2

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE. Refer to this manual for assistance

or consult the local electric utility for further information.

WARNING

At the time of manufacture this water heater was provided with

a combination temperature-pressure relief valve certified by

a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials, as meeting the requirements for Relief Valves and

Automatic Gas Shut-off Devices for Hot Water Supply Systems,

and the current edition of ANSI Z21.22 • CSA 4.4 and the code

requirements of ASME. If replaced, the valve must meet the

requirements of local codes, but not less than a combination

temperature and pressure relief valve certified as meeting the

requirements for Relief Valves and Automatic Gas Shut-off

Devices for Hot Water Supply Systems, ANSI Z21.22 • CSA 4.4

by a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressure not to

exceed the marked hydrostatic working pressure of the water

heater (150 lbs. p.s.i.) and a discharge capacity not less than

the water heater input rate as shown on the model rating plate.

(Electric heaters - watts divided by 1000 x 3412 equal BTU/Hr.

rate.)

Your local jurisdictional authority, while mandating the use of a

temperature-pressure relief valve complying with ANSI Z21.22

• CSA 4.4 and ASME, may require a valve model different from

the one furnished with the water heater.

Compliance with such local requirements must be satisfied

by the installer or end user of the water heater with a locally

prescribed temperature-pressure relief valve installed in the

designated opening in the water heater in place of the factory

furnished valve.

For safe operation of the water heater, the relief valve must not

be removed from it’s designated opening or plugged.

The temperature-pressure relief valve must be installed directly

into the fitting of the water heater designated for the relief valve.

Position the valve downward and provide tubing so that any

discharge will exit only within 6 inches above, or at any distance

below the structural floor. Be certain that no contact is made

with any live electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances. Excessive

length, over 30 feet, or use of more than four elbows can cause

restriction and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between the relief

valve and the tank. Do not connect tubing directly to discharge

drain unless a 6" air gap is provided. To prevent bodily injury,

hazard to life, or property damage, the relief valve must be

allowed to discharge water in quantities should circumstances

demand. If the discharge pipe is not connected to a drain or

other suitable means, the water flow may cause property

damage.

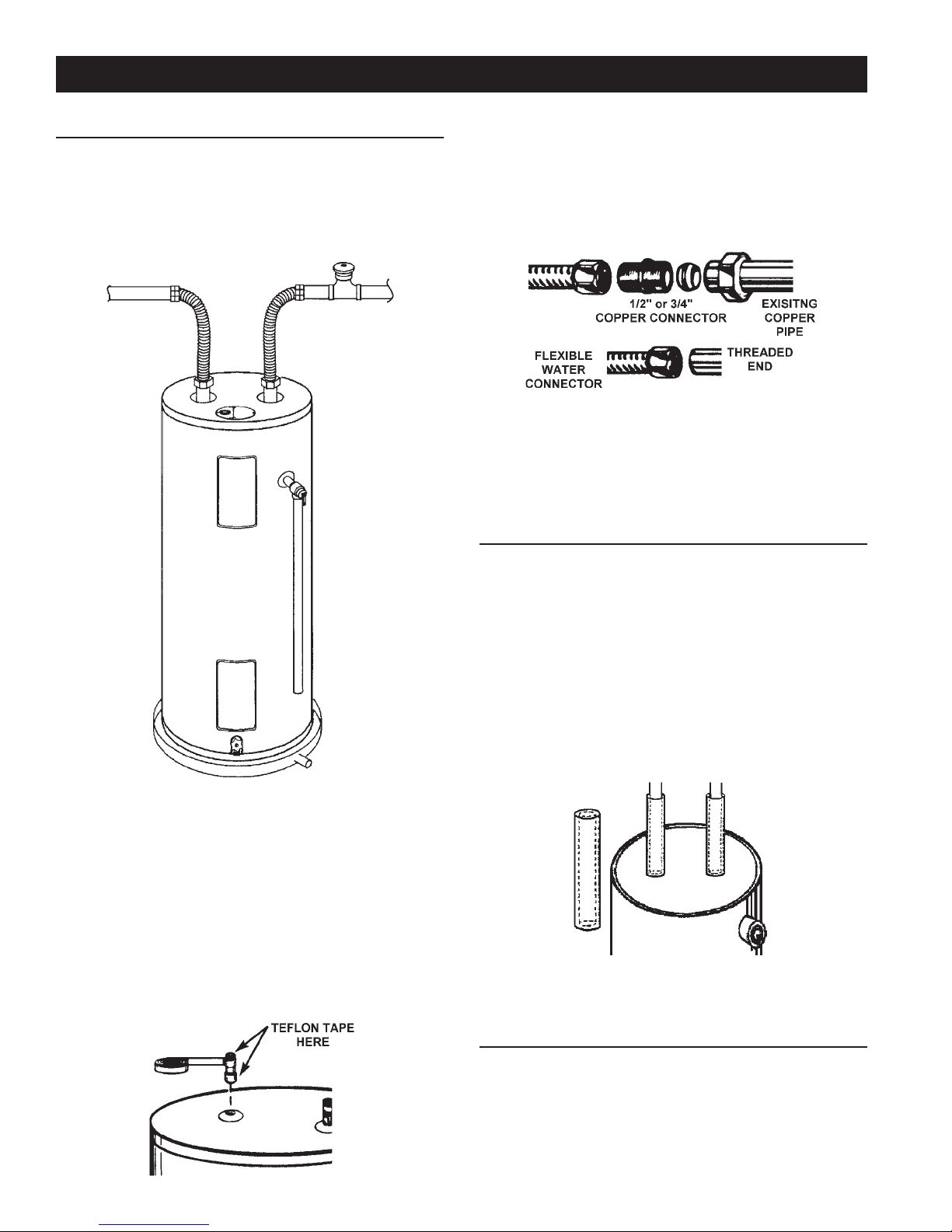

The Discharge Pipe:

• Must not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Must not be plugged or blocked.

• Must be of material listed for hot water distribution.

• Must be installed so as to allow complete drainage of both

the temperature-pressure relief valve, and the discharge

pipe.

• Must terminate at an adequate drain.

• Must not have any valve between the relief valve and tank.

WARNING

HAZARD OF ELECTRICAL SHOCK! Before removing any

access panels or servicing the water heater, make sure the

electrical supply to the water heater is turned “OFF”. Failure to

do this could result in DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

WARNING

HOTTER WATER CAN SCALD: Water heaters are intended to

produce hot water. Water heated to a temperature which will

satisfy space heating, clothes washing, dish washing, and

other sanitizing needs can scald and permanently injure you

upon contact. Some people are more likely to be permanently

injured by hot water than others. These include the elderly,

children, the infirm, or physically/mentally handicapped. If

anyone using hot water in your home fits into one of these

groups or if there is a local code or state law requiring a certain

temperature water at the hot water tap, then you must take

special precautions. In addition to using the lowest possible

temperature setting that satisfies your hot water needs, some

type of tempering device, such as a mixing valve, should be

used at the hot water taps used by these people or at the water

heater. Mixing valves are available at plumbing supply or

hardware stores. Follow manufacturers instructions for

installation of the valves. Before changing the factory setting on

the thermostat, read the “Temperature Regulation” section in

this manual.

WARNING

WATER HEATERS EQUIPPED FOR ONE VOLTAGE ONLY: This

water heater is equipped for one type voltage only. Check the

rating plate near the bottom access panel for the correct voltage.

DO NOT use this water heater with any voltage other than the

one shown on the model rating plate. Failure to use the correct

voltage can cause problems which can result in DEATH,

SERIOUS BODILY INJURY, OR PROPERTY DAMAGE. If you

have any questions or doubts consult your electric company.

WARNING

INSULATING JACKETS:When installing an external water

heater insulation jacket on an electric water heater:

a. DO NOT cover the temperature-pressure relief valve.

b. DO NOT put insulation over the access covers or any access

areas.

c. DO NOT remove operating instructions, and safety related

warning labels and materials affixed to the water heater.

d. DO obtain new warning and instruction labels from the

manufacturer for replacement on the blanket directly over

the existing labels.

WARNING

Do not use this appliance if any part of it has been under water.

An electrical short or malfunction could occur. The water heater

should be replaced.

CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the water

heater must be accomplished in such a manner that if the tank

or any connections should leak, the flow of water will not cause

damage to the structure. For this reason, it is not advisable to

install the water heater in an attic or upper floor. When such

locations cannot be avoided, a suitable drain pan should be

installed under the water heater. Drain pans are available at

your local hardware store. Such a drain pan must be piped to

an adequate drain.

GENERAL SAFETYGENERAL SAFETY

GENERAL SAFETYGENERAL SAFETY

GENERAL SAFETY