6

3. If the vehicle is equipped with air brakes, make

certain to drain the air pressure from all reservoirs

before beginning any work on the vehicle.

4. Following the vehicle manufacturer’s recom-

mended procedures, deactivate the electrical

system in a manner that removes all electrical

power from the vehicle.

5. When working in the engine compartment the en-

gine should be shut off. Where circumstances

require that the engine be in operation, extreme

caution should be used to prevent personal injury

resulting from contact with moving, rotating, leak-

ing, heated, or electrically charged components.

6. Never connect or disconnect a hose or line con-

taining pressure; it may whip. Never remove a

component or plug unless you are certain all sys-

tem pressure has been depleted.

7. Never exceed recommended pressures and always

wear safety glasses.

8. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended proce-

dures. Use only the proper tools and observe all

precautions pertaining to use of those tools.

9. Use only genuine Bendix replacement parts, com-

ponents, and kits. Replacement hardware, tubing,

hose,fittings,etc.shouldbeof equivalent size, type,

andstrengthasoriginalequipmentand be designed

specifically for such applications and systems.

10.Components with stripped threads or damaged

parts should be replaced rather than repaired. Re-

pairs requiring machining or welding should not

be attempted unless specifically approved and

stated by the vehicle or component manufacturer.

11. Prior to returning the vehicle to service, make cer-

tain all components and systems are restored to

their proper operating condition.

REMOVAL

In many instances it may not be necessary to remove the

compressor from the vehicle when installing the various

maintenancekitsandserviceparts.Themaintenancetech-

nicianmustassesstheinstallationanddeterminethecorrect

courseof action.

Theseinstructionsaregeneralandareintendedtobeaguide.In

somecasesadditionalpreparationsandprecautionsareneces-

sary. In all cases follow the instructions contained in the vehicle

maintenancemanualin lieu of theinstructions,precautions and

procedurespresented inthis manual.

1. Block the wheels of the vehicle and drain the air pres-

sure from all the reservoirs in the system.

2. Drain the engine cooling system and the cylinder head

ofthecompressor. Identify anddisconnect all air,water

and oil lines leading to the compressor.

3. Remove as much road dirt and grease from the exte-

rior of the compressor as possible.

4. Remove the discharge and inlet fittings, if applicable, and

note their position on the compressor to aid in reassembly.

Note: If a cylinder head maintenance kit is being

installed, stop here and proceed to

PREPARATION FOR DISASSEMBLY. If

replacing the compressor continue.

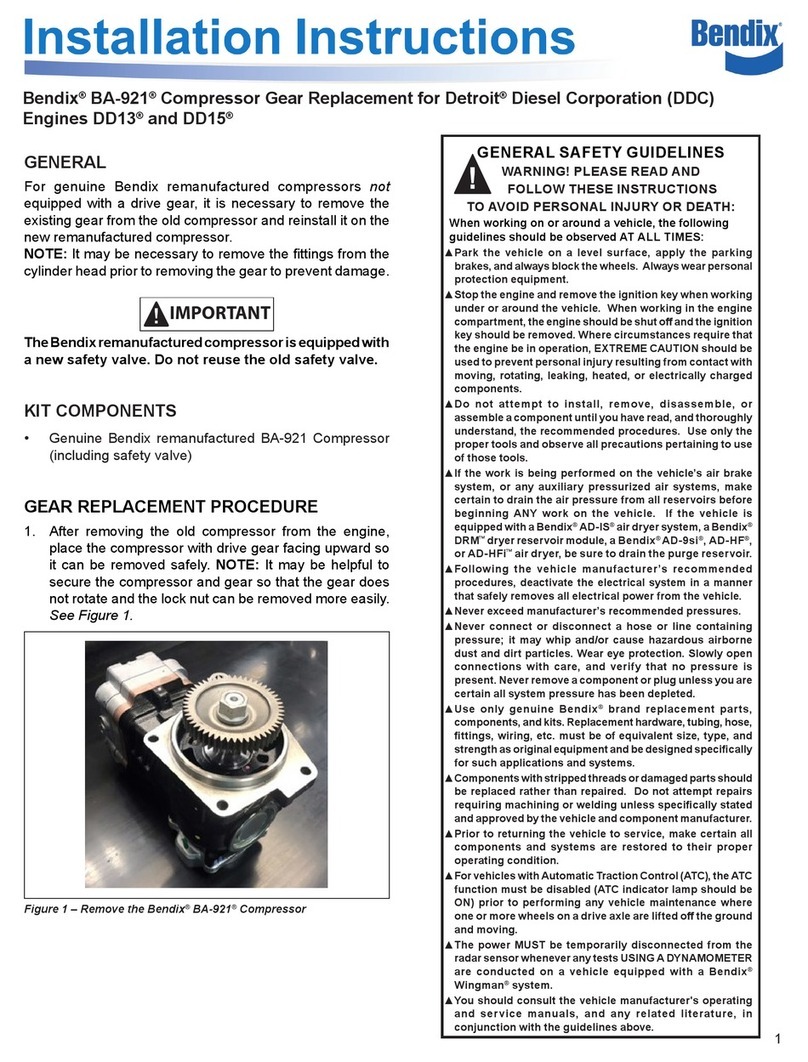

3. Remove any supporting bracketing attached to the

compressorandnotetheir positions on the compressor

to aid in reassembly.

5. Removetheflangemountingboltsandremovethe com-

pressor from the vehicle.

6. Inspectgearand associated drive partsforvisible wear

or damage. Since these parts are precision fitted, they

must be replaced if they are worn or damaged. If re-

placing the compressor or replacing the drive gear,

removethe drivegear from the compressor crankshaft

usingagear puller.

7. If the compressor is being replaced stop here and pro-

ceed to "Installing The Compressor" at the end of the

assemblyprocedure.

PREPARATION FOR DISASSEMBLY

Removethe balance of road dirt and greasefrom the exte-

rior of the compressor with a cleaning solvent. Mark the

rearendcoverorendcoveradapter in relation to the crank-

case. It is recommended but not specifically necessary to

marktherelationship of the cylinderheadto the valve plate

assembly and crankcase and cylinder block assembly.

Aconvenient method toindicate the aboverelationships is

to use a metal scribe to mark the parts with numbers or

lines. Do not use marking methods such as chalk that can

be wiped off or obliterated during rebuilding.

Priorto disassembly make certain that the appropriate kits

and or replacement parts are available. Refer to figure 9

during the entire disassembly and assembly procedure.

CYLINDER HEAD

1. Removethedischarge safety valve (10) from the cylin-

der head.

2. To restrain the spring force exerted by balance piston

spring (5), hold the unloader cover (2) in place while

removingthetwo unloader cover capscrews (1). Care-

fully release the hold on the unloader cover until the

springforceisrelaxed, then remove the unloadercover

(2).

3. Remove the unloader cover gasket (3).