Layout

Building type Specific heating

output in W/m2

Passive energy house

approx. 10

Low-energy house built in 2002

approx. 40

according to energy conservation order regarding heat

insulation 1995

approx. 60

Modern building constructed around 1984

approx. 80

Partially renovated old building constructed pre-1977

approx. 100

Non-renovated old building constructed pre-1977

approx. 200

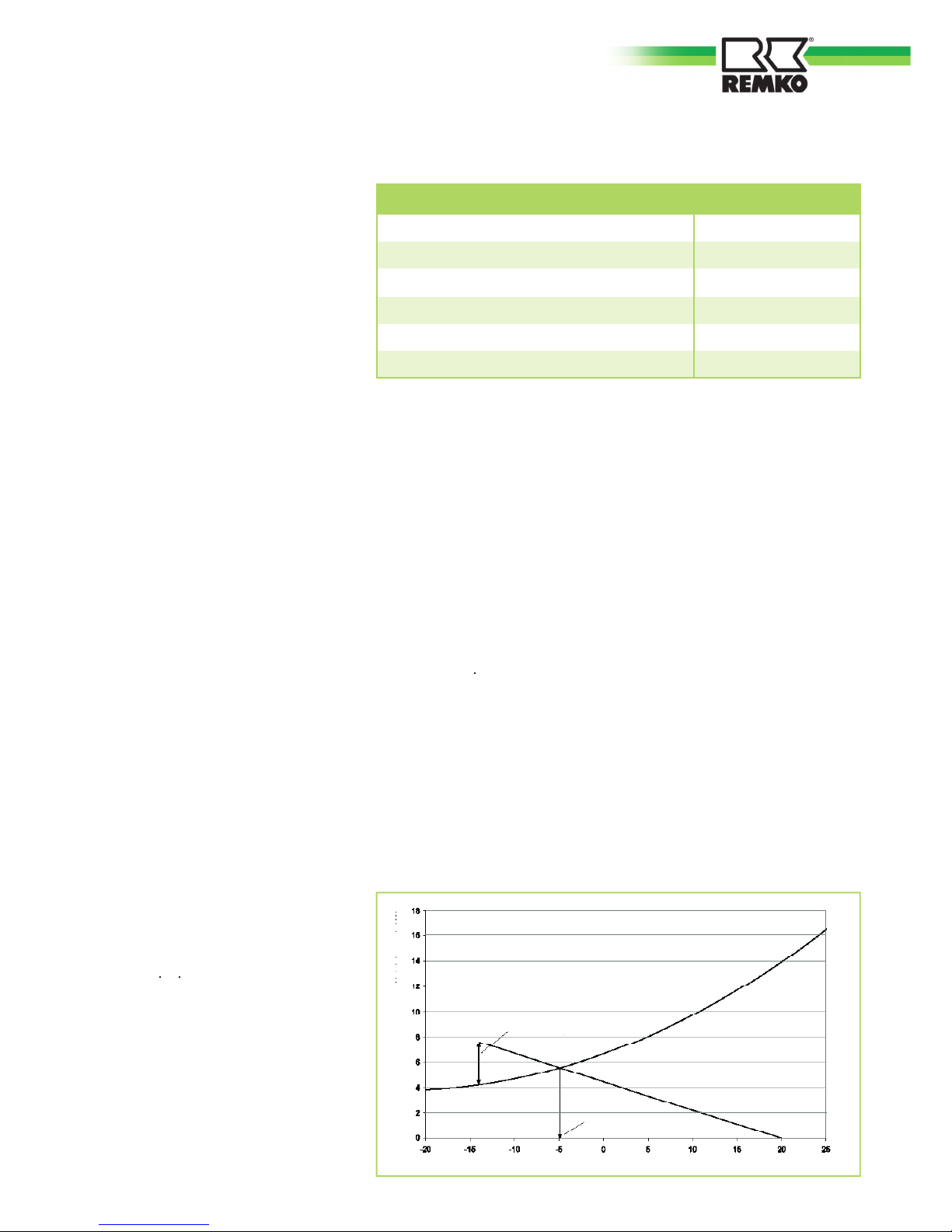

The diagram with the heating ca-

pacity characteristics shows a sim-

plified linear heating requirement.

A connecting line is drawn from the

desired room temperature (20°C)

and the point where the average

low outdoor temperature (local low

for the year) and the heat require-

ment meets (in this case: -14°C and

7.4kW). The intersection of the two

curves are plotted on the X axis

and the temperature of the balance

point is read off. In this case it is

-5°C.

The size of the submersion tube

heater is the difference between

the maximum heat requirement on

the coldest days of the year and the

heating output on these days. In

the example, the required output is

7.4kW – 4.7kW = 2.7kW.

A residential home comprised of

160m² living-space and a heat

requirement of 40 W/m² has been

selected for the example design.

A total of five persons live in the

house. The heating load amounts

to 160m240W/m2=6,400W. Add-

ing a drinking water allowance of

1 kW results in a required heating

power of 7.4kW.

The dimensioning of the heat pump

is given graphically on the diagram

below together with the outdoor-

temperature-dependent building heat

requirements and the heating capacity

characteristics for the heat pump.

A precise calculation of the build-

ing's heating load according to EN

12831 is required for the design

and dimensioning of a heating

system.

However, approximate require-

ments can be determined based

on the year of construction and

the type of building. The adjacent

table shows the approximate spe-

cific heating loads for a number of

building types. The required heat-

ing system output can be calcu-

lated by multiplying the area to be

heated with the given values.

Various factors have to be consid-

ered in order to achieve a precise

calculation.The transmission heat

requirement, the infiltration heat

loss and an allowance for water

heating comprise the total heating

output which has to be provided by

the heating system.

The total area of the floor surfaces,

exterior wall windows, doors and

roofing is required in order to

determine the transmission heat

requirement. In addition, informa-

tion about the materials used in the

building is required, as these lead

to extremely varied thermal trans-

mission coefficients (the so called

K value). Also required is the room

temperature and the average low,

the lowest average outdoor tem-

perature of the year.

The formula for determining the

transmission heat requirement

isQ=A U (tR-TA) and this must be

calculated individually for the areas

surrounding all rooms.

The infiltration heat requirement

takes into consideration how often

the heated room air is exchanged

for cold external air. The room vol-

ume V, the air exchange frequency

n and the specific heat capacity of

the air is also required in addition to

the room temperature and average

low temperature. The formula for

this is Q=V n c (tR-tA).

An approximate allowance for wa-

ter heating per person amounts to

0.2 kW according to VDI 2067.

Temperature in °C

Bivalence point

Necessary additional

power

Heating capacity in kW