4. Complete set

4.1. The list of delivered components is given in table 4.

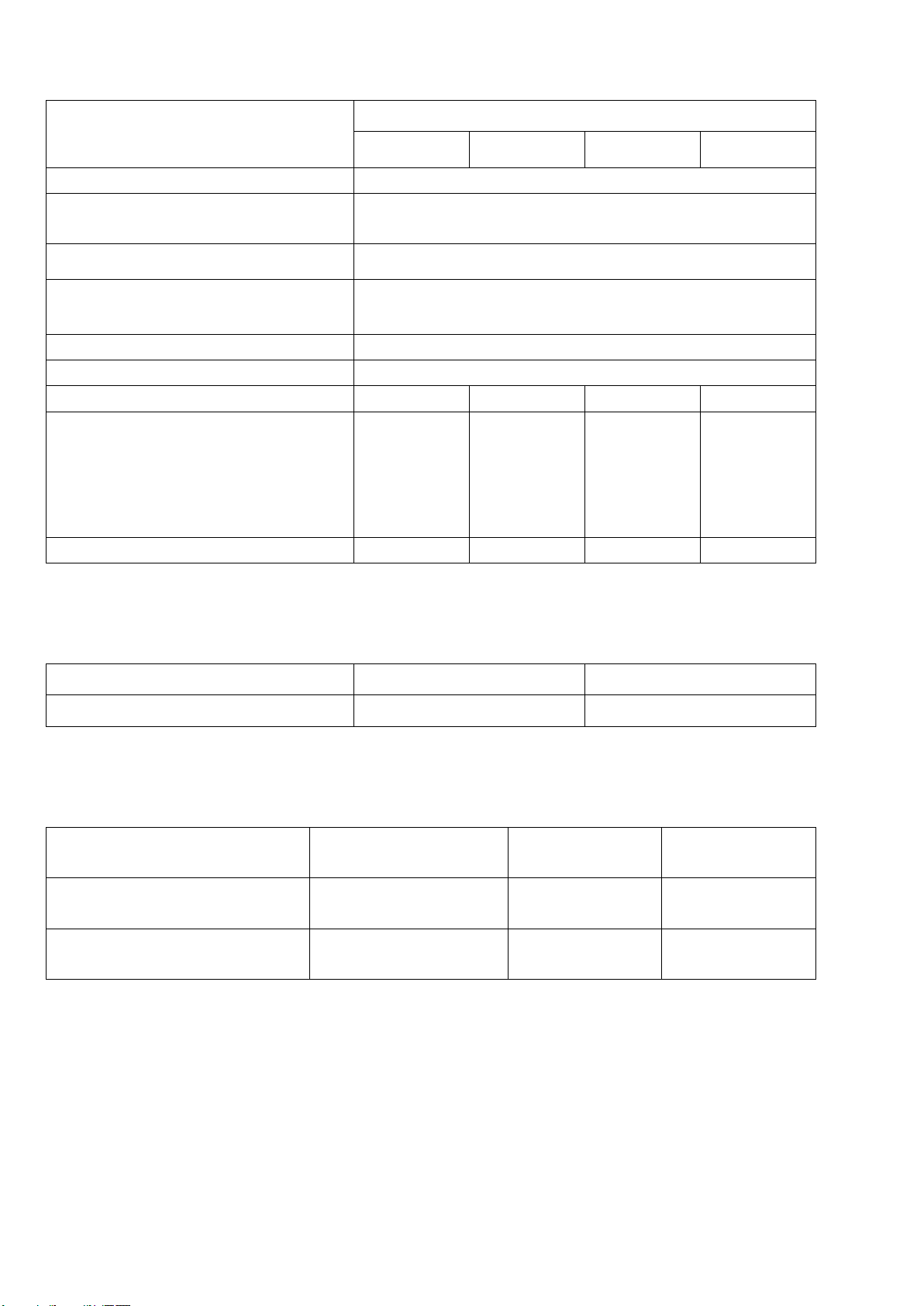

Table 4

Wheels and shock absorbers

Notes: Complete set of wheels and shock absorbers for the compressor SB4/C-100.LB75 (pos. 15, see

pic. 1), complete set of shock absorbers for compressor SB4/F-270.LB75, SB4/F-500.LB75, SB4/F-

270.LB75V (pos. 15, see pic. 2, 3, 4), as well as the details for their fastening are packed separately.

5. System and the operation principal.

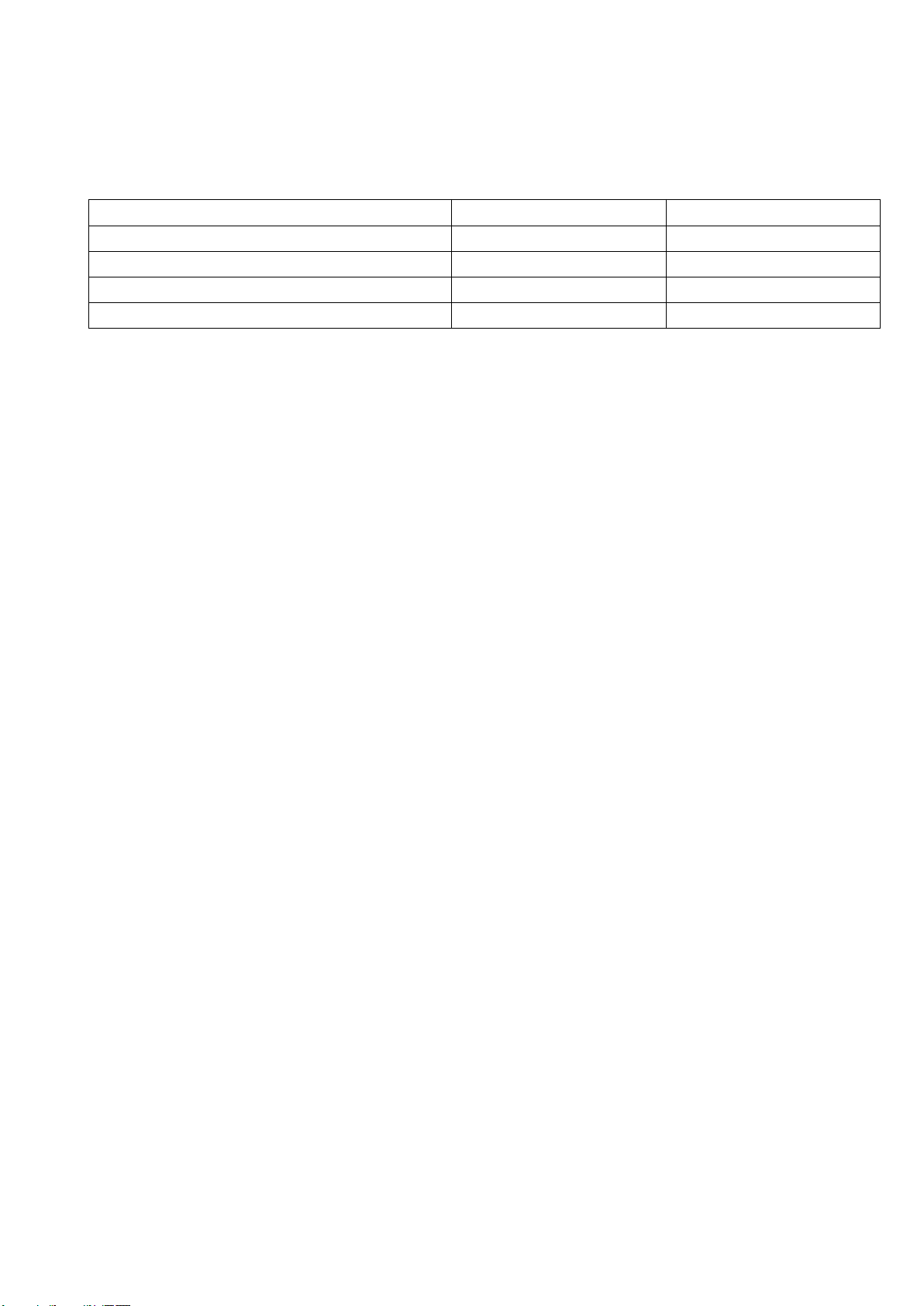

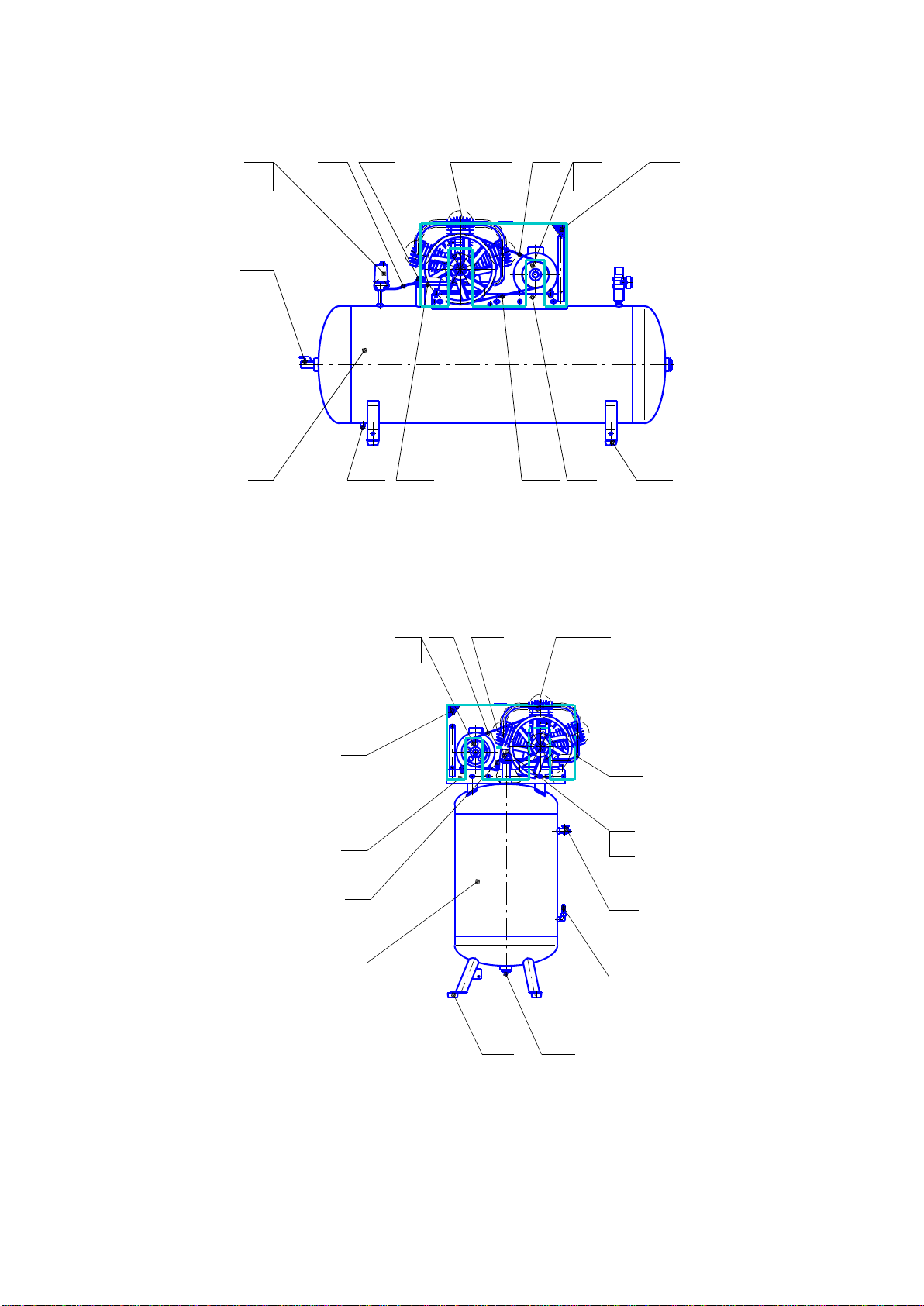

5.1. The compressor (pic. 1) consists of the following main assembly units and compo-

nents: compressor module LB75, receiver 1, bay 2, electric engine 3 with pulley 4, wedge-

type belts 5, protection enclosure 6, pressostate 7, manometer 8, air-outlet unloading pipe 9,

force air pipe 10, discharge cock 11, safety valve 12, check valve 13, overflow valve 14,

wheels and shock absorbers 15.

Compressor module –piston-type, single-stage, double-cylinder with air-cooling –is

made for compressed air production.

Greasing of rubbing surfaces of the compressor module’s components is made by

means of oil spraying. Oil pouring into the crater is accomplished through the carter’s port,

oil drain is accomplished through an aperture in the crater’s bottom, which is blanked with

the cap.

Receiver 1 (see pic. 1, 2, 3, 4) serves for collecting of compressed air, avoidance of

pressure pulsation, condensate and oil segregation. Receiver is also a body, on the base of

which other modules and compressor’s components are mounted.

Receiver has connecting pipes for telepressostate or pressostate 7, check valve 13, over-

flow valve 14, safety valve 12 and holders for mounting of the bay.

Bay 2 is meant for assembling of the compressor’s module, engine, wedge-belt trans-

mission and protection enclosure.

Electric engine 3 is meant for the compressor’s drive.

Telepressostate or pressostate 7 provides the operation of the compressor in automatic

mode and maintains the pressure in the receiver.

Unloading air channel 9 serves for unload of the compressed air out of the force air pipe

10 after the compressor’s shutdown, in order to make its subsequent start easier.

Spigot 11 with the pressure regulator serves for air supply.

Safety valve 12 serves for limiting of the maximum pressure in receiver and is set for

the pressure of the emergency response –(1,05+0,05) MPa.

Check valve 13 ensures the compressed air supply in the direction from the compres-

sor’s module to receiver only.

Discharge cock 14 serves for discharge of condensate from receiver.

Manometer 8 serves for pressure control in receiver.