5.

System Operation (Single Interlock)

To fully activate and discharge water from the Reliable Mod-

el DDX Type D PrePaK in a single interlock application, a fire

detection device (smoke, heat, etc.; or two devices with cross-

zoned detection) must activate. Subsequently, a fire sprinkler

must open.

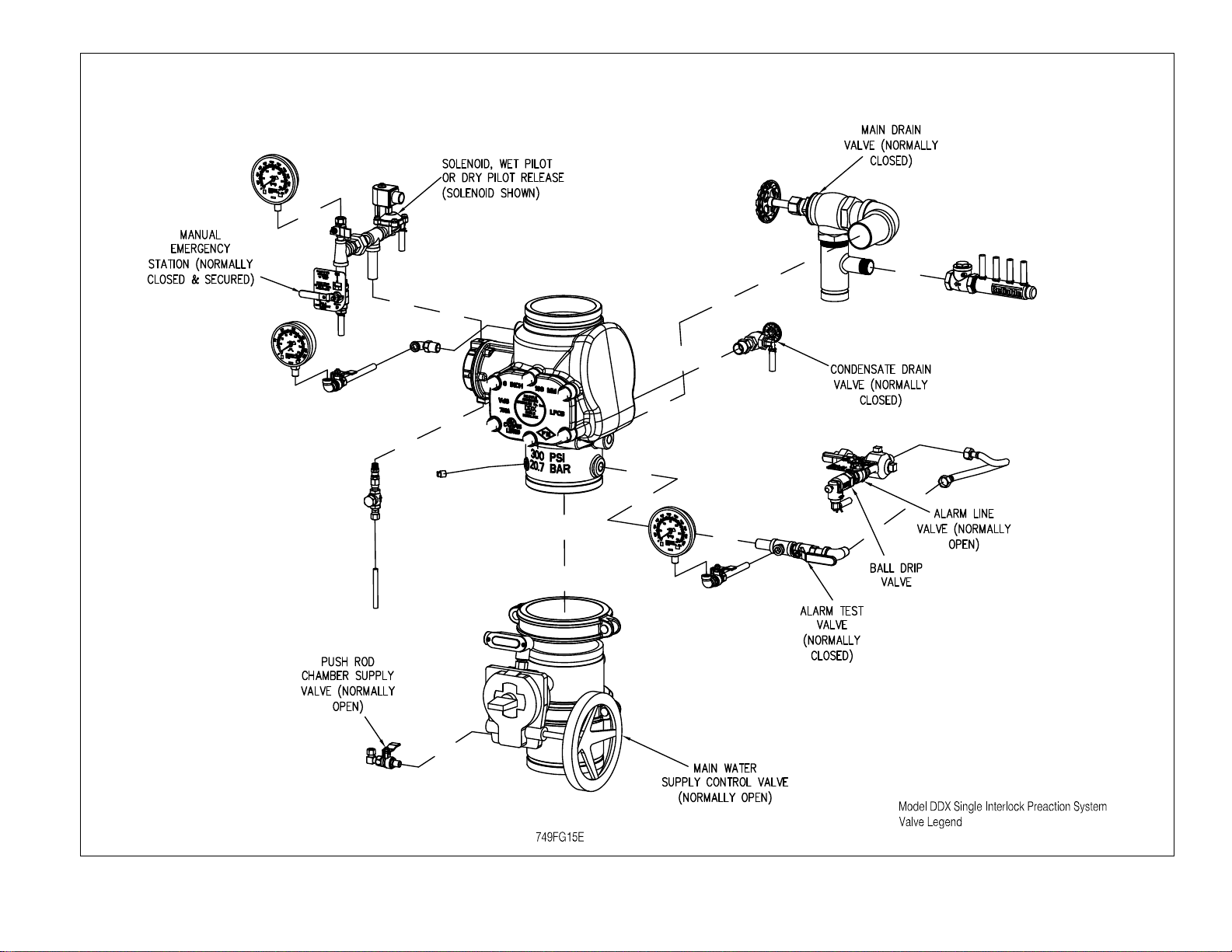

When the single interlock preaction system is set for service,

the supply pressure acts both on the underside of the deluge

valve’s clapper and on the valve’s push rod by means of the

pressurized push rod chamber. The pressure force acting on

the push rod, when utilized with the mechanical advantage of

the deluge valve’s lever, is more than sufficient to hold the clap-

per in the closed position against the water supply pressure.

Energizing the releasing solenoid the pushrod chamber sup-

ply valve allows the deluge valve push-rod chamber to be vent-

ed to drain. Since the pressure cannot be replenished through

the inlet restriction as rapidly as it is vented though the outlet,

the push-rod chamber pressure falls rapidly. When the push-rod

chamber pressure drops below one-third of the supply pres-

sure, the opening force acting beneath the clapper becomes

greater than the push-rod force acting on the lever. This causes

the clapper to open. Refer to Reliable Bulletin 519 for further de-

tails.

Once the clapper has opened, the lever acts as a latch, pre-

venting the clapper from returning to the closed position. Water

from the supply flows through the deluge valve into the system

piping. Water also flows through the deluge the pushrod cham-

ber supply valve alarm outlet to activate any water flow alarm

devices. Note that the solenoid valve will be maintained open by

the Potter Model PFC-4410-RC Releasing Control Panel’s latch-

ing feature until it is reset for operation.

After system shutdown and draining, the Model DDX Deluge

Valve is easily reset without special tools using the external re-

set feature. Restore detection devices by resetting or replacing

any operated device. Once detection devices are restored, (the

Potter Model PFC-4410-RC Releasing Control Panel reset), and

supply pressure is re-supplied to the push-rod chamber, the

deluge valve is reset.

System Operation (Double Interlock)

To fully activate and discharge water from the Reliable Model

DDX Type D PrePaK in a double interlock application, two inde-

pendent events must coexist. An electrical fire detection device

(smoke, heat, etc.) and the system air pressure switch must be

activated. This pressure switch is activated by a reduction of the

system pneumatic pressure as a result of sprinkler operation.

Both of these events will cause the control panel to energize the

solenoid valve, thereby releasing water through the deluge the

pushrod chamber supply valve and into the sprinkler system.

The initiation of either one of these events will only cause an

alarm to annunciate, and will not fill the sprinkler system.

When the double interlock preaction system is set for service,

the supply pressure acts both on the underside of the deluge

valve’s clapper and on the valve’s push rod by means of the

pressurized push rod chamber. The pressure force acting on

the push rod, when utilized with the mechanical advantage of

the deluge valve’s lever, is more than sufficient to hold the clap-

per in the closed position against the water supply pressure.

Energizing the releasing solenoid the pushrod chamber sup-

ply valve allows the deluge valve push-rod chamber to be vent-

ed to drain. Since the pressure cannot be replenished through

the inlet restriction as rapidly as it is vented though the outlet,

the push-rod chamber pressure falls rapidly. When the push-rod

chamber pressure drops below one-third of the supply pres-

sure, the opening force acting beneath the clapper becomes

greater than the push-rod force acting on the lever. This causes

the clapper to open. Refer to Reliable Bulletin 519 for further de-

tails.

Once the clapper has opened, the lever acts as a latch, pre-

venting the clapper from returning to the closed position. Water

from the supply flows through the deluge valve into the system

piping. Water also flows through the deluge the pushrod cham-

ber supply valve alarm outlet to activate any water flow alarm

devices. Note that the solenoid valve will be maintained open by

the Potter Model PFC-4410-RC Releasing Control Panel’s latch-

ing feature until it is reset for operation.

After system shutdown and draining, the Model DDX Deluge

Valve is easily reset without special tools using the external re-

set feature. Restore detection devices by resetting or replacing

any operated device. Once detection devices are restored, (the

Potter Model PFC-4410-RC Releasing Control Panel reset), and

supply pressure is re-supplied to the push-rod chamber, the

deluge valve is reset.

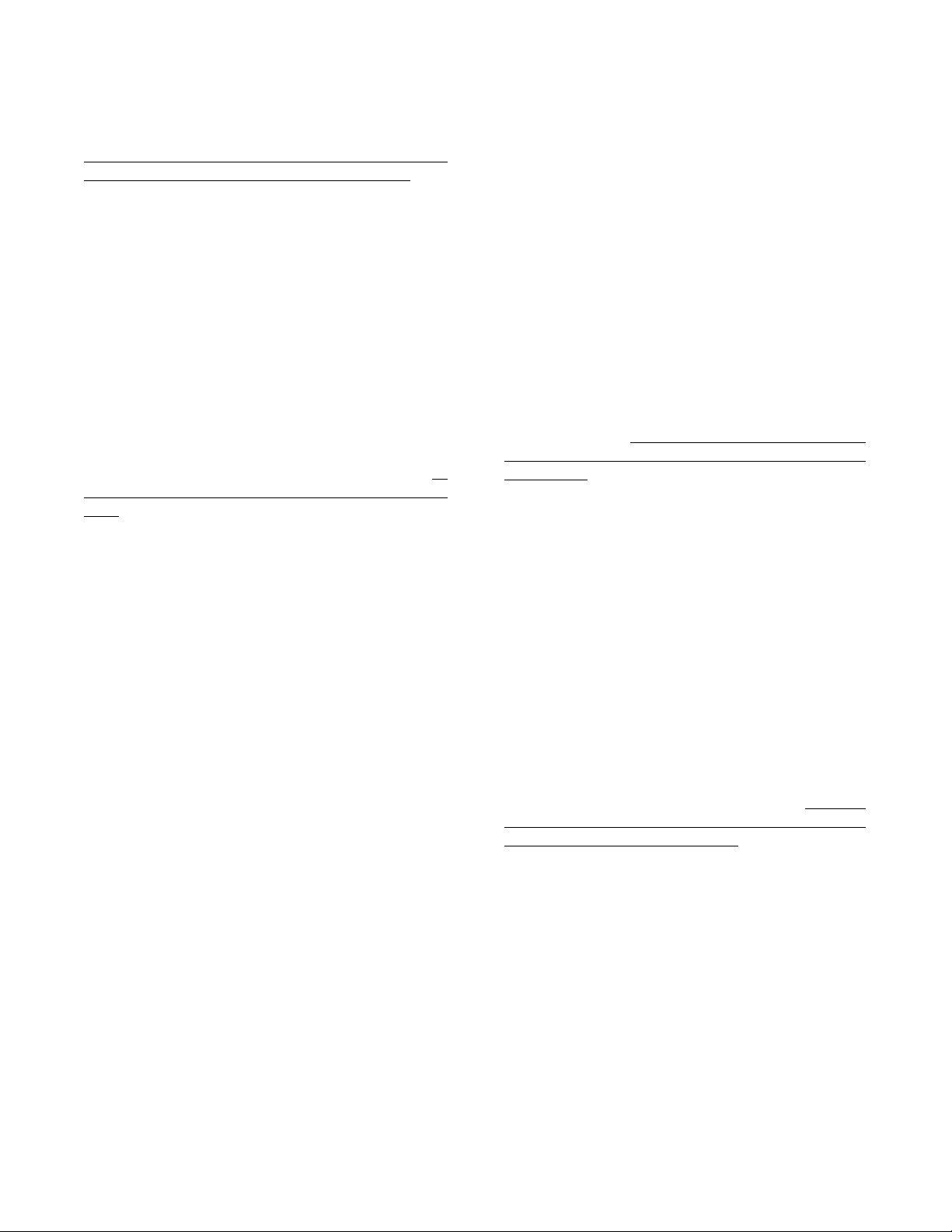

Resetting Single And Double Interlock Systems

1. Close the main valve controlling water supply to the deluge

the pushrod chamber supply valve and close the ¼” air

shutoff valve.

2. Close the pushrod chamber supply valve.

3. Open the main drain the pushrod chamber supply valve

and drain system.

4. Open all drain valves and vents at low points throughout

the system, closing them when flow of water has stopped.

Open the Manual Emergency Release Valve. Note: The

above steps accomplish the relieving of pressure in the

pushrod chamber of the deluge valve.

5. Push in the plunger of ball drip valve to force the ball from its

seat, and drain any water in the alarm line.

6. With the Model B Manual Emergency Station open, push

in and rotate the deluge the alarm test valve external re-

set knob counterclockwise (when facing valve) until you

hear a distinct clicking noise, indicating that the clapper

has closed. Note: The reset knob can be rotated only after

pressure in the pushrod chamber is reduced to atmospher-

ic conditions (0 psig).

7. Inspect and replace any portion of the sprinkler system

subjected to fire conditions.

8. Verify that the following valves are in their respective posi-

tions:

Manual Emergency Release - open

Main Drain Valve - open

Alarm Line Valve - open

Alarm Test Valve - closed

Condensate Drain valve - closed

Air Supply Valves - closed

9. Open the pushrod chamber supply the pushrod chamber

supply valve and allow water to fill the deluge valve push-

rod chamber. Close the Manual Emergency Release valve.