched on.

- Disconnect all external voltages connected to the unit, e.g. at the

pump and the boiler contacts and ensure these cannot accidentally

be switched live.

Emergency

In case of emergency, disconnect the complete control system from

the mains.

Retain this manual and provide it to future owners.

1.4 Requirements with regard to personnel

Authorised specialists

The electrical installations must be performed according to the current

VDE regulations as well as according to the regulations of your local

electric power utility company. These instructions are intended for use

by a qualified person who is holding an ocial certificate in one of

the following professions: electrician or electronics engineer (accord-

ing to the profession designations ocially announced in the Federal

Republic of Germany, as well as according to comparable professions

within the European Community Law).

1.5 Restrictions regarding use of product

This base station is not intended to be used by people (including

children) with restricted physical, sensory or mental skills except if

they are supervised by a person responsible for their safety or have

received instructions on how to use this base station.

Children should be supervised in order to ensure that they do not play

with the device.

1.6 Compliance

This product is labelled with the CE Marking and therefore complies-

with the requirements from the following guidelines:

- 2004/108/EG with amendments “Council Directive on the approxi-

mation of the laws of the Member States relating to Electromagnetic

Compatibility”

- 2006/95/EG with amendments “Council for Coordination of the

Regulations of EU Member Countries regarding the electrical

equipment for use within certain voltage limits”

Increased protection requirements may exist for the overall installation,

the compliance of which is the responsibility of the installer.

3