1Safety.........................................................................................................................................4

1.1 Residual risks....................................................................................................................................4

1.2 Information and obligations for the operator.....................................................................................5

1.3 Intended use .....................................................................................................................................5

1.4 Impermissible operating conditions...................................................................................................5

2Description of machine ............................................................................................................6

2.1 Overview of the machine...................................................................................................................6

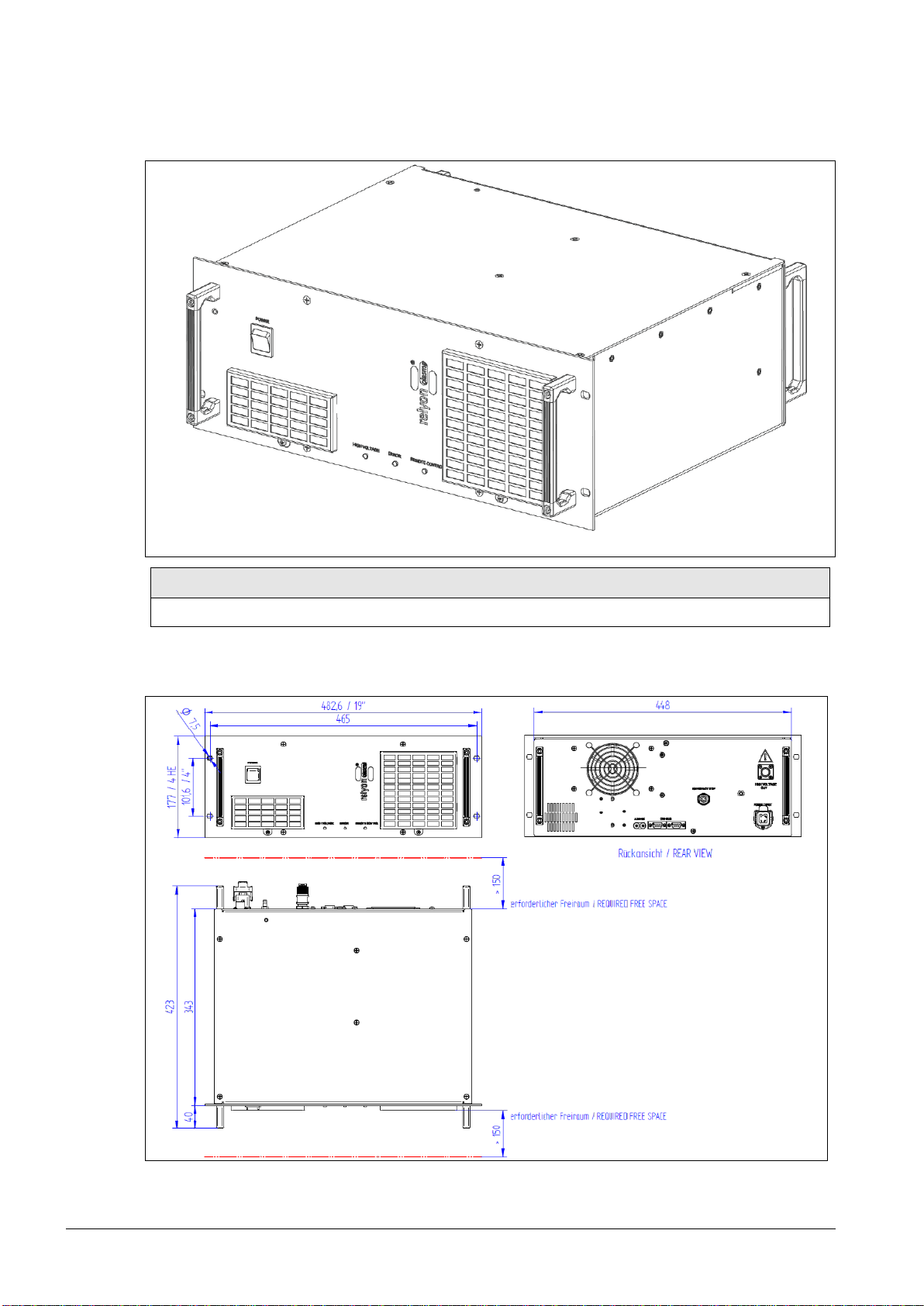

2.2 Installation dimensions......................................................................................................................6

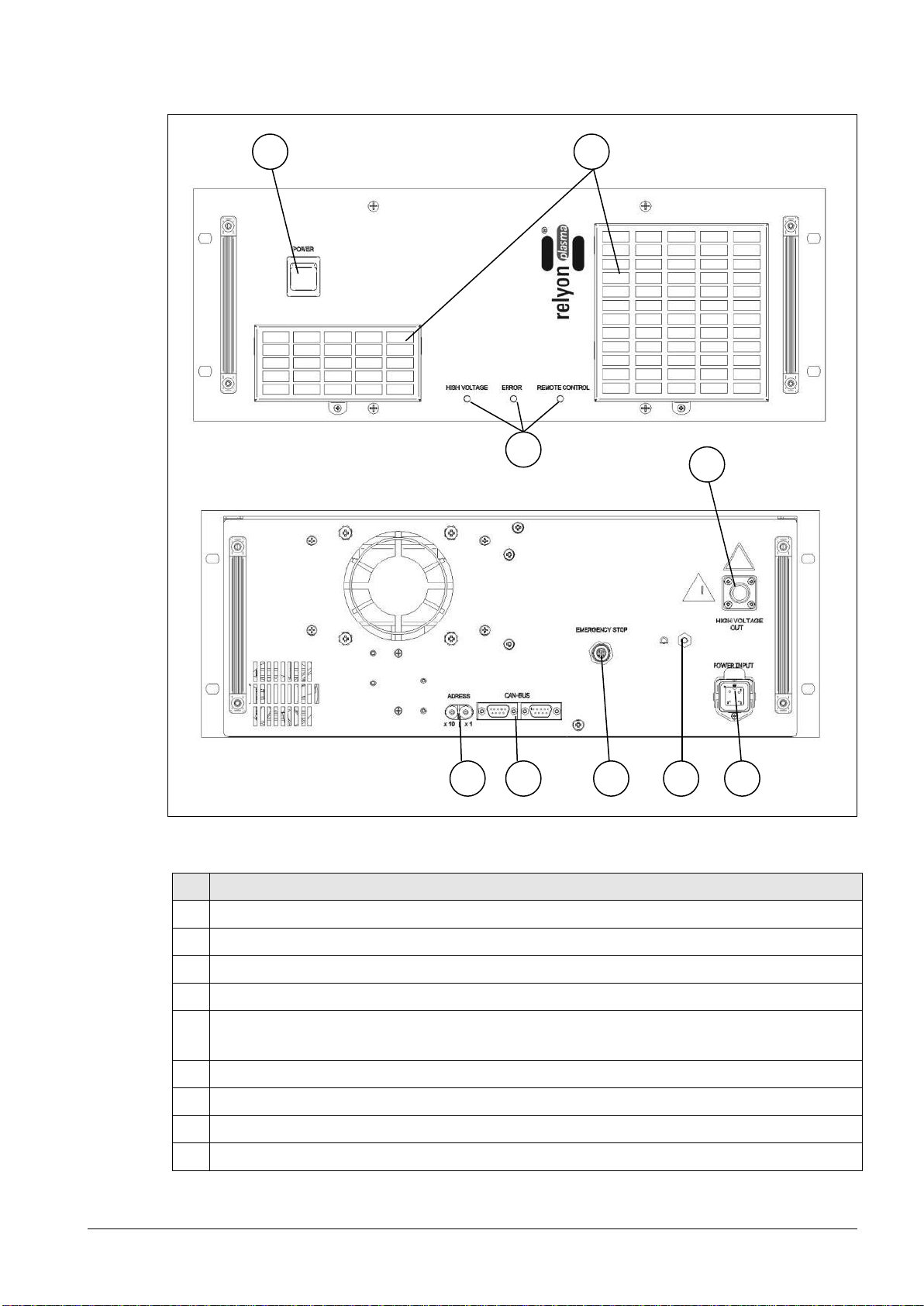

2.3 Description and connections.............................................................................................................7

2.4 Power connector pin assignment......................................................................................................8

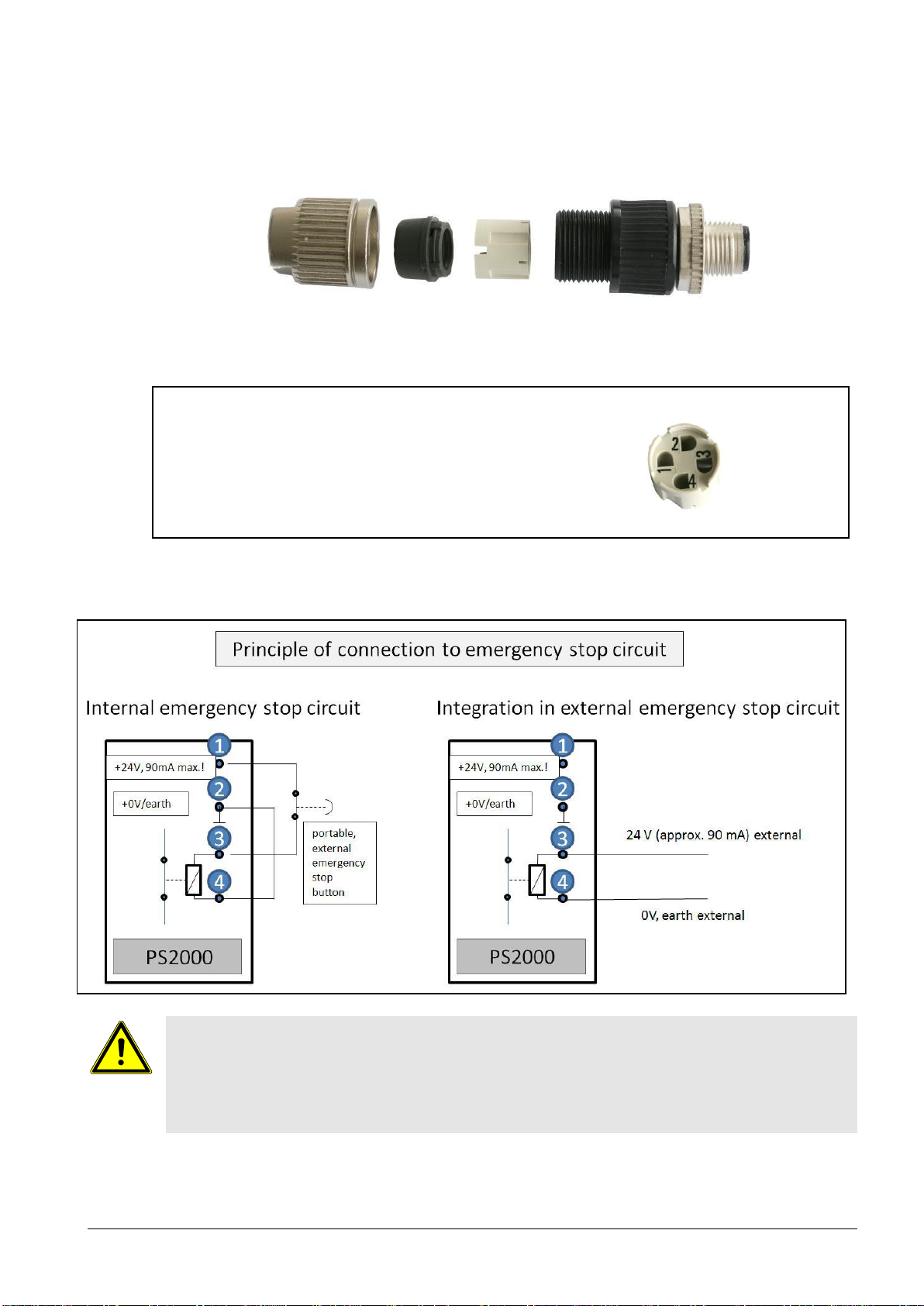

2.5 Pin assignment of emergency stop plug...........................................................................................9

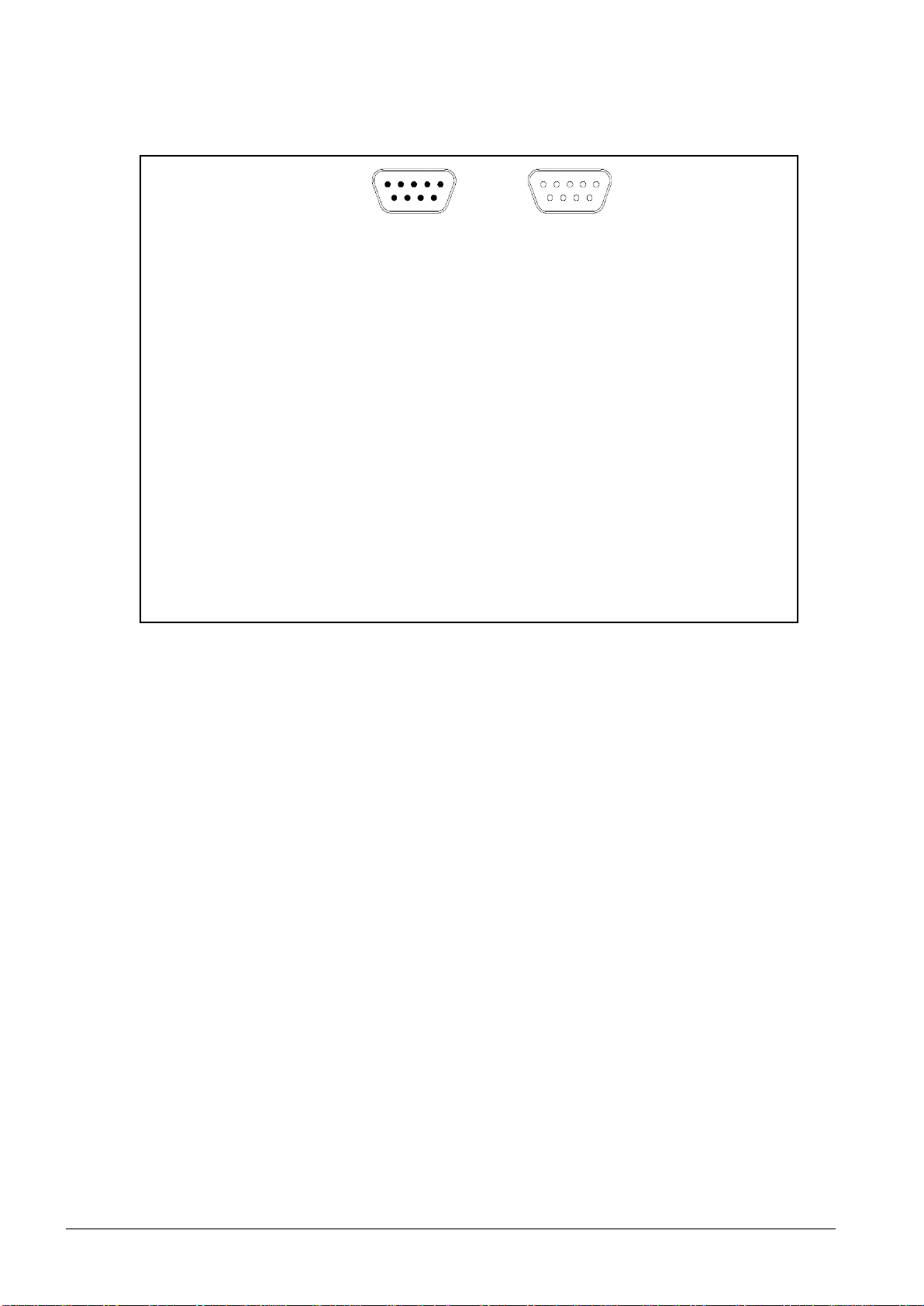

2.6 Pin assignment of CAN bus socket/plug (9-pin sub D socket/plug) ...............................................10

2.7 Scope of delivery.............................................................................................................................10

3Technical data.........................................................................................................................11

3.1 Technical data.................................................................................................................................11

3.2 Permissible operating parameters..................................................................................................11

4Transport/storage ...................................................................................................................12

5Unpacking and installation ....................................................................................................12

5.1 Unpacking .......................................................................................................................................12

5.2 Installation requirements.................................................................................................................12

5.2.1 Installing and starting up one single PS2000 ...................................................................12

5.2.2 Installing and starting up several PS2000s running in parallel.........................................14

6Operation.................................................................................................................................15

6.1 Controls / displays...........................................................................................................................15

6.2 Switching on and operating the machine........................................................................................15

6.2.1 Switching on and operating machine without bus communication...................................15

6.2.2 Switching on and operating machine with bus communication........................................16

6.3 Switching off the machine...............................................................................................................22

6.4 Error acknowledgement..................................................................................................................22

7Taking out of service ..............................................................................................................23

8Maintenance and cleaning .....................................................................................................24

8.1 Maintenance....................................................................................................................................24

8.2 Cleaning..........................................................................................................................................24

9Troubleshooting .....................................................................................................................25

9.1 Overview of faults / errors...............................................................................................................25

9.2 Customer service............................................................................................................................25

10 Environment............................................................................................................................26

10.1 Disposal ..........................................................................................................................................26

11 Conformity / standards...........................................................................................................26

11.1 CE ...................................................................................................................................................26

11.2 Product standards...........................................................................................................................26