27274092611 i

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Features. ................................................................................................................................................. 1-1

1.4 Accessories ............................................................................................................................................. 1-2

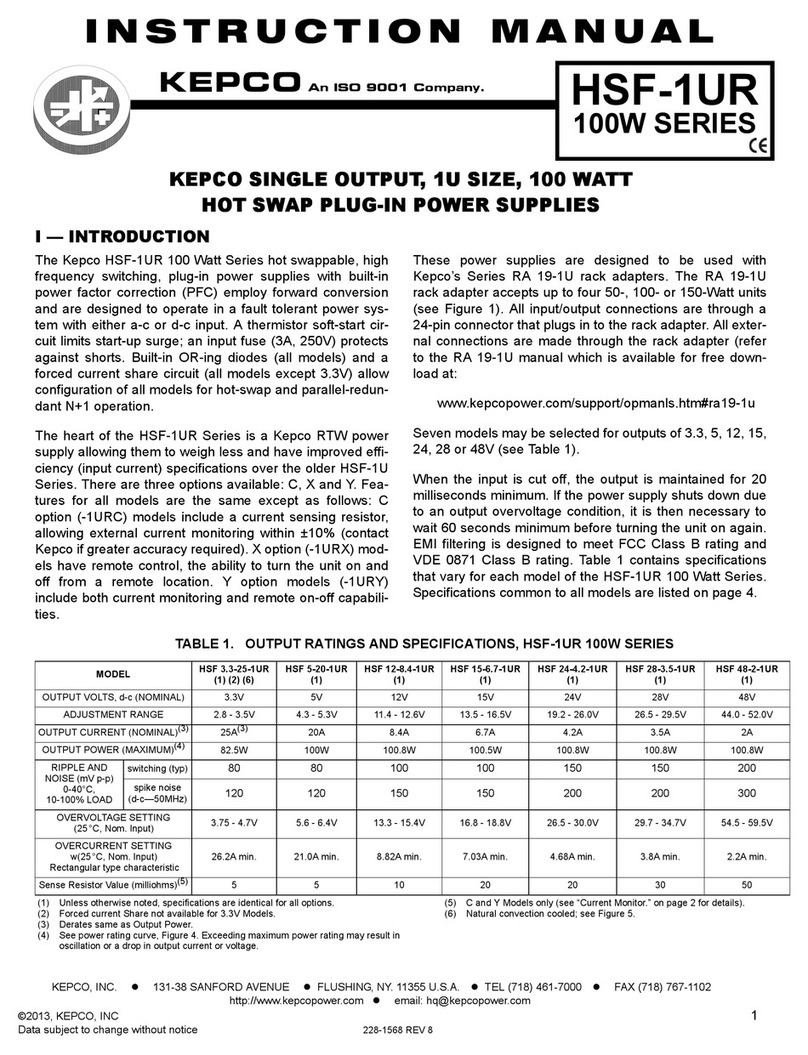

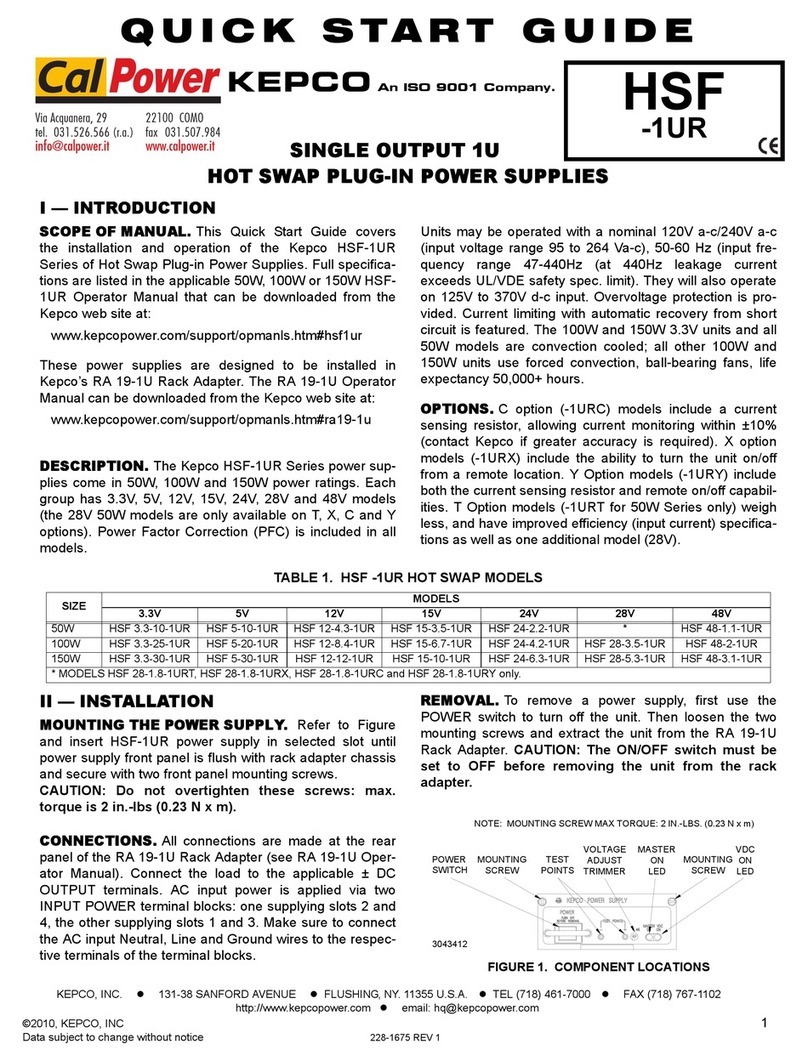

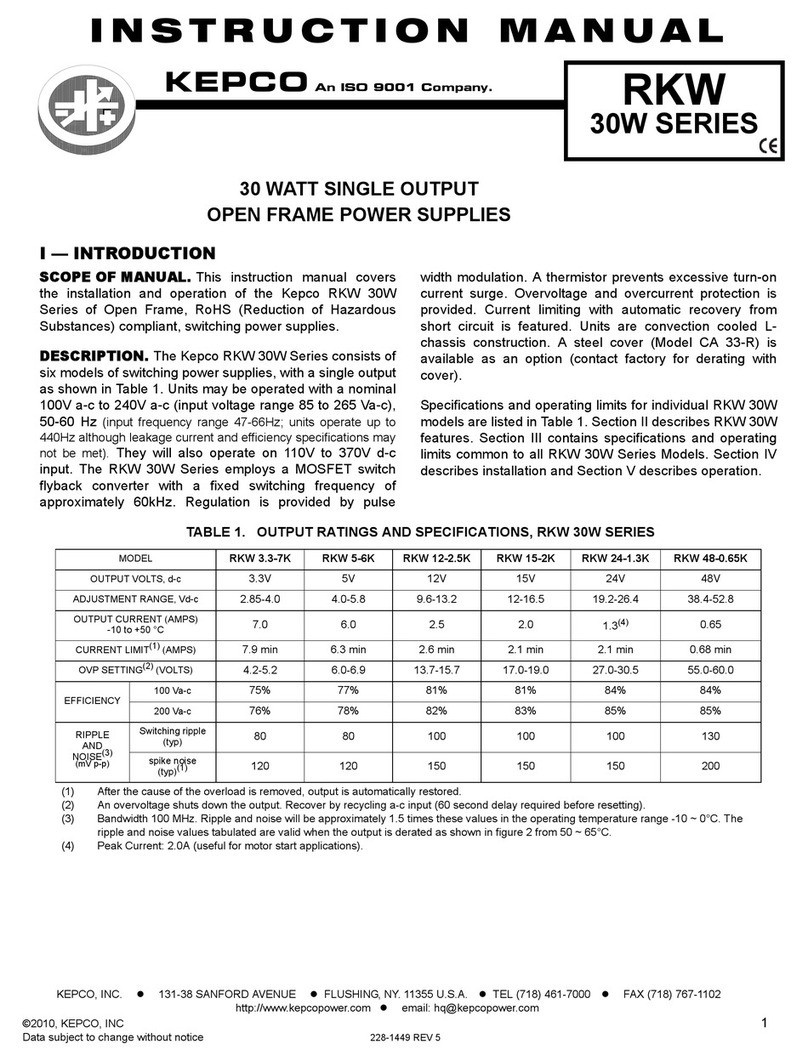

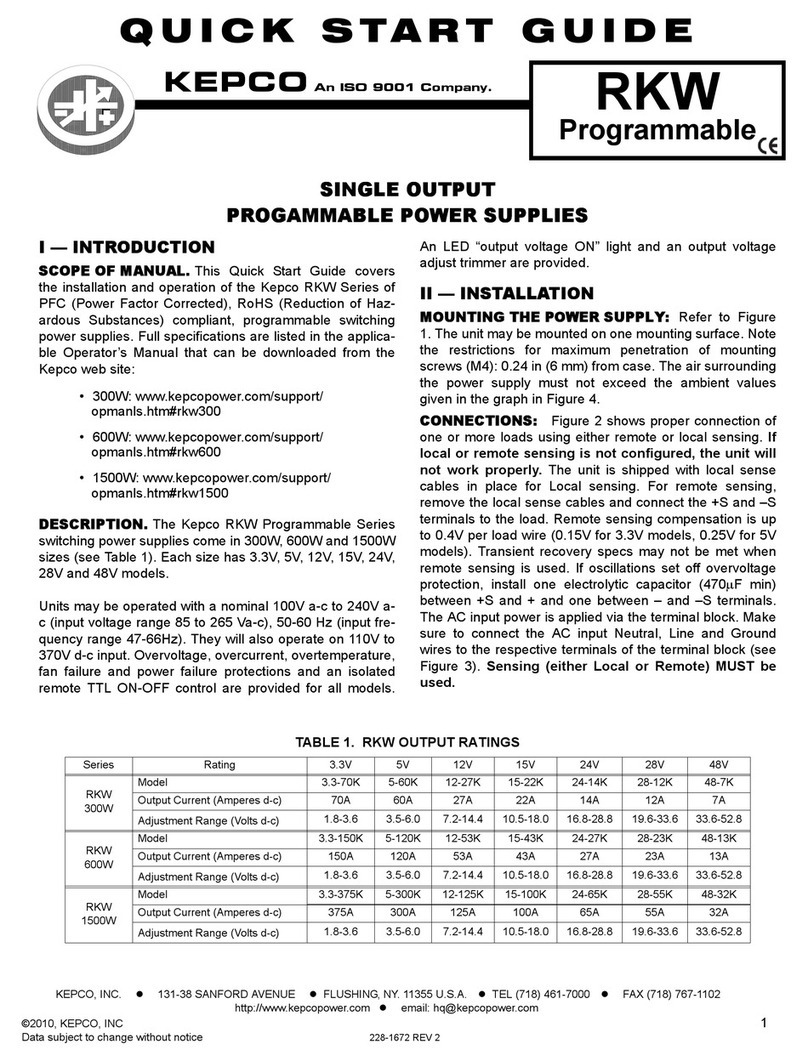

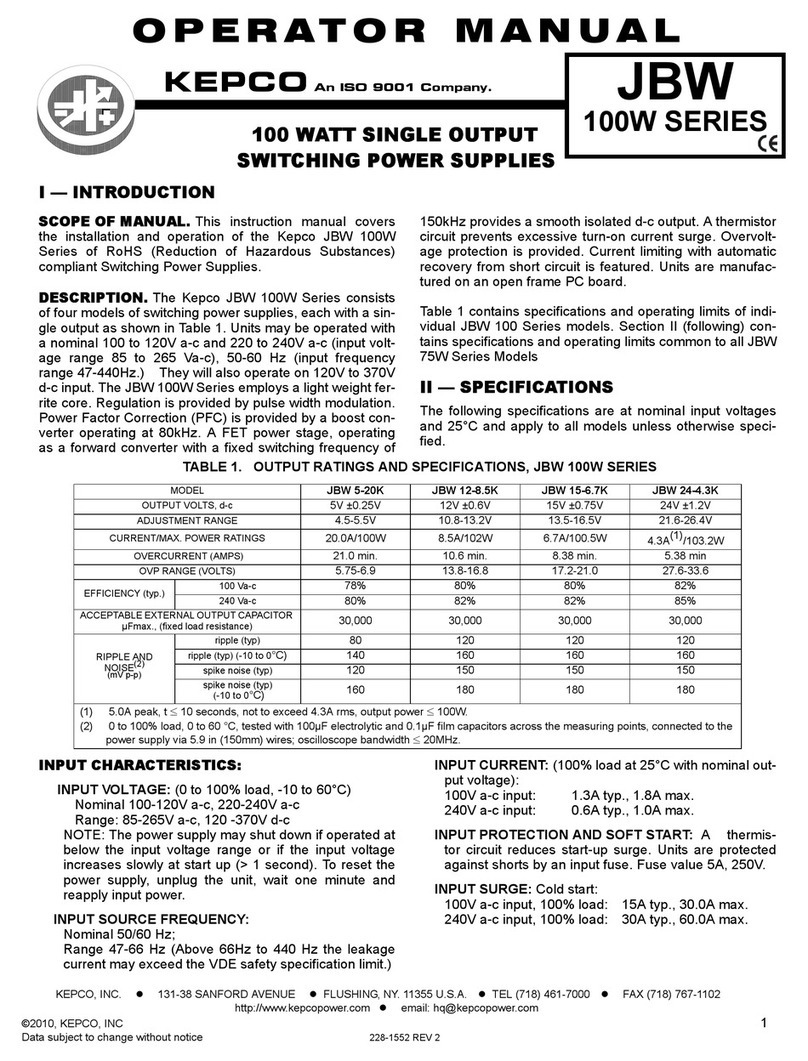

1.5 Specifications .......................................................................................................................................... 1-2

1.6 Specifications, Mechanical ...................................................................................................................... 1-4

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Terminations............................................................................................................................................ 2-1

2.3 AC Input Requirements ........................................................................................................................... 2-3

2.4 Cooling .................................................................................................................................................... 2-4

2.5 Preliminary Operational Check................................................................................................................ 2-4

2.6 Installation ............................................................................................................................................... 2-5

2.7 Grounding................................................................................................................................................ 2-5

SECTION 3 - OPERATION

3.1 Standard Power Supply Operation, Local Control................................................................................... 3-1

3.1.1 General.............................................................................................................................................. 3-1

3.2 Load Connection ..................................................................................................................................... 3-1

3.2.1 Local Error Sensing ........................................................................................................................... 3-1

3.2.2 Remote Error Sensing ....................................................................................................................... 3-2

3.2.3 Grounded Load Connection............................................................................................................... 3-2

3.3 Output Adjustment................................................................................................................................... 3-3

3.4 Introduction to Remote Programming ..................................................................................................... 3-3

3.4.1 General.............................................................................................................................................. 3-3

3.4.2 Equations Showing the Operation of the Kepco Bridge..................................................................... 3-5

3.5 General Rules for Remote Programming ................................................................................................ 3-6

3.5.1 Grounding.......................................................................................................................................... 3-6

3.5.2 Connections....................................................................................................................................... 3-6

3.5.3 Programming Resistors ..................................................................................................................... 3-6

3.5.4 External Switching ............................................................................................................................. 3-6

3.6 Output Voltage Programming With External Resistance......................................................................... 3-6

3.7 Constant Current Operation .................................................................................................................... 3-7

SECTION 4 - CALIBRATION

4.1 General.................................................................................................................................................... 4-1

4.2 Test Equipment Required........................................................................................................................ 4-1

4.3 Output Voltage Calibration ...................................................................................................................... 4-1

4.3.1 Voltage Pre-calibration Setup ............................................................................................................ 4-1

4.3.2 Zero Output Voltage Calibration ........................................................................................................ 4-2

4.3.2.1 Zero Output Voltage (Local Programming) Calibration................................................................ 4-2

4.3.2.2 Zero Output Voltage (Remote Programming) Calibration............................................................ 4-2

4.3.3 Zero VOLTAGE Monitor Calibration .................................................................................................. 4-2

4.3.4 Zero CURRENT Monitor Calibration.................................................................................................. 4-3

4.3.5 Local Full Scale (FS) Output Voltage Calibration .............................................................................. 4-3

4.3.6 Remote Full Scale (FS) Output Voltage Calibration .......................................................................... 4-3

4.3.7 Full Scale (FS) VOLTAGE Monitor Calibration.................................................................................. 4-3

4.4 Output Current Limit calibration............................................................................................................... 4-4

4.4.1 Current Limit Pre-calibration Setup.................................................................................................... 4-4

4.4.2 Full Scale (maximum) Output Current Limit Calibration .................................................................... 4-4

4.4.3 FS Current Monitor Calibration.......................................................................................................... 4-4

4.4.4 Minimum Output Current Check ........................................................................................................ 4-5

4.5 Overvoltage Protection (OVP) Test and Adjustment............................................................................... 4-5