4Research, Inc. • USA • Ph: 952.9419-9009 • Fax: 952.949-9559 • tsdsales@researchinc.com • www.researchinc.com

Section 2 - Installation and Operation:

Safety

The maximum water/glycol temperature is 140ºF (60ºC). Precaution should be taken to

ensure this temperature is not exceeded. Refer to the installation section for proper sizing

instructions.

WARNING!

Hazardous voltages are present within the heating/cooling/control system. Setting the set

point potentiometer or control signal to minimum does NOT eliminate these hazardous

voltages.

Always remove AC line voltage from the system before making contact with internal

assemblies, line or load wiring, or fuses.

CAUTION!

Up to 480 volts AC may be present at IR heater with longer lengths (25” and 38”).

Do not make any wiring connections when power is applied.

Disconnect power before performing any maintenance or service to the system.

Use extreme caution when adjusting calibration potentiometers on modules when

power is applied.

Always use an isolated oscilloscope for checking waveforms.

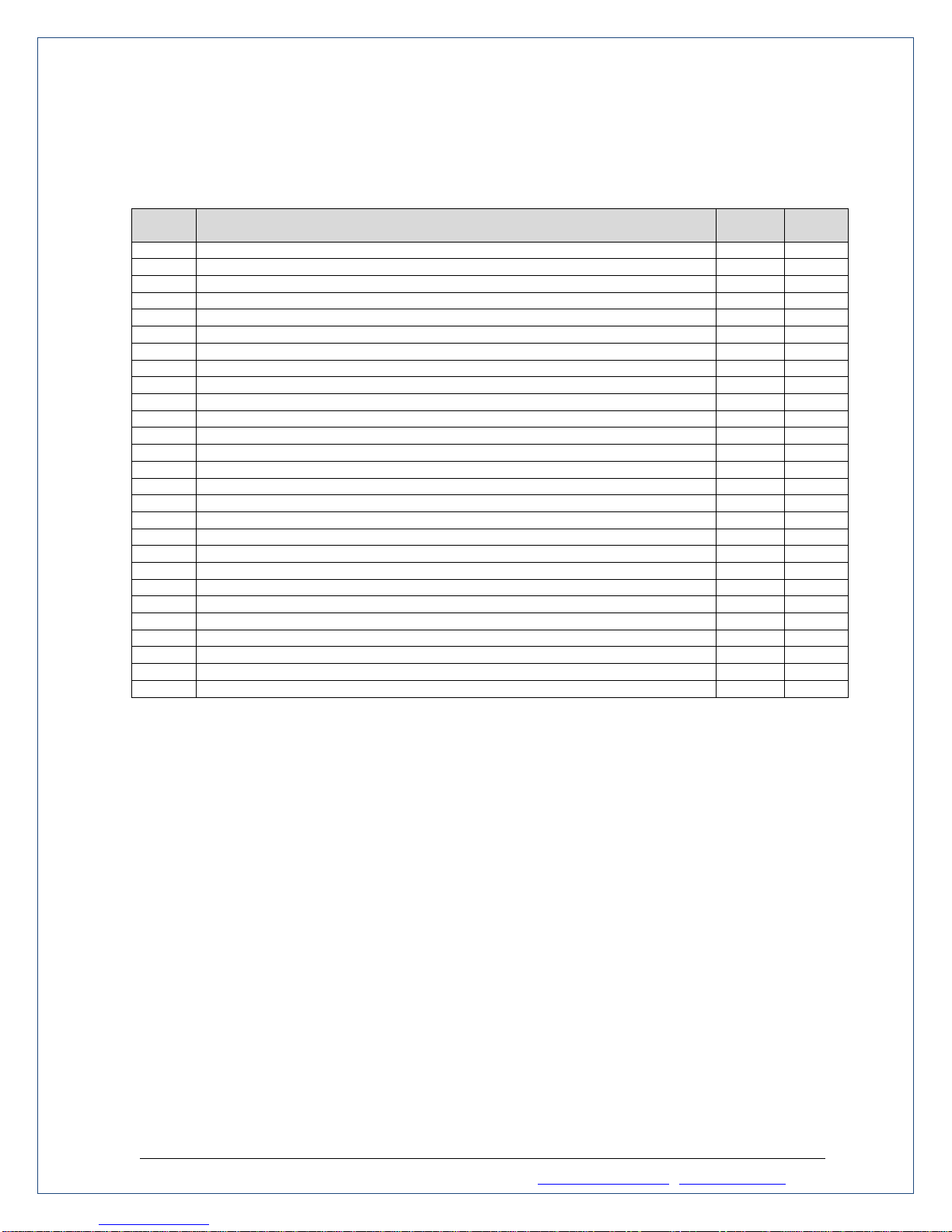

Sizing

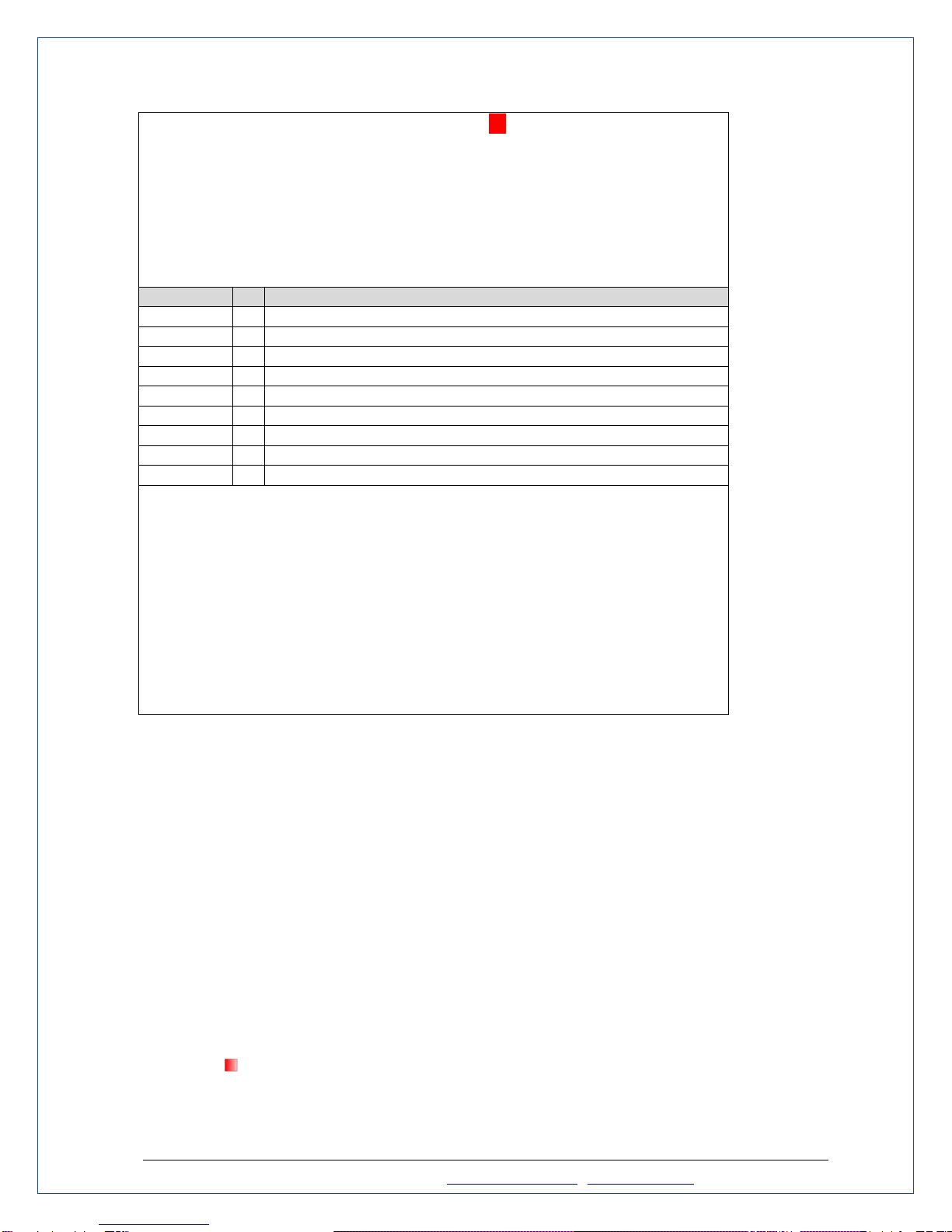

The C104 can handle up to 5 KW of cooling load. The amount of cooling load is dependent

upon the heater style, lamp wattage, and heating application. Table 1 shows how to size

the C104. These steps are outlined below:

1. Determine heater wattage –This is a simple calculation based upon the wattage of

the lamps in the heater times the number of lamps in the system.

2. Determine the cooling factor (Fc). This takes into account how much heat is going

into the reflector that will be carried away by the cooling system.

3. Determine the number of C104 units required. Each C104 can handle up to 5 KW. If

the calculated cooling load is less than 5 KW, then one unit will work. Multiple C104

units can be used in parallel. Consult factory.