-1

l S. ADJUSTING

THEFEED

TI'MIIHG

l) To obtainthe standard

feedtiming.alignsetscrew

@

on feedeccentriccam O with setscrew

@ onmain

shaft

thrustcollar @

Tomakeadjustment,

loosentrvosetscrews

@ torelease

the feedeccentriccam,

properll,'

position

theeccentric

cam.Thenretishtenthesetscrews.

To advancethe feedtimins

in orderto Drevent

uneven

materialfeed, move the Jeed e.cetrtric

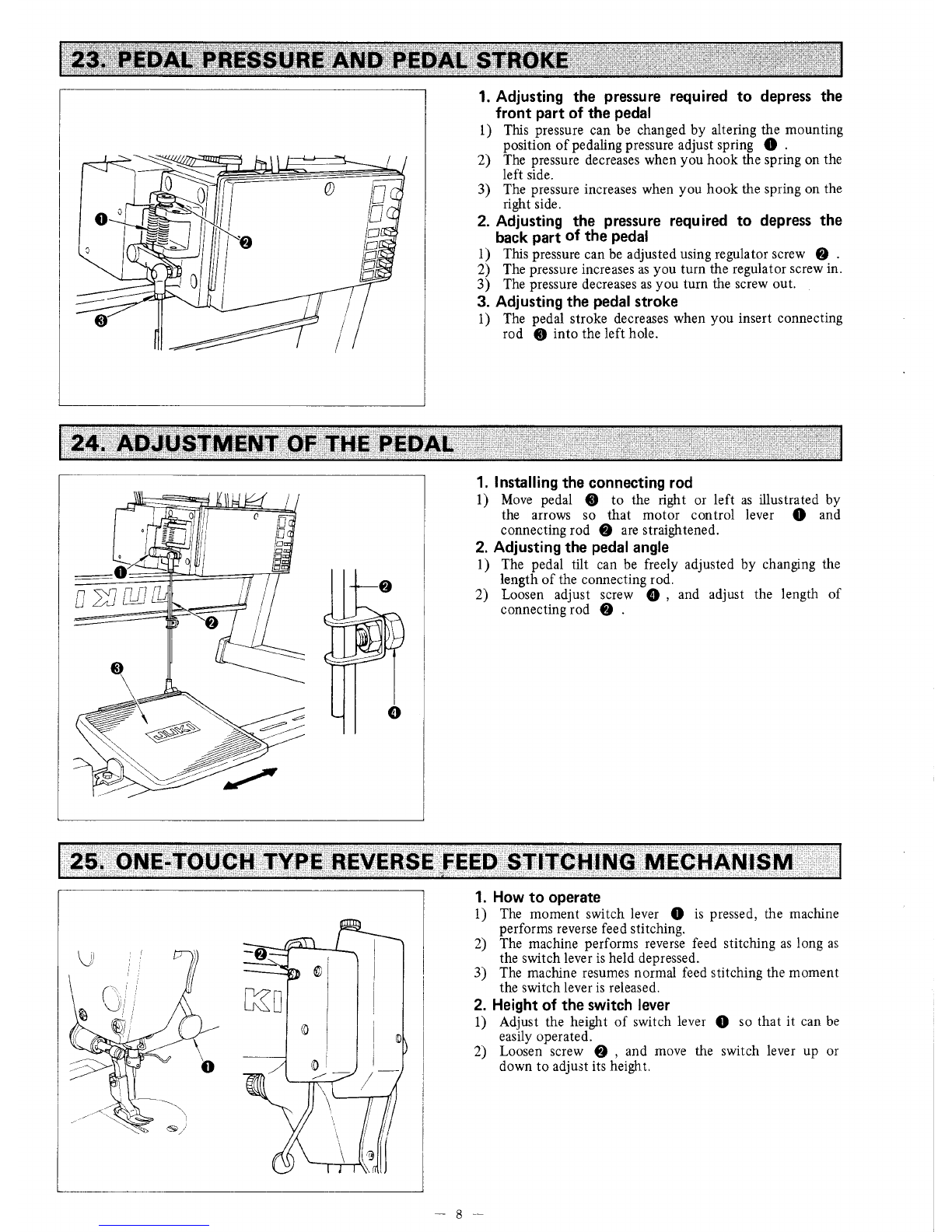

cam in the

directionofthearrow.

To delay the feed timing in order to increase

stitch

tightness,move

the feedeccentriccanr

in theopposite

direction

fromthe

arrow.

Be carefulnot to move

thefeed

orelseneedle

breakaee

mavresult

?)

4)

s) eccentric

cam too far,

I

(Standard

feed

timing)

||

Needle

:zzrww\oNzzzz 16s631

Feed

dog ' plate

16. TILT

OF

THEFEED

DOG

Thestandard

tilt (horlzontal)

of the

leeddog

is

obtained

when marker dot 6 on the feedbar shaftis aligned

withmarker

dot @ onfeed

rocker O

To tilt thefeed

dog

withitsfront

upinordertoprevent

puckering,

loosen

the setscrew,andturn the feed

bar

shaft90 degrees

in the direction

of the arrow.using

a

screwdriver.

@ Frontup @ Standard @ Frontdown @ Throat

plate

3) To tilt the feeddog with its front down in orderto

prevent

unevenmaterialfeed,turn the feedbarshaft90

degrees

in theoppositedirection

from thearrow.

(Precaution)

Whenever

the feeddog tilt is adjusted,the

feed

dogheightwill bechanged.So,it isnecessarytocheck

theheightaftertilt adjustment.

&vr.rn

^

)\

-N\-\ ,rl

"N*"\ I

--r-----v

1)

L)

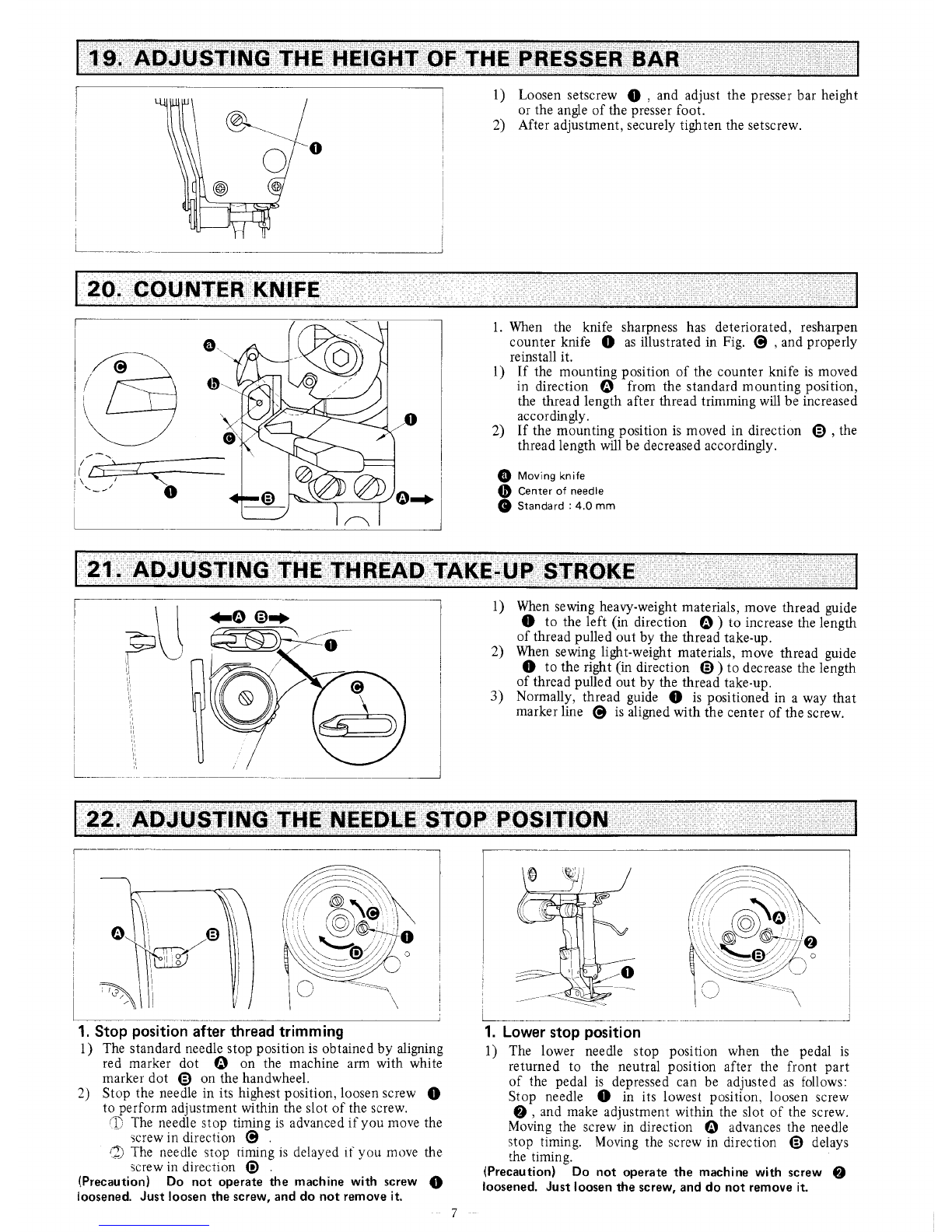

17.HEIGHTO'F

THEFEEDDOG

Thefeed

dogis factory-adjustedso that it juts out from

the throat platesurface

0.8 mm to 0.9 mm (1 mm for

DDL-5550H-6).

For the DDL-5550A-6,

it juts out 0.7mm to 0.8mm.

If thefeed

dog

juts out to6much.

puckering

mayresult

when sewing light-weightmaterials. (Recommended

protrusion:

0.7mm to0.8mm)

To adjusttheheight

of thefeeddog:

@ l,oosenscrew @ ofcrank O

@ Movethefeedbarup or downto makeadjustment.

@ Securely

tightenscrew @ .

1)

2)

{l

@ Feed

dog @ Throat plate

(DDL-b5506)

0<?-0.9..

_NVVWV{\),-

o t7-

6

(DDL-5550A6) o 7-0 8"

-

_NNNNV{\}

@ tr-

{t

1

8. NEEDLE.TO-HOOKRELATIONSHIP

1.

Adjustthe timing betweenthe needleandthe

hook

as

follows:

1) Turn the handwheelto bright the needlebar down to

thelowest

pointof its

stroke,

andloosensetscrew

O .

(Adjusting

theneedle

barheight)

)) '(fot i og needle) Aligrimirker line 6 onneedlebar

O with the bottom end of needlebarlower bushing

@ ,thentightensetscrew

l)

(Fora DA needle)Align markerline @ on needle

bar

O with the bottom end of needlebar lowerbushing

0 ,thentightensetscrew

Q

(Adjustingposition @ of the

hook)

3) (For

a

DBneedle)

Loosenthe three hook setscrews,

turn the handwheel,

and align marker line @ on

ascending

needlebar O with thebottomend

ofneedle

barlower

bushing

@

(For

aDA needle)

Loosenthe three hook setscrews,

turn the handwheel,

and align marker line O on

ascending

needlebar O withthebottomend

ofneedle

bar

lower

bushing@ .

4) After makingtheadjustments

mentioned

in the above

steps,align

hook blade

point tp with the centerof

needie

@ . Provide

a clearance

of 0.04

mm to0.1

mm

between

theneedle

and

thehook, then

securelytighten

thehooksetscrews.

il ''o r i >-v-'-

. wJrn

trpraclngttrertoor.,tp..irv

its

part

rtro.irrqrssE

111092251

for DDL-5550H-61.