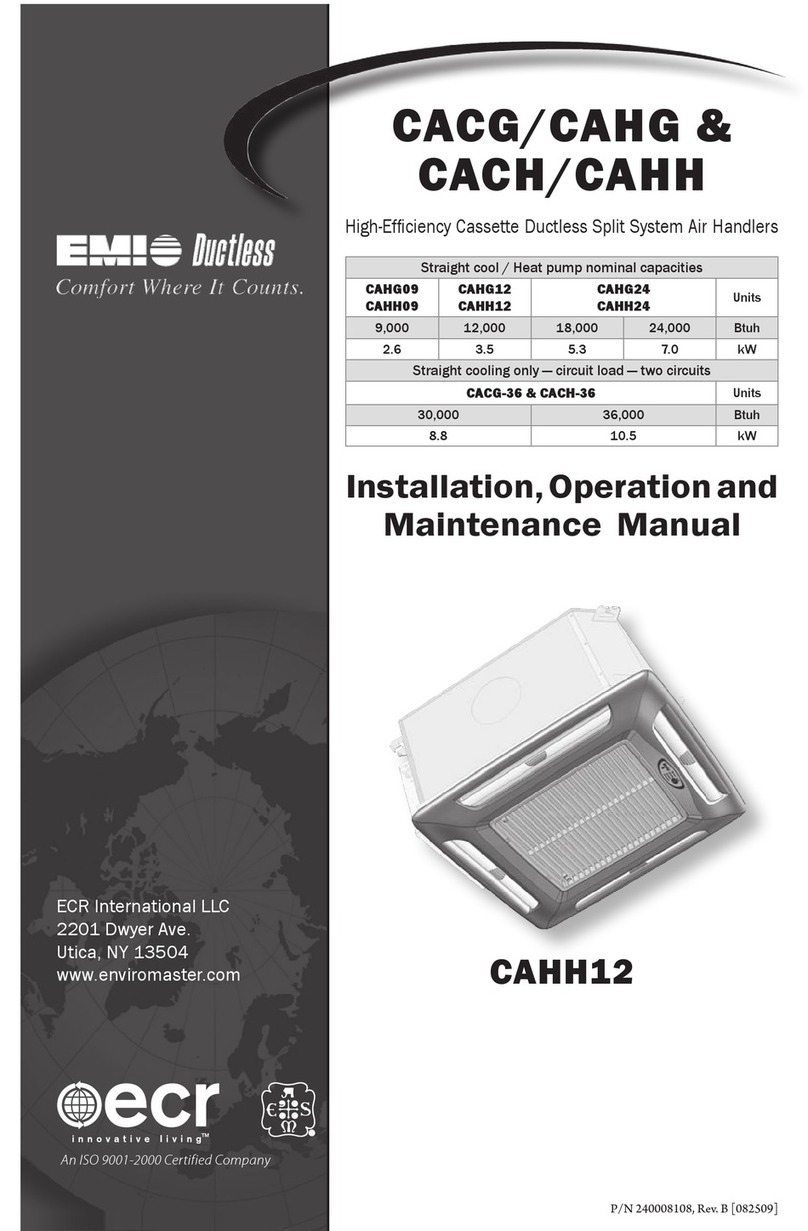

SECTION THROUGH FASCIA

FASCIA BLANKING PIECE

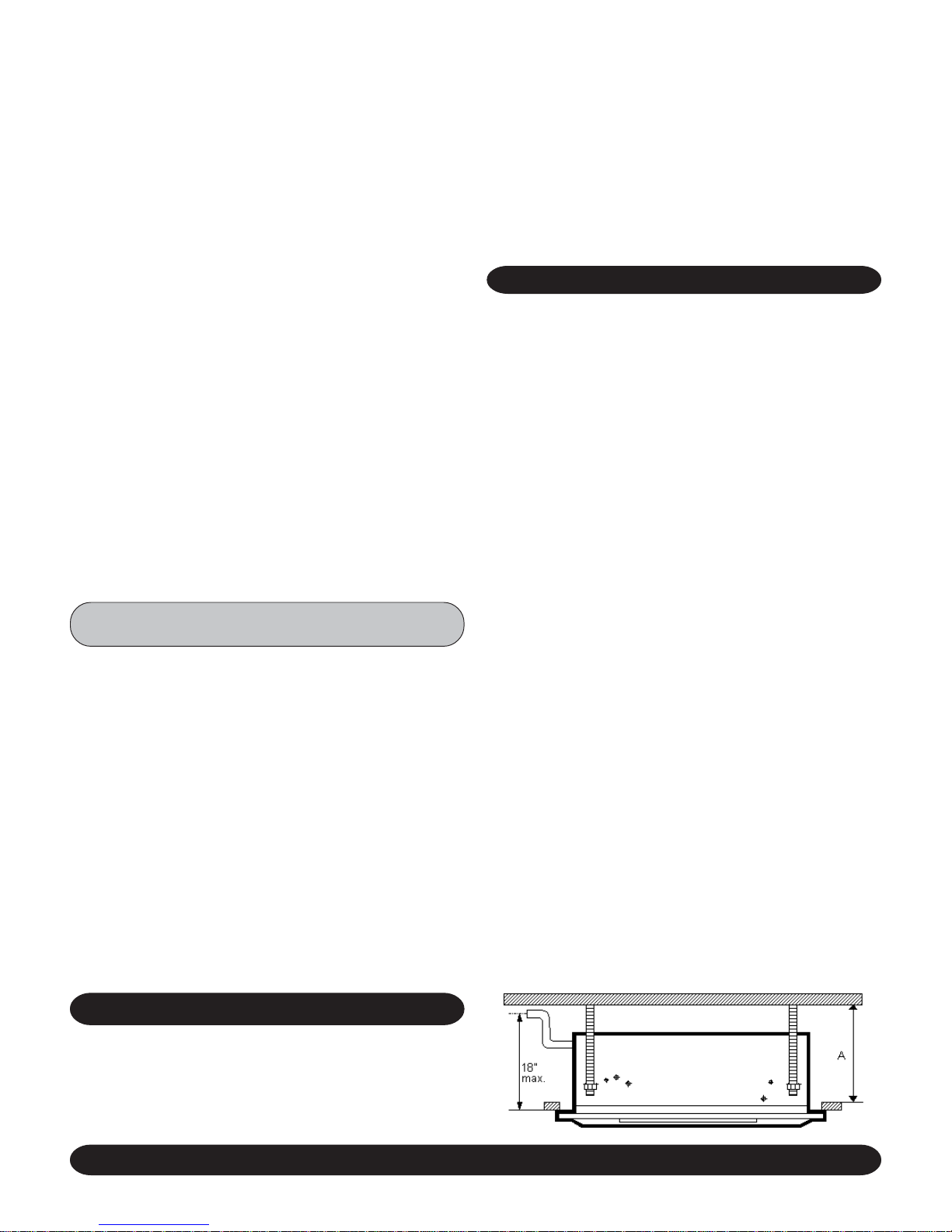

3. Condensate pipework should slope downwards in the

directionofwaterflow withaminimumgradientof(1” per

10’). There must not be any uphill gradients other than

in the first 18” of pipework from the Cassette.

4. When multiple Cassettes are connected to a common

condensate drain, ensure the drain is large enough to

cope with the volume of condensate from several

Cassettes.Itisalsorecommendedtohave an airventin

thecondensate pipework to preventany air locks.

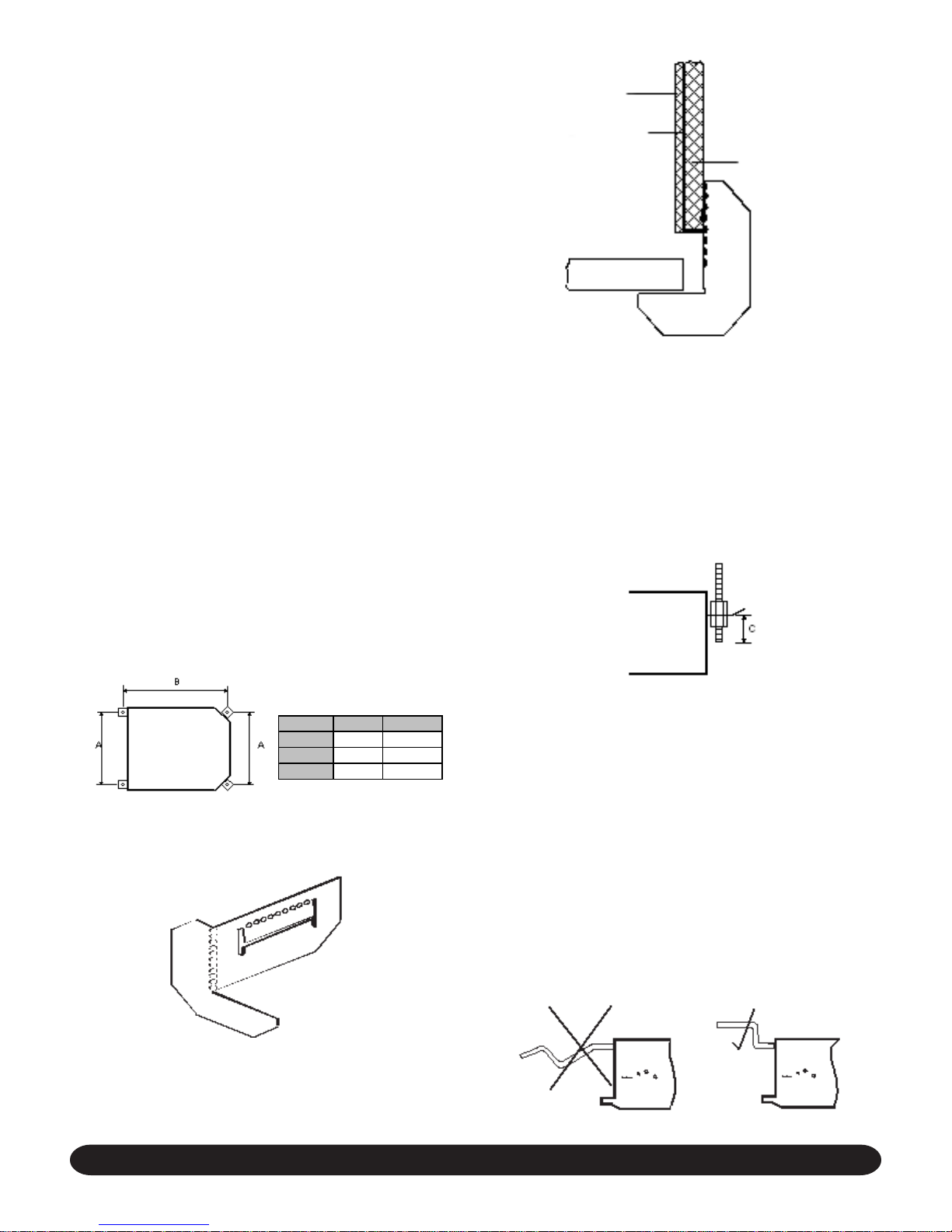

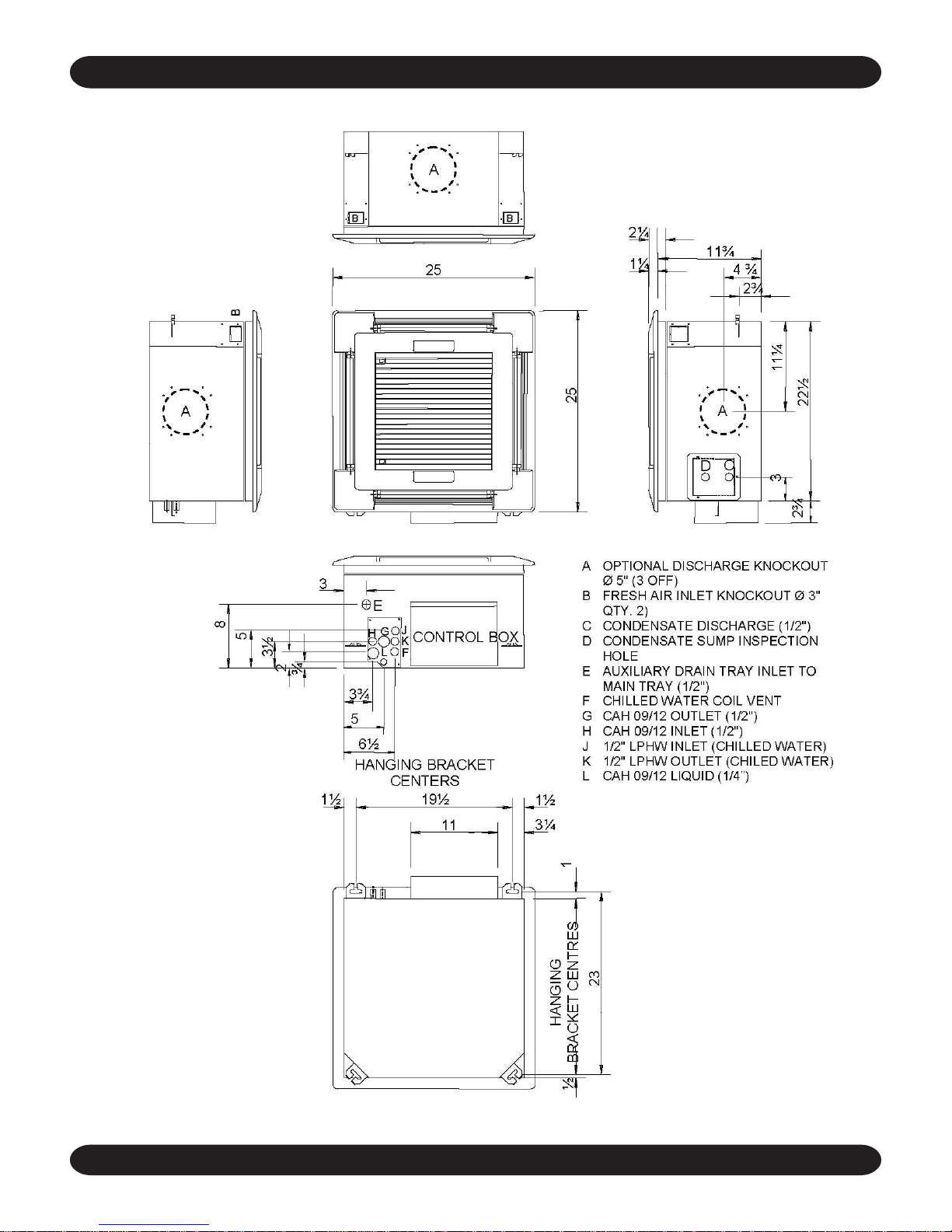

DUCT COLLARS: Branch duct and fresh air duct collars

can be attached to the Cassette chassis by following the

stepsbelow:

1.Refertotherelevant illustrationforyourCassette(pages

6 -7 in this IOM) to become familiarized with knock-out

holelocations.

2. The insulation is pre-cut to aid location and removal of

the relevant section. Rub hand across surface of

insulationto reveal exact location ofknock-out.

3. Remove the metal knockout from the chassis.

4. Attach the duct collar to the chassis using self tapping

screws.

NOTE:Branchductsareroundand5-6”indiameter.

Fresh Air ducts are square and 3” in diameter.

INSULATION: Refrigerant, chilled water and condensate

pipes should be insulated right up to the Cassette chassis.

Chilledwatervalvesmustalsobeinsulatedtopreventsweat-

ing.

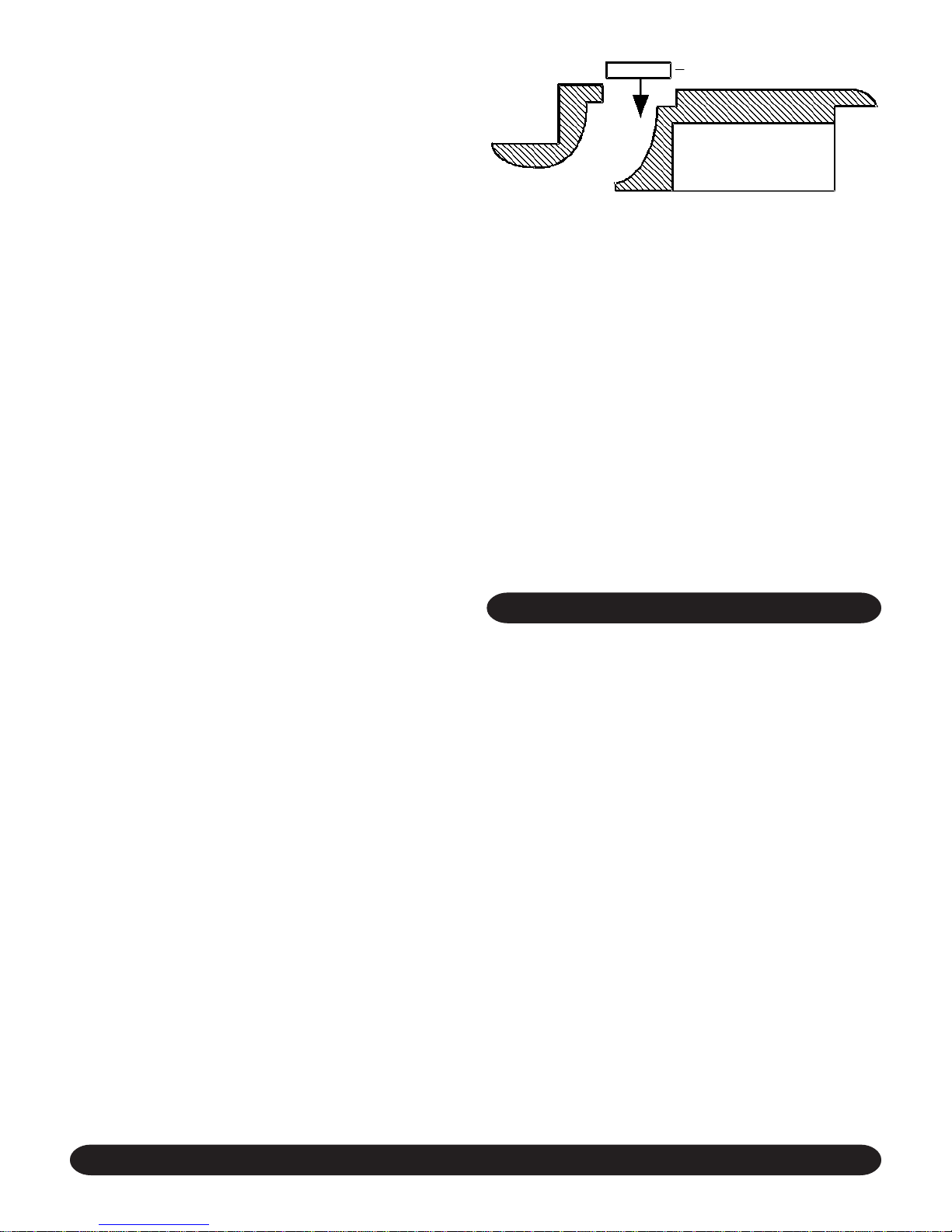

ASSEMBLY: Once the services have been connected the

fourfasciamountingboltscanbeunscrewedapproximately

1”from the condensate tray support channels.

ThefasciacannowbeunpackedreadyforfittingtotheCas-

sette chassis. Ensure the black fir tree fasteners holding

thefasciapolystyrene are pushed in firmlyincase of transit

vibration. If a fascia aperture needs blanking off, then take

one of the polystyrene blanking pieces and push it into the

recess in the polystyrene fascia insulation. Fit by removing

the inlet grilles and filters, locating the four fascia mounting

bolts on the chassis through the four keyhole brackets on

the fascia and then sliding the fascia sideways until it locks

into position.

NOTE: Upto two non-adjacent sides can be blanked

off.

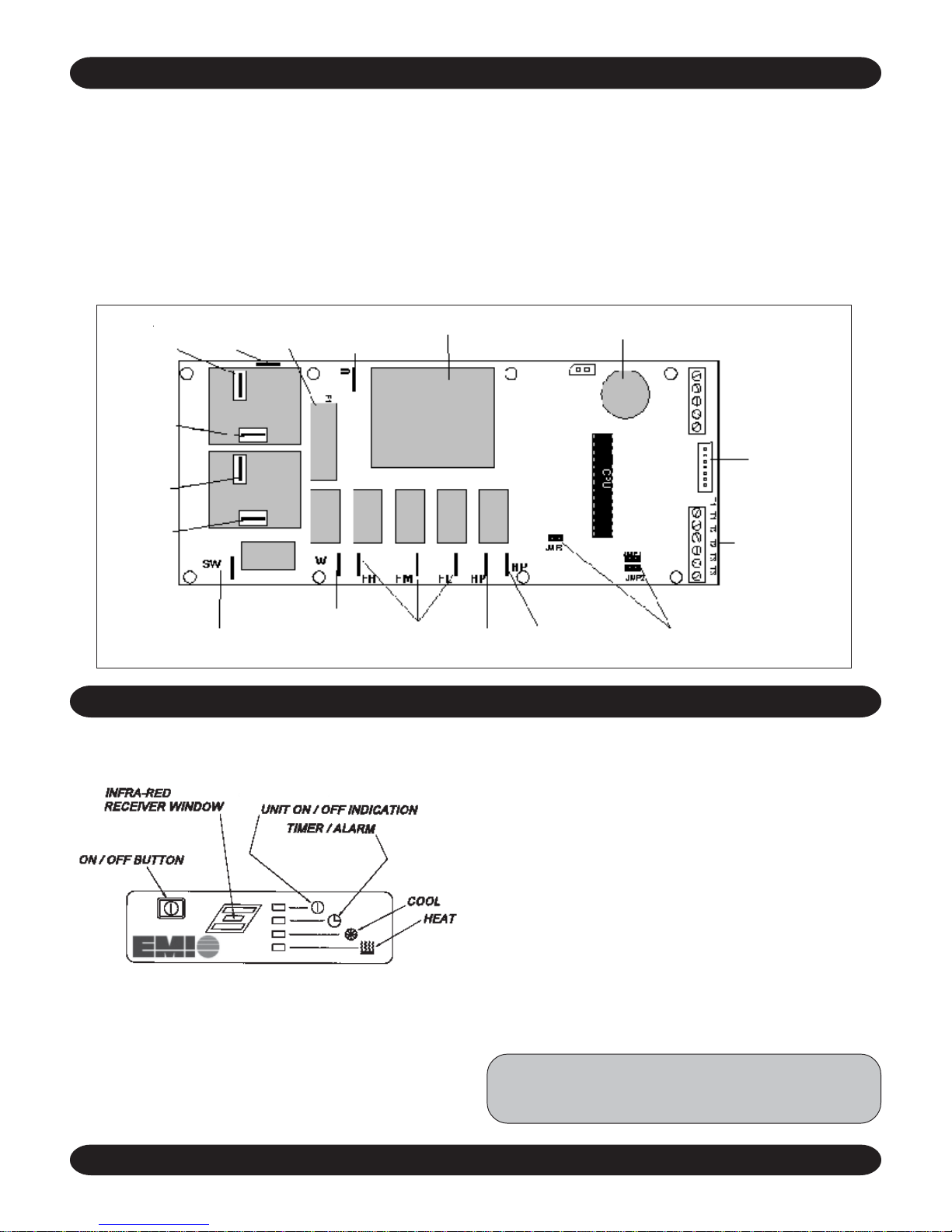

NOTE: On electro-mechanical units, the fascia must

beinstalledwiththeEMIlogo along the same edge of

the unit as the electrical panel. On units fitted with

microprocessorcontrols,orientthefasciawiththedis-

play panel along the same edge of the unit as the

electricalpanel.

Beforetighteningthefasciatotheunit,connectthetwohalves

of the vane motor’s plug and socket connection (where ap-

plicable).

Onmicroprocessorcontrolledunits, ensure that the display

panel cable is routed to the electrical panel and securely

fastenedtoits connectoronthemicroprocessor circuitboard.

(Refer to the unit’s electrical wiring schematic). Take care

to ensure that the connector is connected in the proper ori-

entation and that the wires are not routed such that they

maybecome trapped, cut, broken orchaffed.

Thefasciacannowbetighteneduptothe Cassette chassis

until a good seal is obtained between fascia and chassis.

NOTE: Do not over tighten the bolts. To do so may

cause damage to the fascia.

With filters in place, the inlet grilles can now be fitted to the

fascia to complete the installation.

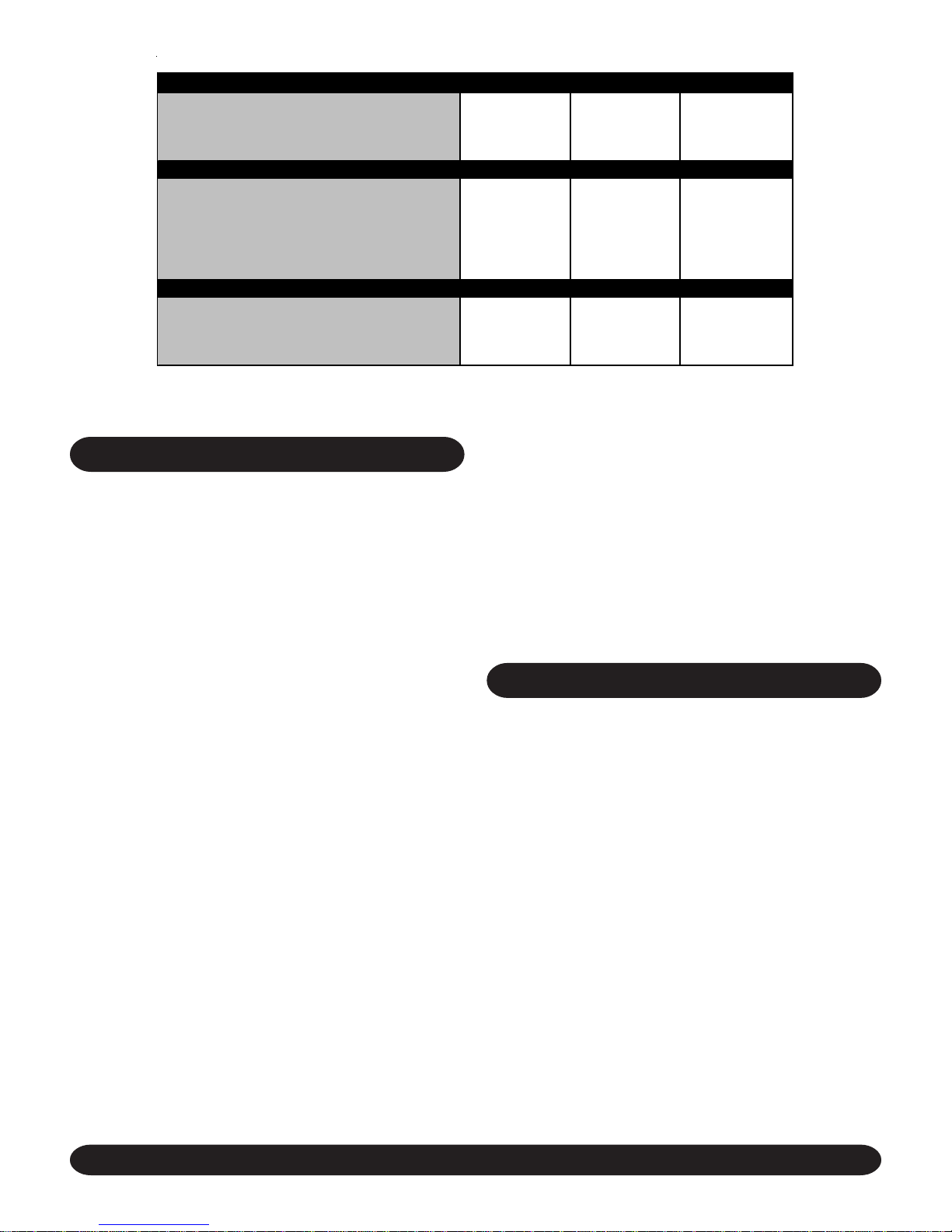

ELECTRICAL DATA

(See Appendix 1 on page 18 for wiring charts and instruc-

tions.)

All power and interconnecting wiring between units should

becarriedouttoconform with local/nationalelectricalcodes.

A fused and dedicated electrical supply of the appropriate

phase,frequencyandvoltage shouldbeinstalledbythecus-

tomer.Itisalsorecommendedthatalocal disconnect switch

be connected within 3’ of the unit. In some areas this may

beacoderequirement.

EMIequipment in its standard form is designed for anelec-

tricalsupplyof208-230V,1Ph,60Hz.When connection to a

115V, 1Ph, 60Hz supply is necessary, a factory mounted

buck boost transformer will be fitted to the unit.

Thewiresshould be capable of carryingthe maximum load

currentundernon-faultconditionsatthestipulated voltages.

Avoid large voltage drops on cable runs, particularly in low

voltage wiring. The correct cable size must be used to en-

sure a voltage drop of less than 1 volt in the control wiring.

Once the refrigeration pipe work is complete, the electrical

supply can be connected by routing the cable through the

appropriatecasingholeandconnectingthesupplyandground

cables to the unit’s power terminals. On the medium and

large cabinets, it will be necessary to remove the insulated

condensate tray support rail, adjacent to the casing hole.