Doc ID: 191-2870A

OVERVIEW

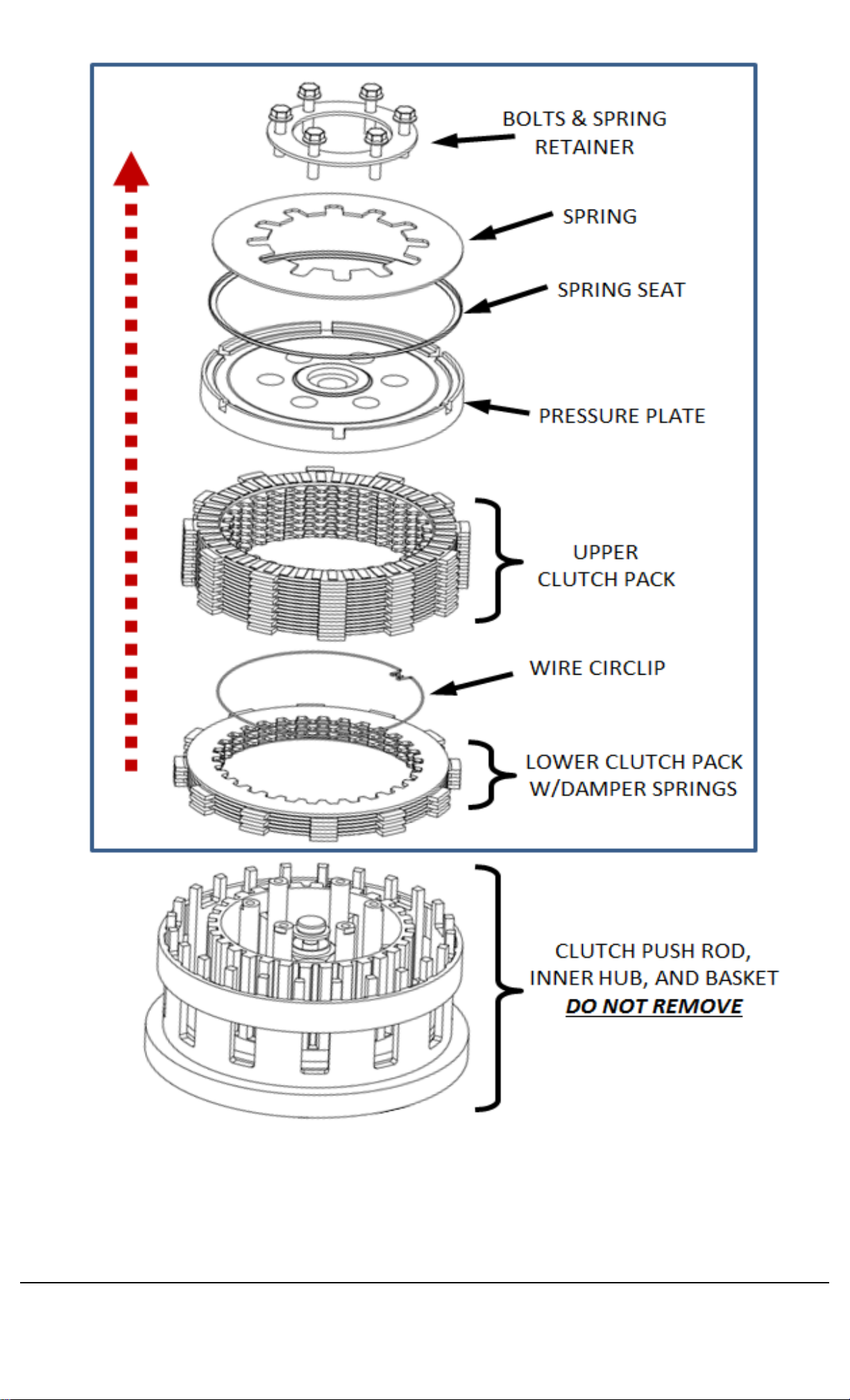

This kit replaces many of the OE (Original Equipment) clutch

parts. The following is a summary of what is replaced:

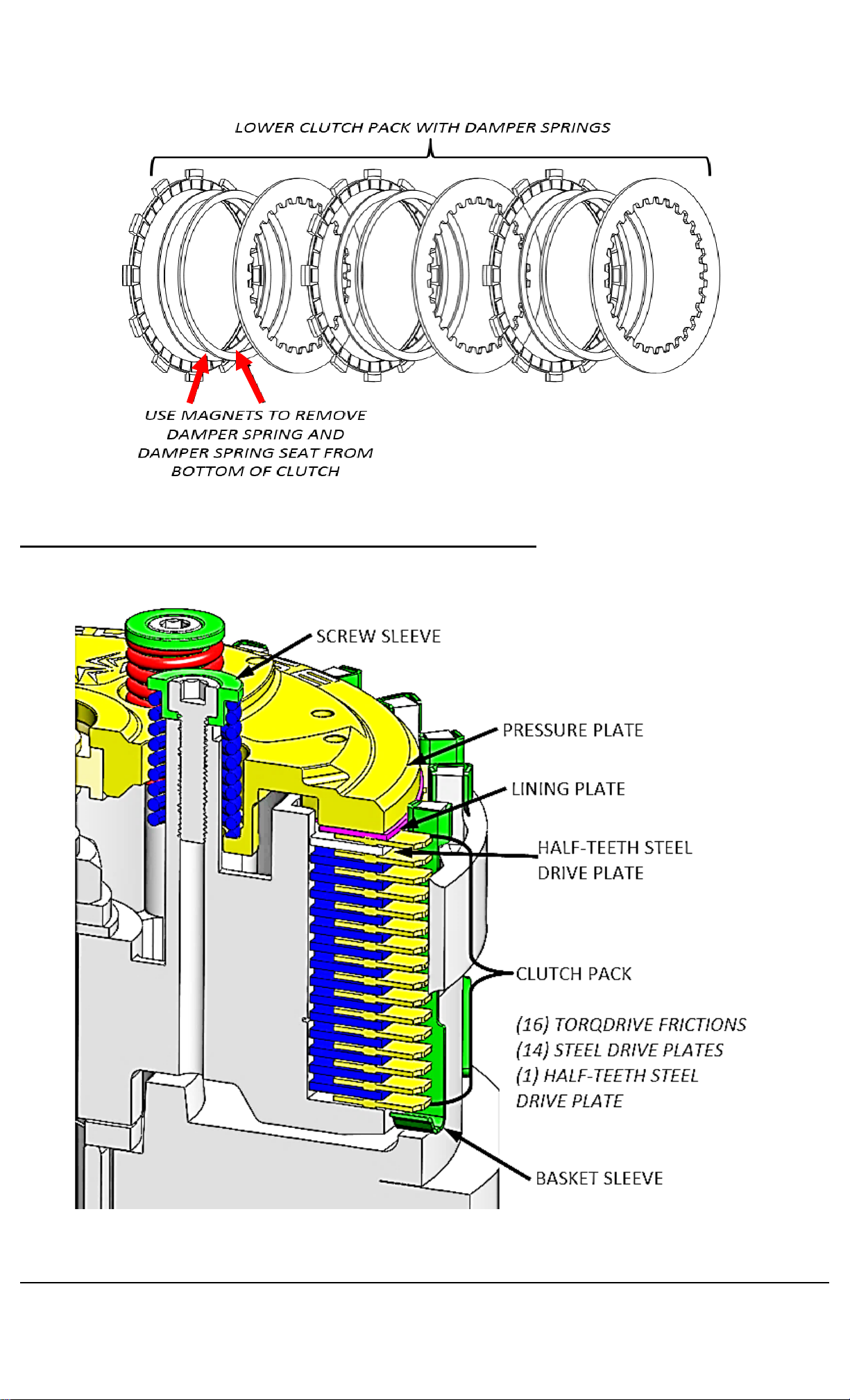

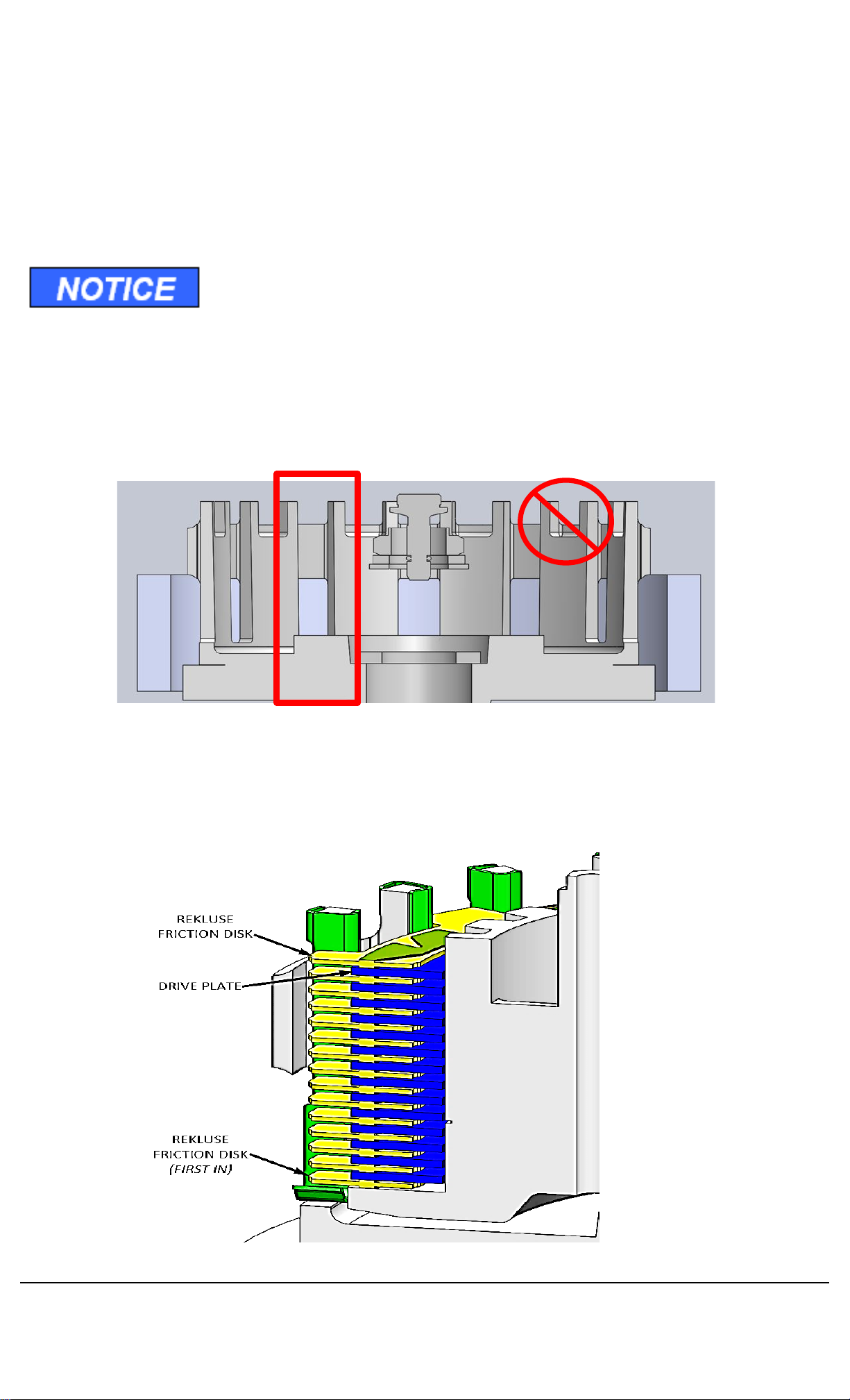

•This kit will replace all the OE frictions and drive plates with a

Rekluse thin friction clutch pack.

•The OE pressure plate is replaced with a Rekluse pressure

plate.

•The OE pressure plate springs are replaced with high quality

Rekluse springs.

INSTALLATION TIPS

•Read the separate included Safety

Information document before

operating the vehicle with the

product installed.

•Read this entire document before

performing any steps.

•If you install this product for a customer or another person,

instruct them to read the Safety Information document and

the Installation and User Guide before operating the bike

with the product.

•Protect eyes and skin – wear safety glasses and work gloves.

•Use the torque values listed in the instructions. Otherwise,

use the torque specifications found in your OE service

manual.

•Use clean, quality oil with the JASO-MA or JASO-MA2

certification for motorcycles for best performance.