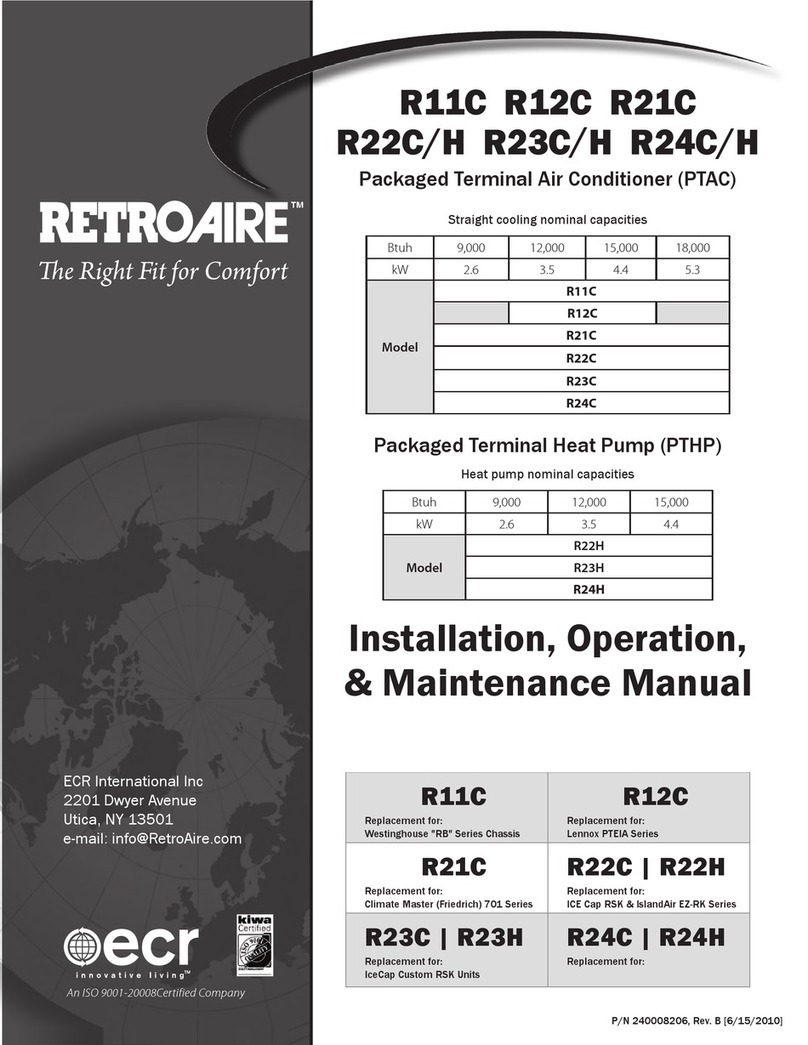

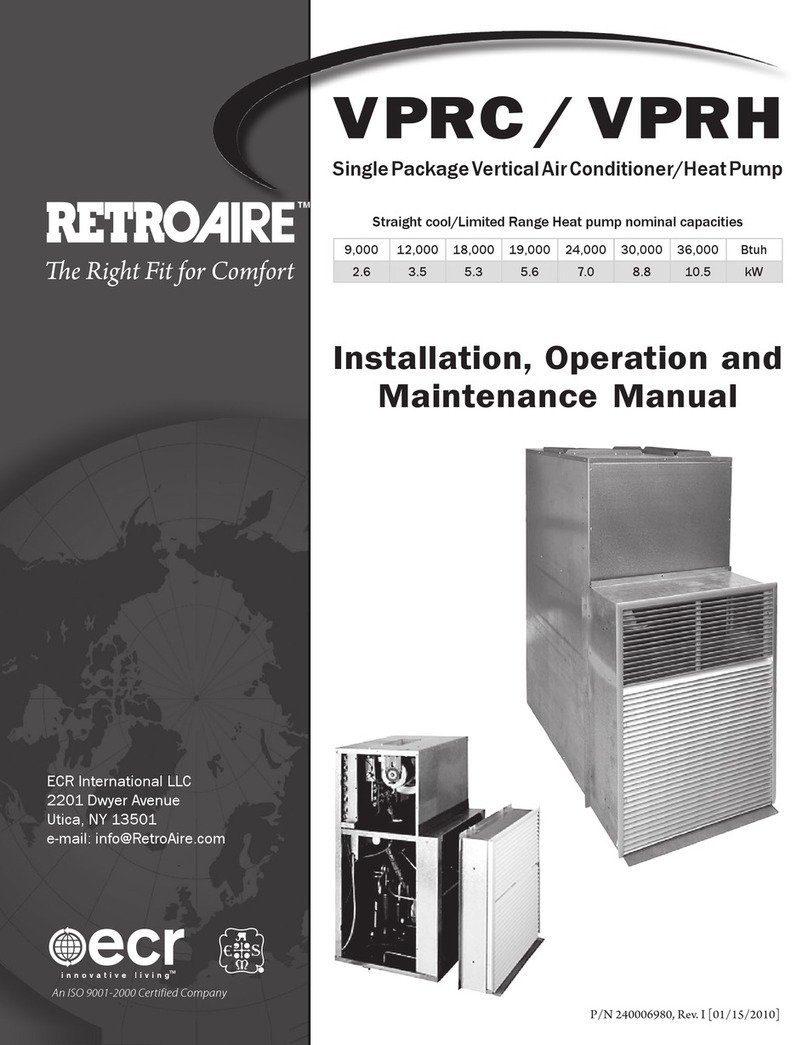

General Product Information

Product description

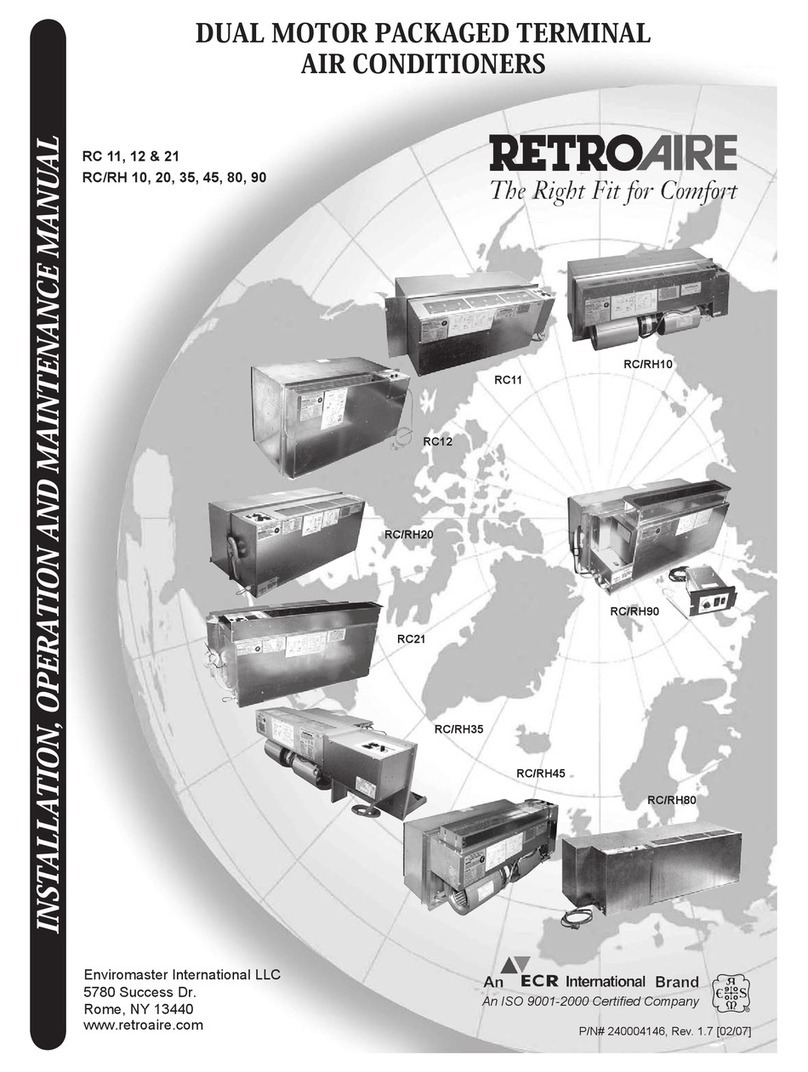

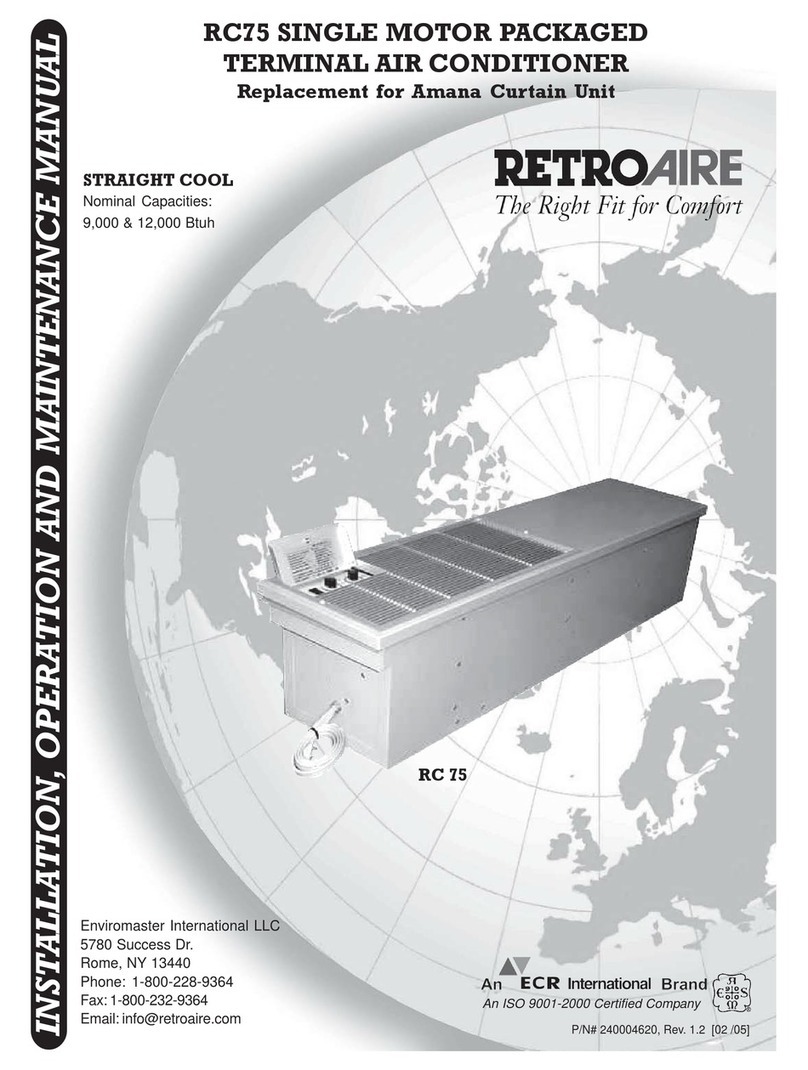

RetroAire Replacement Packaged Terminal Air Condition/Heat

Pumps units are available in straight cooling (PTAC) or as heat pump

systems (PTHP). Both the PTAC and PTHP congurations t the

wall sleeves of the units listed on the front cover. Heat pumps (PTHP)

reduce energy costs and will operate

in mechanical heat mode down

to an outdoor temperature of 40°F (4.4°C), Below 40°F (4.4°C)

heating is accomplished by an auxillary heat option.

e

Retroaire PTAC/PTHP units:

Use R-410A refrigerant. is refrigerant is not aected by a phase out• schedule.

Include high-eciency rotary compressors, protected by a 5-year war-• ranty.

Include an enhanced, high-eciency heat exchangers.•

Oer two fan speeds.•

Incorporate positive condensate re-evaporation to improve eciency.•

Have an optional motorized fresh-air feature with a positive pressure• seal.

RetroAire PTAC/PTHP ratings meet or exceed ASHE 90.1 Stan-

dards for energy eciency:

PTAC/PTHP units are available in nominal sizes of 9,000 Btuh, (2.6kW)• 12,000 Btuh (3.5kW) or 15,000 Btuh (4.4kW).

PTAC units (straight cooling only) are also available at 18,000 Btuh• (5.3kW).

Energy Eciency Rating (EER) as high as 10.•

Coefficient of performance (COP) ratings as high as 2.90 for heat•

pumps.

Standard controls and components

Construction

20-gauge galvanized steel construction of chassis.•

Condenser bae options to accommodate extended wall sleeve applica-• tions. (Consult the factory for special order items).

Powder-coated condenser and evaporator drain pan.•

Foam strip seal for supply air duct.•

Weather strip insulation.•

Air systems

Motors are thermally-protected PSC type.•

Air-stream surfaces are insulated with " ber-glass or " (3.2 mm)• Volara™.

e indoor fan is a foward-curved type, directly mounted to the motor• sha.

Unit mount controls include a eld selection switch to control indoor fan by• either cycling with compressor operation or continuously with the unit.

Condensate removal

e outdoor fan incorporates condensate slinger ring Condensate• is thrown onto the coil, where it evaporates, improving system perfor-

mance.

ermostatic drain pan valve for condensate elimination when outdoor• temperature drops below 60°F (15°C) (heat pump units only).

Controls

Unit-mounted operating controls include thermostat, fan speed control,• heat/cool switch, fan cycle switch, fresh air switch (if equipped)

Ability to utilize 1-stage or 2-stage thermostat. 2 stage thermostat is capable• of activating emergency heat if an auxiliary heat source is available.

Low ambient protection see "Microprocessor control board" for• details.

Ability to control a normally-open or normally-closed motor valve switch• (on hydronic heat units only). Valve controls must be ordered for 24V

or line voltage.

All hydronic heat units include molex plugs for connection of hydronic• valve motor.

Remote mount controls include fan speed control and fresh air switch (if• equipped)

All units are equipped with manual reset high pressure switch which• prevents abnormal high pressure operation, increasing compressor reli-

ability.

Microprocessor control board

e universal control board is used in straight cooling, electric resistance• heat, hydronic heat, or cooling/heat pump applications.

Random start timer prevents multiple units from simultaneous startups• aer power interruption or on initial power-up.

Fan purge fan remains on for 60 seconds aer heat/cool is satised.•

Anti-short-cycle compressor protection prevents the compressor from• rapid cycling, increases compressor reliability.

Freeze-protection prevents evaporator coil freeze up, improving compres-• sor reliability.

Low ambient lockout prevents compressor operation in outdoor tem-• peratures less than 40°F (4.4°C). (On PTHP units supplied with unit-

mounted control, the control causes automatic changeover to auxiliary

heat, if installed.)

Test operation all timers are temporarily suppressed to allow ease of• testing or troubleshooting.

Control board LED provides self-diagnostic troubleshooting codes, see• "Sequence of operation."

Factory-installed options (consult the factory)

265/277V(12 and 15 only)•

115V (09 &12 Models Only)•

Corrosion-resistant coil option used for seacoast and harsh-envi-• ronment usage; coated aluminum n/copper tube condenser coil.

Motorized fresh-air damper•

Supplemental electric heat see heat options on• “Model coding” on

page 11.

Hydronic heat controls•

Front air intake•

Field-installed accessories

Hydronic heat the coil assembly is shipped loose for eld installation.•

Remote wall thermostat digital 1-stage or 2-stage available.•

Wall sleeves, louvers, and cabinets•

Aquastat - delays fan start-up until coil reaches 100°F (38°C) to virtually• eliminate "cold" blow condition.

Hydronic control valve , Water 2 way & 3 way•

Hydronic control valve, Steam 2 way•

Hydronic Isolation valve, 1/2 in Sweat Connection.•

Insta

ation, O

eration, an

Maintenance Manua

•

The Right Fit for Comfort 4P/N 240008223, Rev. K [05/14/2012]