Pipe connections

General

Pipes and other cold surfaces must be insulated with dif-

fusion-proof material to prevent condensation. Where

the cooling demand is high, fan convectors with drip trays

and drain connection are needed.

The brine circuit must be supplied with a pressure expan-

sion vessel. If there is already a level vessel installed this

should be replaced.

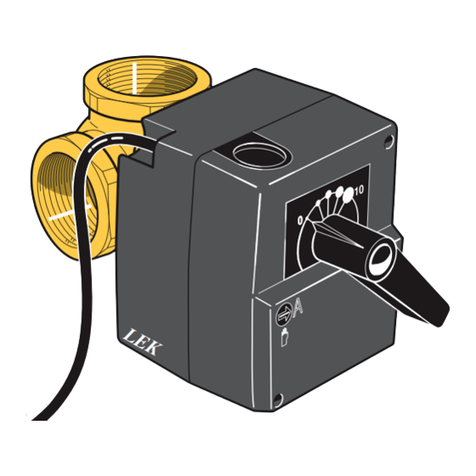

Check valve, mixing valve and circulation

pump

႑Install the supplied check valve between two T-pipe

connections to PCS 44 nearest the heat pump on

brine in (see the outline diagram).

႑Install the mixing valve (QN18) on the flow line to the

fan convector (port 1) so that port 1 is open towards

port 2 (blue coloured) when the motor is in idle mode.

In the event of a signal, port 1 opens towards port 3

(red coloured). The return line from the fan convector

is connected to the mixing valve (port 2) as well as

brine in closest to the heat pump.

႑Install the extra circulation pump (GP13) after the

mixing valve (QN18) on the flow line to the fan con-

vector.

LEK

Colour marking

1

2

3

Temperature sensor

႑Install the flow temperature sensor for the cooling

system (BT64) on the pipe after the circulation pump

(GP13) in the direction of flow.

႑Install the return line sensor for the cooling system

(BT65) on the pipe from the cooling system.

Install the temperature sensors with cable ties with the

heat conducting paste and aluminium tape. Then insulate

with supplied insulation tape.

NOTE

Sensor and communication cables must not be

placed near power cables.

Pump and pressure drop diagrams

Flöde

kPa

l/h

10

200

0

0

20

400

30

600

40

800

50

1000

60

1200

70

1400 1600 1800 2000

l/s

0,50,40,30,20,10

Max flöde:1700 l/h

Available pressure Max flow: 1700 l/h

Flow

10

B