CONTENTS

1.Brief instruction..............................................1

2 . M a i n s p e c i f i c a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.Operation preparation..............................................1

4. In st al li ng th e kn ee li ft er me ch an is m. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .1

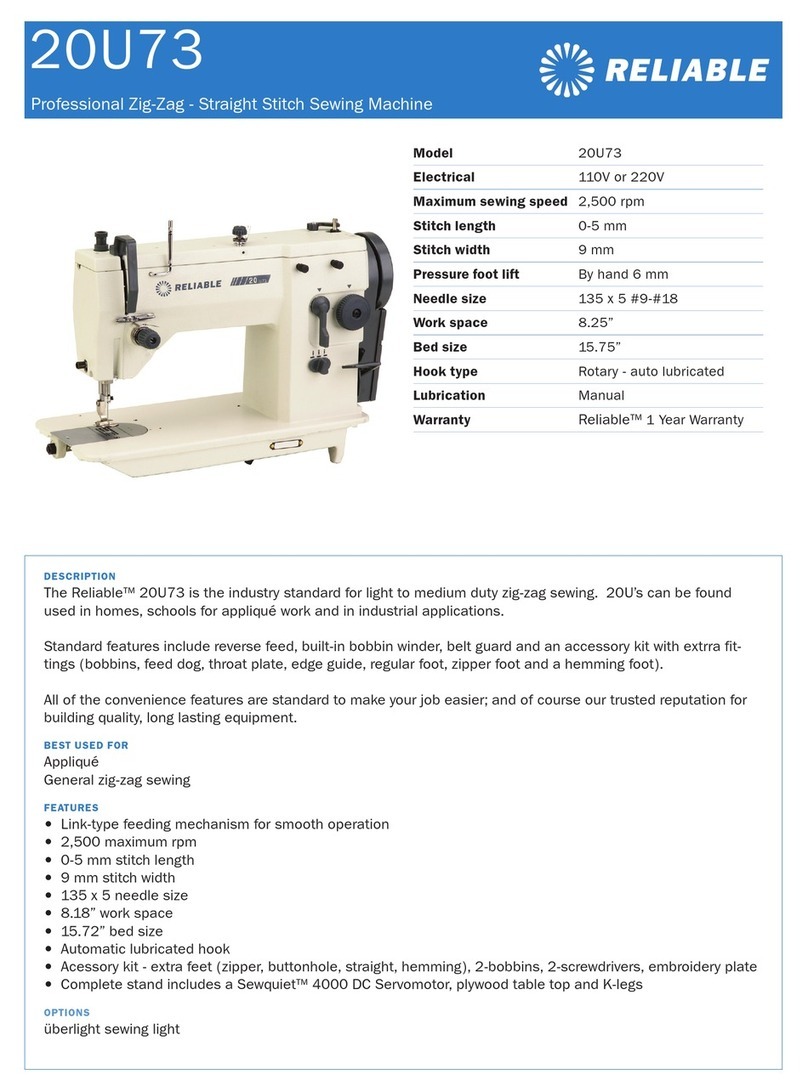

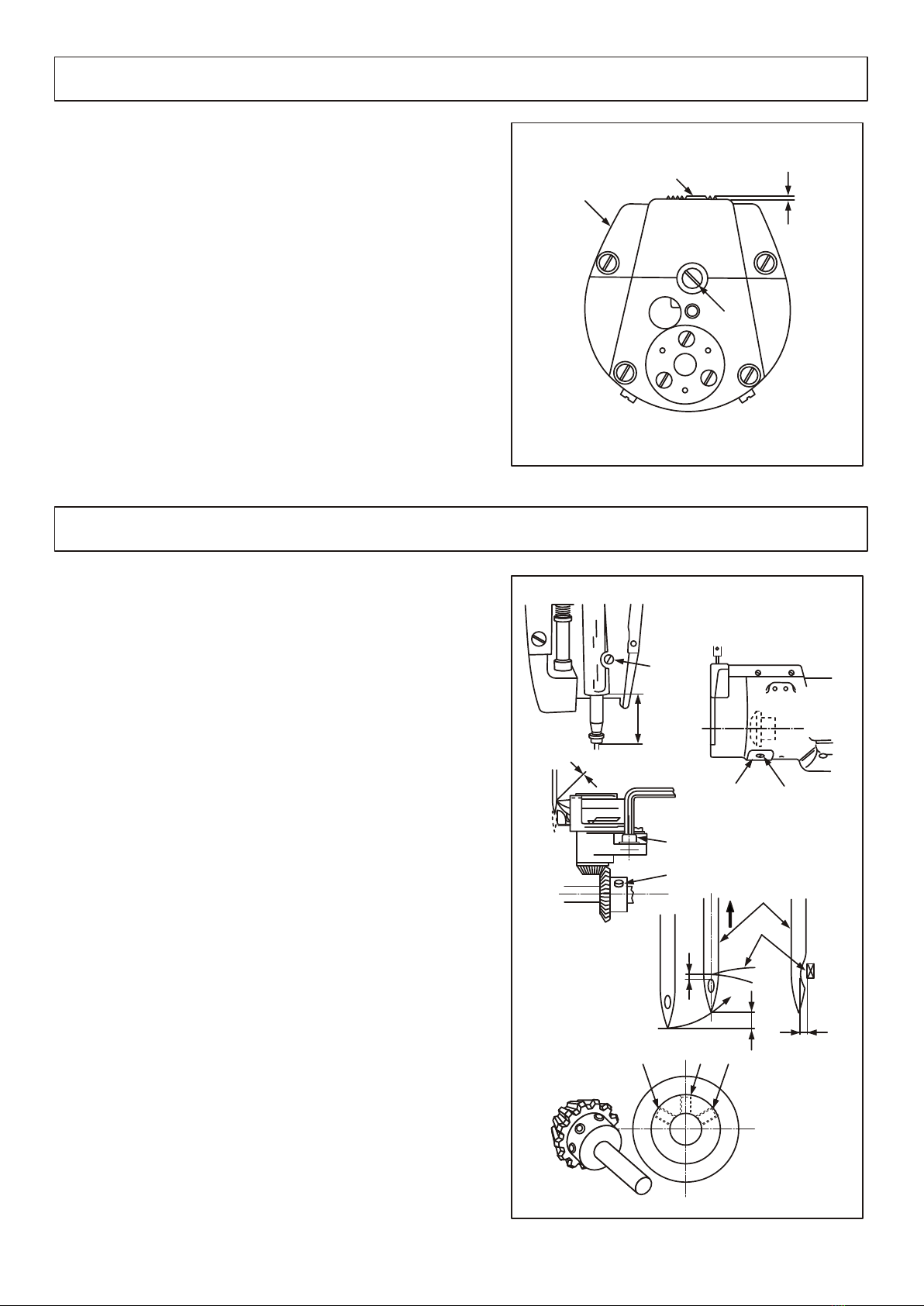

5.Lubrication.................................................2

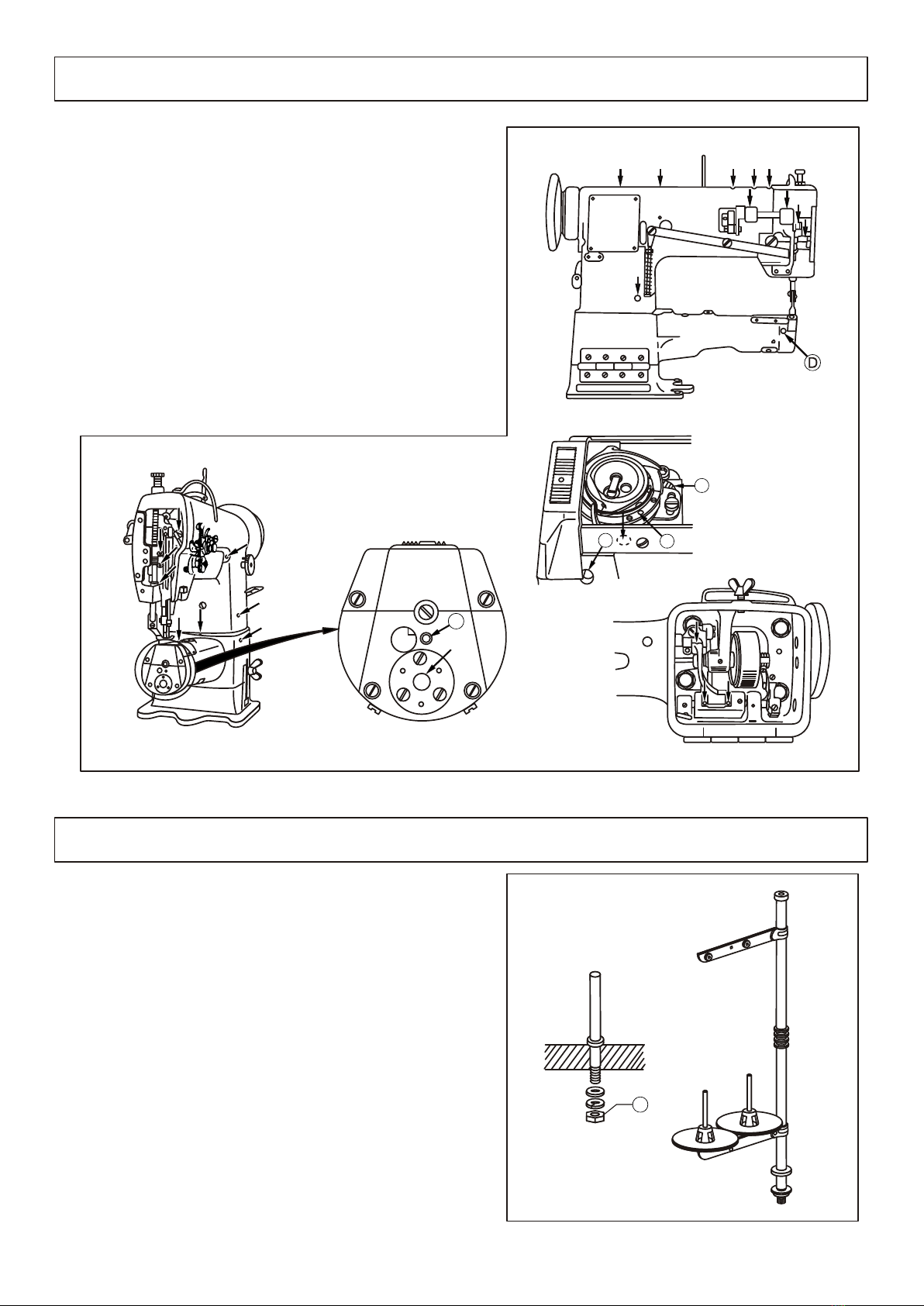

6 . I n s t a l l i n g t h e t h r e a d s t a n d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

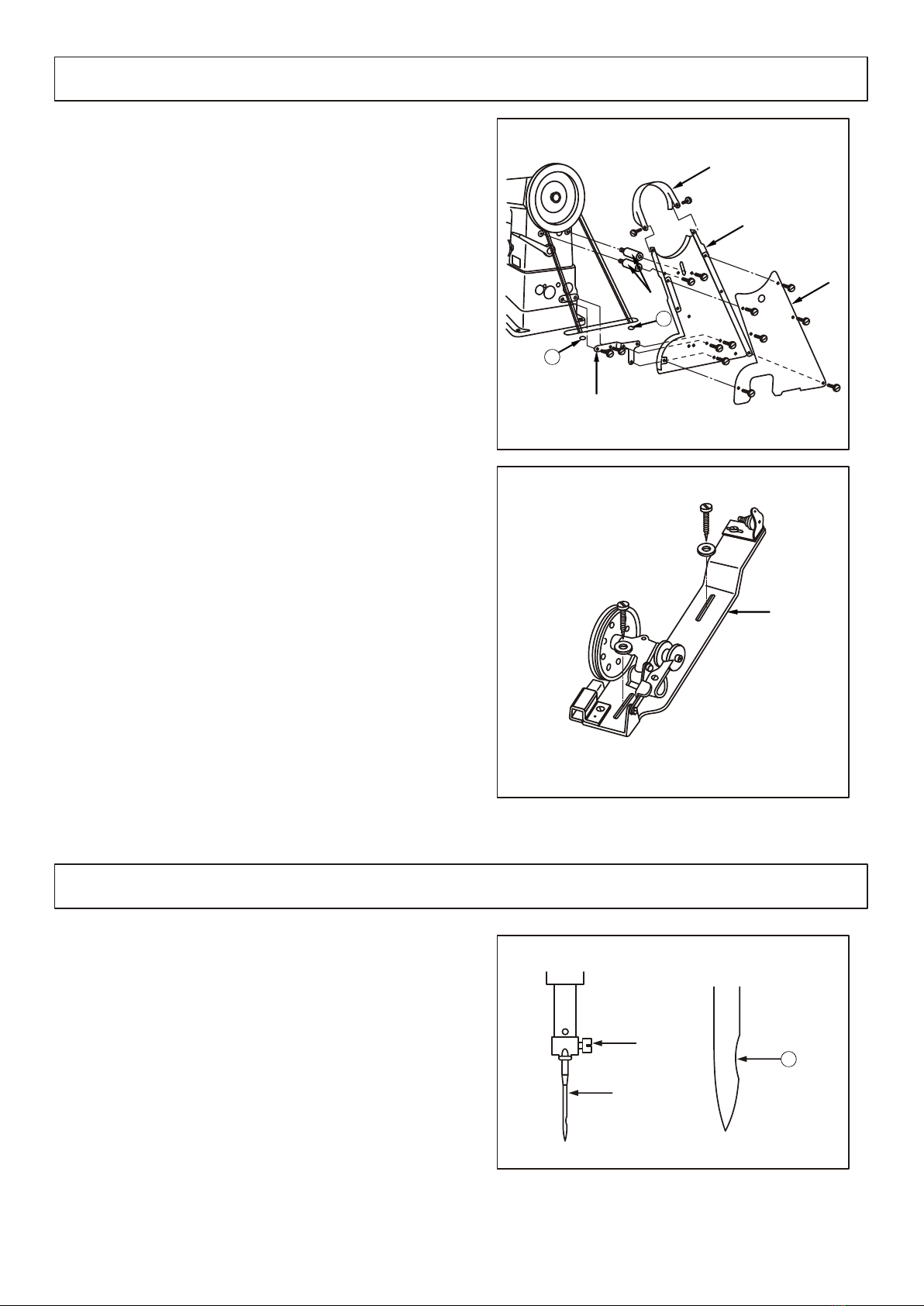

7. In st al li ng th e be lt co ve r an d bo bb in wi nd er .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .3

8 . I n s t a l l i n g t h e n e e d l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

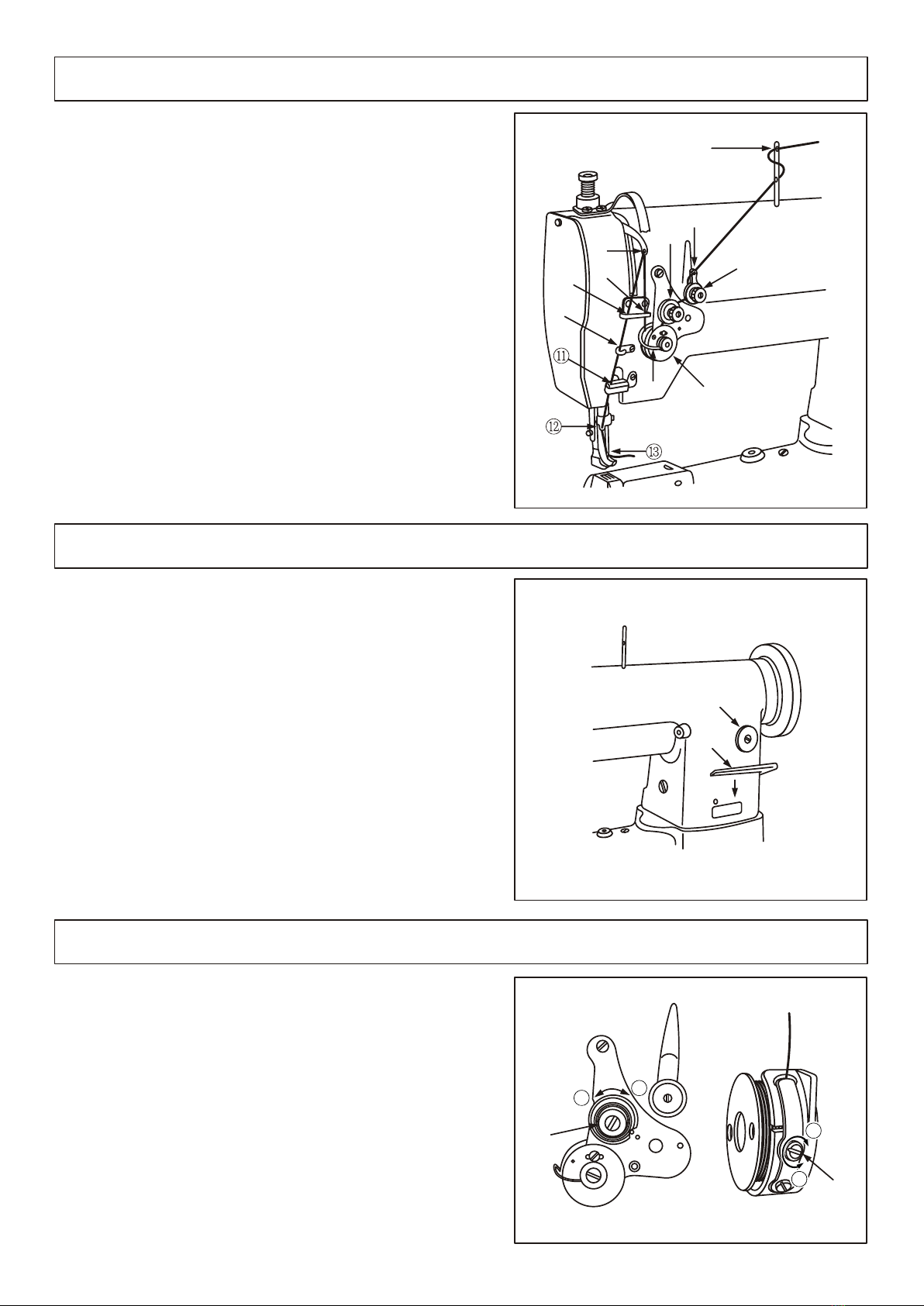

9 . I n s t a l l i n g t h e b o b b i n c a s e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 0 . W i n d i n g t h e b o b b i n t h r e a d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 1 . P u t t h e b o b b i n i n t o b o b b i n c a s e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 2 . T h r e a d i n g t h e n e e d l e t h r e a d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 3 . A d j u s t i n g t h e s t i t c h l e n g t h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 4 . T h r e a d t e n s i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 5 . T h r e a d t a k e - u p s p r i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1 6 . A d j u s t i n g t h e p r e s s u r e o f p r e s s e r f o o t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

17.Adjusting the height of presser foot.........................................6

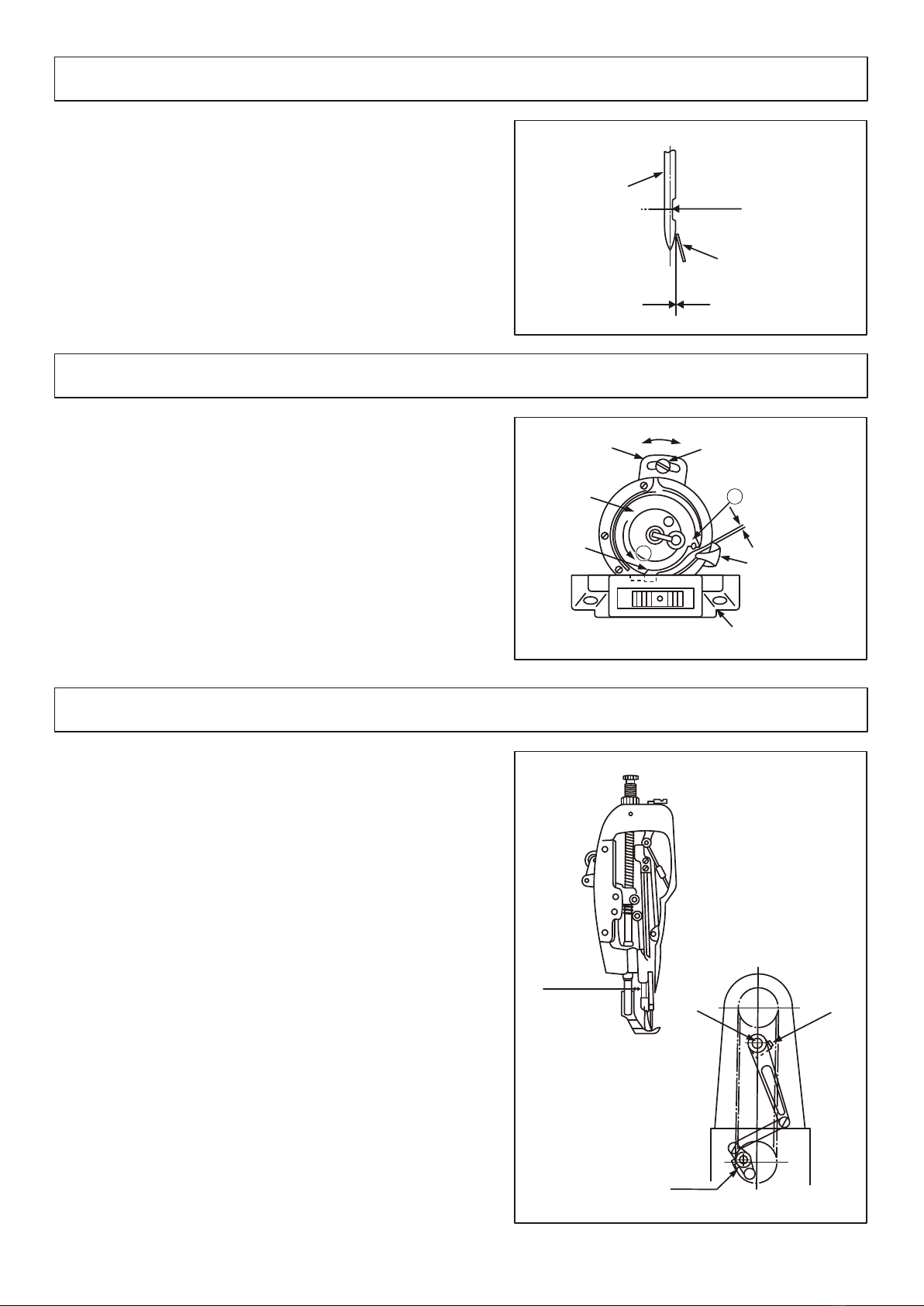

1 8 . A d j u s t i n g t h e h e i g h t o f f e e d d o g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 9 . A d j u s t i n g t h e n e e d l e a n d h o o k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

20.Adjusting the needle guard plate.....................................8

21.Adjusting the inner hook guide.......................................8

2 2 . A d j u s t i n g t h e l e n g t h w a y s p o s i t i o n o f n e e d l e b a r f r a m e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 3 . S a f e t y c l u t c h d e v i c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 4 . R e l o a d i n g t h e t i m i n g b e l t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

25.Ttrouble and remedy...................................10

1.Casting components..........................................11-12

2 . U p p e r s h a f t a n d t h r e a d t a k e - u p l e v e r c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3 - 1 4

3 . N e e d l e b a r a n d h o o k d r i v i n g s h a f t c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5 - 1 6

4 . P r e s s e r f o o t c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7 - 1 8

5 . U p p e r f e e d m e c h a n i s m c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9 - 2 0

6 . L o w e r f e e d m e c h a n i s m c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1 - 2 2

7.Thread tension components.......................................23-24

8. Be lt co ve r an d bo bb in wi nd er co mp on en ts .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 25 -2 6

9 . K n e e l i f t e r c o m p o n e n t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 7 - 2 8

1 0 . A c c e s s o r i e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 9 - 3 0

Operation instruction

Parts list