5.

switch.

System Electrical Requirements

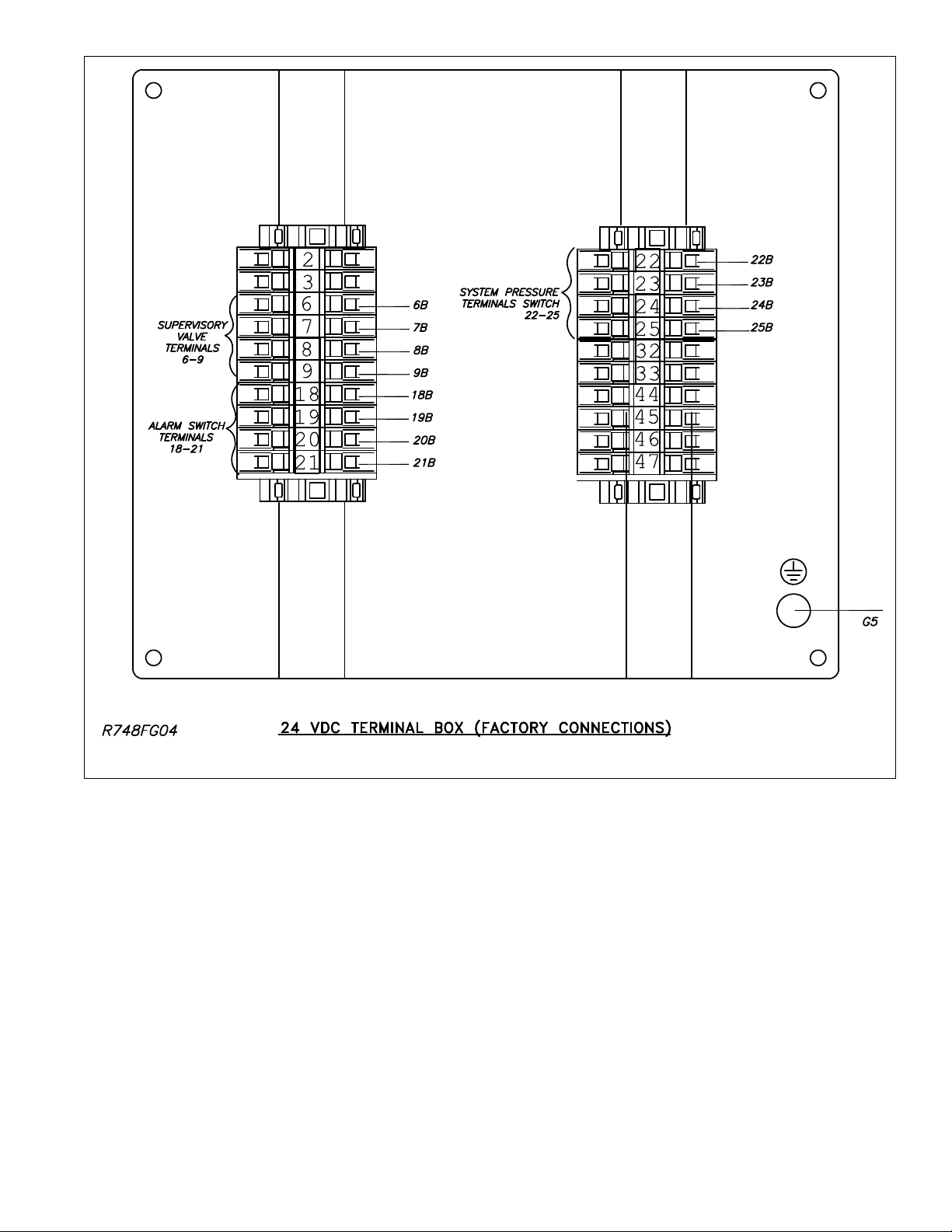

All 24 VDC electrical connections in the Reliable Model

DDX-LP PrePak are translated to a water tight terminal box

mounted on the inside of the enclosure. All field wiring con-

nections are made at this terminal box.

A separate power connection is provided for the optional

air compressor.

Note: The air compressor must be connected to a

grounded metallic, permanent wiring system, or an equip-

ment grounding terminal or lead on the product. Power sup-

ply wiring must conform to all required safety codes and be

installed by a qualified person. Check that the supply volt-

age agrees with that listed on compressor nameplate. Also

the wires running from the main electrical supply to the com-

pressor must agree with the values specified in Table C. An

undersized wire is a potential fire hazard and will cause a

drop in line voltage resulting in loss of power causing the

compressor to overheat.

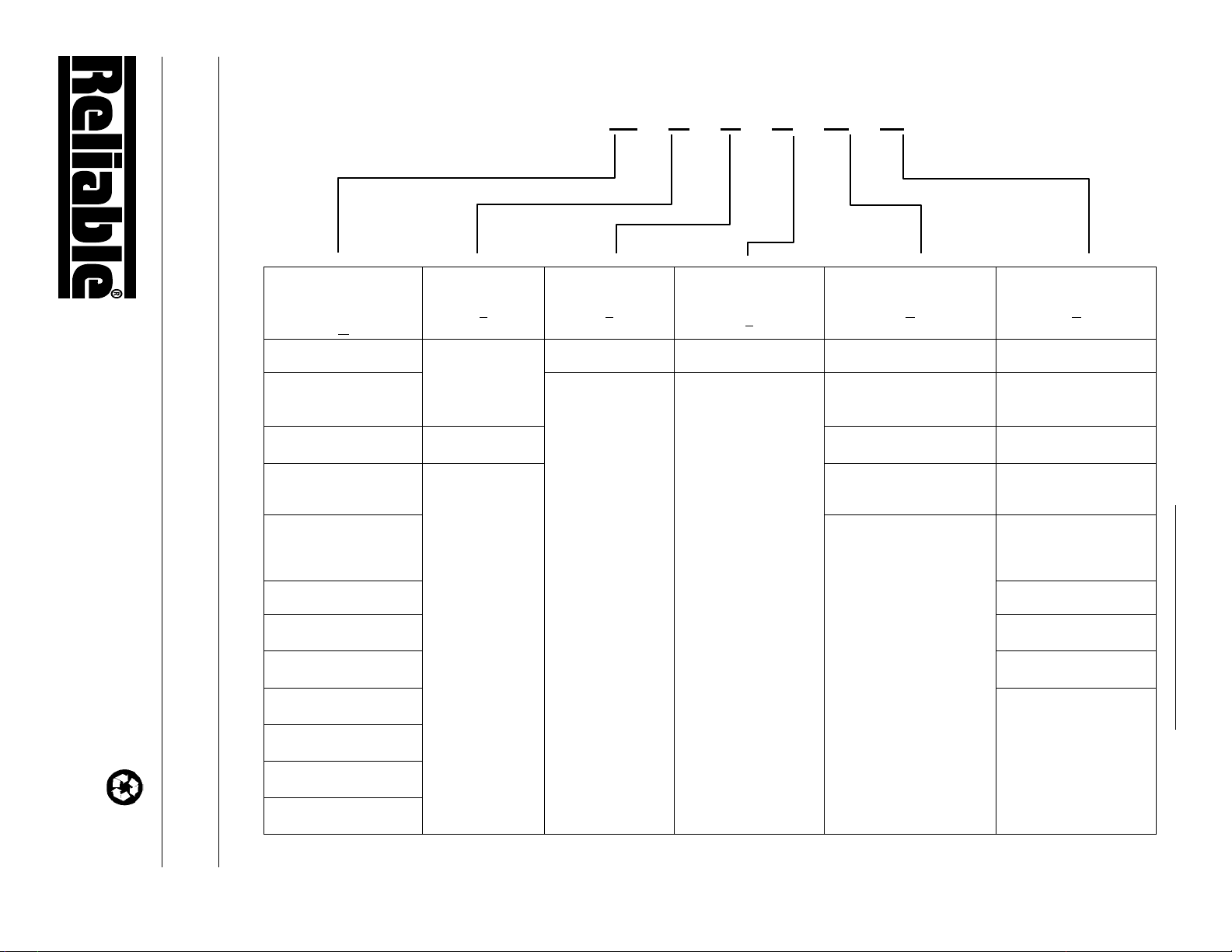

Table C

Amps Volts Length of cord in feet

120v 20 50 100 150 200 250 300 400 500

240v 60 100 200 300 400 500 600 800 1000

0-2 18 18 18 16 16 14 14 12 12

2-3 18 18 16 14 14 12 12 10 10

3-4 18 18 16 14 12 12 10 10 8

4-5 18 18 14 12 12 10 10 8 8

5-6 18 16 14 12 10 10 8 8 8

6-8 18 16 12 10 10 8 6 6 6

8-10 18 14 12 10 8 8 6 6 4

10-12 16 14 10 8 8 6 6 4 4

12-14 16 12 10 8 6 6 6 4 2

14-16 16 12 10 8 6 6 4 4 2

16-18 14 12 8 8 6 4 4 2 2

18-20 14 12 8 6 6 4 4 2 2

The Reliable Model DDX-LP PrePak is available with the

following factory installed electrical devices:

1. A system low air pressure switch, which is used to

monitor sprinkler piping.

2. An alarm pressure switch, which indicates actuation

of the system.

3. An optional low nitrogen pressure switch, which indi-

cates a depleted nitrogen supply.

4. An optional air compressor.

5. A supervised supply side butterfly water control valve.

6. A optional supervised system side butterfly water con-

trol valve.

The factory electrical connections of these devices are

illustrated in Fig. 3.

Maintenance

The Reliable DDX-LP PrePak and associated equipment

shall periodically be given a thorough inspection and test.

NFPA 25, Standard for Inspection, Testing and Maintenance

of Water Based Fire Protection Systems, provides minimum

maintenance requirements. Systems should be tested, op-

erated, cleaned and inspected at least annually, and parts

replaced as required. Periodically open the condensate

drain valve beneath the air tank to drain any condensate ac-

cumulation. Reliable Technical Bulletins 338 and 519 pro-

vide additional information for maintaining the Model DDX-

LP PrePak Deluge Valve.

System Setup (Refer to Figure 2)

1. Close the main valve controlling water supply to the

Model DDX-LP PrePak deluge valve. Also, close the

two ¼” valves supplying air or nitrogen to the system.

2. Close the pushrod chamber supply valve.

3. Open the main drain valve and drain the system.

4. Open all drain valves and vents at low points through-

out the system, closing them when flow of water has

stopped.

5. Open the Manual Emergency Release valve. Note: The

above steps accomplish the relieving of pressure in the

pushrod chamber of the deluge valve.

6. Push in the plunger of ball drip valve to force the ball

from its seat, and drain any water in the alarm line.

7. Push in and rotate the deluge valve’s external reset knob

counter-clockwise (when facing valve) until you hear a

distinct clicking noise, indicating that the clapper has

reset. Note: The reset knob can be rotated only after

pressure in the pushrod chamber is reduced to atmo-

spheric conditions (0 psig).

8. Inspect and replace any portion of the sprinkler system

subjected to fire conditions.

9. Verify that the following valves are in their respective po-

sitions prior to continuing:

Manual Emergency Release - open

Main Drain Valve - open

Alarm Line Valve - open

Alarm Test Valve - closed

Condensate Drain valve - closed

Air/Nitrogen Supply Valves - closed

10. Open pushrod chamber supply valve and allow water

to fill the pushrod chamber. Close the Manual Emer-

gency Release valve after any trapped air has had a

chance to escape from the deluge valve’s pushrod

chamber.

11. Upon seeing this solid flow of water coming out of the

Model LP Dry Pilot Actuator, open the Rapid-Air Fill

Valve thereby rapidly applying compressed air or ni-

trogen into the Model LP Dry Pilot Actuator and the

sprinkler system until the pressure conforms to Table

A levels, as indicated by the system air pressure

gauge. The Model LP Dry Pilot Actuator will eventually

close during this pressurizing process and water will

stop flowing through the drain tube. At this point, the

pressure gauge on the pushrod chamber pressure will

equalize to the available water supply pressure. Once

the actuator is set up correctly, close the Rapid-Air Fill

Valve and open the Regulated Air Shutoff Valve.

Note: For systems using nitrogen as the primary

source, the system may be set up using the nitrogen

source following the steps above. The air compres-

sor, if present, may then be placed into operation as

the backup pneumatic source.